A device and method for preparing copper-clad ceramic substrates by twin-target magnetron sputtering

A copper-clad ceramic substrate and target magnetron sputtering technology, used in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problem that the adhesion between metal layer and blank ceramic sheet is difficult to meet high-power heat dissipation Substrates, metal films and blank ceramic substrates have poor adhesion and large differences in thermal expansion coefficients, so as to protect the environment, enhance adhesion and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

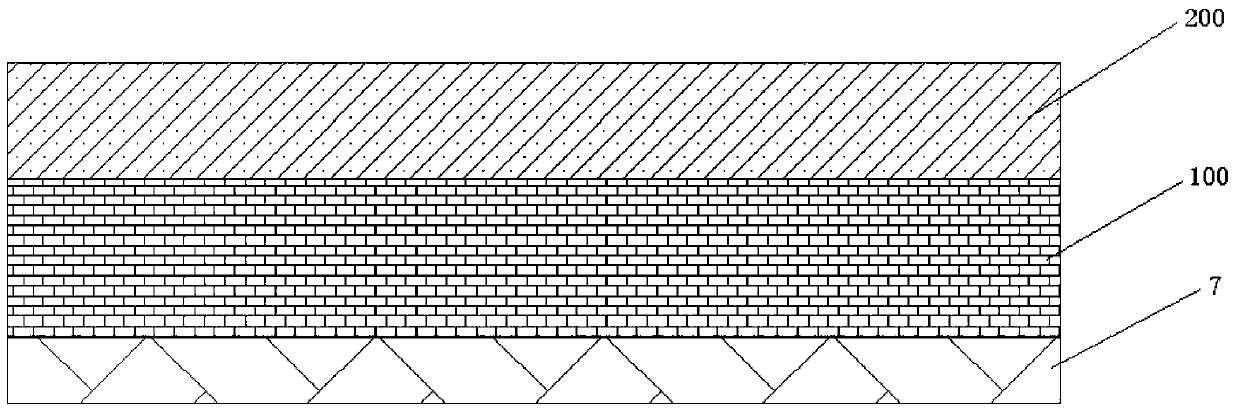

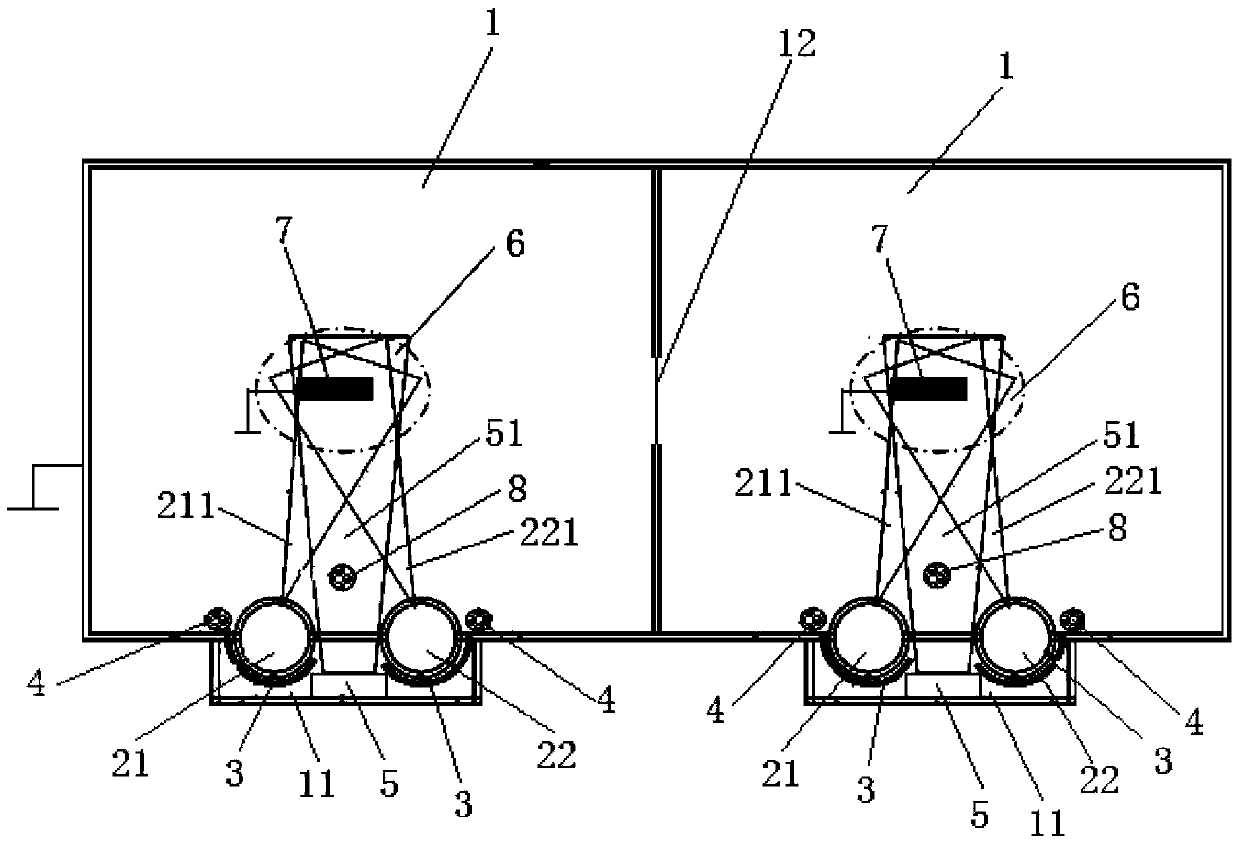

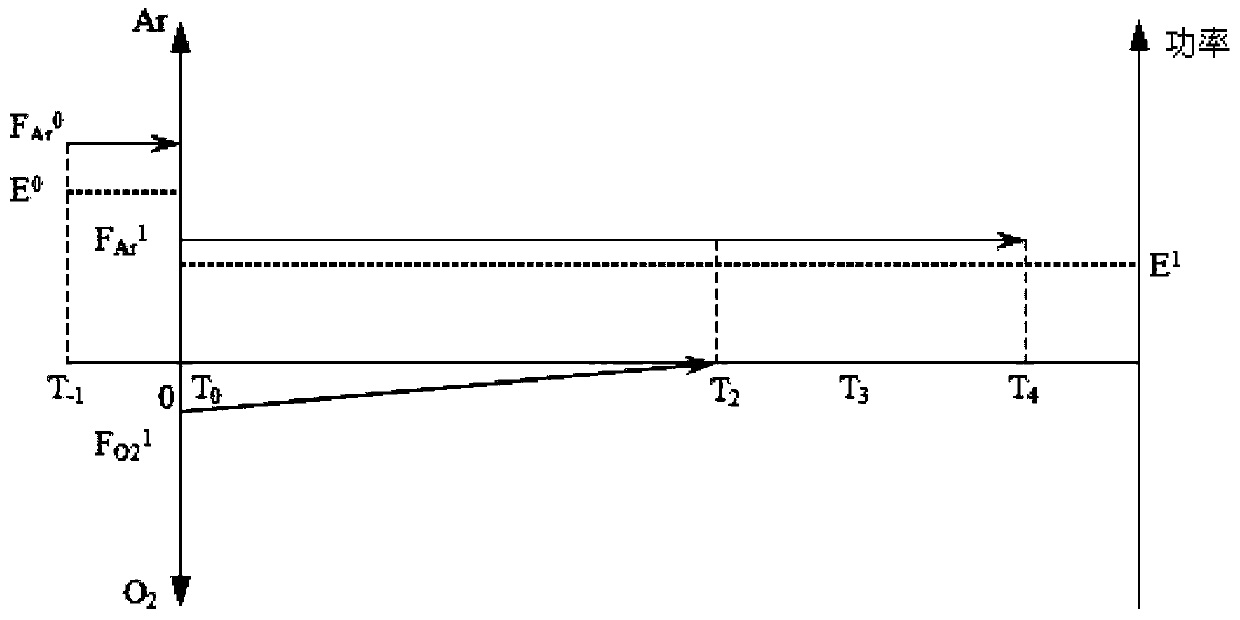

[0041] refer to Figure 1~Figure 5 , a device for preparing a copper-clad ceramic substrate by twin-target magnetron sputtering according to the present invention, comprising: at least one sputtering vacuum chamber 1, placed vertically, shaped as a cylindrical barrel or a square box, and equipped with Vacuum pump (not shown) and heating element (not shown), the inner wall of one side in the height direction protrudes outward to form a housing chamber 11; at least one pair of twin pairs of targets, each pair of twin pairs of targets corresponds to a sputtering vacuum chamber 1. It includes a metal cylindrical target 21 and a copper alloy cylindrical target 22, which are located in the sputtering vacuum chamber 1 and symmetrically arranged on both sides of the accommodating chamber 11. The metal cylindrical target 21 and the copper alloy cylindrical target 22 are yin and yang to each other Pole; at least two arc extinguishing covers 3, which are arc-shaped, and the arc is matche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com