Thermal barrier coating for single crystal superalloy thermal protection and preparation method thereof

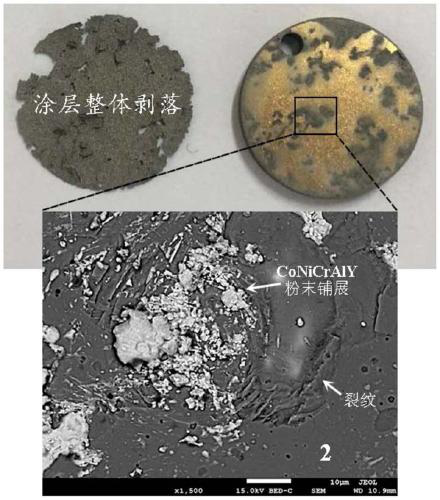

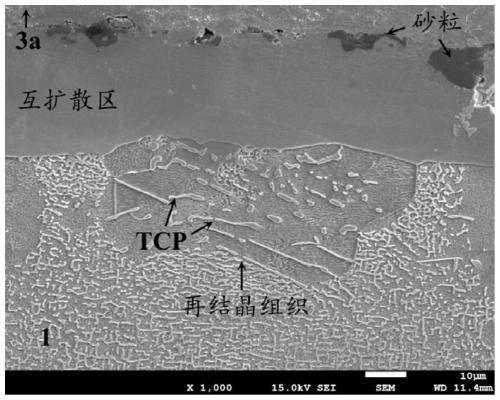

A technology of superalloy and thermal barrier coating, applied in metal material coating process, coating, metal processing equipment, etc., can solve the problem of easily damaged ceramic barrier layer, the roughness of ceramic barrier layer cannot meet the preparation requirements of spray coating, etc. problem, to achieve the effect of ensuring the interface bonding performance and avoiding recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Select the wafer sample of wire-cut nickel-based single crystal superalloy DD33 as the substrate 1, and use sandpaper and polishing paste to grind the substrate 1 to remove the heat-affected zone on the surface of the substrate 1. The thickness of the grinding off is about 200μm;

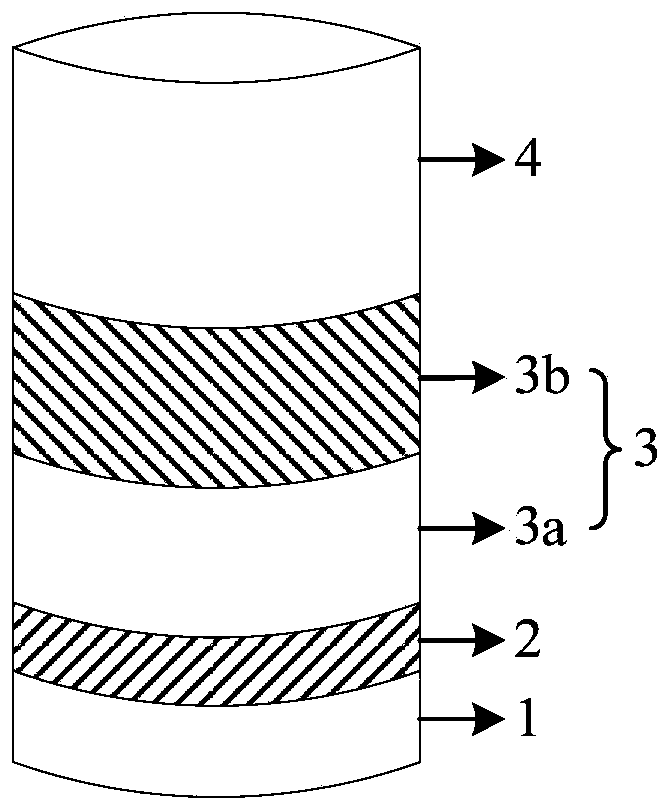

[0037] Step 2. Using arc ion plating equipment to prepare a TiN barrier layer 2 with a thickness of 2 μm on the surface of the substrate 1; wherein, the target material is a Ti target with a purity >99.9%, and the gases used in the experiment are argon and nitrogen with a purity of 99.999%. The deposition temperature is 450°C, the pressure is 1Pa, the current is 90A, and the bias voltage is -100V;

[0038] Step 3. Using arc ion plating equipment to prepare a NiCoCrAlYHf coating with a thickness of 50 μm on the barrier layer 2 as the lower bonding layer 3a, the measured surface roughness Ra of the lower bonding layer 3a is (1.63±0.2) μm; wherein, The deposition temperature when prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com