Coating for outer surface of zircalloy cladding tube and manufacturing method

A manufacturing method and a technology for cladding tubes, which are applied in the coating process of metal materials, coating, and plating of superimposed layers, etc., can solve the problems of affecting the structural integrity, destroying the integrity of the coating, and reducing the thickness of the coating. , to achieve the effect of avoiding rupture failure, avoiding mutual diffusion of elements, and enhancing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

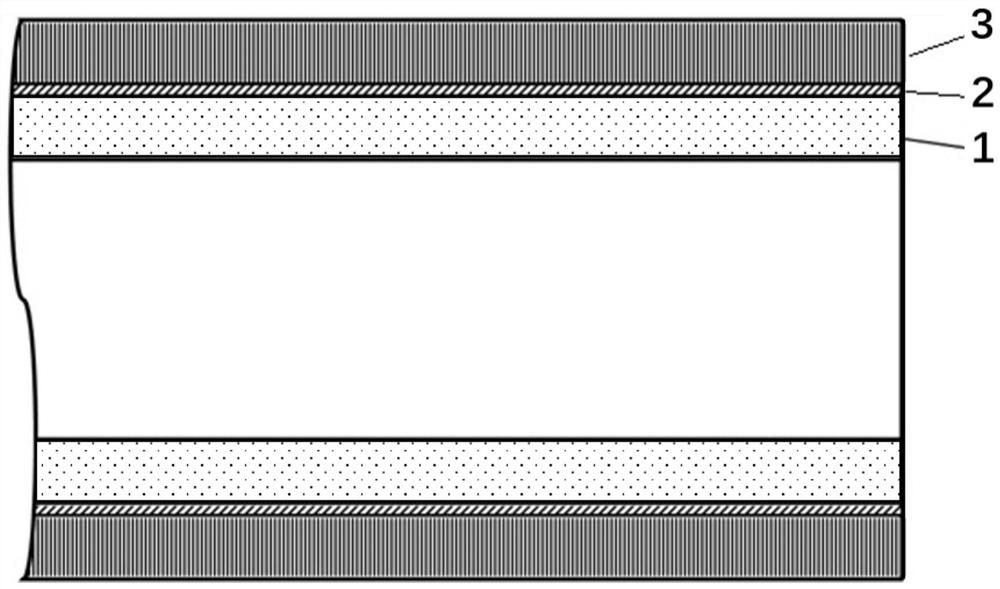

[0017] The first layer coated on the surface of the zirconium alloy shell is a ZrN layer, which is used to isolate the Cr working layer from the Zr matrix; the second layer is a Cr working layer, which resists high temperature water and high temperature steam corrosion.

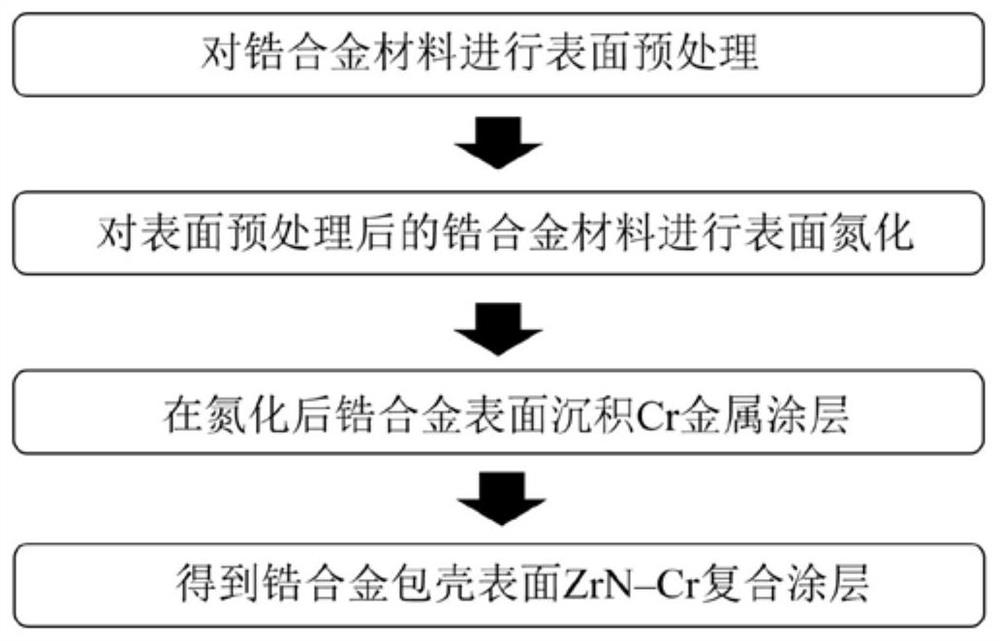

[0018] A method for manufacturing a coating on the outer surface of a zirconium alloy cladding tube, comprising the following steps,

[0019] First, performing surface pretreatment on the zirconium alloy cladding tube substrate;

[0020] Second, performing surface nitriding on the zirconium alloy cladding tube substrate after surface pretreatment to obtain the ZrN transition layer;

[0021] Thirdly, a Cr working layer is deposited on the surface of the zirconium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com