Mo-Si-B/TiN composite coating and preparation method thereof

A composite coating, mo-si-b technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of poor oxidation resistance, brittleness and easy formation of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

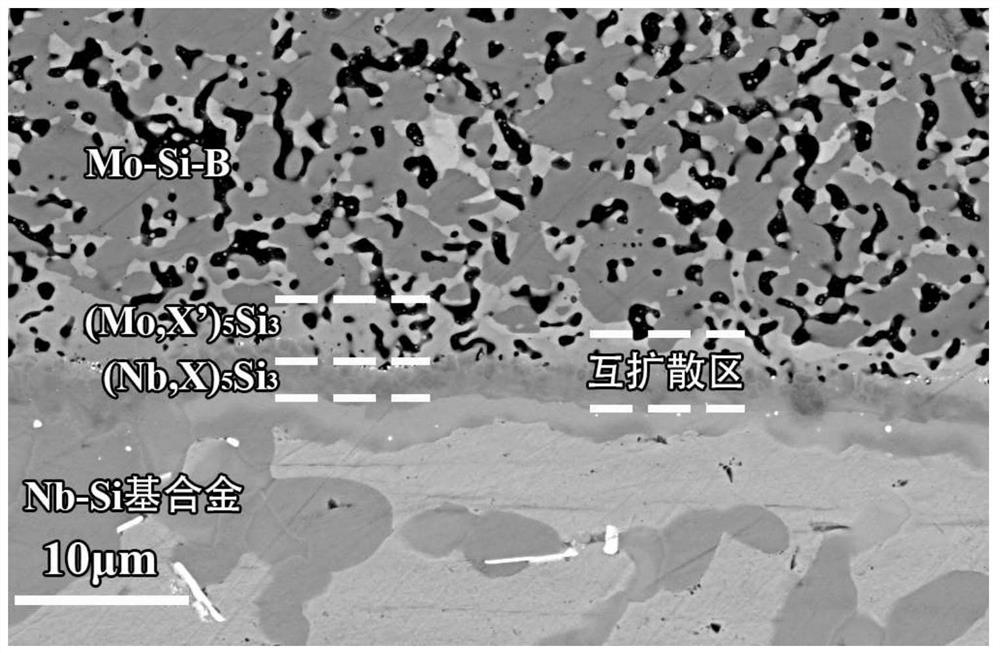

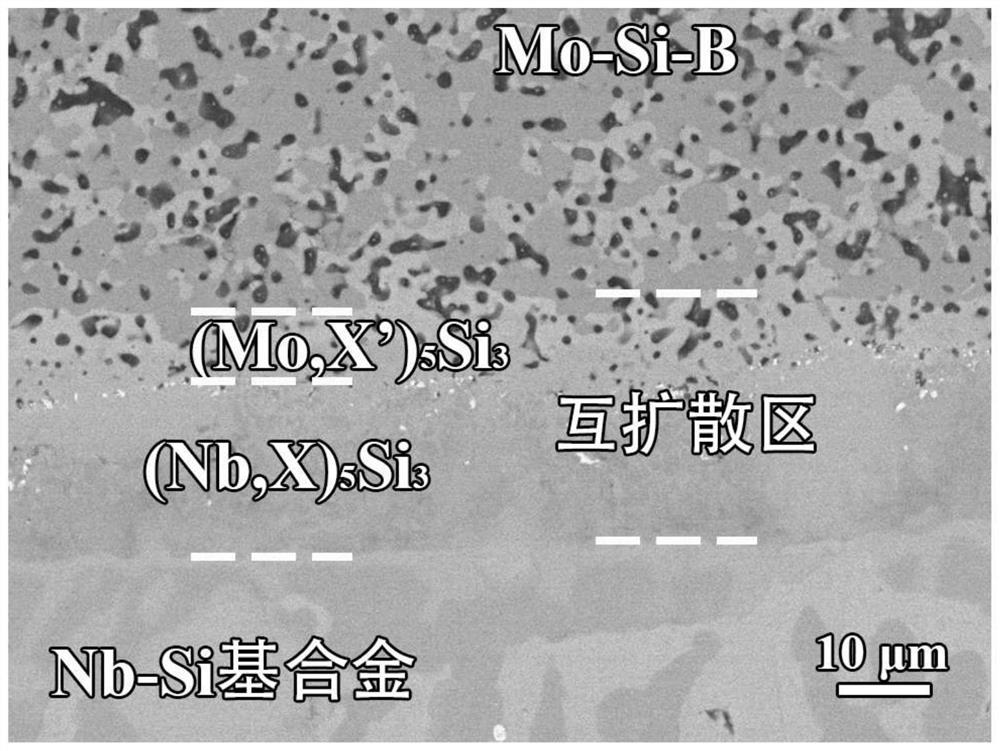

[0036] Based on the same inventive concept, the present invention also provides a method for preparing a Mo-Si-B / TiN composite coating, comprising the following steps:

[0037] S1: Using Nb-Si-Ti-Cr-Al-Hf six-component alloy as the first synthetic raw material, the first synthetic raw material was sequentially subjected to non-consumable vacuum arc melting and induction melting to obtain Nb-Si-based alloy ingots at 1250 °C Under the condition of annealing for a preset time t, cut a disc sample with a diameter of 8mm to 12mm and a thickness of 2mm to 3mm as the substrate; where, 0h<t≤60h;

[0038] S2: Select the alloying element whose nominal chemical composition is Mo-nSi-mB as the second synthetic raw material, conduct non-consumable vacuum arc melting on the second synthetic raw material to obtain Mo-Si-B alloy ingot, and Mo-Si-B alloy ingot Perform mechanical crushing to obtain Mo-Si-B alloy powder, and use a planetary ball mill to perform ball milling on the Mo-Si-B alloy ...

Embodiment 1

[0045] The first step is the preparation of the matrix.

[0046] Select the alloy element whose nominal chemical composition is Nb-16Si-22Ti-17Cr-2Al-2Hf (atomic percentage, at%) as the first synthetic raw material, and use non-consumable vacuum arc melting and induction melting to obtain Nb-Si based alloy ingots , and then annealed at 1250 ° C for 50 h, and cut into disc samples with a diameter of 12 mm and a thickness of 2 mm as the substrate.

[0047] The second step: preparation of Mo-Si-B mixed layer material.

[0048] Select the alloy element whose nominal chemical composition is Mo-62Si-5B (atomic percentage, at%) as the second synthetic raw material, and use non-consumable vacuum arc melting to obtain Mo-Si-B alloy ingot. For Mo-Si-B alloy ingot Perform mechanical crushing to obtain Mo-Si-B alloy powder, and then use a planetary ball mill to perform ball milling on the Mo-Si-B alloy powder to obtain Mo-Si-B alloy powder with a particle size of 2-4 μm.

[0049] The th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com