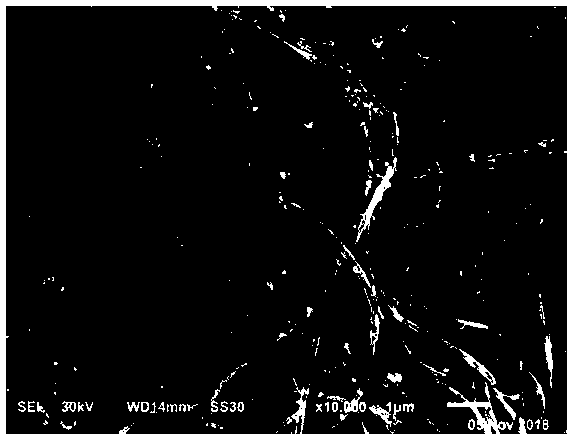

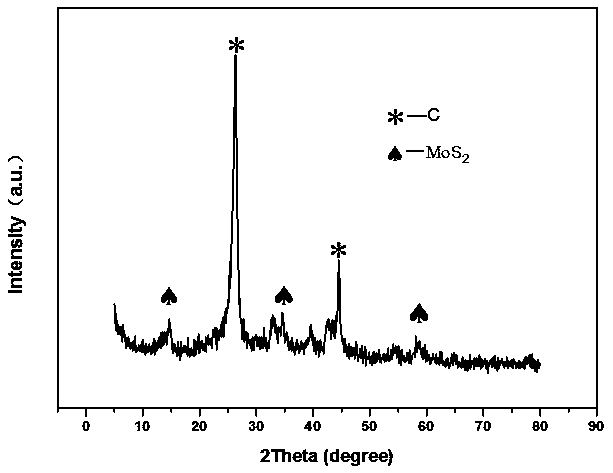

Preparation method and application of nano molybdenum disulfide/nitrogen-doped carbon nanotube array hybrid composite electrode

A nano-molybdenum disulfide and nanotube array technology, applied in the field of electrode materials, can solve problems such as poor stability, achieve excellent electrical conductivity, small contact resistance, improve charge-discharge capacity and cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific implementation of a method for preparing a nanomolybdenum disulfide / nitrogen-doped carbon nanotube array hybrid composite electrode is carried out according to the following steps:

[0038] (1) Preparation of conductive carbon black layer / carbon fiber fabric base material

[0039] Take 1g of acetylene black and 0.036g of ammonium persulfate respectively in a three-necked flask, add 200mL of deionized water, mechanically stir in a constant temperature water bath at 30°C for 20h, filter with suction, wash, and vacuum dry at 80°C for 24h, then the acetylene black The oxidation of the carbon paper is completed; in order to remove the impurities on the surface of the carbon paper, the carbon paper is cut into a size of 3 × 3 cm and then immersed in isopropanol solution, 80Hz ultrasonic 20min to remove the impurities on the surface of the carbon paper, take out and dry; take 0.08g to oxidize Acetylene black, 6.06g of ferric nitrate and 15g of acidic silica sol wi...

Embodiment 2

[0052] (1) Preparation of conductive carbon black layer / carbon fiber fabric base material

[0053] Take 1g of conductive carbon black and 0.072g of ammonium nitrate in a three-necked flask, add 150mL of deionized water, stir mechanically in a constant temperature water bath at 25°C for 18h, filter with suction, wash, and vacuum dry at 80°C for 24h, then the conductive carbon The black oxidation is completed; in order to remove the impurities on the surface of the carbon cloth, the carbon cloth is cut into a size of 3 × 3 cm and dipped in an ethanol solution, and the impurities on the surface of the carbon cloth are removed by ultrasonication at 100Hz for 30 minutes, then taken out and dried; take 0.1g of the oxidized Conductive carbon black, 2g of nickel nitrate and 20g of alkaline silica sol with a mass fraction of 35% were stirred at room temperature for 24 hours to make a suspension; after the surface of the carbon cloth was cleaned, the suspension was evenly applied to one ...

Embodiment 3

[0061] (1) Preparation of conductive carbon black layer / carbon fiber fabric base material

[0062] Take 1g of conductive graphite and 0.018g of ammonium chlorate in a three-necked flask, add 230mL of deionized water, stir mechanically in a constant temperature water bath at 35°C for 20h, filter with suction, wash, and vacuum dry at 70°C for 30h, then the conductive graphite The oxidation of the carbon felt is completed; in order to remove the impurities on the surface of the carbon felt, the carbon felt is cut into a size of 3×3 cm and immersed in a methanol solution, and the impurities on the surface of the carbon felt are removed by ultrasonication at 100 Hz for 20 minutes, then taken out and dried; take 0.1 g of the oxidized conductive Graphite, 3g of nickel acetate and 15g of acidic silica sol with a mass fraction of 40% were stirred at room temperature for 30 hours to form a suspension; after the surface of the carbon felt was cleaned, the suspension was evenly applied to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com