Diffusion-resistant high-entropy alloy coating material, high-temperature-resistant coating material as well as preparation method and application thereof

A high-entropy alloy and coating material technology, applied in metal material coating process, coating, superimposed layer plating and other directions, can solve the problems of poor chemical matching, thermal shock failure, poor blocking effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

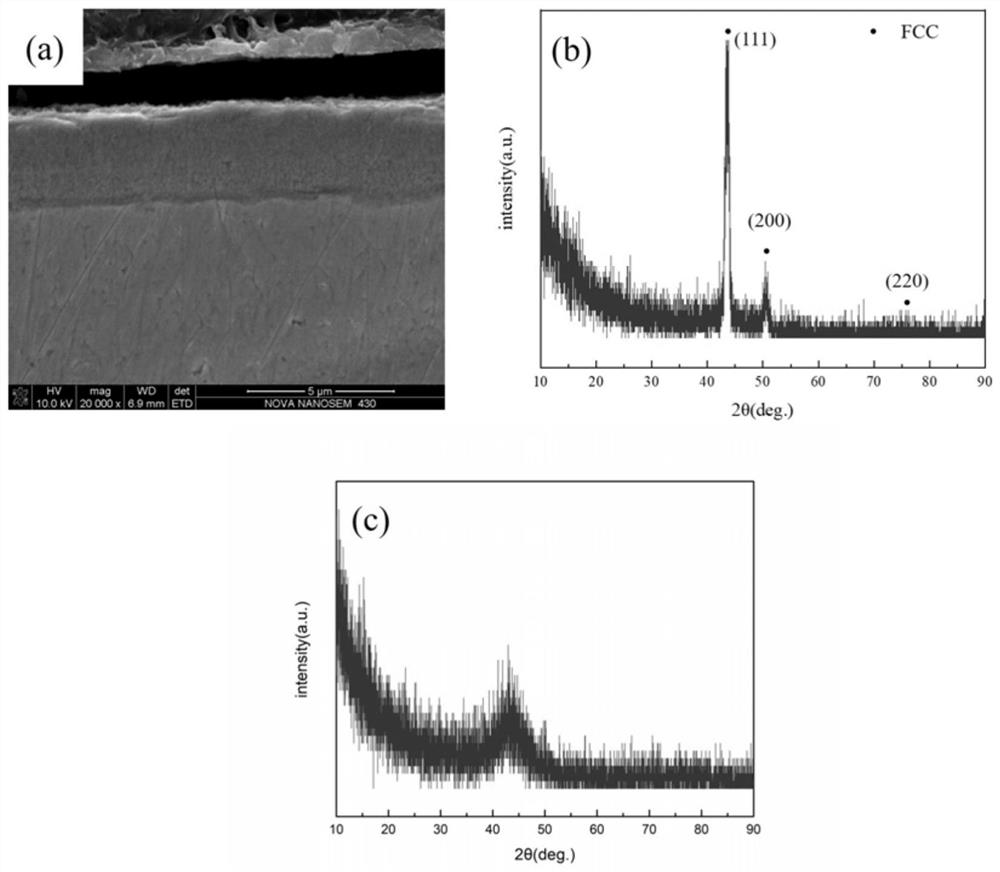

[0026] S1. Preparation of diffusion-resistant high-entropy alloy coating materials

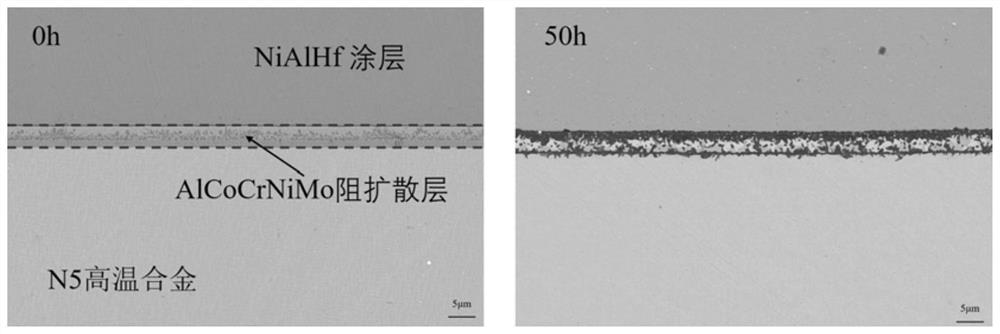

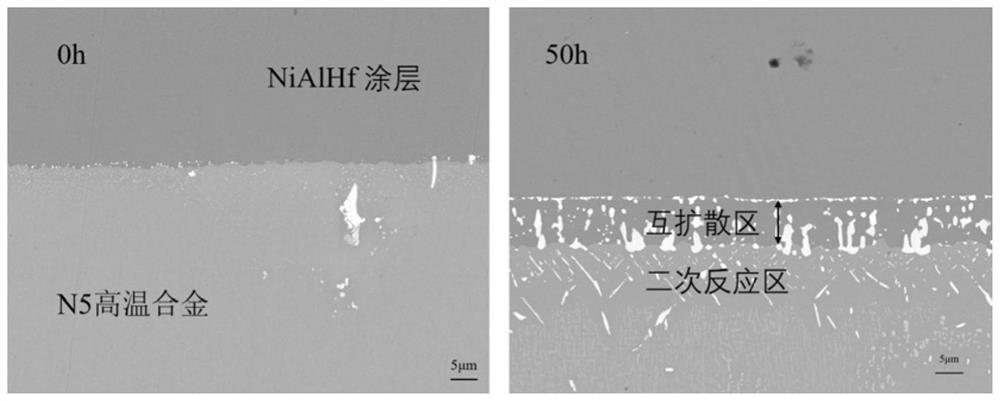

[0027] A diffusion-resistant high-entropy alloy coating is formed on the surface of the substrate, and the elements of the diffusion-resistant high-entropy alloy coating include Al, Co, Cr, Ni and Mo. The invention found that the high-entropy alloy coating formed by the above five elements can effectively inhibit the interdiffusion of alloy components between the substrate and other coatings (especially high-temperature coatings) and the precipitation of harmful phases at the interface, and improve the high-temperature oxidation resistance of the coating. At the same time, it avoids the reduction of the mechanical properties of the base material caused by interdiffusion, and prolongs the service life of the parts. If the elements therein are replaced, such as replacing Co with Ti, such a good diffusion resistance effect cannot be achieved at all.

[0028] Further, by atomic percentage, the el...

Embodiment 1

[0040] This embodiment provides a method for preparing a high temperature resistant coating material, which is prepared by the following method:

[0041] (1) Target material preparation: Al, Co, Cr, Ni and Mo metal powders are uniformly mixed according to the atomic percentage ratio of 1:1:1:1:1, and a single alloy prepared by powder metallurgy is used as the target material .

[0042] (2) Substrate pretreatment: using nickel-based superalloy (N5) as the substrate, the surface of the substrate is ground and polished, then ultrasonically cleaned with acetone, alcohol and deionized water, and dried.

[0043] (3) Diffusion-resistant coating deposition: Magnetron sputtering is used to deposit a high-entropy alloy coating on the surface of the cleaned substrate. The process parameters are: the background vacuum is less than 5×10 -3 Pa, the substrate temperature is 200°C, the target power is 250W, the substrate DC bias is -100V, the duty cycle is 70%, the target-base distance is 12...

Embodiment 2

[0046] This embodiment provides a method for preparing a high-temperature-resistant coating material, which differs from Embodiment 1 only in that in step (3), the process parameters for coating deposition are: the background vacuum is less than 5×10 -3 Pa, substrate temperature 150°C, target power 300W, substrate DC bias voltage -300V, duty cycle 90%, target-base distance 10cm, working argon gas pressure 0.8Pa, ion source 1.2A. The control coating thickness is 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com