Improved electric compressor for new energy automobile

A technology of new energy vehicles and electric compressors, which is applied in the direction of machines/engines, liquid fuel engines, pump combinations for elastic fluid rotary piston type/oscillating piston type, etc., which can solve uneven compression, reduced operating reliability, Problems such as high leakage rate, to achieve the effect of reducing the leakage failure rate, improving the reliability of the whole machine, and increasing the deposition area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

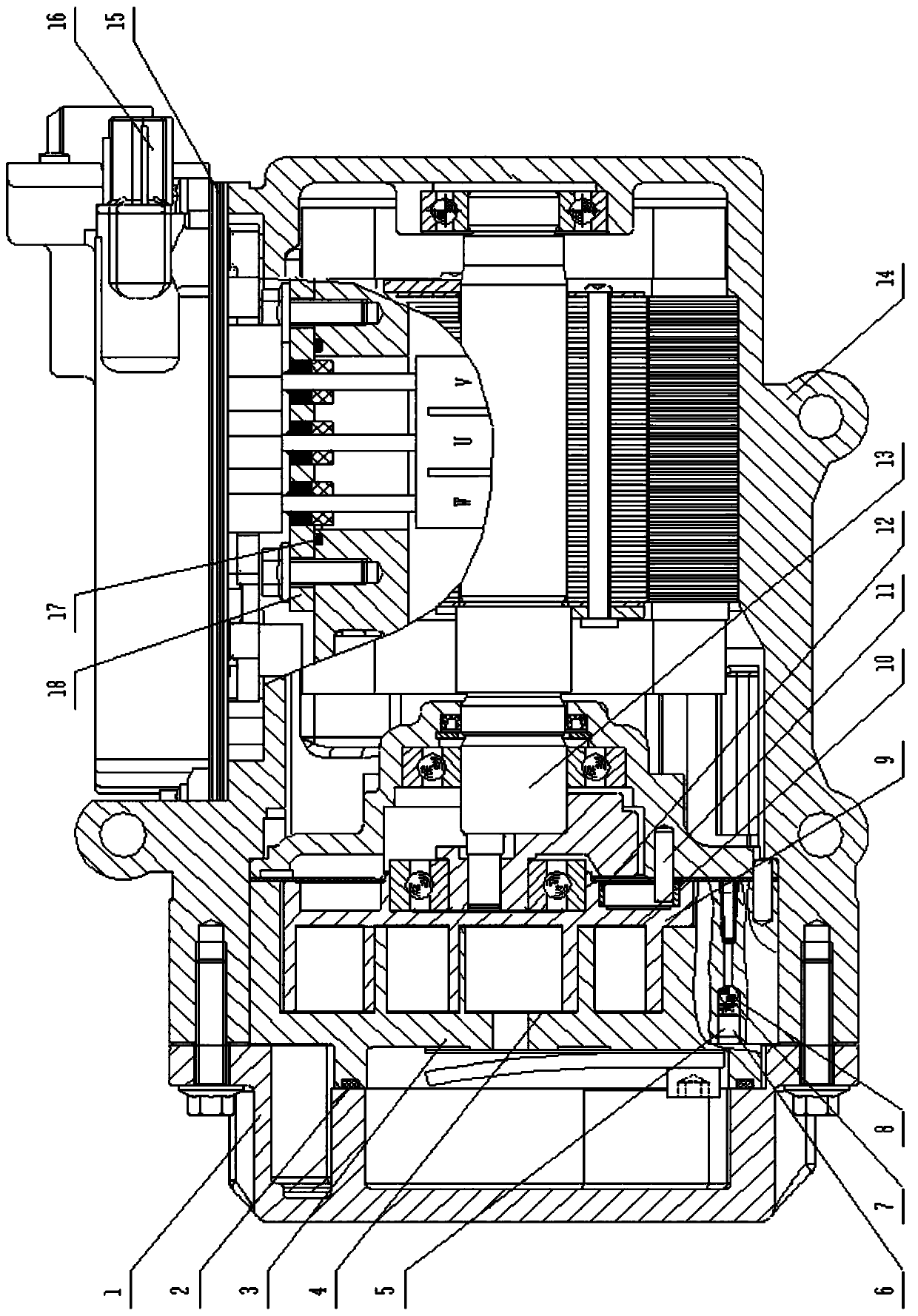

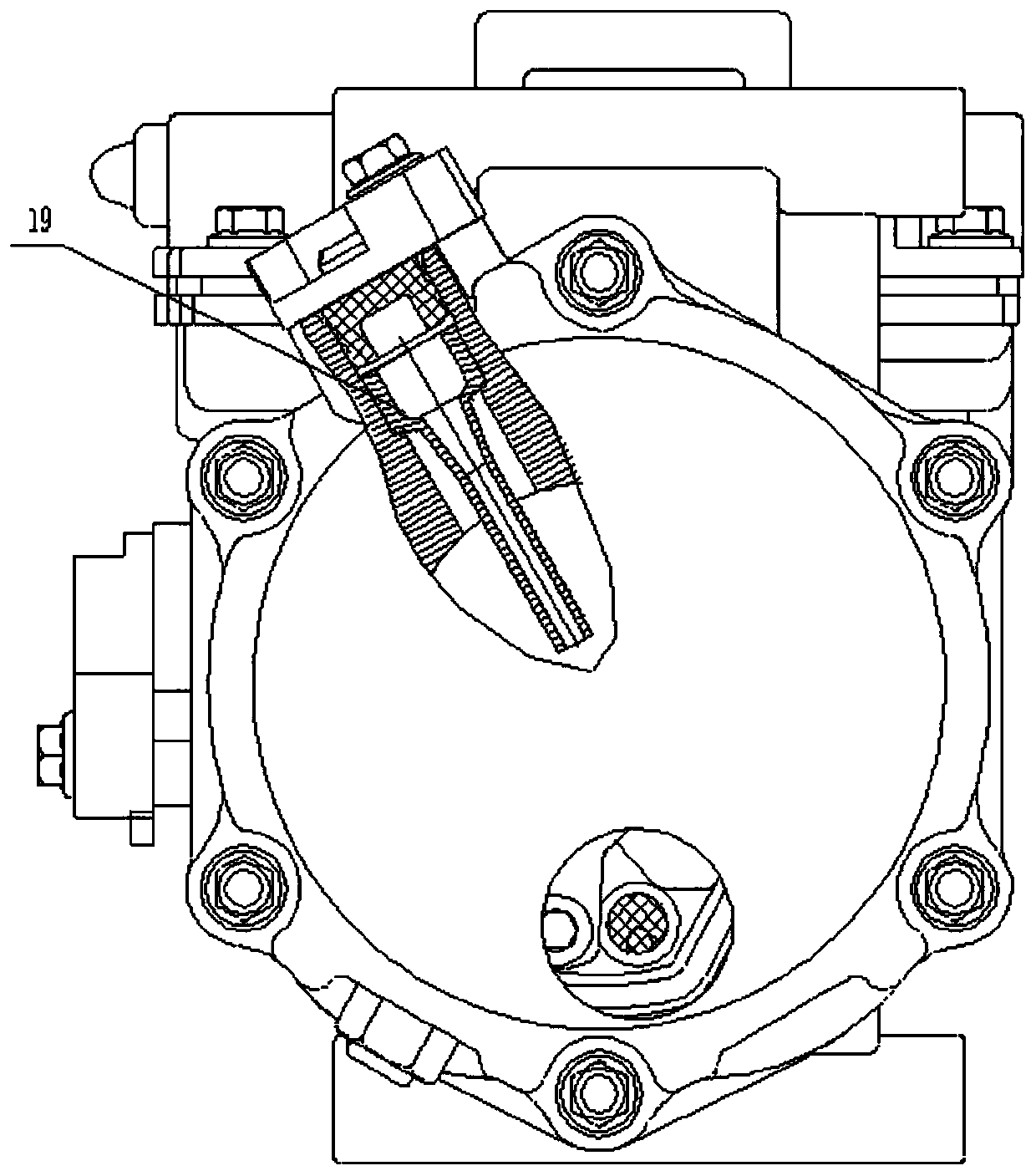

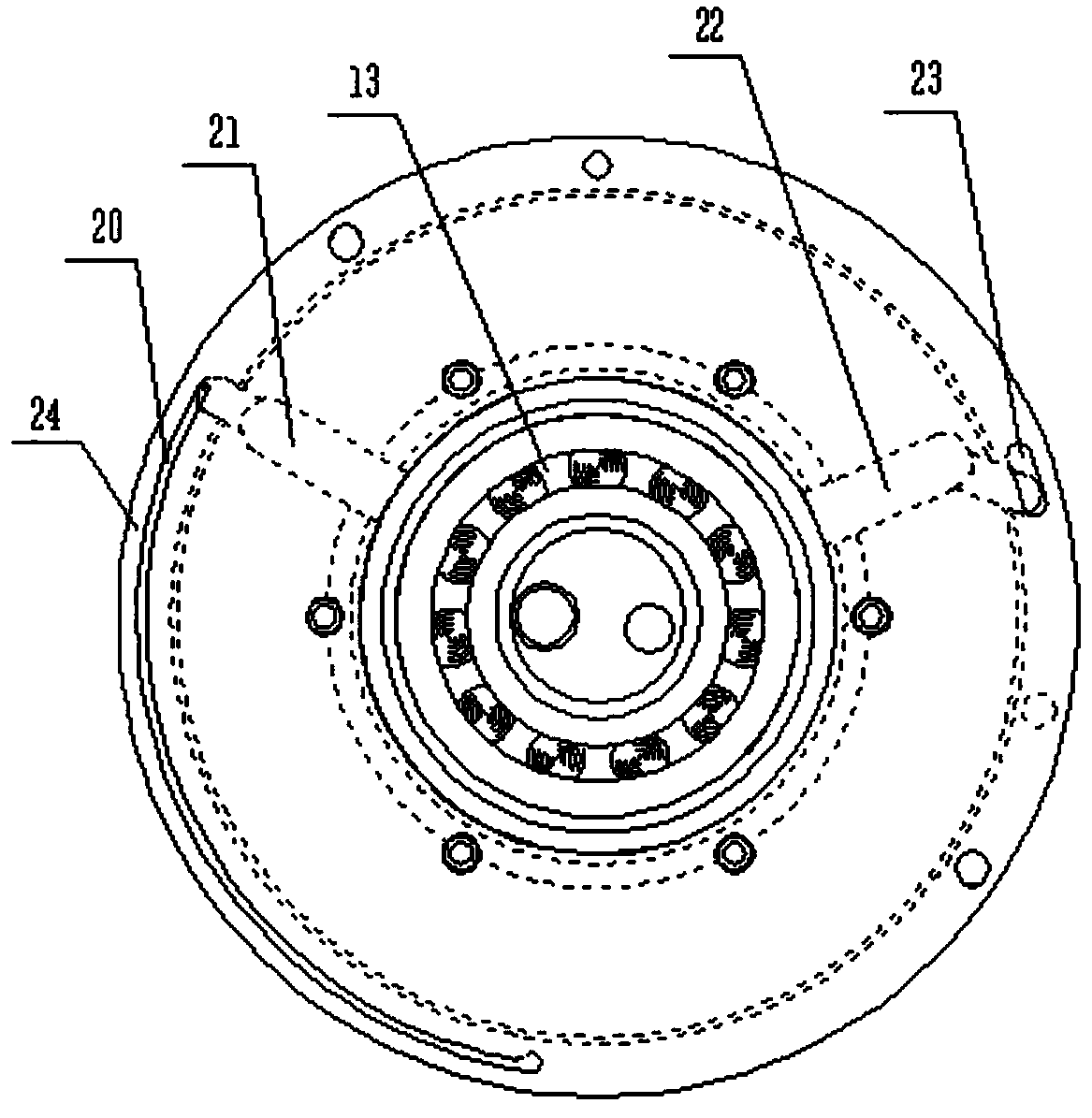

[0034]An improved electric compressor for new energy vehicles as shown in 1-11, in this embodiment, includes a rear cover part 1, a fixed scroll part 3, a moving scroll 9, a bearing seat part 13, and a motor housing The body part 14 and the controller part 16. A special-shaped gasket is arranged between the rear cover part 1 and the motor housing part 14, and they are fixed and connected as a whole by bolts to form an overall airtight cavity. The rear cover part Including a back cover and a separation pipe 19, the lower side of the back cover is provided with a special-shaped sinking cavity, and the back cover is provided with an exhaust step hole, and a separation pipe 19 is provided in the exhaust step hole, and the oil-gas mixture is separated Under the action of high-speed centrifugal force in the pipe 19, the gas is discharged with the separation pipe 19 and the exhaust hole, and flows along the inner wall of the separation pipe 19 in the exhaust chamber of the rear cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com