Gasification furnace

A gasification furnace and gasification chamber technology, which is applied in the field of gasification, can solve the problems of changes in the bed resistance in the gasification furnace, affecting the long-term operation of the gasification furnace, and blocking the outlet of the gasification furnace, and achieves continuous slagging process. Stable, ensuring long-term operation, and improving the effect of operating stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

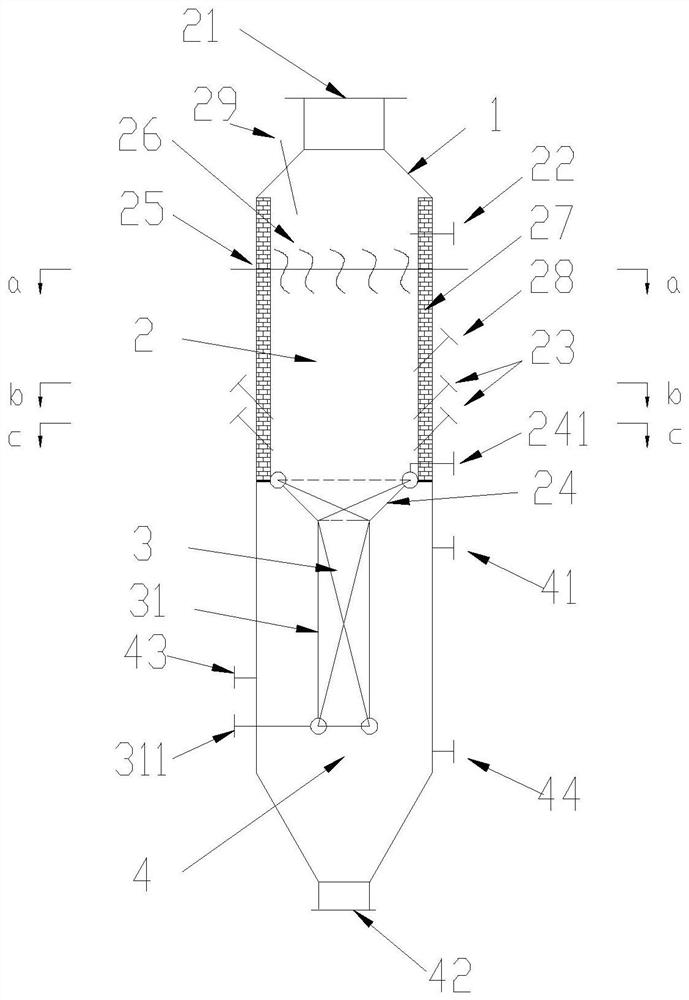

[0033] A gasification furnace, comprising a gasification furnace shell 1, the gasification furnace shell 1 has a gasification chamber 2 and a chilling chamber 4 arranged up and down, and the top of the gasification furnace shell 1 is provided with a gasification chamber 2 Connected raw material inlet 21, the bottom of the gasification furnace shell 1 is provided with a slag outlet 42 communicating with the quenching chamber 4; The first end of the passage 3 is connected, and the second end of the lower slag passage 3 extends into the chilling chamber 4 .

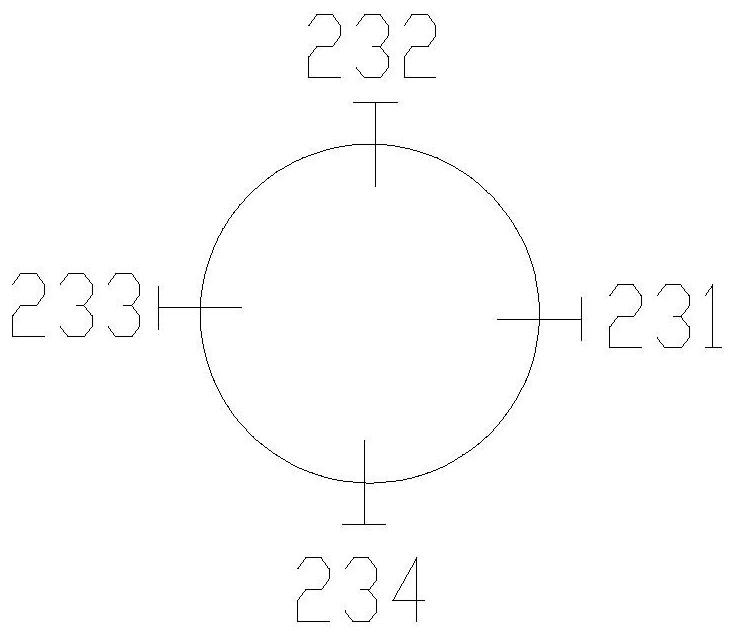

[0034] In this embodiment, the gasification chamber 2 has a first gas outlet 22 and a gasification agent inlet 23, the first gas outlet 22 is located at the upper end of the gasification agent inlet 23; the cooling chamber 4 is near one end of the gasification chamber 2 A second gas outlet 41 is provided, and the quenching chamber 4 has a quenching water inlet 43 and a quenching water outlet 44 .

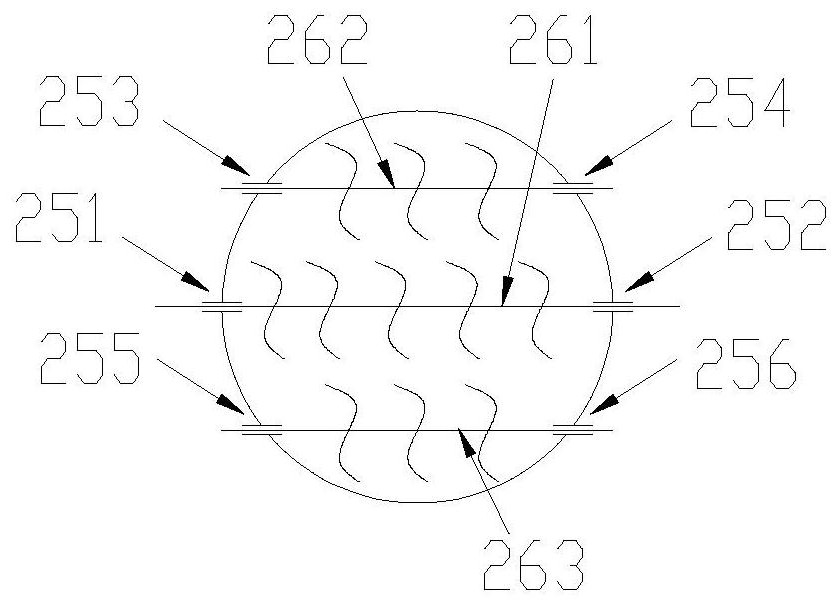

[0035] Wherein, there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com