A method for preparing cds/zns nanowire heterojunction

A nanowire and single-crystal nanotechnology, which is applied in the field of nano-heterojunction preparation, achieves the effect of uniform morphology, easy promotion, and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

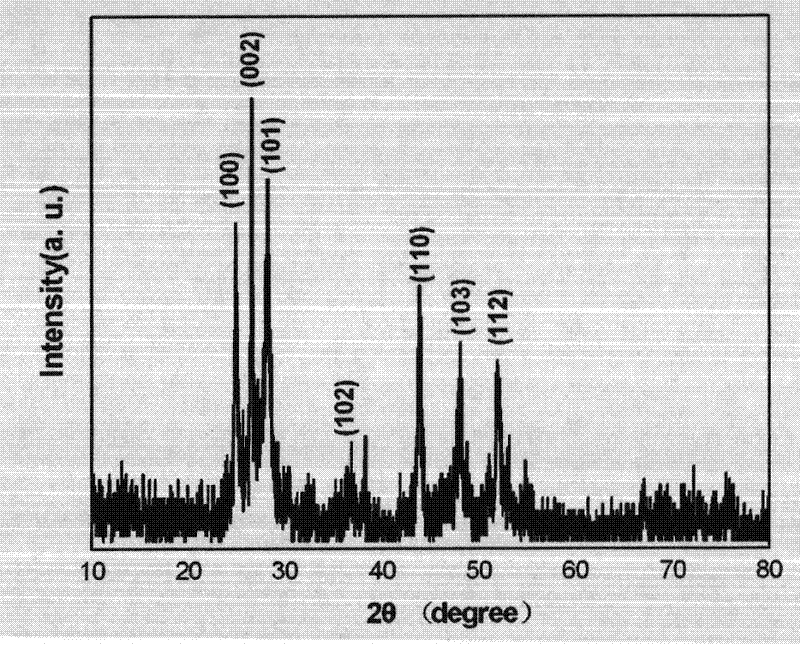

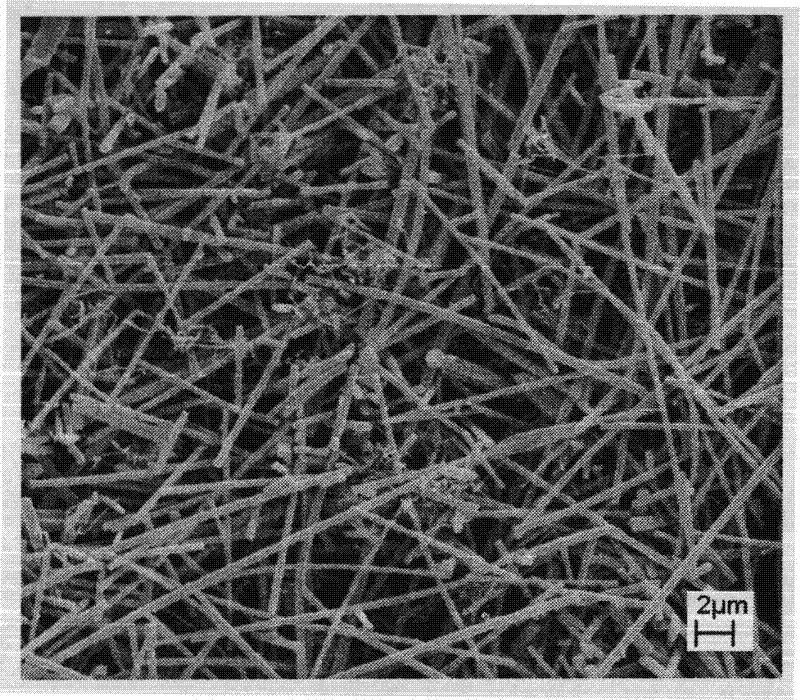

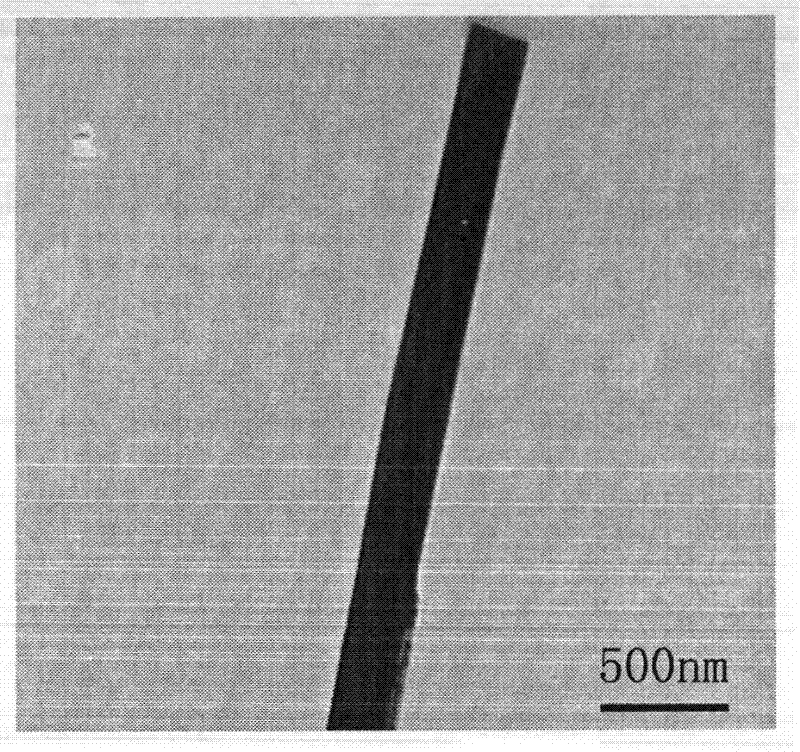

[0021] The first step is to use CdS powder as the raw material and Bi powder as the catalyst. After the two are uniformly mixed at 1mol:0.05mol, the powder is placed on the molybdenum heater, and the conductive surface of the ITO glass is used as the substrate. Place it at about 1.0cm above the evaporation source, airtight the evaporation chamber, when the vacuum degree is 1×10 -2 After Pa, the current was gradually increased to 120A at a current increase rate of 10A / 3.5min and kept for 10 minutes. A large area of uniform yellow deposit is deposited on the surface of the substrate. Analyze and test this product and get: (1) by figure 1 XRD analysis showed that the product obtained was hexagonal CdS, which corresponds to card No. 65-3414 in the ICDD PDF card library; (2) SEM analysis showed that the product obtained was a large area, uniform nanowire. The diameter range is 80-300nm and the length is about 15-40μm (see figure 2 ); (3) by image 3 From the TEM image, it can be ...

Embodiment 2

[0023] The first step is to use CdS powder as the raw material and Bi powder as the catalyst. After the two are uniformly mixed at 1mol:0.05mol, the powder is placed on the molybdenum heater, and the conductive surface of the ITO glass is used as the substrate. Place about 1.0cm above the evaporation source, airtight the evaporation chamber, when the vacuum degree is 5×10 -2 After Pa, the current was gradually increased to 120A at a current increase rate of 10A / 3min and kept for 7min. A large area of uniform yellow deposit is deposited on the surface of the substrate. In the second step, after taking out the sample, place it on a molybdenum heating boat using ZnS as a raw material, and use a large area of uniformly grown CdS single crystal nanowire as a substrate, and place the substrate about 1.6 cm above the evaporation source, and seal it. Evaporation chamber, the vacuum degree is 1.7×10 -2 After Pa, the current was gradually increased to 140A at a current increase rate ...

Embodiment 3

[0025] The first step is to use CdS powder as the raw material and Bi powder as the catalyst. After the two are uniformly mixed at 1mol:0.05mol, the powder is placed on the molybdenum heater, the Si wafer is used as the substrate, and the substrate is placed in the evaporation source. At about 1.3cm above, the evaporation chamber is sealed, when the vacuum degree is 2×10 -2 After Pa, the current was gradually increased to 100A at a current increase rate of 10A / 3.5min and kept for 10 minutes. A large area of uniform yellow deposit is deposited on the surface of the substrate. In the second step, after taking out the sample, place it on a molybdenum heater using ZnS as a raw material, and use a large area of uniformly grown CdS single crystal nanowire as a substrate, and place the substrate about 1 cm above the evaporation source, and evaporate in a sealed manner. Chamber, the vacuum degree is 5×10 -2 After Pa, the current was gradually increased to 120A at a current increase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com