Yttrium barium copper oxide superconducting thin film mixed with samarium and manufacture method thereof

A technology of superconducting thin film and yttrium barium copper oxide is applied in the field of samarium-doped yttrium barium copper oxide superconducting thin film and its preparation field, and can solve the problems of high cost, low deposition efficiency, not suitable for large-scale industrial production and the like, Achieve low cost, improve critical current density, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

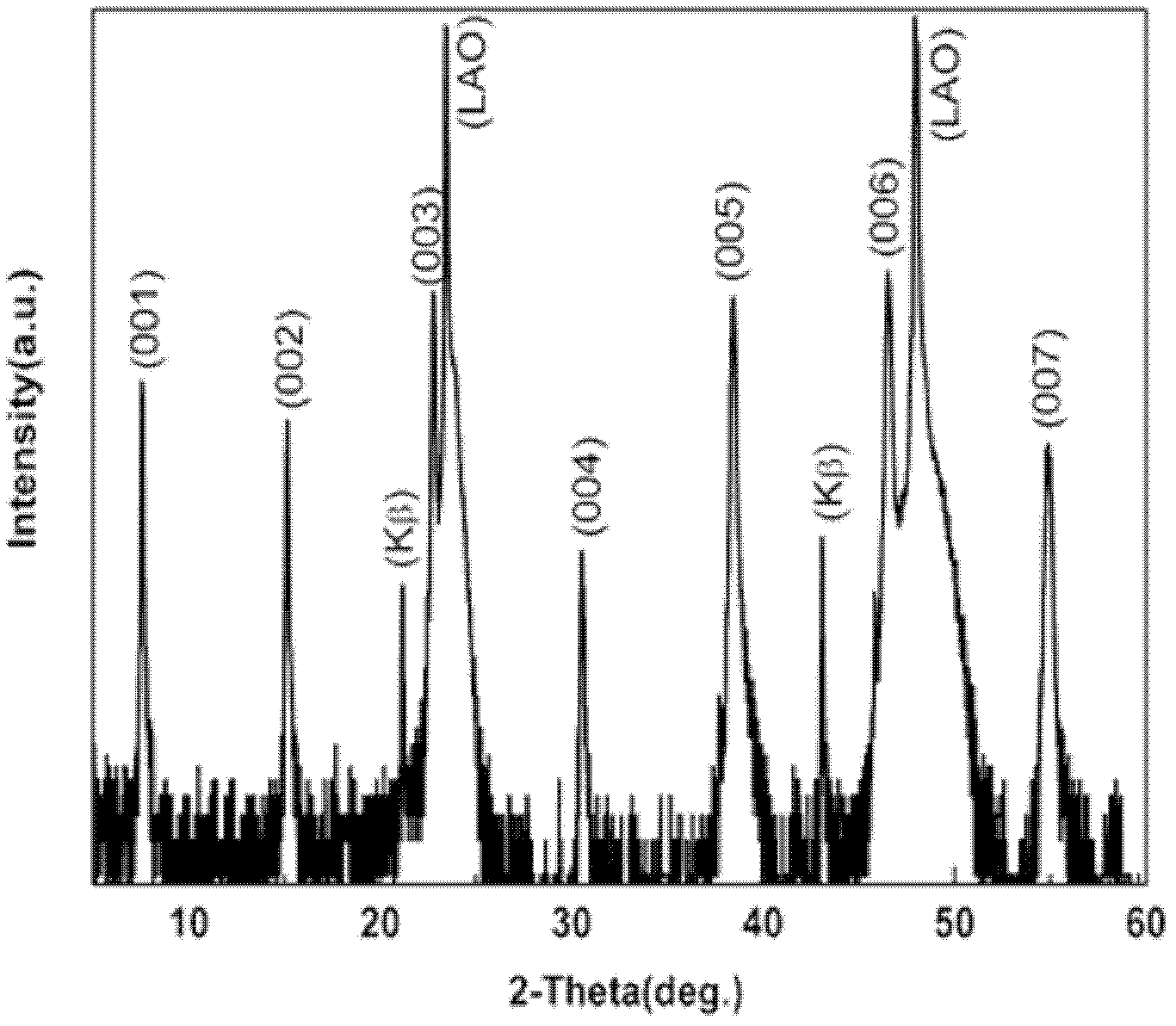

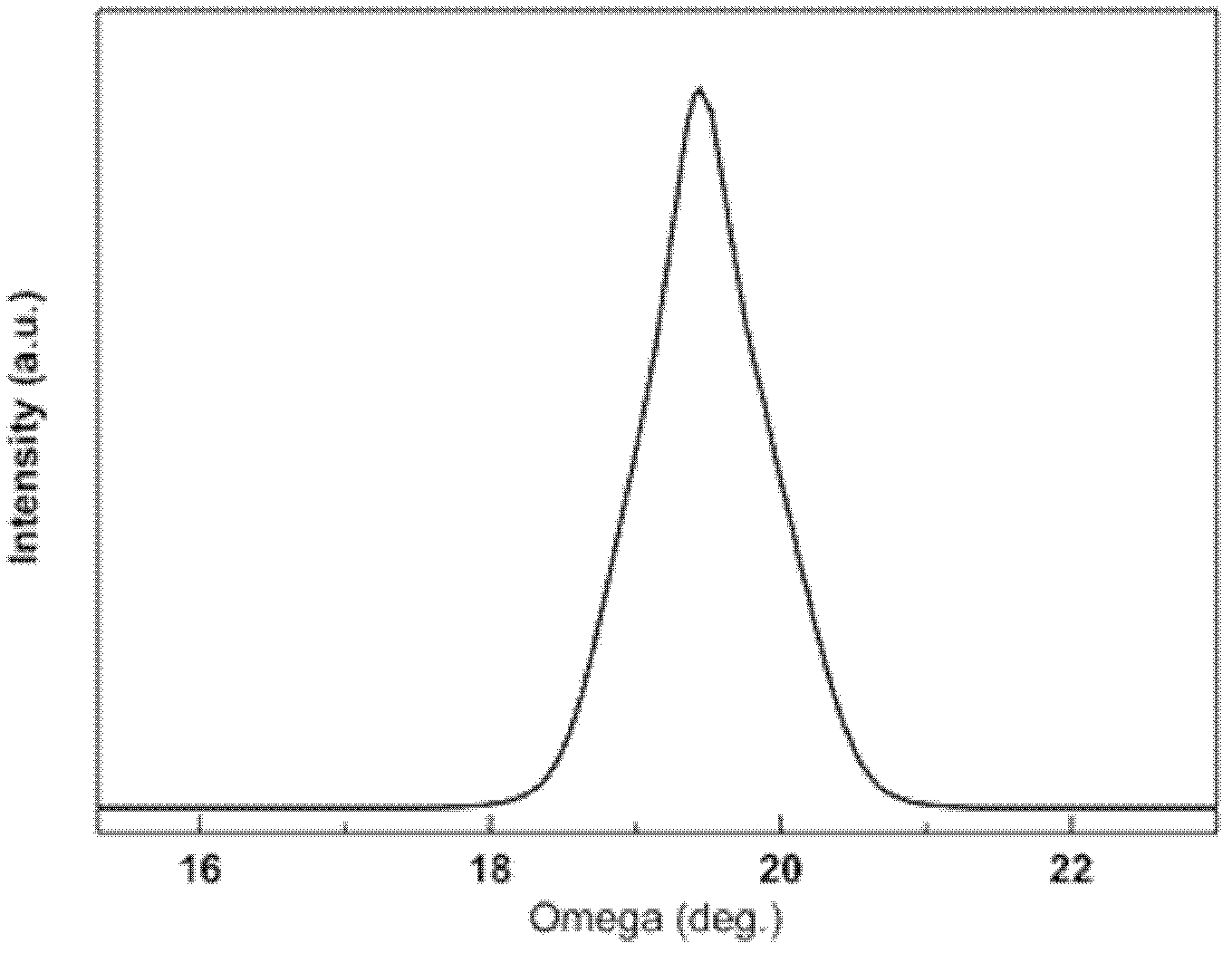

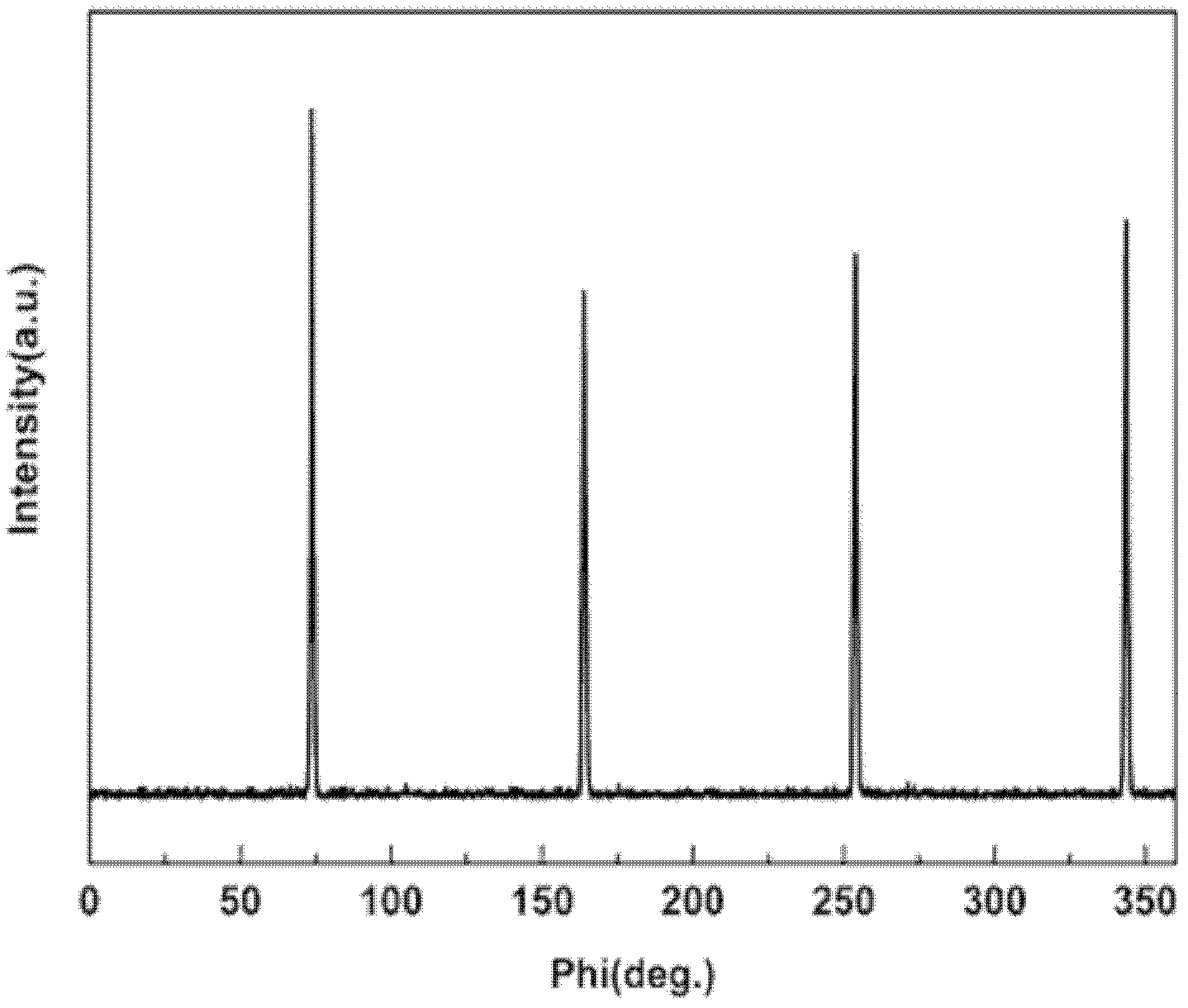

Image

Examples

Embodiment 1

[0035] wxya 0.1 Ba 1.9 Cu 3 o y Preparation of superconducting film: (6.5≤y≤7.0, but this value is not controllable, and it is difficult to test the specific content of oxygen in the film under existing conditions, so it is generally replaced by y)

[0036] Step 1, preparation of precursor solution:

[0037] 101. Add yttrium acetate, samarium acetate, barium acetate and copper acetate to deionized water according to the atomic ratio of yttrium: samarium: barium: copper = 1:0.1:1.9:3 to obtain a suspension;

[0038] 102. According to the stoichiometric ratio of the reaction between trifluoroacetic acid and yttrium acetate, samarium acetate, barium acetate and copper acetate, add 30% excess volume of trifluoroacetic acid to the mixed solution described in 101, stir well and reflux at 80°C for 6 hours , to obtain a blue clear solution; the reaction formula is as follows:

[0039] R(CH 3 COO) n +nCF 3 COOH=R(CF 3 COO) n +nCH 3 COOH

[0040] Where R is Y, Ba, Cu or Sm; wh...

Embodiment 2

[0047] wxya 0.2 Ba 1.8 Cu 3 o y Preparation of superconducting film: (6.5≤y≤7.0, but this value is not controllable, and it is difficult to test the specific content of oxygen in the film under existing conditions, so it is generally replaced by y)

[0048] Step 1, preparation of precursor solution:

[0049] 101. Add yttrium acetate, samarium acetate, barium acetate and copper acetate to deionized water according to the atomic ratio of yttrium: samarium: barium: copper = 1:0.2:1.8:3 to obtain a suspension;

[0050] 102. According to the stoichiometric ratio of the reaction between trifluoroacetic acid and yttrium acetate, samarium acetate, barium acetate and copper acetate, add 30% excess volume of trifluoroacetic acid to the mixed solution described in 101, stir well and then reflux at 80°C for 8 hours , to obtain a blue clear solution; the reaction formula is as follows:

[0051] R(CH 3 COO) n +nCF 3 COOH=R(CF 3 COO) n +nCH 3 COOH

[0052] Where R is Y, Ba, Cu or...

Embodiment 3

[0060] wxya 0.3 Ba 1.7 Cu 3 o y Preparation of superconducting film: (6.5≤y≤7.0, but this value is not controllable, and it is difficult to test the specific content of oxygen in the film under existing conditions, so it is generally replaced by y)

[0061] Step 1, preparation of precursor solution:

[0062] 101. Add yttrium acetate, samarium acetate, barium acetate and copper acetate to deionized water according to the atomic ratio of yttrium: samarium: barium: copper = 1:0.3:1.7:3 to obtain a suspension;

[0063] 102. According to the stoichiometric ratio of the reaction of trifluoroacetic acid with yttrium acetate, samarium acetate, barium acetate and copper acetate, add 30% excess volume of trifluoroacetic acid to the mixed solution mentioned in 101, stir well and reflux at 80°C for 7 hours , to obtain a blue clear solution; the reaction formula is as follows:

[0064] R(CH 3 COO) n +nCF 3 COOH=R(CF 3 COO) n +nCH 3 COOH

[0065] Where R is Y, Ba, Cu or Sm; when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com