Preparation method of high temperature superconductive coating conductor buffer layer

A technology of coated conductors and high-temperature superconductors, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as slow preparation speed, difficulty in long tapes, and complicated equipment, and achieve low equipment cost and small surface roughness , the effect of good c-axis texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

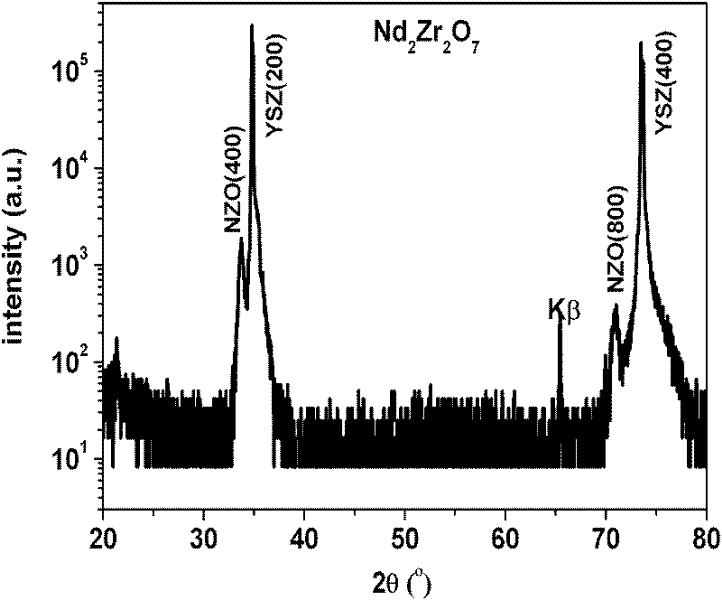

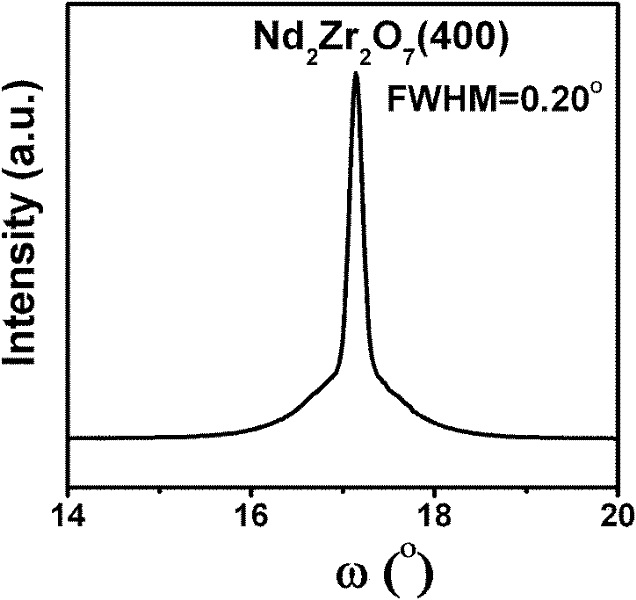

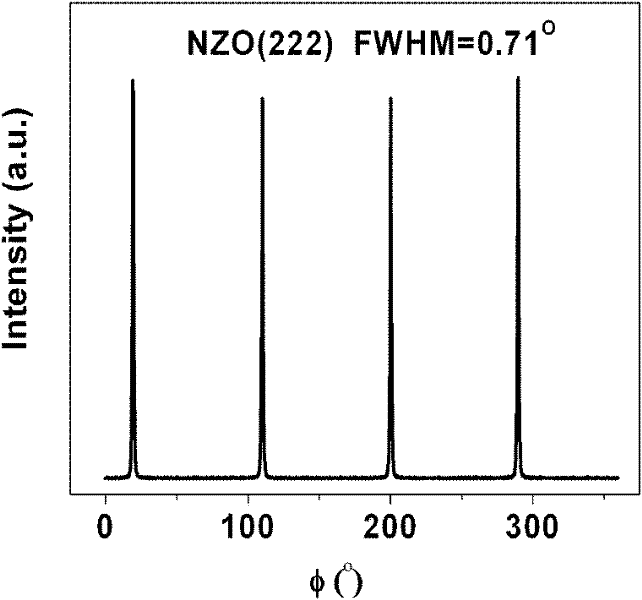

[0035] (1) Nd(acac) 3 2H 2 O and Zr(acac) 4 Mix by a molar ratio of 1:1, then add an organic solvent to the mixture to prepare a precursor solution with a molar concentration of cations of 0.4mol / L; the organic solvent is a mixed solvent of propionic acid and methanol, and in the mixed solvent propionic acid and methanol The volume ratio is 3:2;

[0036] (2) Add 50 μL of the precursor solution described in step (1) dropwise on the ultrasonically cleaned YSZ single crystal substrate (10mm×10mm), and spin coat it with a spin coater at a rotation rate of 2500 rpm for 30s. Apply the precursor solution evenly on the substrate, and then dry it at a temperature not higher than 200°C;

[0037] (3) The YSZ single crystal substrate after drying in the step (2) is placed in the tube furnace, and the gas flow rate is 48L / h Ar-4%H 2 Under the atmosphere, heat up to 500°C at a heating rate of 25°C / min and then hold for 1 hour, then continue to heat up to 1000°C at a heating rate of 25°C...

Embodiment 2

[0041] The preparation method of this embodiment is the same as that of Example 1, wherein the difference is that the raw material used is Sm(acac) 3 ·H 2 O, prepared Sm with good c-axis texture and small surface roughness (RMS less than 5nm) 2 Zr 2 o 7 The buffer layer.

[0042] Sm prepared in this example 2 Zr 2 o 7 The X-ray diffraction pattern of the buffer layer is as Figure 5 , Sm 2 Zr 2 o 7 The ω-scan spectrum of the buffer layer is as follows Figure 6 , Sm 2 Zr 2 o 7 The Φ scan pattern of the buffer layer is as follows Figure 7 , Sm 2 Zr 2 o 7 The atomic force microscope (AFM) photograph of the buffer layer is as Figure 8 .

[0043] From Figure 5 It can be seen that, except for the (200), (400) diffraction peaks of the YSZ single crystal substrate and the K β Outside the peak, only Sm 2 Zr 2 o 7 The (400) and (800) diffraction peaks of the film indicate that only a single Sm 2 Zr 2 o 7 phase with a c-axis orientation. From Figure 6 an...

Embodiment 3

[0045] (1) Nd(acac) 3 2H 2 O and Zr(acac) 4 Mix by a molar ratio of 1:1, then add an organic solvent to the mixture to prepare a precursor solution with a molar concentration of cations of 0.4mol / L; the organic solvent is a mixed solvent of propionic acid and methanol, and in the mixed solvent propionic acid and methanol The volume ratio is 3:2;

[0046] (2) Add 50 μL of the precursor solution described in step (1) dropwise on the Ni-W alloy substrate (10mm×10mm) after ultrasonic cleaning, and spin-coat at a spin rate of 2500 rpm for 30s with a coater , so that the precursor solution is evenly coated on the substrate, and then dried at a temperature not higher than 200°C;

[0047] (3) Place the Ni-W alloy substrate after drying in the step (2) in the tube furnace, and in the Ar-4%H that the gas flow rate is 48L / h 2 Under the atmosphere, heat up to 300°C at a heating rate of 25°C / min and then hold for 1 hour, then continue to heat up to 1000°C at a heating rate of 25°C / min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com