Growth method of CdTe nanorod by catalyst assistant vacuum heat evaporation

A technology of catalysts and nanorods, which is applied in the field of catalyst-assisted vacuum thermal evaporation to grow CdTe thin films with nanorods in microscopic appearance, can solve the problems that it is difficult to obtain large-area uniform nanostructures and no reports have been seen, and achieve Uniform shape, simple operation, large deposition area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

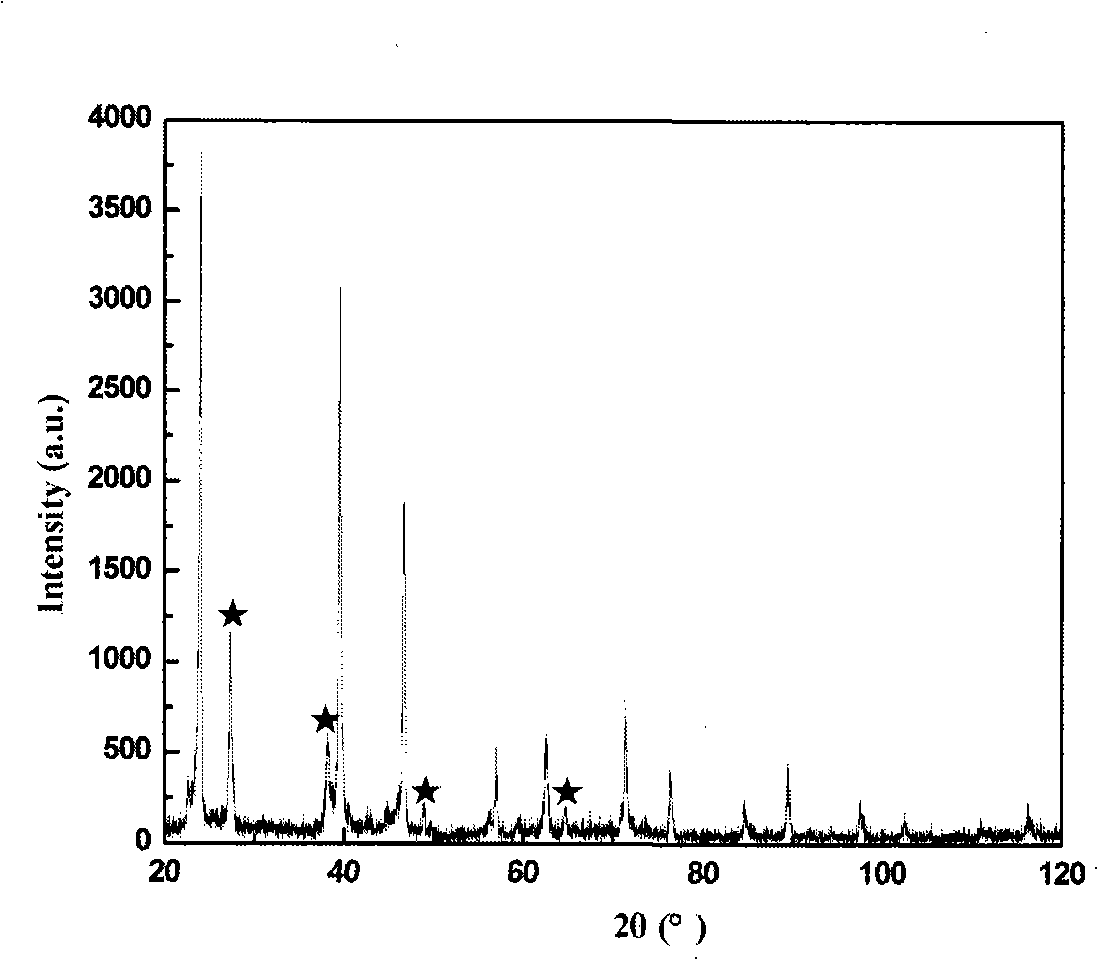

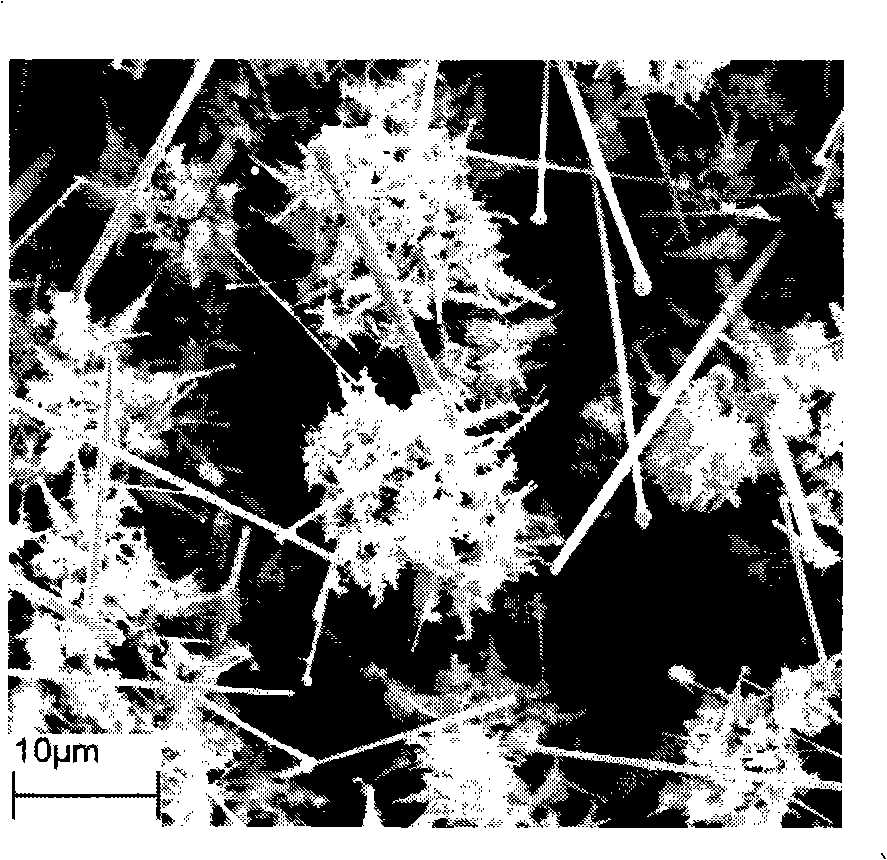

[0017] High-purity CdTe powder (99.5%) is used as raw material, high-purity metal bismuth powder is used as catalyst, the two are mixed according to the ratio of 1mol:0.25mol, put into a ceramic boat and placed on a nickel heater, and ITO glass is used as a base The sheet was placed approximately 4 mm from the evaporation source. When the vacuum reaches 2×10 -3 At this time, the current was gradually increased to 70A at a current increase rate of 2A / min, and then deposited for 15min. The XRD analysis results show that the main phase of the product is cubic CdTe, and the catalyst is hexagonal Bi, such as figure 1 . The surface morphology of the film observed by SEM is nanowires with a length of 30-50 μm and a diameter of 100-300 nm, such as figure 2 .

Embodiment 2

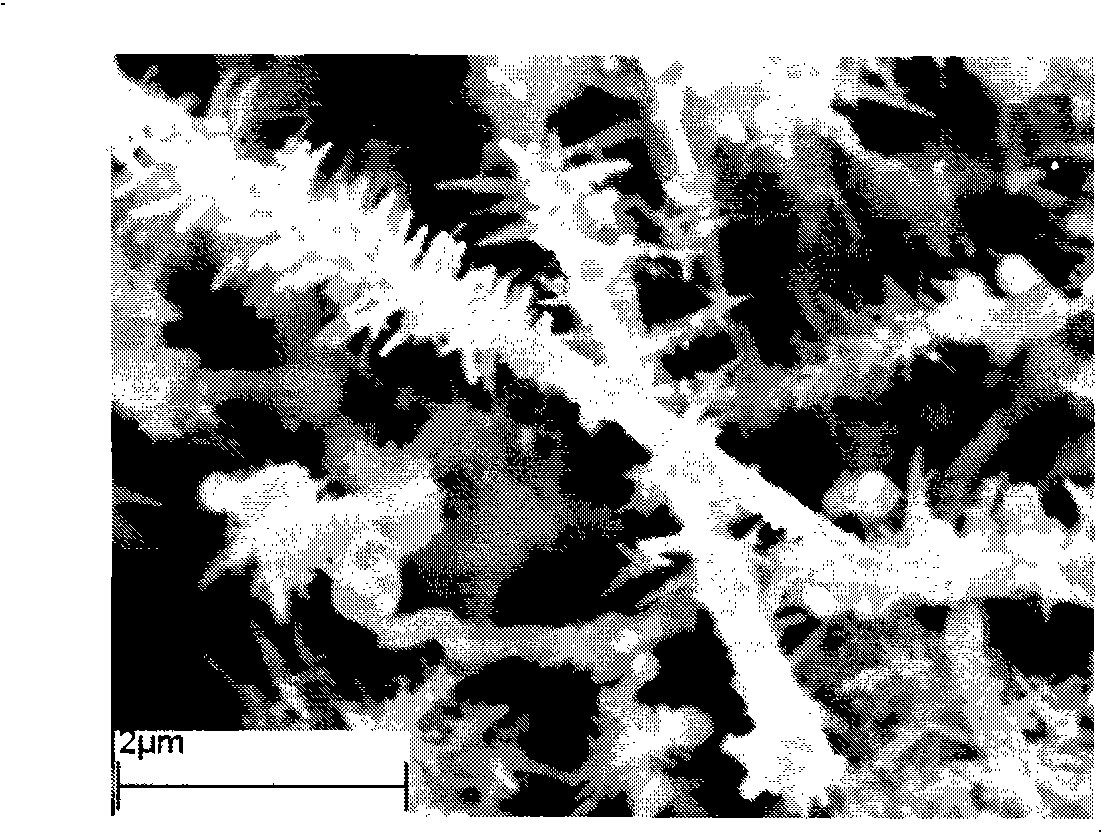

[0019] High-purity CdTe powder (99.5%) is used as raw material, high-purity metal bismuth powder is used as catalyst, the two are mixed according to the ratio of 1mol:0.125mol, put into a ceramic boat and placed on a nickel heater, and ITO glass is used as a base The sheet was placed approximately 4 mm from the evaporation source. When the vacuum reaches 2×10 -3 At the same time, the current was gradually increased to 50A at a current increase rate of 2A / min, and then gradually increased to 60A at a current increase rate of 1A / min, and deposited for 15min. The surface morphology of the film observed by SEM is a nanorod with a branched structure with a trunk diameter of about 500 nm and a branch diameter of about 50 nm, such as image 3 .

Embodiment 3

[0021] High-purity CdTe powder (99.5%) is used as raw material, high-purity metal bismuth powder is used as catalyst, the two are mixed according to the ratio of 1mol:0.125mol, put into a ceramic boat and placed on a nickel heater, and quartz glass is used as a base The sheet was placed approximately 4 mm from the evaporation source. When the vacuum reaches 2×10 -4 At the same time, the current was gradually increased to 50A at a current increase rate of 2A / min, and then gradually increased to 60A at a current increase rate of 1A / min, and deposited for 15min. The surface morphology of the film observed by SEM is a flower-like cluster, and nanorods with a diameter of about 100 nm grow on the surface, such as Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com