Organic-metal nano composite film as well as preparation method and application thereof

A composite film and metal nanotechnology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of small film preparation area, impurity particle pollution, high cost of reactants, etc., and achieve the height of phase structure Controllable, large deposition area, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The organic this embodiment - preparation of metal nano composite film, comprising the steps of:

[0042] 1) # 60, # 600 and # 1500 sandpaper number of successively grinding polytetrafluoroethylene mesh titanium target and a target, and then wipe clean after full infiltration ethanol nonwoven fabric;

[0043] 2) the target silicon wafer after polishing and cleaning charged magnetron sputtering chamber by the mechanical pump and molecular pump vacuum chamber evacuated to 3 × 10 -4 PA, the target shutter remains closed, argon flow rate adjustment of the degree of vacuum of 0.5 Pa, at a substrate temperature of 30 ℃, target - substrate distance 50mm, 30min pre-sputtering DC power at 100W, 200W rf power condition;

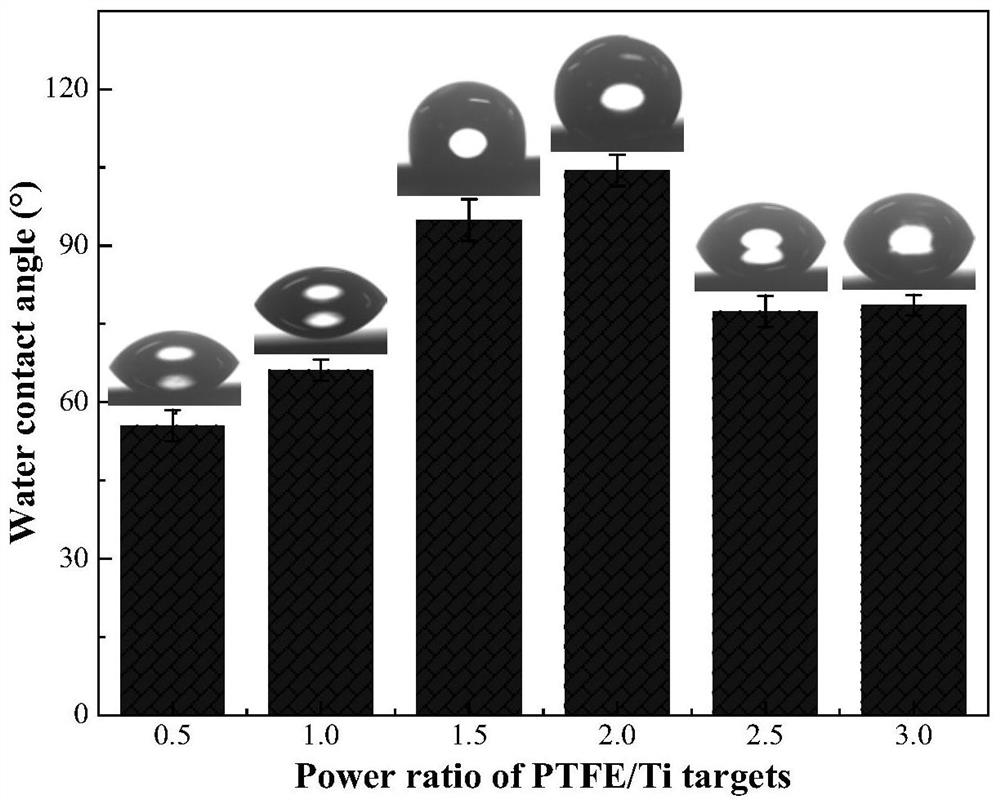

[0044] 3) adjusting the flow of argon so that the coating chamber pressure was raised to 1.0 Pa, DC and RF power is turned on, and the target polytetrafluoroethylene titanium target is started, the DC power was adjusted to 100W, RF power of 50W, the substrate temper...

Embodiment 2

[0047] The organic this embodiment - preparation of metal nano composite film, comprising the steps of:

[0048] 1) # 60, # 600 and # 1500 sandpaper mesh number of target sequence and grinding polytetrafluoroethylene titanium target, after full infiltration of absolute ethanol nonwoven wipe clean;

[0049] 2) Pump the coating chamber to 3 × 10 -4 PA, keep the target baffle closed, adjust the argon flow rate to cause the vacuum to 0.5Pa, at the substrate temperature of 30 ° C, the target-base distance 50mm, and the DC power 100W, the radio frequency power 200W is pre-sputtered under the conditions of 30 min;

[0050] 3) Adjusting the argon flow rate to raise the vacuum to 1.0Pa, turn the DC and RF power supply, enabling the polytetrafluoride target and the titanium target, adjust the DC power to 100W, the radio frequency power is 100 W, the substrate temperature is 25 ° C, At the same time, two target baffles are opened, and the single crystal silicon substrate rotation speed is 150 ...

Embodiment 3

[0053] The organic-metal nano-composite film of the present embodiment includes the following steps:

[0054] 1) Sitting of 60 #, 600 # and 1500 # disciplines in sequentially polished polytetrafluoroide target and titanium target, and then wiper wiper wiper and wiped adequate water absolute ethanol;

[0055] 2) Pump the coating chamber to 3 × 10 -4 PA, keep the target baffle closed, adjust the argon flow rate to cause the vacuum to 0.5Pa, at the substrate temperature of 30 ° C, the target-base distance 50mm, and the DC power 100W, the radio frequency power 200W is pre-sputtered under the conditions of 30 min;

[0056] 3) Adjusting the argon flow rate to raise the vacuum to 1.0Pa, turn on the DC and RF power, enabling the polytetrafluoroethylene target and the titanium target, adjust the DC power to 100W, the radio frequency power is 150W, the substrate temperature is 25 ° C, At the same time, two target baffles are opened, and the single crystal silicon substrate rotation speed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com