Preparation method of glass-substrate/silver nano-film/polyaniline electrochromic film

A glass substrate, electrochromic technology, applied in the field of electrochromic thin film preparation, can solve the problems of high preparation cost, complicated operation, poor uniformity of metal thin film, etc., and achieve excellent color changing effect, uniform conductivity and high conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

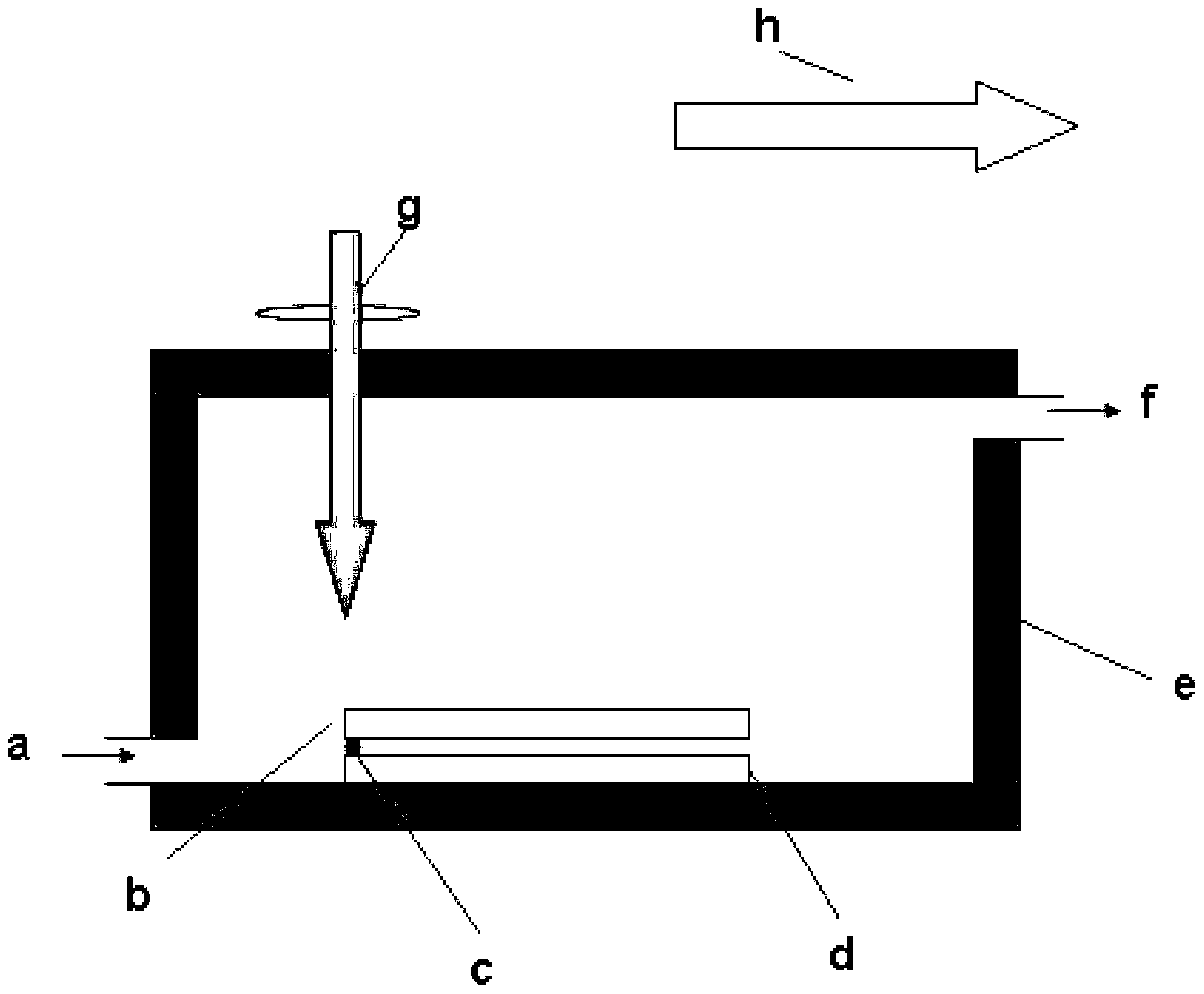

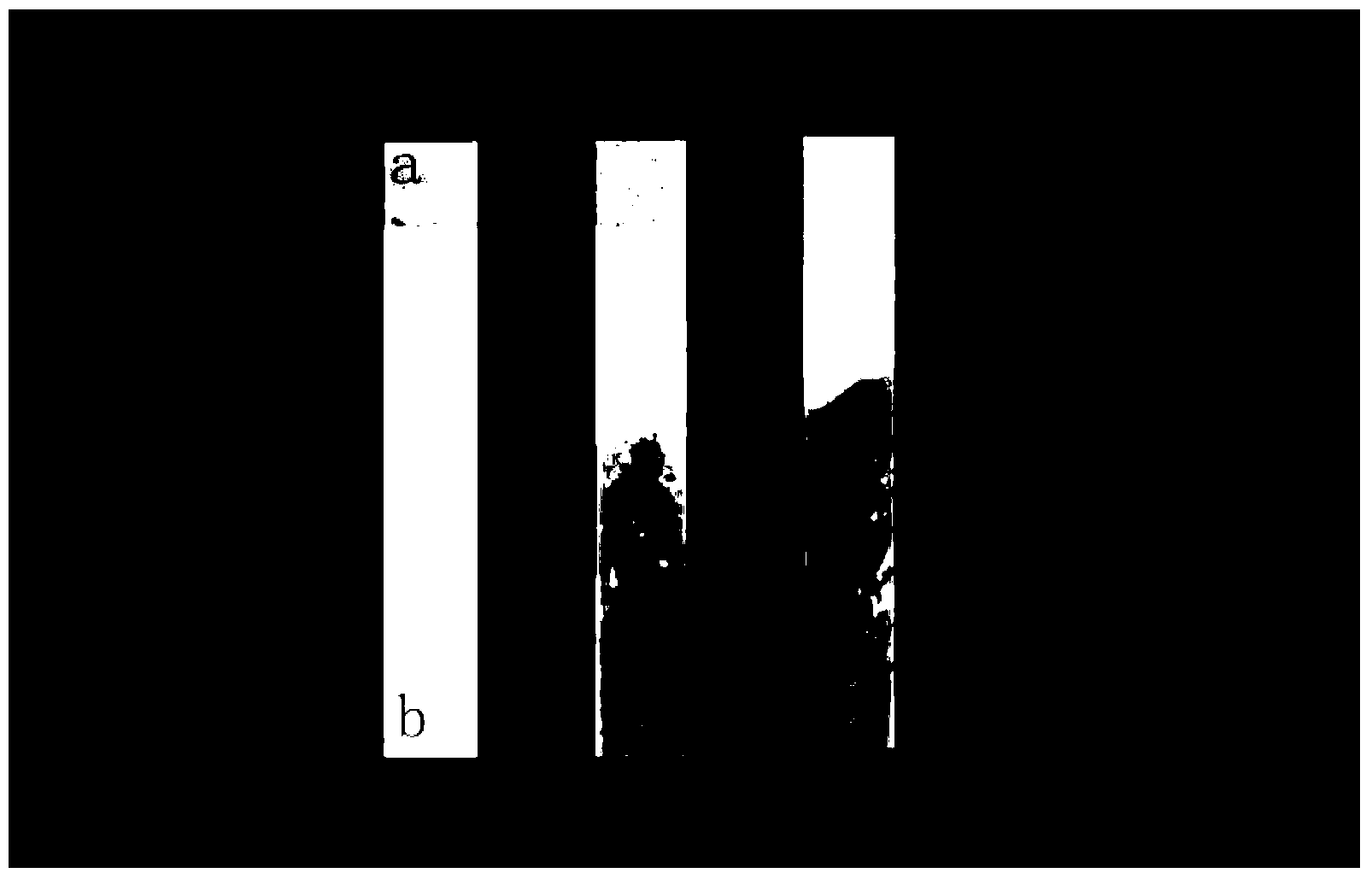

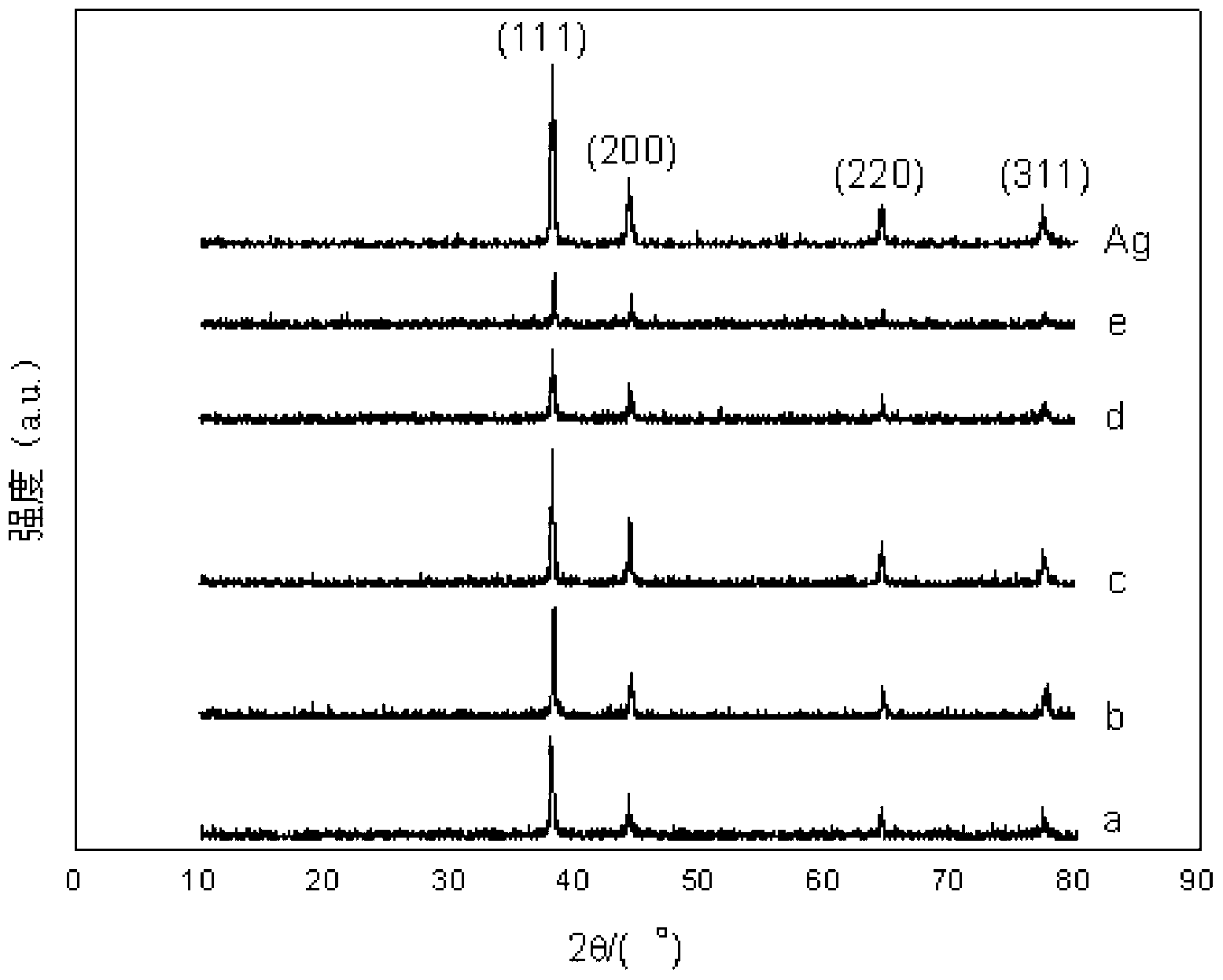

[0041] Embodiment 1: In this embodiment, the preparation method of the glass substrate silver / polyaniline electrochromic film is carried out according to the following steps:

[0042] 1. The pretreated silver flake with a purity of 99.7% is used as the target material, and the cleaned glass flake is used as the base. The glass flake is placed directly above the silver flake. The distance is 5 μm, and the vertical targeting pulse laser method is used to scan the target material under the conditions of a laser beam with a wavelength of 1064 nm, a pulse laser output power of 10W-25W, and a deposition number of 1-20 times at room temperature and in an argon atmosphere. Silver flakes to obtain glass flakes with silver nano-films, namely glass substrates / silver nano-films;

[0043] 2. Add 26.0ml of hydrochloric acid with a mass concentration of 37% to 174.8ml of distilled water to obtain dilute hydrochloric acid; dissolve 45.6g of ammonium persulfate with 100ml of dilute hydrochlori...

specific Embodiment approach 2

[0048] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the output power of the pulsed laser in step 1 is 17W. Others are the same as the first embodiment.

specific Embodiment approach 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the output power of the pulsed laser in Step 1 is 13W. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com