Multi-group hot filament reaction equipment

A technology of reaction equipment and heat grouping, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of inability to deposit different substances, and achieve convenient operation, enlarge deposition area, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

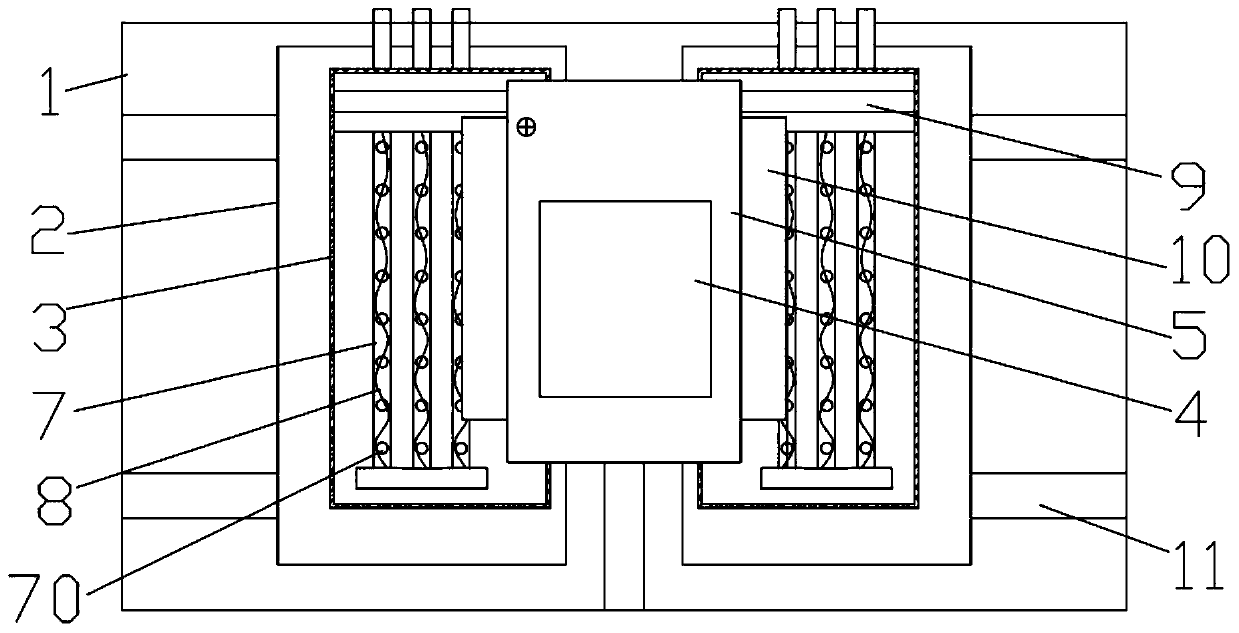

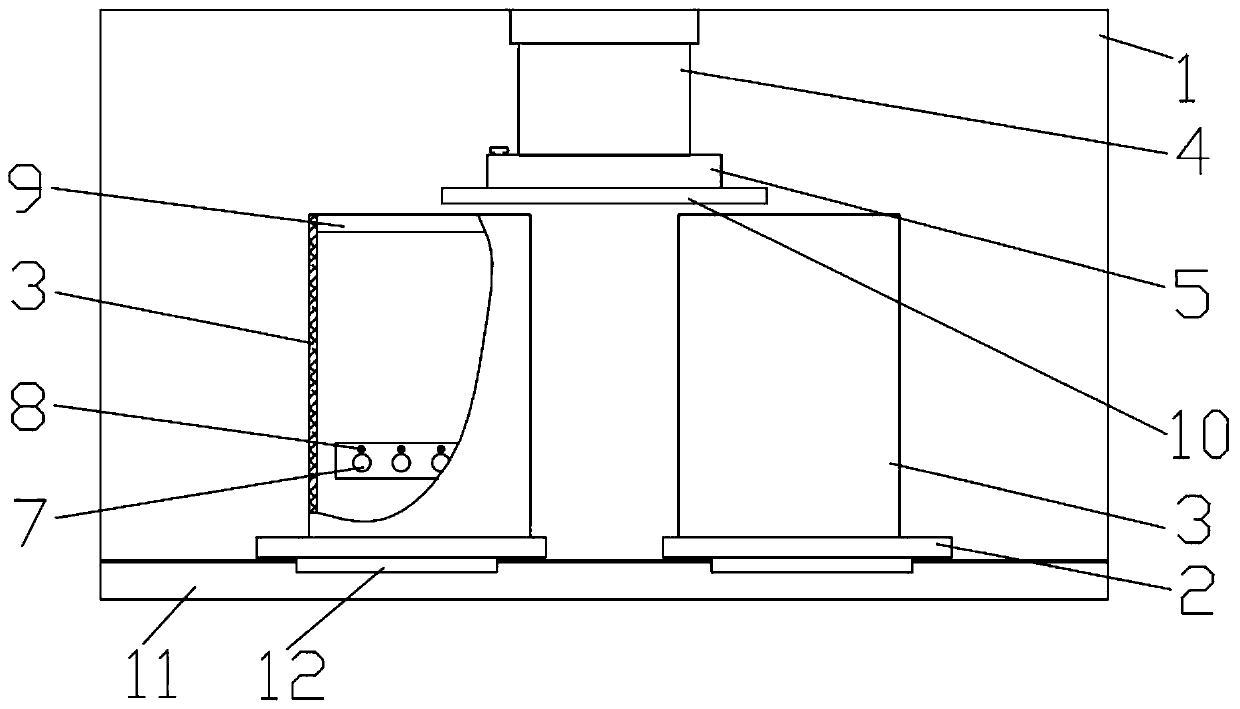

[0022] The invention provides a multi-group hot wire reaction equipment, the structure of which is as follows: figure 1 and figure 2 shown. It includes a casing 1, in which several mobile platforms 2 are arranged side by side along the length direction, and the mobile platforms 2 are all arranged in the casing 1 through a sliding mechanism, and reaction chambers are fixedly arranged on the mobile platforms 2 3. The reaction chamber 3 is provided with a hot wire vapor deposition reaction assembly; the top of the housing 1 is also fixed with a heating device 4, and the bottom of the heating device 4 is provided with a substrate tray 5, and the lining The bottom tray 5 is used to mount a substrate (not shown in the figure). As preferably, the material of the reaction chamber 3 is inert ceramics to prevent reaction with gas, including alumina ceramics, zirconia ceramics and tricalcium phosphate ceramics; in the first embodiment, the height of the reaction chamber 3 is 3 ~ 6cm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com