Method for self-assembling photonic crystal

A photonic crystal and self-assembly technology, applied in crystal growth, chemical instruments and methods, colloidal chemistry, etc., can solve the problems of inability to prepare large-area photonic crystals, photonic crystals cannot be bent, etc., to improve utilization, reduce usage, The effect of increasing the deposition area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

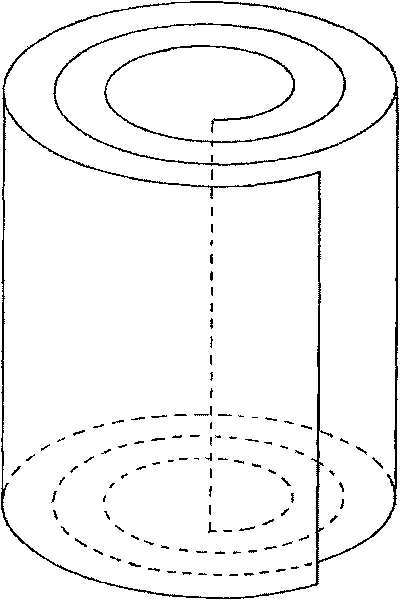

[0013] Embodiment 1: The method for self-assembling photonic crystals in this embodiment is as follows: 1. Surface treatment of the substrate: ultrasonically clean the substrate with deionized water for 10min-30min with acetone for 10min-30min, and then blow it to the surface with nitrogen Dry or bake in a drying oven at 20°C-60°C until dry, then treat with oxygen plasma for 1min-10min; 2. Colloid solution configuration: polystyrene and polymethyl methacrylate with a spherical diameter of 50nm-5μm , silicon dioxide or titanium dioxide pellets are added to the solvent to obtain a solution with a monodispersity of less than or equal to 5% and a mass fraction of 0.005%-5%, and then the resulting solution is ultrasonically oscillated for 10min-30min to obtain a colloidal solution; 3. Put the substrate into the container after cleaning with deionized water for 10-30 minutes, ultrasonically cleaning with acetone for 10-30 minutes, rinsing with deionized water and drying, then add the...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the substrate in Step 1 is directly put into the colloid solution obtained in Step 2 without any treatment. Others are the same as the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the temperature of the drying oven in Step 1 is 35°C-65°C. . Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com