Method for depositing semiconductor film on flexible substrate

A flexible substrate and semiconductor technology, applied in semiconductor devices, climate sustainability, liquid chemical plating, etc., can solve the problems of inability to achieve semiconductor film deposition, insufficient utilization of reaction solutions, and high cost of semiconductor films, and achieve a simple structure. , Low manufacturing cost, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

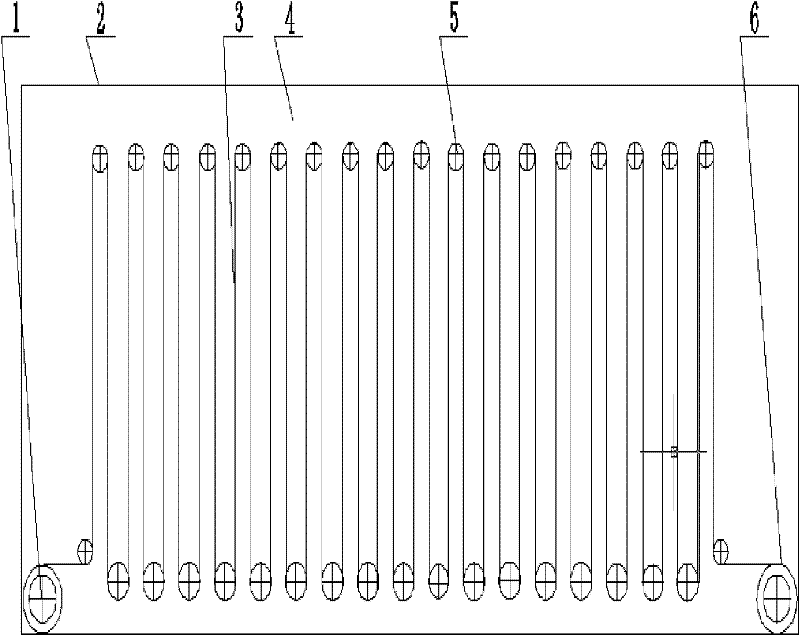

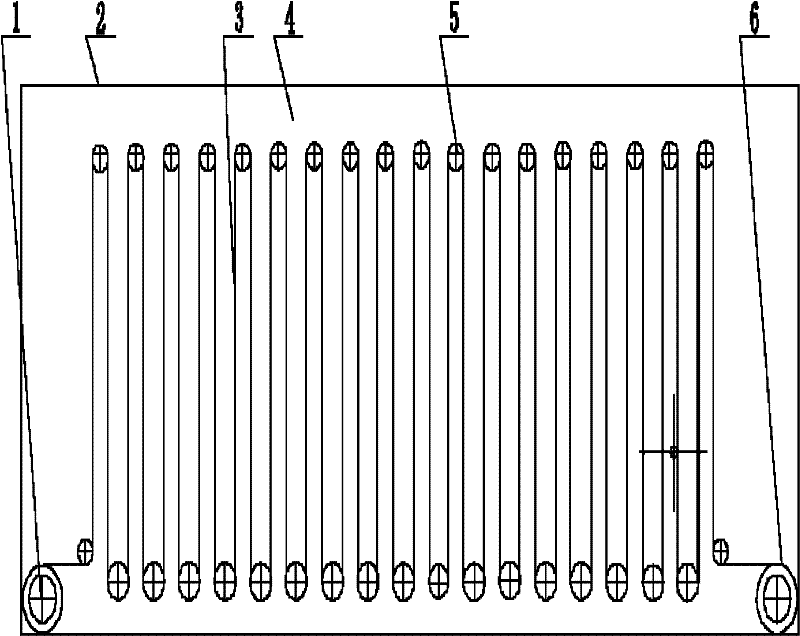

[0020] Embodiment: refer to attached figure 1 . Polypropylene plastic is poured on the stainless steel plate as the material for preparing the reaction tank 2. According to the size requirements, a rectangular plate is cut out as the reaction tank bottom plate 4, and four side panels and reaction tanks corresponding to the size of the reaction tank bottom plate Upper cover; a hole is drilled on both sides of the polypropylene plastic surface of the bottom plate of the reaction tank near the length direction, for installing the reel 1 with the motor and the reel 6 without the motor; the bottom plate of the reaction tank is close to the length direction A row of holes with the same hole spacing are drilled at both ends of each of the two ends, and are used to install the fixed shaft 5 used to support the flexible substrate. horn.

[0021] A smooth fixed shaft whose length is greater than the width of the flexible substrate is made of polypropylene plastic, and the fixed shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com