Electrolysis unit for efficiently recovering heavy metal ions

A heavy metal ion, high-efficiency technology, applied in the direction of cells, can solve the problems of small electrolytic deposition area, complex operation and maintenance, low electrolytic efficiency, etc., and achieve the effect of facilitating collection, improving deposition efficiency, and reducing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

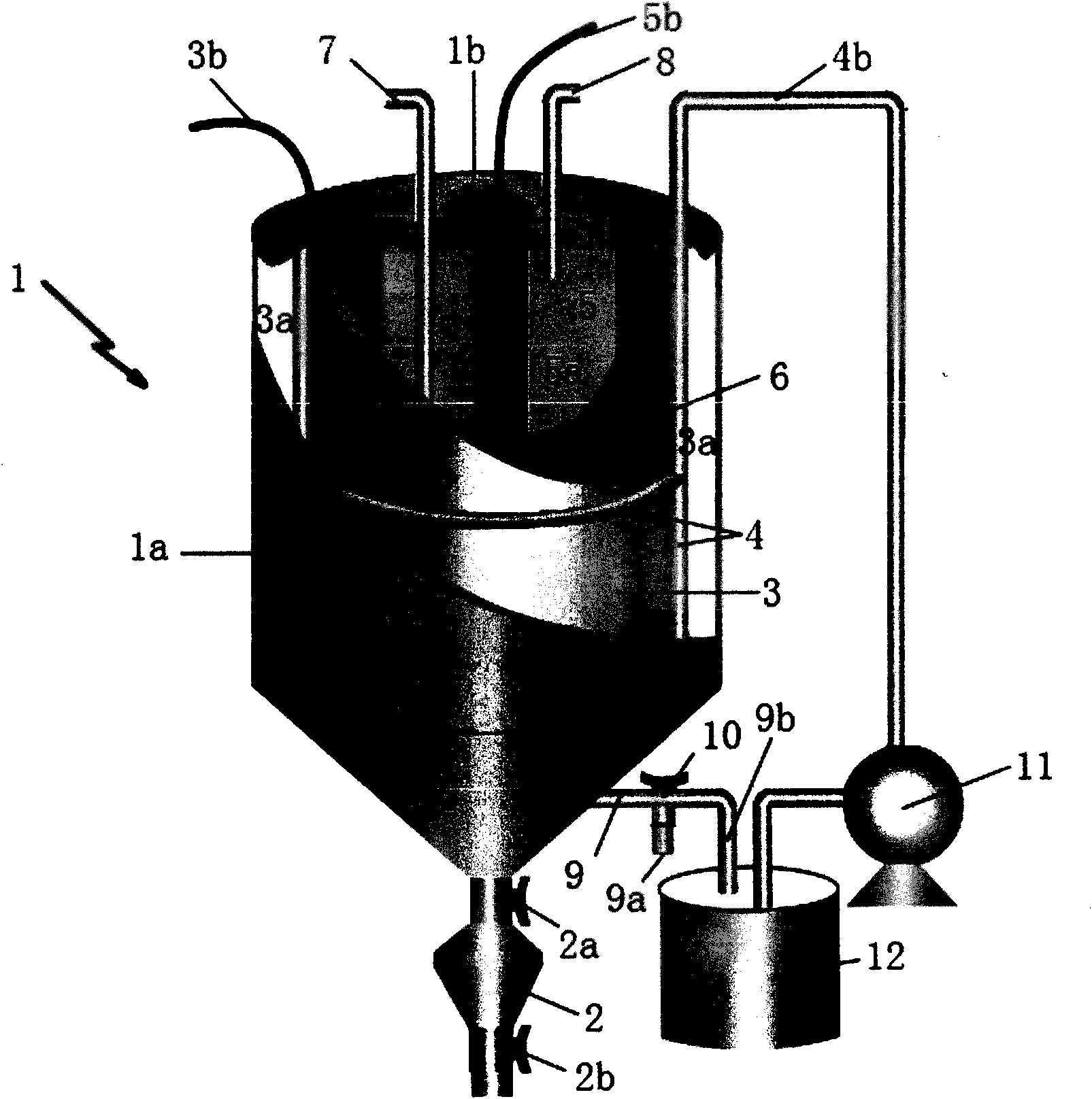

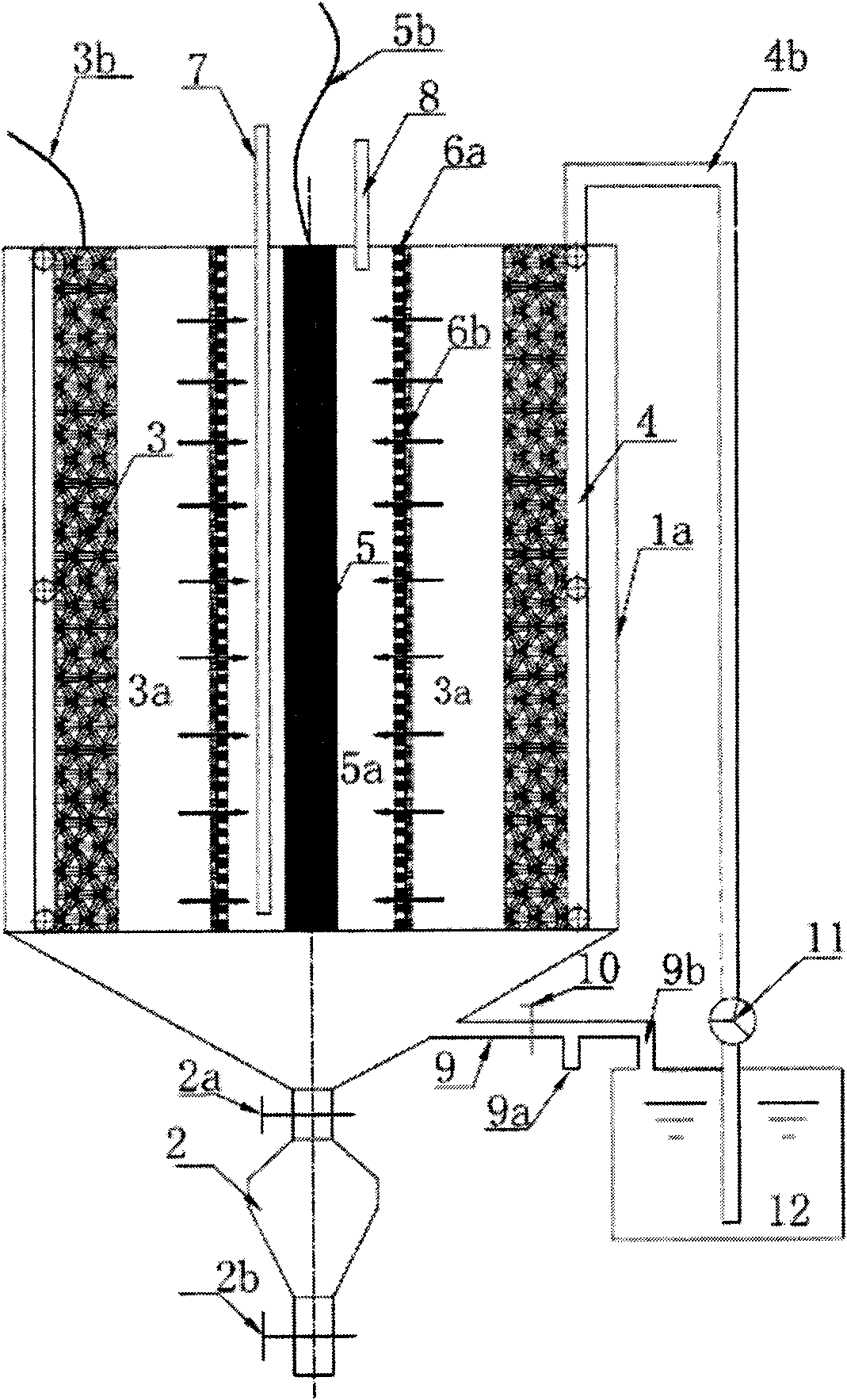

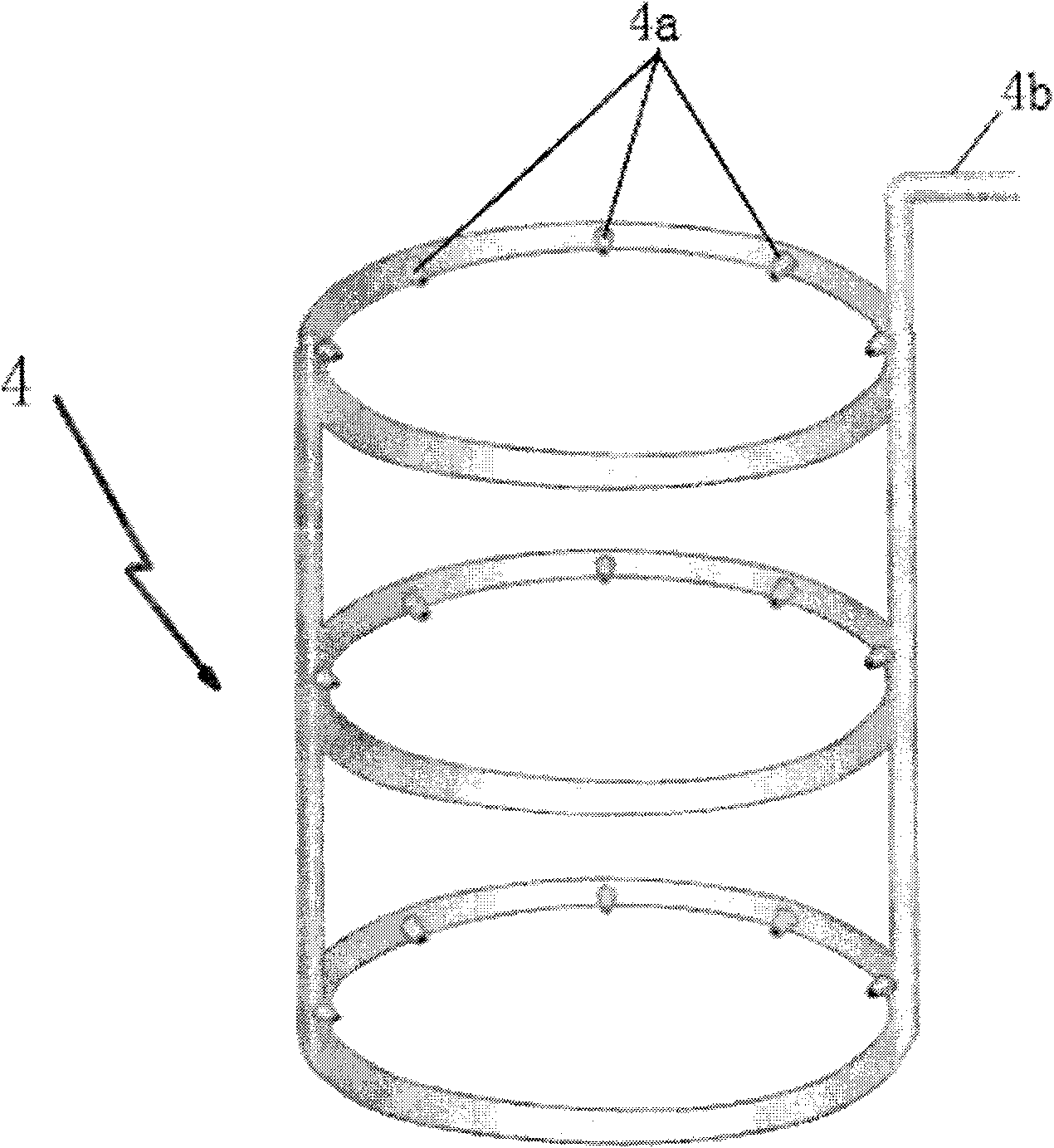

[0017] use Figure 1 to Figure 3 The structure of the electrolysis device disclosed by the present invention is explained. The electrolytic cell 1 is composed of a cell body 1a and an upper cover 1b; the bottom of the cell body 1a is conical, and is provided with a metal powder storage bucket 2 and butterfly valves 2a and 2b, the butterfly valve 2a is a normally open valve, and the butterfly valve 2b is a normally closed valve. The cathode 3 is a multi-dimensional network structure, supported by the cathode support 4 and placed in the tank 1a in a fixed shape, the cathode support 4 is a PVC pipe, and is provided with a plurality of symmetrically distributed high-pressure nozzles 4a with openings facing the cathode 3 (such as image 3 shown). The anion-exchange membrane module 6 is placed between the cathode 3 and the anode 5 to form the cathode chamber 3a and the anode chamber 5a; the anion-exchange membrane module 6 uses a PVC pipe 6a with fine pores as the skeleton, and is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com