Method for preparing AlN mono-crystal nanobelts and nano-branch structure

A single-crystal nano-branched structure technology, applied in chemical instruments and methods, single-crystal growth, single-crystal growth and other directions, to achieve uniform morphology, good crystallinity, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

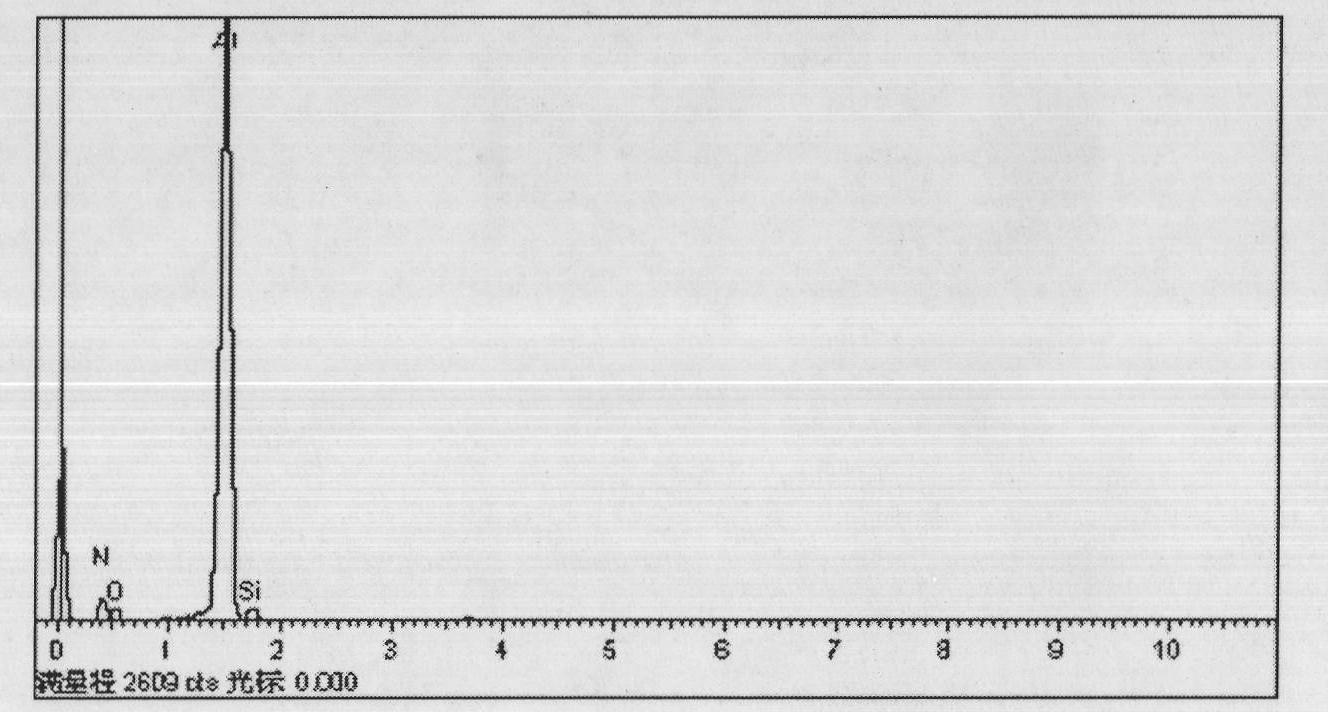

Embodiment 1

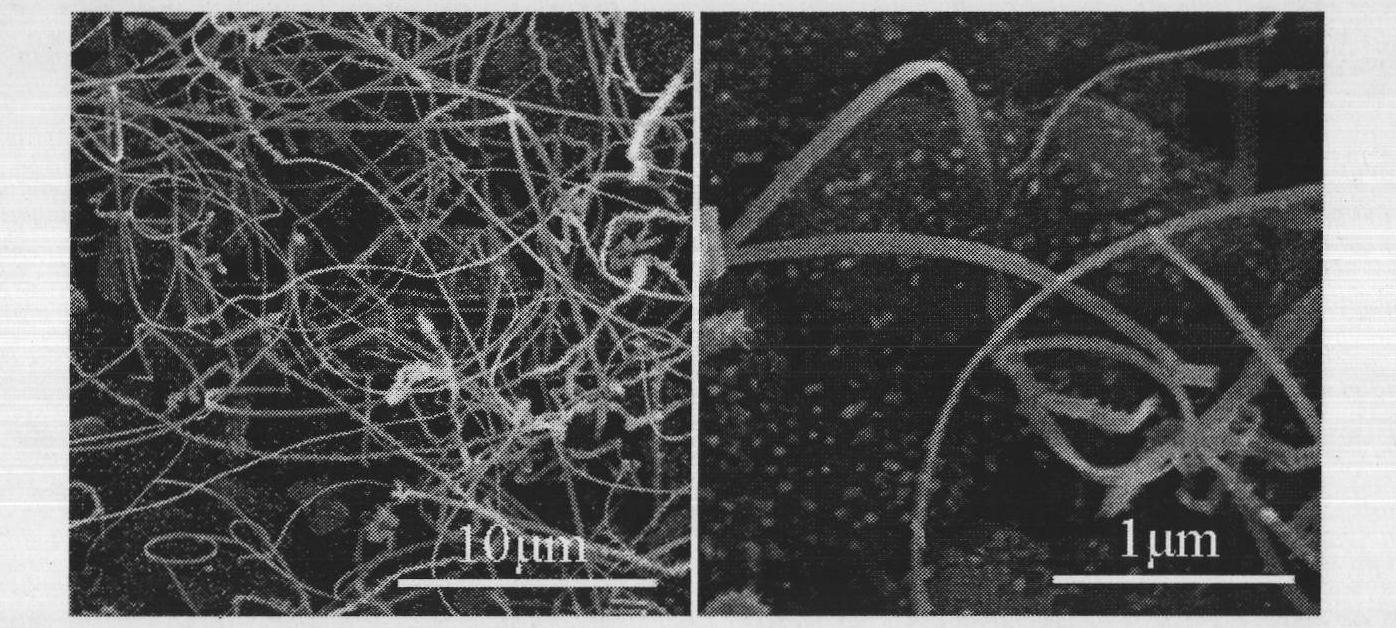

[0025] 0.2 g of Al powder with a purity of 99.99% was put into a ceramic boat, and the polycrystalline Al that had been ultrasonically cleaned with alcohol and deionized water 2 o 3 The substrate is placed 5mm directly above the source as a substrate button, and the ceramic boat is placed in the central area of the tube furnace. After sealing the container, start vacuuming. When the vacuum degree of the corundum tube system reaches 1×10 -2 The flow rate is 200cm in Pa 3 / min (sccm) of argon into the system. Next, the system was heated, and when the furnace temperature reached 1400° C., ammonia gas with a flow rate of 30 sccm was fed in for one hour. Finally, stop the heating system and turn off the ammonia gas when the temperature drops to 800 °C, and naturally cool to room temperature under the protective atmosphere of argon. After cooling, the substrate was taken out, and a white substance was collected on the surface of the substrate. Scanning electron microscope ana...

Embodiment 2

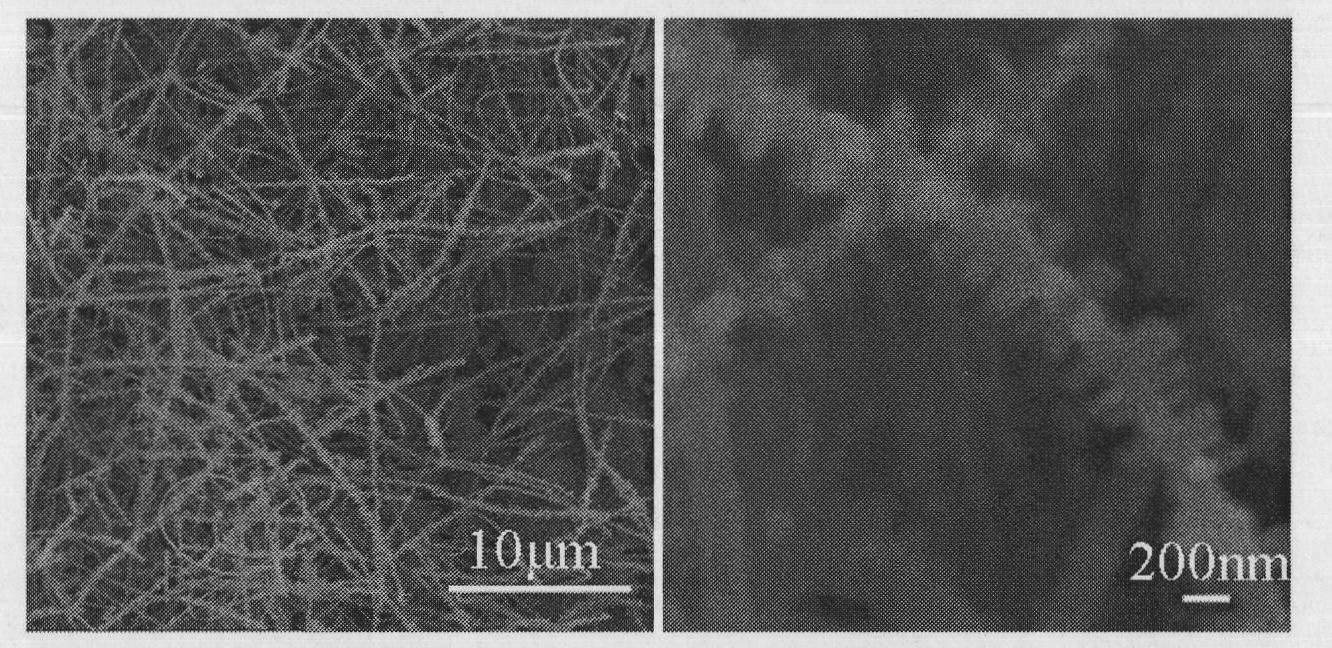

[0027] 0.2 g of Al powder with a purity of 99.99% was put into a ceramic boat, and the polycrystalline Al that had been ultrasonically cleaned with alcohol and deionized water 2 o 3 The substrate is placed 5mm directly above the source as a substrate button, and the ceramic boat is placed in the central area of the tube furnace. When the system vacuum reaches 1×10 -2 The flow rate is 200cm in Pa 3 / min (sccm) of argon into the system. At the same time, the system was heated, and when the furnace temperature reached 1400° C., ammonia gas with a flow rate of 30 sccm was fed in for half an hour. Finally, stop the heating and turn off the ammonia gas when the temperature drops to 800 °C, and naturally cool to room temperature under the protective atmosphere of argon. After cooling, the substrate was taken out, and an off-white substance was collected on the surface of the substrate. Scanning electron microscope analysis shows that the morphology of the substrate area is a n...

Embodiment 3

[0029] 0.2 g of Al powder with a purity of 99.99% was put into a ceramic boat, and the polycrystalline Al that had been ultrasonically cleaned with alcohol and deionized water2 o 3 The substrate is placed 5mm directly above the source as a substrate button, and the ceramic boat is placed in the central area of the tube furnace. After sealing the container, start vacuuming. When the vacuum degree of the corundum tube system reaches 1×10 -2 The flow rate is 200cm in Pa 3 / min (sccm) of argon into the system. Next, the system was heated, and when the furnace temperature reached 1400° C., ammonia gas with a flow rate of 30 sccm was introduced and kept for two hours. Finally, stop the heating system and turn off the ammonia gas when the temperature drops to 800 °C, and naturally cool to room temperature under the protective atmosphere of argon. After cooling, the substrate was taken out, and a white substance was collected on the surface of the substrate. The results showed t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com