Hydro-thermal synthesis preparation method of copper, zinc, tin and sulfur films

A technology of copper-zinc-tin-sulfur and hydrothermal synthesis, which is applied in metal material coating process, coating, liquid chemical plating, etc., can solve the problem of difficulty in ensuring film thickness and chemical composition uniformity, increasing battery manufacturing cost, and device performance problems such as decline, to achieve good market application prospects, high material utilization, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

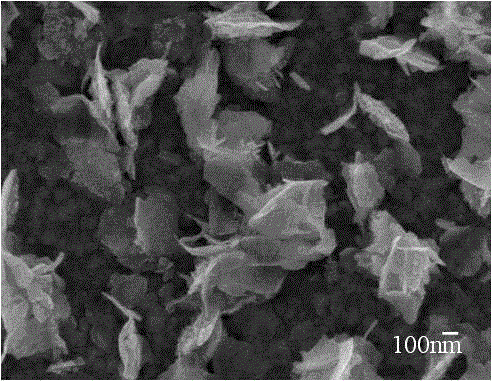

[0030] Embodiment 1: The method for hydrothermal synthesis of the copper-zinc-tin-sulfur thin film in this embodiment includes the following steps:

[0031] 1) Prepare CuCl solution with a concentration of 0.1mol / L and ZnSO with 0.05mol / L respectively 4 Solution, 0.05mol / L SnCl 4 ·5H 2 O solution, 1mol / L EDTA-NH 3 Solution and 0.2mol / L C 2 H 5 NS solution.

[0032] 2) Measure 8.0ml of the CuCl solution and 8.0ml of ZnSO with a graduated cylinder 4 Solution and 8.0ml of SnCl 4 ·5H 2 O solution, mix and pour it into a beaker, stir evenly at room temperature to obtain a precursor solution.

[0033] 3) After the precursor solution in step 2) is evenly stirred, measure 1.6ml of EDTA-NH with a graduated cylinder 3 The mixed solution is added to the precursor solution, and then 4.675 g of the complexing agent urea is weighed into the precursor solution and stirred evenly at room temperature.

[0034] 4) After stirring uniformly, adjust the pH value of the mixed solution obtained in step 3) wi...

Embodiment 2

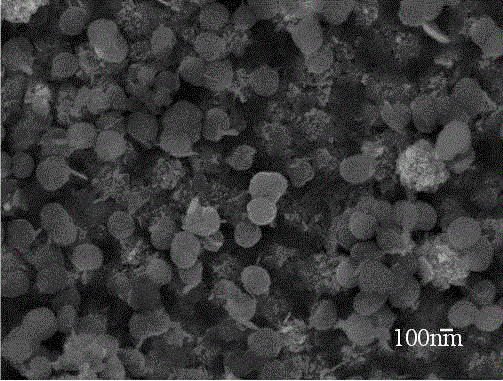

[0039] Embodiment 2: The method for hydrothermally synthesizing a copper-zinc-tin-sulfur film in this embodiment includes the following steps:

[0040] 1) Prepare CuCl solution with a concentration of 0.2mol / L and ZnCl with 0.1mol / L respectively 2 Solution, 0.1mol / L SnCl 4 ·5H 2 O solution, 1mol / L EDTA-NH 3 Solution and 0.4mol / L of H 2 NCSNH 2 Solution.

[0041] 2) Measure 8.0ml CuCl solution and 8.0ml ZnCl with a graduated cylinder 2 Solution and 8.0ml of SnCl 4 ·5H 2 O solution, mix and pour it into a beaker, stir evenly at room temperature to obtain a precursor solution.

[0042] 3) After the precursor solution in step 2) is evenly stirred, measure 3.2ml of EDTA-NH with a graduated cylinder 3 The mixed solution was added to the precursor solution, and then 18.704g of the complexing agent ammonium fluoride was weighed into the precursor solution, and stirred evenly at room temperature.

[0043] 4) After stirring evenly, adjust the pH value of the mixed solution obtained in step 3) wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com