High-temperature brazing filler metal for soldering C/C and C/SiC composite materials and preparation methods thereof

A technology of composite materials and high-temperature solder, which is applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of low high-temperature strength retention rate of joints and poor joint performance, so as to ensure the mechanical properties of joints, Low cost, good wettability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

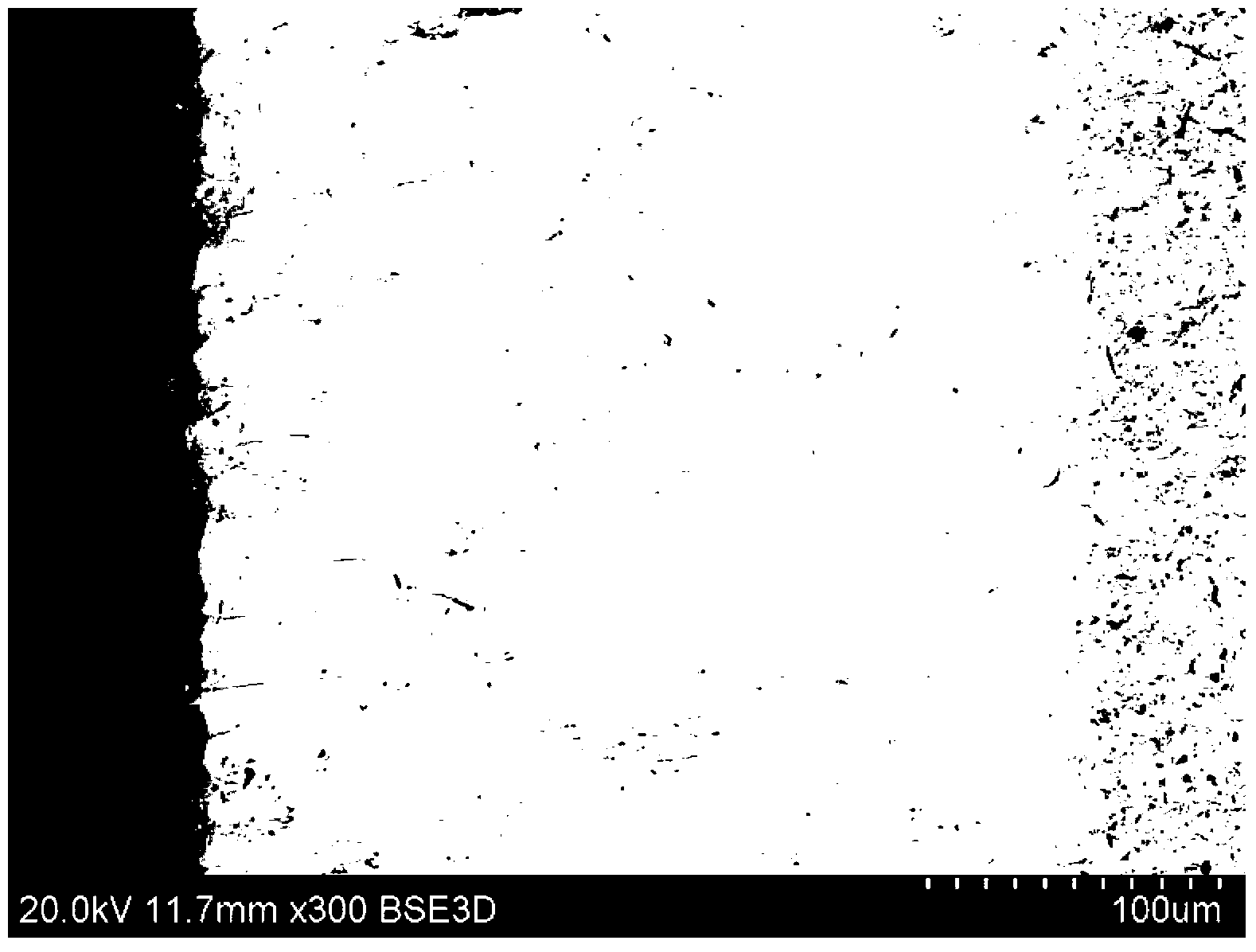

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode one: the high-temperature brazing material of brazing C / C and C / SiC composite materials in this embodiment is composed of 25-35 parts of Ni, 65-75 parts of Zr or ZrH by weight fraction 2 production.

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the high-temperature solder for brazing C / C and C / SiC composite materials is composed of 30 parts of Ni, 70 parts of Zr or ZrH by weight fraction 2 production. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the Ni purity is 99.0% to 99.9%, the Zr purity is 99.0% to 99.9%, and the ZrH 2 The purity is 99.0% to 99.9%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com