Three-dimensional layered MXene electromagnetic shielding foam and preparation method thereof

An electromagnetic shielding and foam technology, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of low absorption and shielding efficiency, complicated preparation process, poor mechanical properties, etc., and achieve good compression cycle characteristics, high mechanical strength, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Mix and stir 5M LiF and 6M HCl, then slowly add 2g of Ti to the solution 3 AlC 2 Powder, stirred for 24h. After the reaction, the suspension was centrifuged with deionized water at 3500rpm for 5 times, each time for 3min, and then the rotation speed was adjusted to 10000rpm for 10min, and the upper black solution obtained by centrifugation was the few-layer Ti 3 C 2 T x Dispersion of MXene.

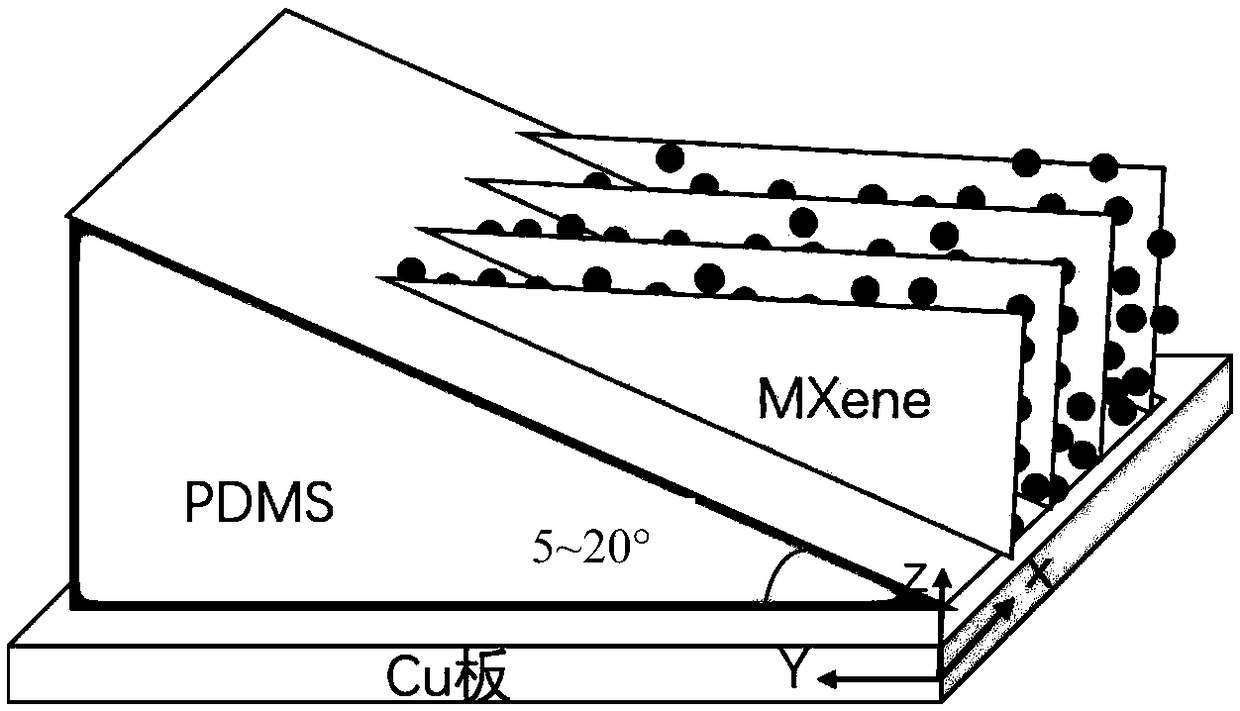

[0032] (2) Ti with a concentration of 15mg / mL 3 C 2 T x The dispersion was placed in a polytetrafluoroethylene mold with a wedge-shaped polydimethylsiloxane base (slope 20°), and directional freezing was performed with liquid nitrogen until Ti 3 C 2 T x The solution freezes completely, as figure 1 shown.

[0033] (3) The frozen Ti 3 C 2 T x The dispersion and the mold were dried in a freeze dryer for 48 hours at a temperature of 30°C. After drying, the mold was demolded to obtain a layered Ti 3 C 2 T x foam, shaped like figure 2 shown.

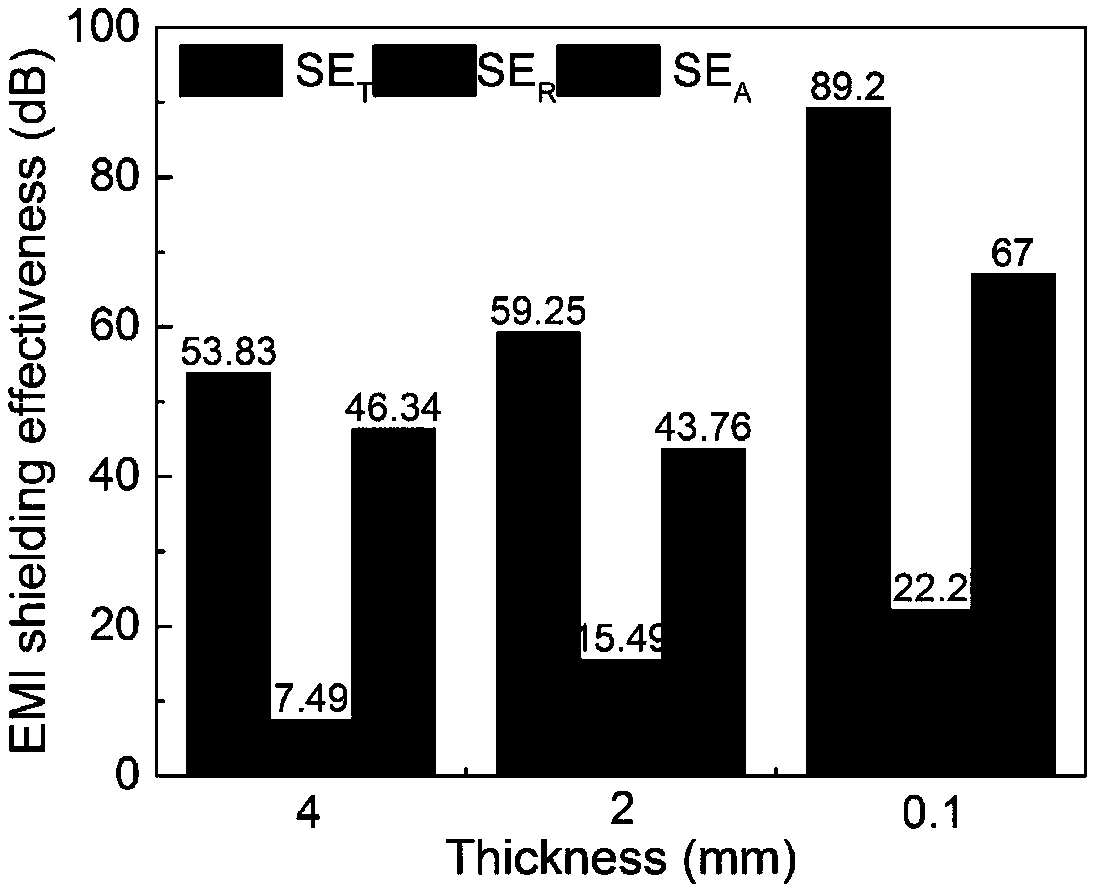

[0034] The prepared...

Embodiment 2

[0036] (1) Mix and stir 8M LiF and 8M HCl, then slowly add 1g of Ti to the solution 2AlC powder, stirred for 36h. After the reaction, the suspension was centrifuged with deionized water at 3500rpm for 5 times, each time was 3min, and then the rotating speed was adjusted to 8000rpm, and the time was 30min. The upper black solution obtained by centrifugation was the few-layer Ti 2 CT x of the dispersion.

[0037] (2) Ti with a concentration of 9mg / mL 2 CT x The dispersion was placed in a polytetrafluoroethylene mold with a wedge-shaped PDMS base (slope 15°), and directional freezing was performed with liquid nitrogen until Ti 2 CT x The solution freezes completely.

[0038] (3) Place the frozen MXene dispersion and the mold in a freeze dryer for 36 hours to dry at 0°C, and demould after drying to obtain a layered Ti 2 CT x Foam.

[0039] The prepared layered Ti 2 CT x The electromagnetic shielding effectiveness of the foam can reach 70dB, of which the absorption shiel...

Embodiment 3

[0041] (1) Mix and stir 12M LiF and 8M HCl, then slowly add 2g of Ti to the solution 3 AlCN powder, stirred for 48h. After the reaction, the suspension was centrifuged with deionized water at 3500rpm for 7 times, each time was 3min, and then the rotation speed was adjusted to 9000rpm, and the time was 20min. The upper black solution obtained by centrifugation was the few-layer Ti 3 CNT x of the dispersion.

[0042] (2) Ti with a concentration of 6mg / mL 3 CNT x The dispersion was placed in a polytetrafluoroethylene mold with a wedge-shaped PDMS base (slope 10°), and directional freezing was performed with liquid nitrogen until Ti 3 CNT x The solution freezes completely.

[0043] (3) The frozen Ti 3 CNT x The dispersion and the mold were placed in a freeze dryer for drying treatment 72, the drying temperature was -73°C, and the mold was demoulded after drying to obtain a layered Ti 3 CNT x Foam.

[0044] The prepared layered Ti 3 CNT x The electromagnetic shielding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com