Coating material for surface modification of PBO (Poly-p-phenylene Benzobisoxazole) fibers, surface modified PBO fibers and preparation and application thereof

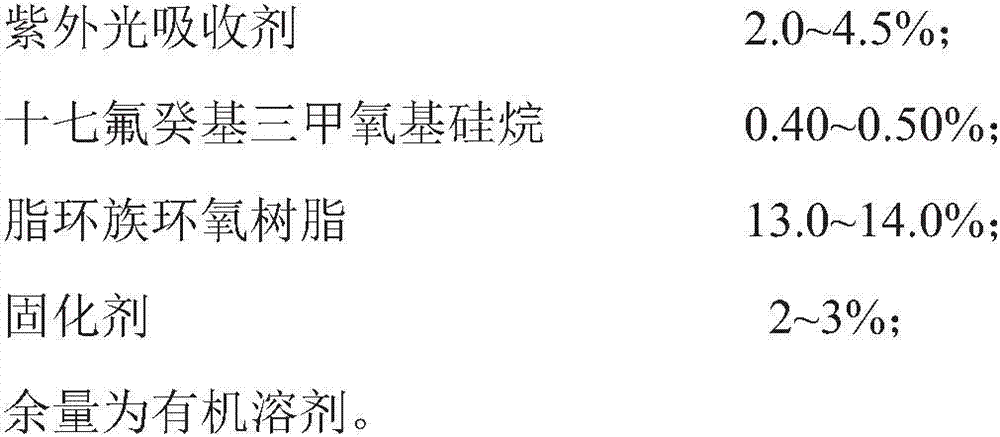

A coating material and fiber surface technology, applied in the field of functional polymer composite materials, can solve the problems of short service life and high cost of PBO fibers, achieve high hydrophobic performance and weather resistance, increase service life and waterproof performance, and improve hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

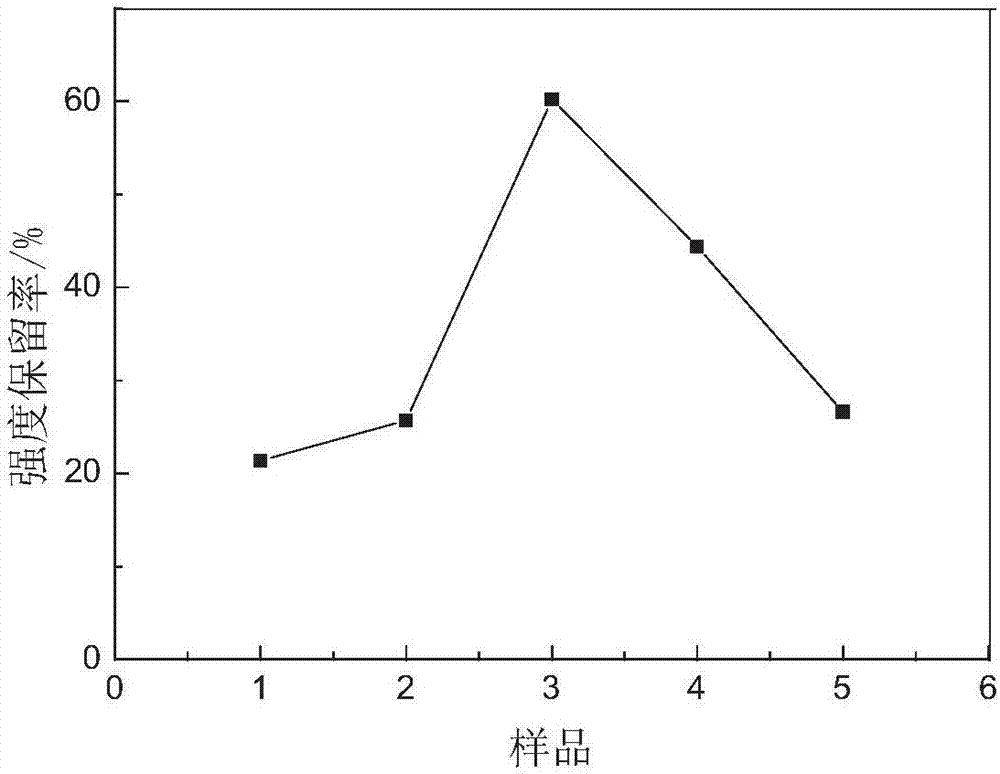

Examples

Embodiment 1

[0056] 1) Soak the PBO fiber in alcohol solution for 24 hours, wash it with distilled water and dry it; use an ethanol solution containing 5% coupling agent KH-560 to ultrasonically vibrate the PBO fiber for 10 minutes, and cure it at 120°C for 1 hour;

[0057] 2) 1 g of heptadecafluorodecyltrimethoxysilane and 33.33 g of isopropanol were mixed and ultrasonically treated for 1 to 2 hours to obtain a 3 wt % solution of heptadecafluorodecyltrimethoxysilane in isopropanol;

[0058] 3) Dissolve 3g of cycloaliphatic epoxy resin (JEW-0114, epoxy value 0.478, Changshu Jiafa Chemical Co., Ltd.) in 15g of ethyl acetate solution, and stir until the cycloaliphatic epoxy resin is completely dissolved in acetic acid In the solution of ethyl ester; The isopropanol solution (heptadecafluorodecyltrimethoxysilane 0.09g, 2.91 g of isopropanol) was evenly mixed in the ethyl acetate solution of cycloaliphatic epoxy resin, then 0.54 g of curing agent low-molecular polyamide 650 was added, and ultr...

Embodiment 2

[0061] 1) Soak the PBO fiber in alcohol solution for 24 hours, wash it with distilled water and dry it; use an ethanol solution containing 5% coupling agent KH-560 to ultrasonically vibrate the PBO fiber for 10 minutes, and cure it at 120°C for 1 hour;

[0062] 2) Mixing 1 g of heptadecafluorodecyltrimethoxysilane with 33.33 g of isopropanol and ultrasonically treating it for 1 to 2 hours to obtain a 3 wt % solution of heptadecafluorodecyltrimethoxysilane in isopropanol;

[0063] 3) Dissolve 3g of cycloaliphatic epoxy resin (JEW-0114, epoxy value 0.478, Changshu Jiafa Chemical Co., Ltd.) in 15g of ethyl acetate solution, and stir until the cycloaliphatic epoxy resin is completely dissolved in acetic acid In the solution of ethyl ester; The isopropanol solution (heptadecafluorodecyltrimethoxysilane 0.09g, isopropanol) of heptadecafluorodecyltrimethoxysilane obtained by 1g ultraviolet absorber UV-328 and 3g step 2) Propanol (2.91g) was evenly mixed in the ethyl acetate solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

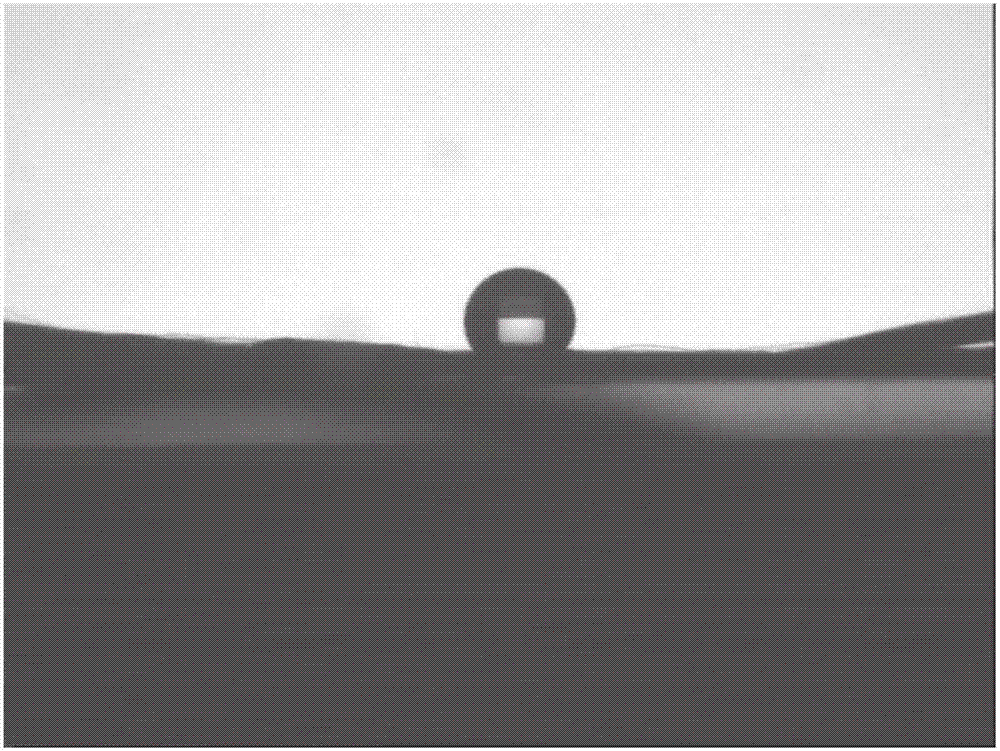

| Water contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com