Preparation method of uvioresistant aramid fiber

An anti-ultraviolet and aramid fiber technology, which is applied in the field of fiber spinning, can solve the problems of oxidative degradation, poor anti-ultraviolet performance, and material aging, and achieve the effects of no pollution to the environment, good anti-ultraviolet performance, and improved anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

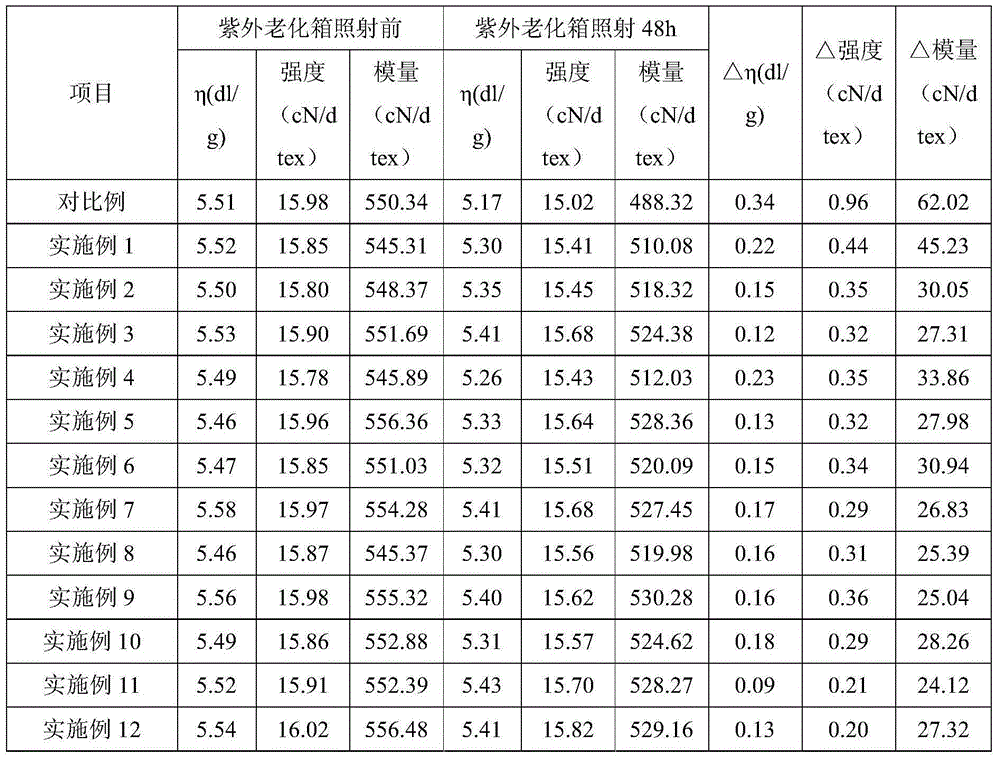

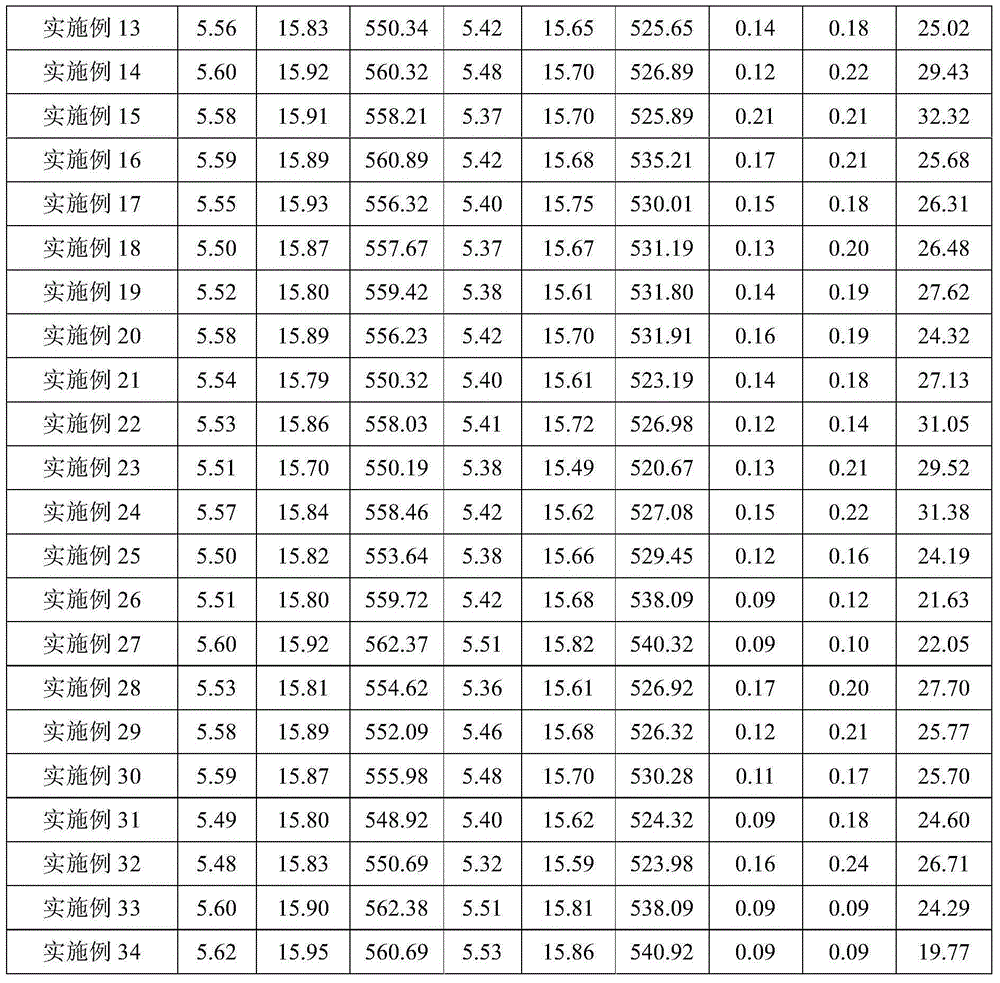

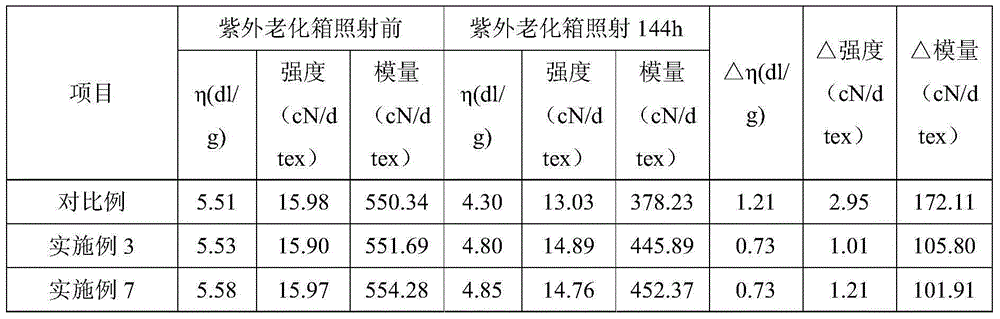

Examples

Embodiment 1

[0030] Add 3Kg of spinning oil YMA-12 to a 5L stainless steel container, and then add 0.015Kg (0.5%) of 2-(2‵-hydroxy-5‵-methylphenyl)benzotriazepam to the oil For azole anti-ultraviolet absorber UV-P, stir well to make it evenly mixed. The production process is the same as that of the comparative example. See Table 1 for the experimental data.

Embodiment 2

[0032] Add 3Kg of spinning oil YMA-12 to a 5L stainless steel container, and then add 0.06Kg (2%) of 2-(2‵-hydroxy-5‵-methylphenyl)benzotriazepam to the oil For azole anti-ultraviolet absorber UV-P, stir well to make it evenly mixed. The production process is the same as that of the comparative example. See Table 1 for the experimental data.

Embodiment 3

[0034] Add 3Kg of spinning oil YMA-12 to a 5L stainless steel container, and then add 0.15Kg (5%) of 2-(2‵-hydroxyl-5‵-methylphenyl)benzotriazepam to the oil For azole anti-ultraviolet absorber UV-P, stir well to make it evenly mixed. The production process is the same as that of the comparative example. See Table 1 for the experimental data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com