Method for treating surface of workpiece

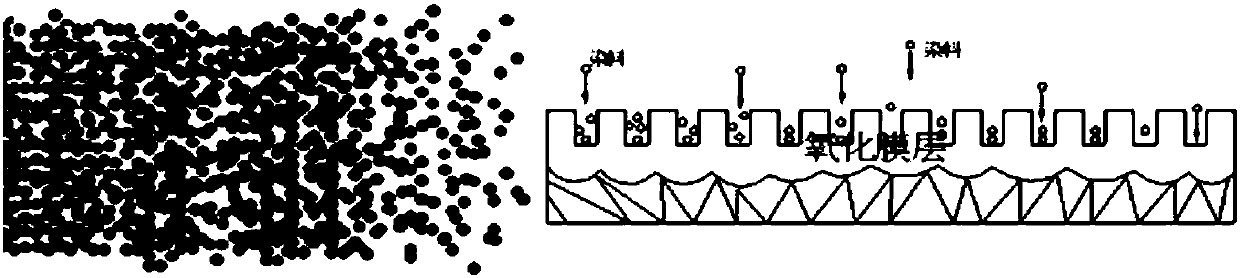

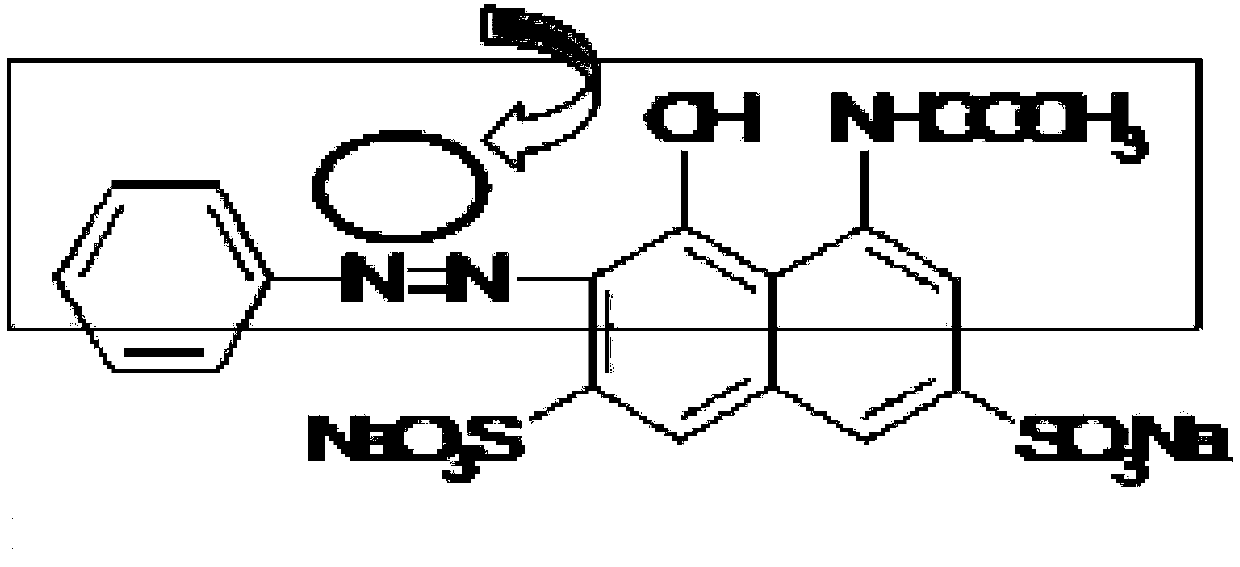

A technology of workpiece and dyeing solution, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of large color difference variation, product fading, uneven dyeing, etc., to improve UV resistance and increase dyeing processing time , Improve the effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

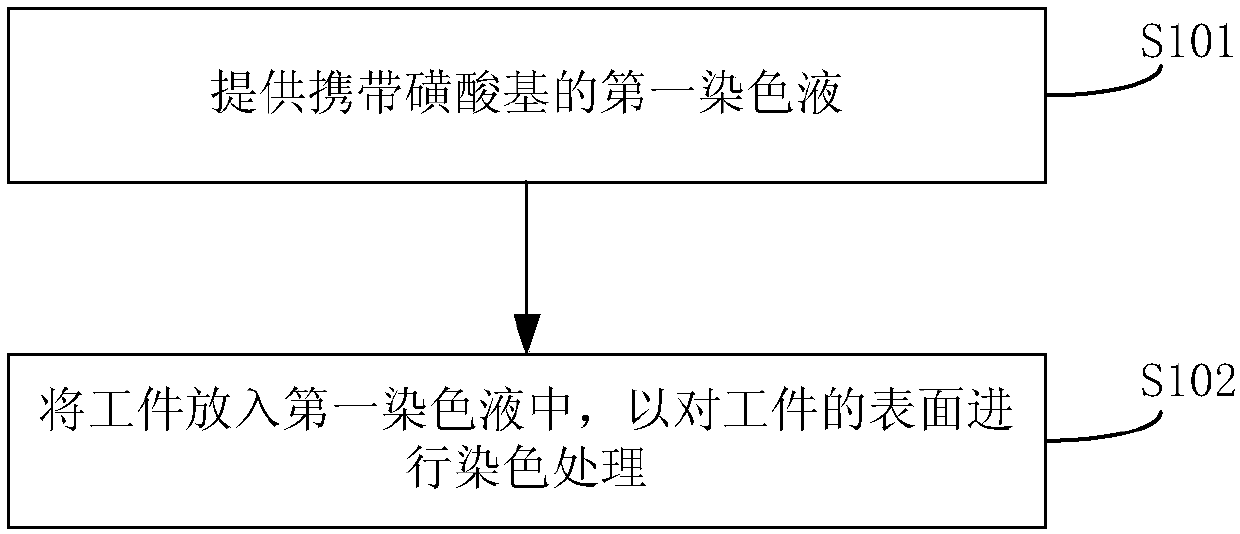

Method used

Image

Examples

Embodiment 1

[0045] Second staining solution (staining solution with red dye ratio): 1g / L of TAC PINK-RL and 1g / L of Orange 3LW, the amount of sodium sulfate added is 3g / L, and the concentration after adding sodium sulfate: 2g / L TAC PINK-RL and 2g / L Orange 3LW. The workpiece is a metal structural part of a mobile phone.

[0046] QUV aging test results: Δa=1, ΔE=3.

Embodiment 2

[0048] Second staining solution (staining solution with red dye ratio): 1.2g / L of TAC PINK-RL and 1.5g / L of Orange3LW, the amount of sodium sulfate added is 4g / L, and the concentration after adding sodium sulfate: 2.5g / L L of TAC PINK-RL and 3g / L of Orange3LW. The workpiece is a metal structural part of a mobile phone.

[0049] QUV aging test results: Δa=0.2, ΔE=1.

Embodiment 3

[0053] The second staining solution (staining solution with rose gold dye ratio): 0.3g / L TAC PINK-GLH and 0.05g / L TACYELLO-SGL, the amount of potassium sulfate added is 4g / L, and the concentration after adding potassium sulfate: 0.5g / L TAC PINK-GLH and 0.4g / L TAC YELLO-SGL. The workpiece is a metal structural part of a mobile phone.

[0054] QUV aging test results: Δa=1, ΔE=1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com