Three-dimensional carbon fiber fabric reinforced mullite ceramic and preparation method thereof

A carbon fiber fabric and three-dimensional carbon fiber technology is applied in the field of three-dimensional carbon fiber fabric reinforced mullite ceramics and its preparation, and can solve the problems of insufficient mechanical properties, insufficient toughness and strength, and low material density of three-dimensional carbon fiber reinforced mullite ceramics. , to ensure efficient densification, increased strength retention, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

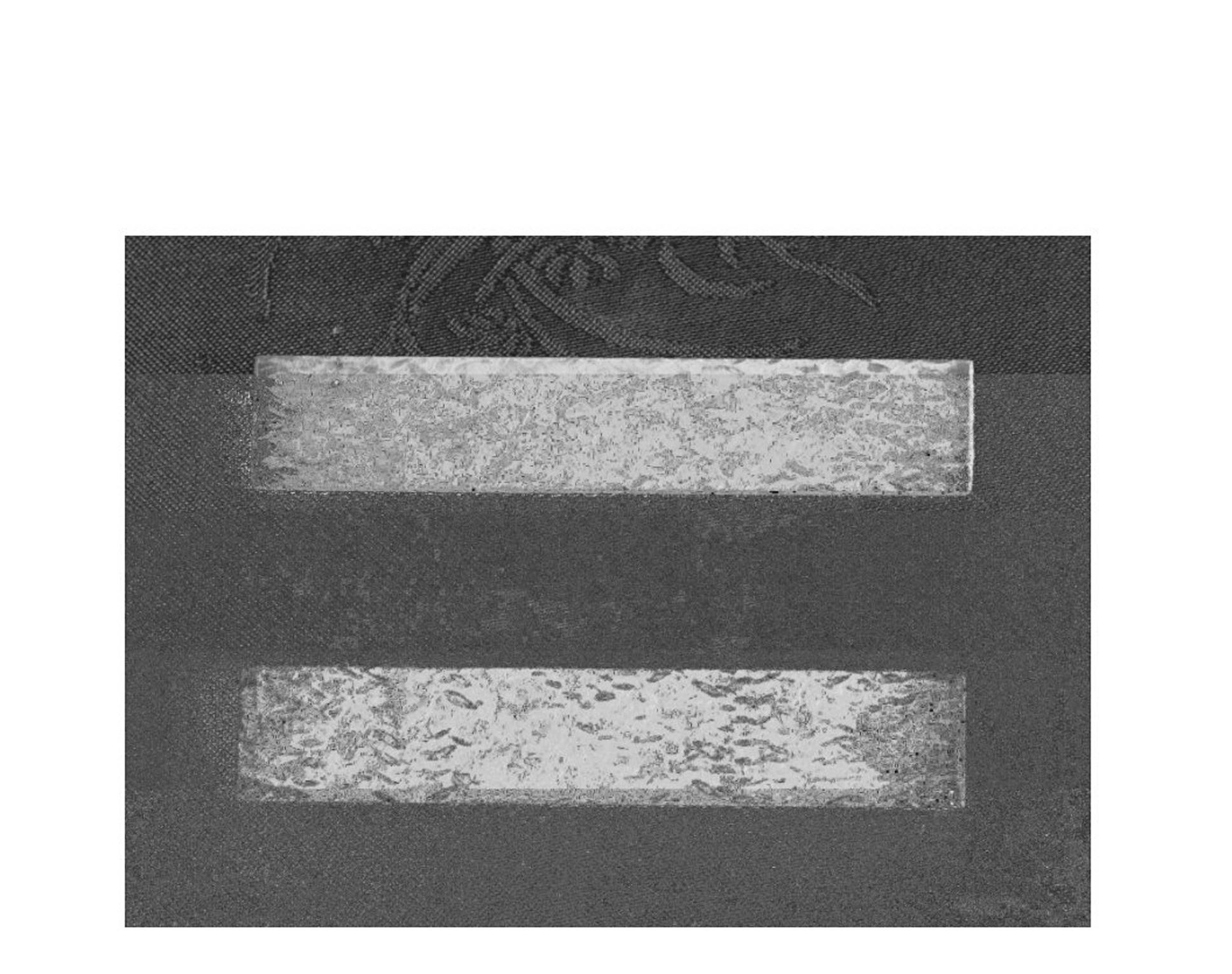

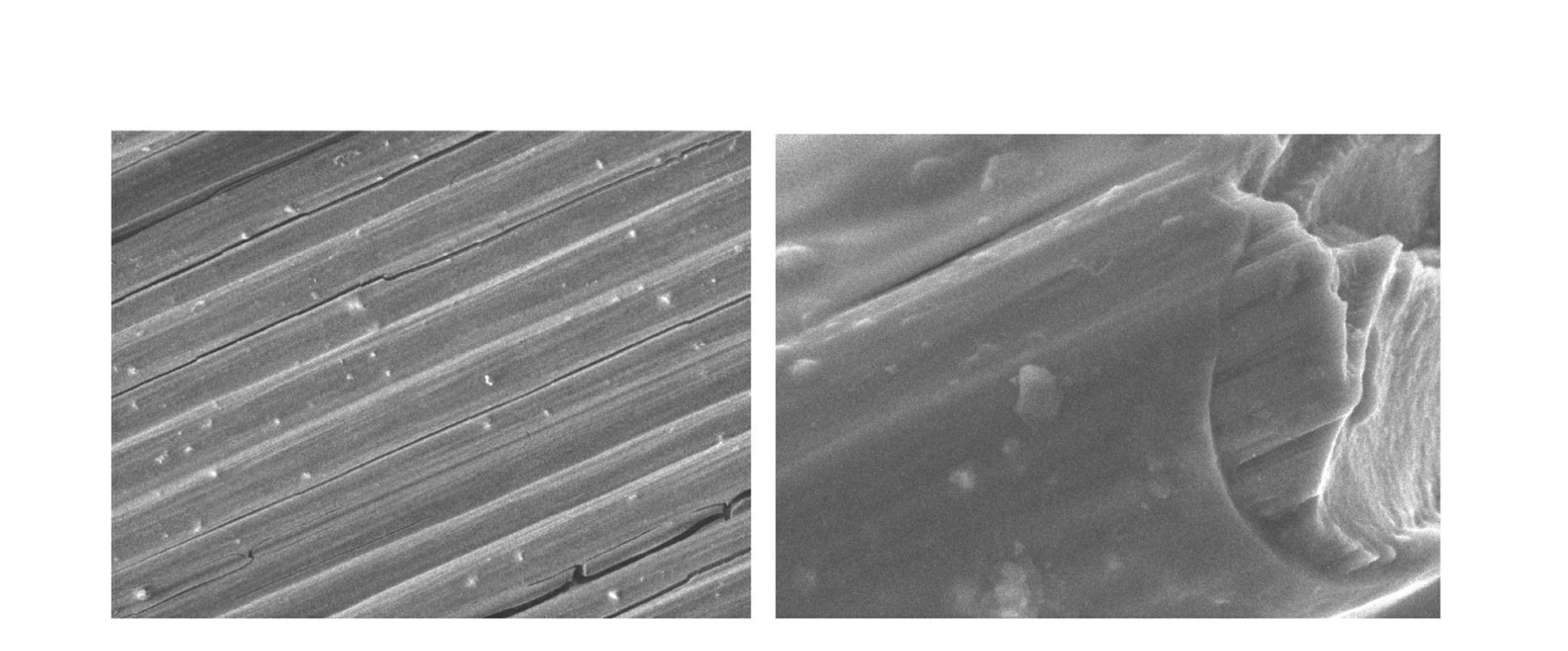

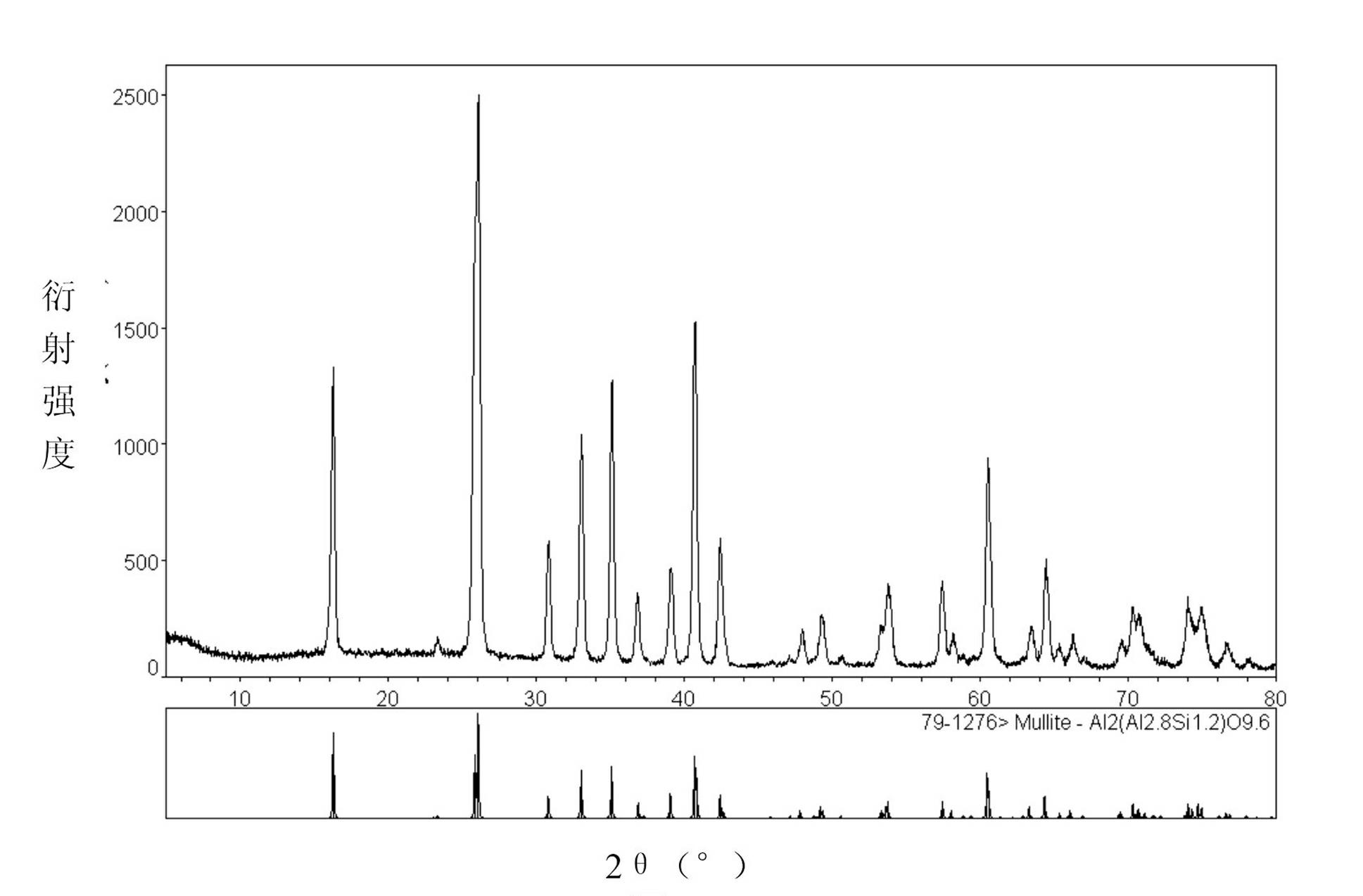

[0027] a kind of like figure 1 The shown three-dimensional carbon fiber fabric reinforced mullite ceramics of the present invention uses mullite as a matrix, and a three-dimensional carbon fiber fabric with a volume fraction of 50.5% is used as a reinforcement, and there is formed between the mullite matrix and the three-dimensional carbon fiber fabric reinforcement. The silicon carbide interface phase is formed by preparing a silicon carbide coating on the surface of the three-dimensional carbon fiber fabric. In this ceramic, the ceramic matrix is made of mullite sol with a solid phase content of 36.25%, and the mullite sol is made of silica sol with a solid phase content of 40% and a solid phase content of 35% with a mass ratio of 1:3. % aluminum sol mixed uniformly.

[0028] A method for preparing the above-mentioned three-dimensional carbon fiber fabric reinforced mullite ceramics, comprising the following specific steps:

[0029] (1) Preparation of silicon carbide coa...

Embodiment 2

[0040] A kind of three-dimensional carbon fiber fabric reinforced mullite ceramics of the present invention, with mullite as matrix, with the three-dimensional carbon fiber fabric that volume fraction is 55% as reinforcing body, form carbonization between mullite matrix and three-dimensional carbon fiber fabric reinforcing body The silicon interface phase and the silicon carbide interface phase are formed by preparing a silicon carbide coating on the surface of a three-dimensional carbon fiber fabric. In this ceramic, the ceramic matrix is made of mullite sol with a solid phase content of 31.1%, and the mullite sol is made of Silica sol with a solid phase content of 35% and aluminum sol with a solid phase content of 30% are uniformly mixed with a mass ratio of 1:3.5.

[0041] A method for preparing the above-mentioned three-dimensional carbon fiber fabric reinforced mullite ceramics, comprising the following specific steps:

[0042] (1) Preparation of silicon carbide coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com