Method for treating aged landfill leachate by continuous flow fixed bed autotrophic nitrogen removal

A technology for landfill leachate and autotrophic denitrification, applied in sustainable biological treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Deal with leachate and other problems to achieve the effect of saving carbon sources, reducing operating costs and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

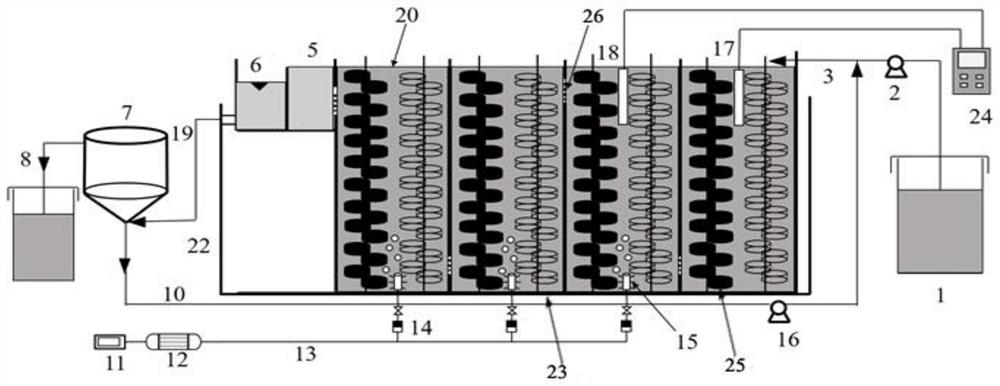

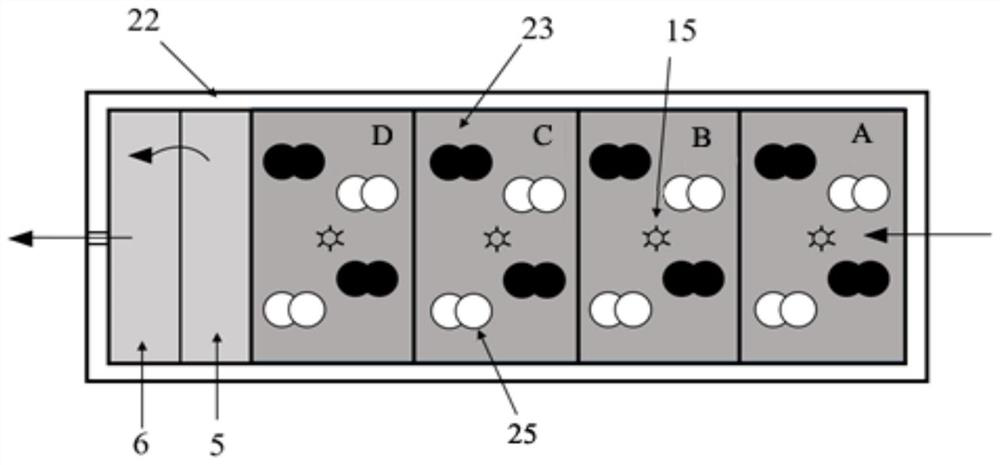

[0034] Embodiment 1: Combining figure 1 and figure 2 This embodiment will be described. The method of the continuous flow fixed bed autotrophic denitrification treatment of aged landfill leachate in this embodiment is described. The devices used in the method include a water inlet tank 1, a peristaltic pump 2, a reaction chamber 23, a secondary sedimentation tank 7, and a return pipe. 10. Connecting pipe 19, air pump 12, aeration pipe 13, water outlet pipe 8 and water inlet pipe 3;

[0035] The water inlet tank 1 and the peristaltic pump 2, the peristaltic pump 2 and the reaction chamber 23 are communicated with the water inlet pipe 3;

[0036] The reaction chamber 23 and the secondary sedimentation tank 7 are communicated with the connecting pipe 19;

[0037] The outlet pipe 8 is connected with the secondary settling tank 7; a return pump 16 is provided between the secondary settling tank 7 and the water inlet pipe 3, and the secondary settling tank 7 and the return pump 1...

specific Embodiment approach 2

[0057] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the lateral flow autotrophic denitrification biofilm sludge is stored at a low temperature of 4°C. Others are the same as the first embodiment.

Embodiment 1

[0059] The old landfill leachate is passed into the continuous flow fixed bed autotrophic denitrification system of the specific embodiment one that has completed the adaptation stage of the continuous flow fixed bed autotrophic denitrification system (step 2), and the hydraulic retention time in the control reaction chamber 23 is 48h, the reaction chamber 23A is not aerated, the reaction chamber 23B, C and D are aerated, and the aeration flow rates are 150mL / min, 150mL / min, and 150mL / min respectively; the reflux flow is equal to Influent flow; that is, to realize the treatment of old landfill leachate.

[0060] In this embodiment, the water bath incubator 22 is used to control the operating temperature of the reaction chamber 23 within the range of 28±2°C.

[0061] The water quality components of the actual waste old landfill leachate are shown in Table 1:

[0062] Table 1

[0063] index concentration index concentration pH 8 Cr 7.6*10 -2

SS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com