Sample transfer device for thick plate inspection and test

A transfer device, inspection and testing technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of difficult to meet production requirements, high cost, high labor intensity, etc., to meet the requirements of production rhythm, reduce speed requirements, and reduce scheduling effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

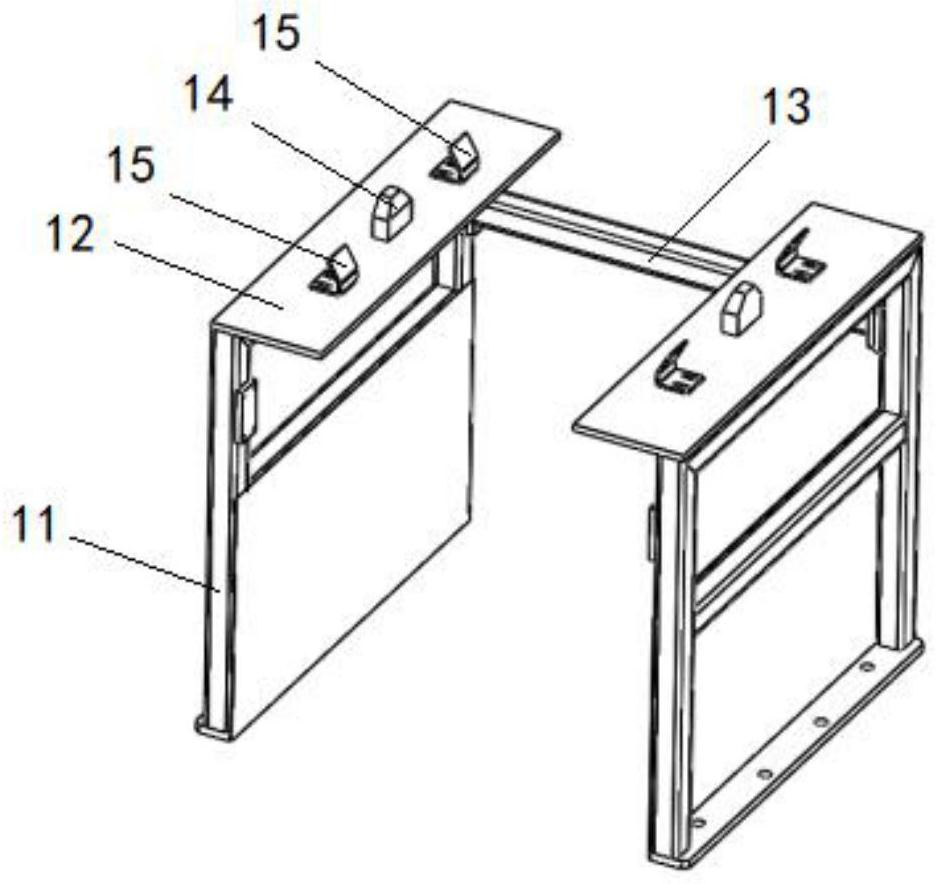

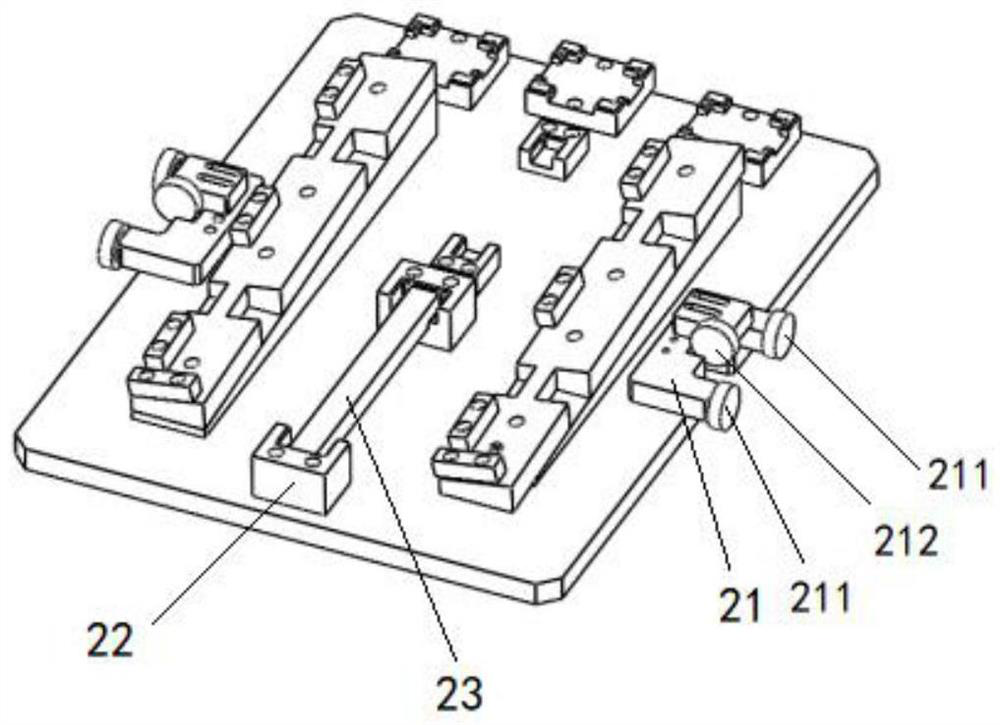

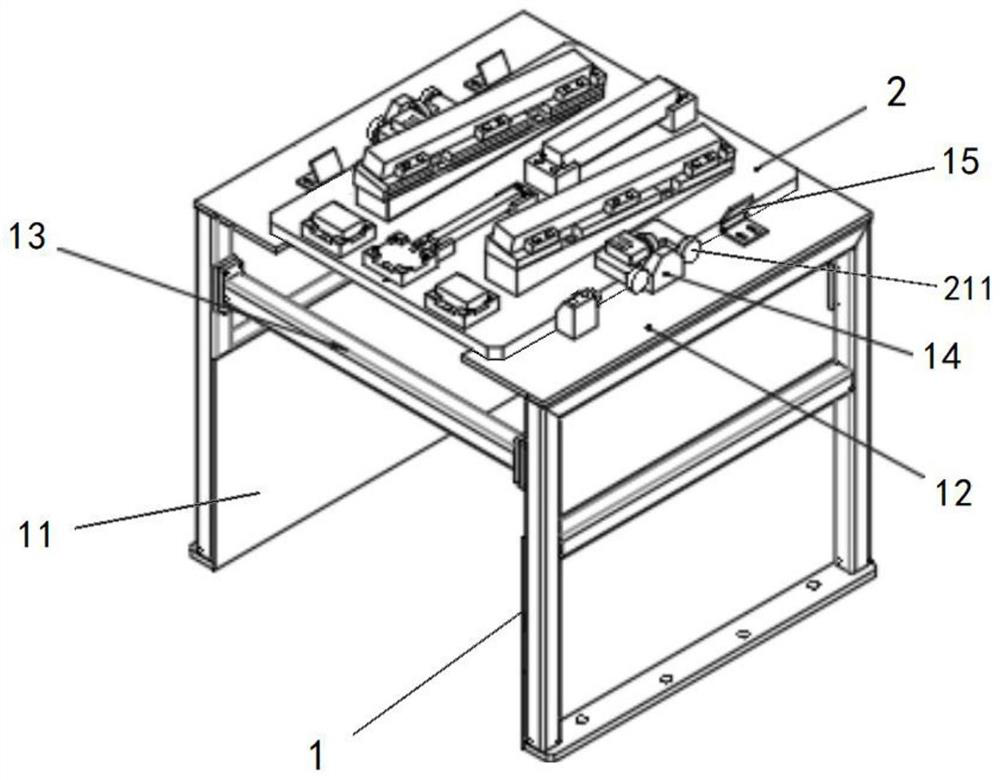

[0015] Below in conjunction with embodiment the present invention will be described in further detail, as Figures 1 to 3 As shown, a sample transfer device for thick plate inspection and testing includes a turnover tray 2 for placing samples 23 and a transfer frame 1 for supporting the turnover tray 2: the transfer frame 1 includes two side plates 11 and the beam 13 connecting the two side plates 11, the two side plates 11 are respectively provided with left and right platforms 12, and the left and right platforms 12 are respectively provided with a set of limit devices; the turnover tray 2. A set of roller positioning devices 21 are provided on the left and right sides respectively; When the roller positioning device 21 of the revolving pallet 2 is lowered in alignment with the limiting device of the transfer frame 1, the roller positioning device 21 falls into the limiting device and is held by the limiting device by relying on the gravity of the pallet itself. The device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com