Feeding device of electric monorail transportation system for automobile factory

A technology that uses electric singles and transportation systems, applied in the direction of lifting devices, lifting frames, etc., can solve problems such as high risk factor and inconvenient adjustment of workpieces, achieve low cost, meet production cycle requirements, and ensure safety and convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

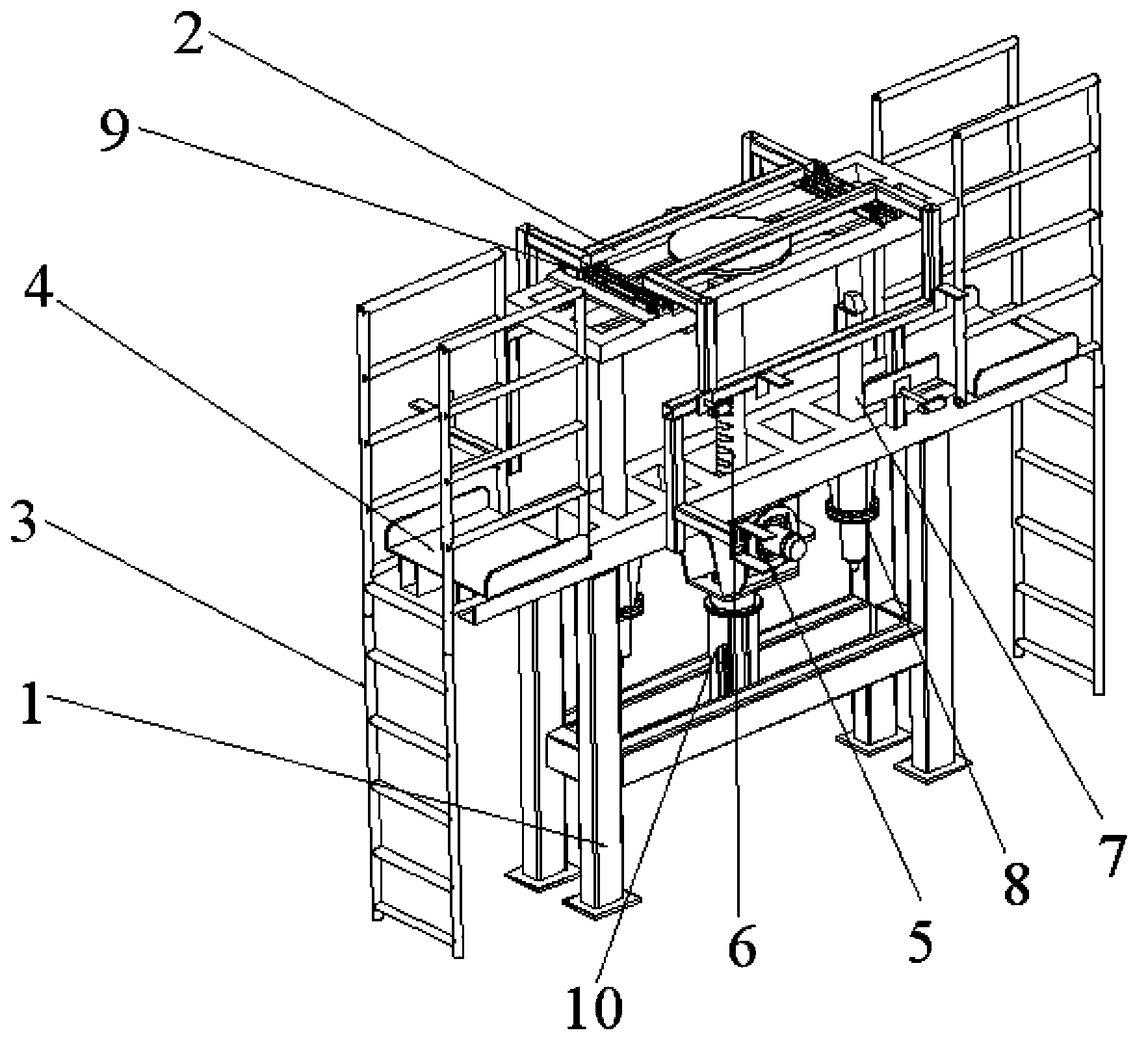

[0027] A feeding device for an electric monorail transportation system used in an automobile factory, its structure is as follows figure 1 As shown, it includes components such as a base body 1, a motor, a gear, a power link 6, a guide link 7, a cylinder, and a linear guide rail 9. Substrate 1 is a welded frame, and the bottom is connected to the ground with 16 expansion bolts. The entire matrix 1 is a welded rectangular structure, which is very firm and can fully bear the weight of everything. A movable platform 2 is arranged on the top of the base body 1, and a maintenance platform 4 and a maintenance ladder 3 are arranged on both sides. The power connecting rod 6 is arranged in the middle part of the base body 1, and the upper part of the power connecting rod 6 is flexibly connected with the movable platform 2, and drives the movable platform 2 to rise and fall through lifting motion. The used motor and gears are connected to the power connecting rod 6, and the driving po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com