Spot welding system of air-conditioner backboard robot

A robot and robot body technology, applied in welding power supply, welding equipment, resistance welding equipment, etc., can solve problems such as hardware errors and unknown system defect damage, accidents, inconsistent spot welding positions, etc., to meet production cycle requirements and improve The effect of safety and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

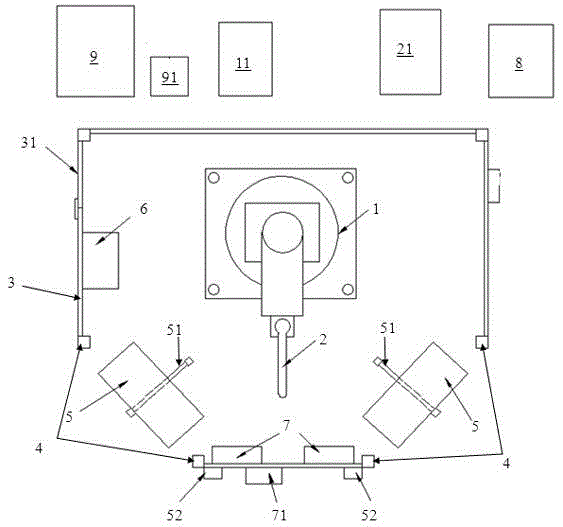

[0032] like figure 1 As shown, a robot spot welding system for an air-conditioning backplane includes: a control device, which includes a system PLC control cabinet 9 and a touch screen 91 connected to the system PLC control cabinet 9, and the touch screen 91 is used to monitor the system status; the welding robot system, which Connect the system PLC control cabinet 9, which includes the robot body 1 and the welding tongs 2 installed on the robot body 1; the tooling table, which connects the system PLC control cabinet 9, and the robot body 1 transports the welding tongs 2 to the tooling platform and carry out spot welding to the workpiece on the tooling platform; operating area, this operating area includes safety fence 3 and safety door 31, described robot body 1 and welding tongs 2 are all placed in operating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com