An automatic gluing machine

A gluing machine, automatic technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of affecting assembly quality, high working rhythm, low working rhythm, etc., to meet the requirements of production rhythm and improve gluing The effect of high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

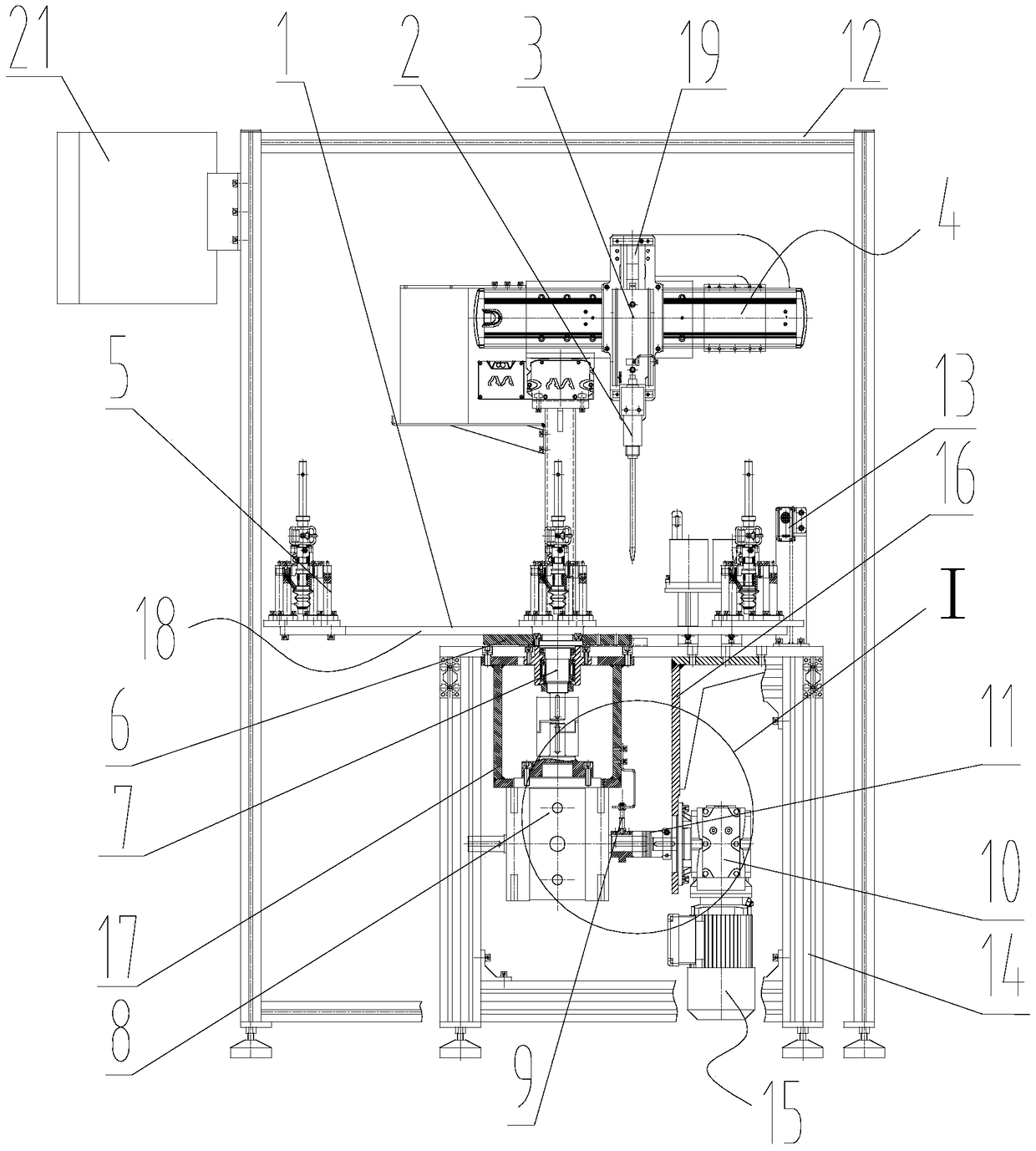

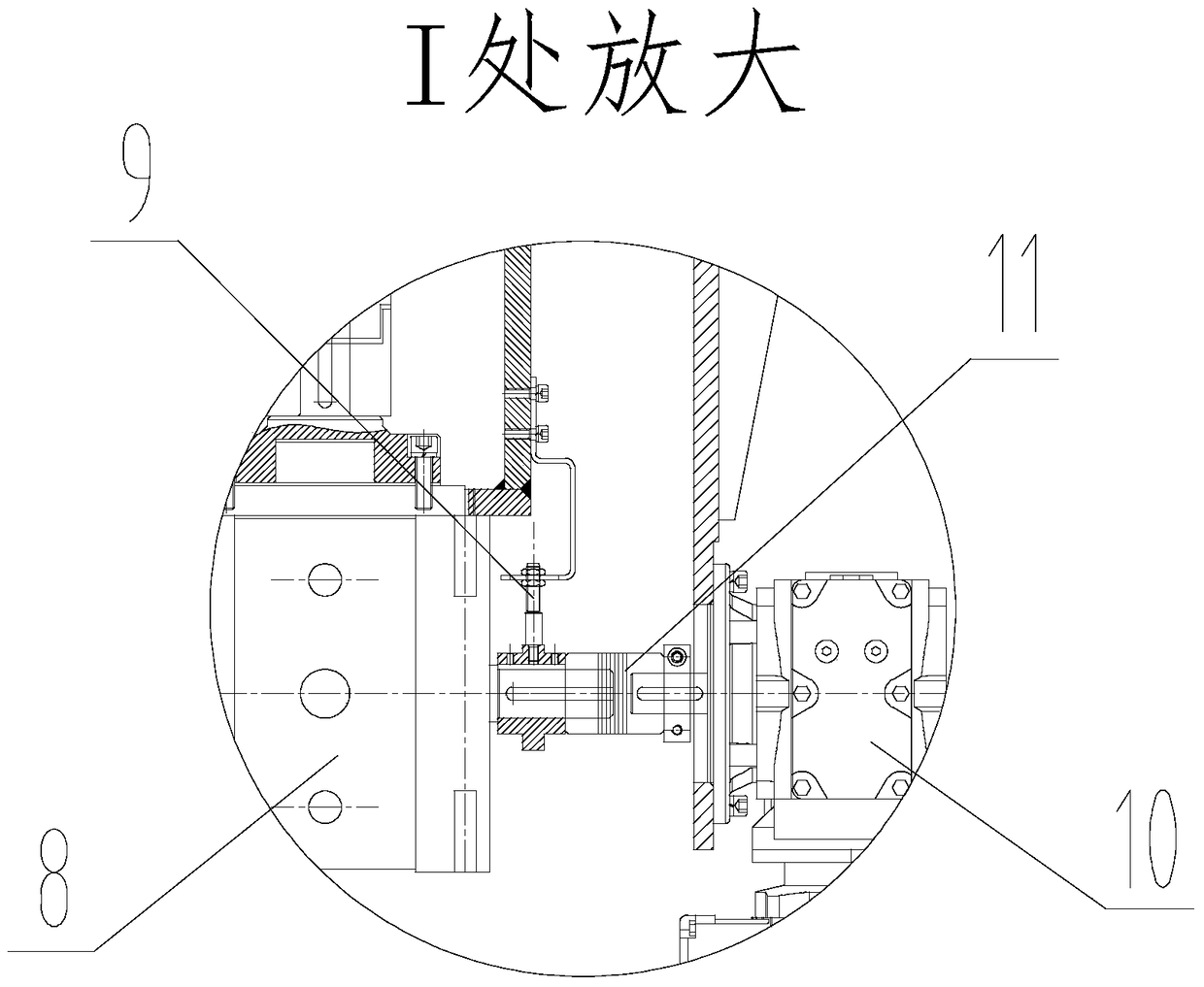

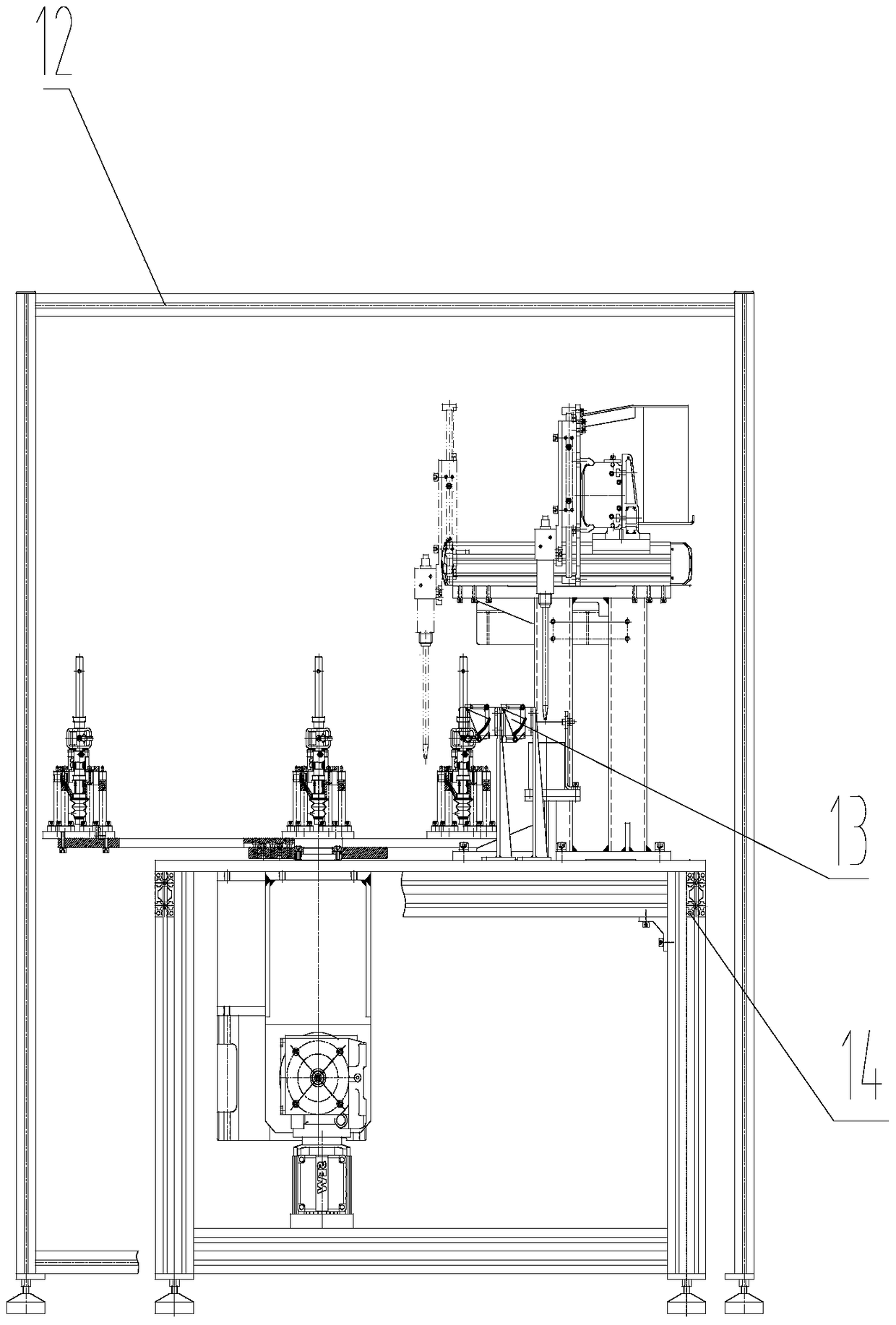

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] like Figures 1 to 4 As shown, the present invention includes a driving mechanism 15, a divider 8, a rotating mechanism 18, a positioning tool 5, a plane right-angle moving mechanism 4, a cylinder 3, a glue gun 2, a safety protection frame 12 and a workbench 14, wherein the workbench 14 is set In the safety protection frame 12, a support plate 16 and a support 17 are provided on the underside of the workbench 14, the driving mechanism 15 is installed on the support plate 16, and the divider 8 is installed on the support 17. The drive mechanism 15 includes a connected motor and a speed reducer 10, the output shaft of the speed reducer 10 is fixedly connected with the input shaft of the splitter 8 through a coupling 11, and the splitter 8 is used to output the speed reducer 10 Continuous rotation is transformed into intermittent rotation at a fixed angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com