Method of accurate control for removing filter-stick of high-speed filter-stick forming device

A filter rod forming machine and precise control technology, which is applied in the direction of e-liquid filter elements, electrical components, tobacco, etc., can solve the problems such as the control of valves that cannot be eliminated, and achieve the effect of meeting the production cycle requirements and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

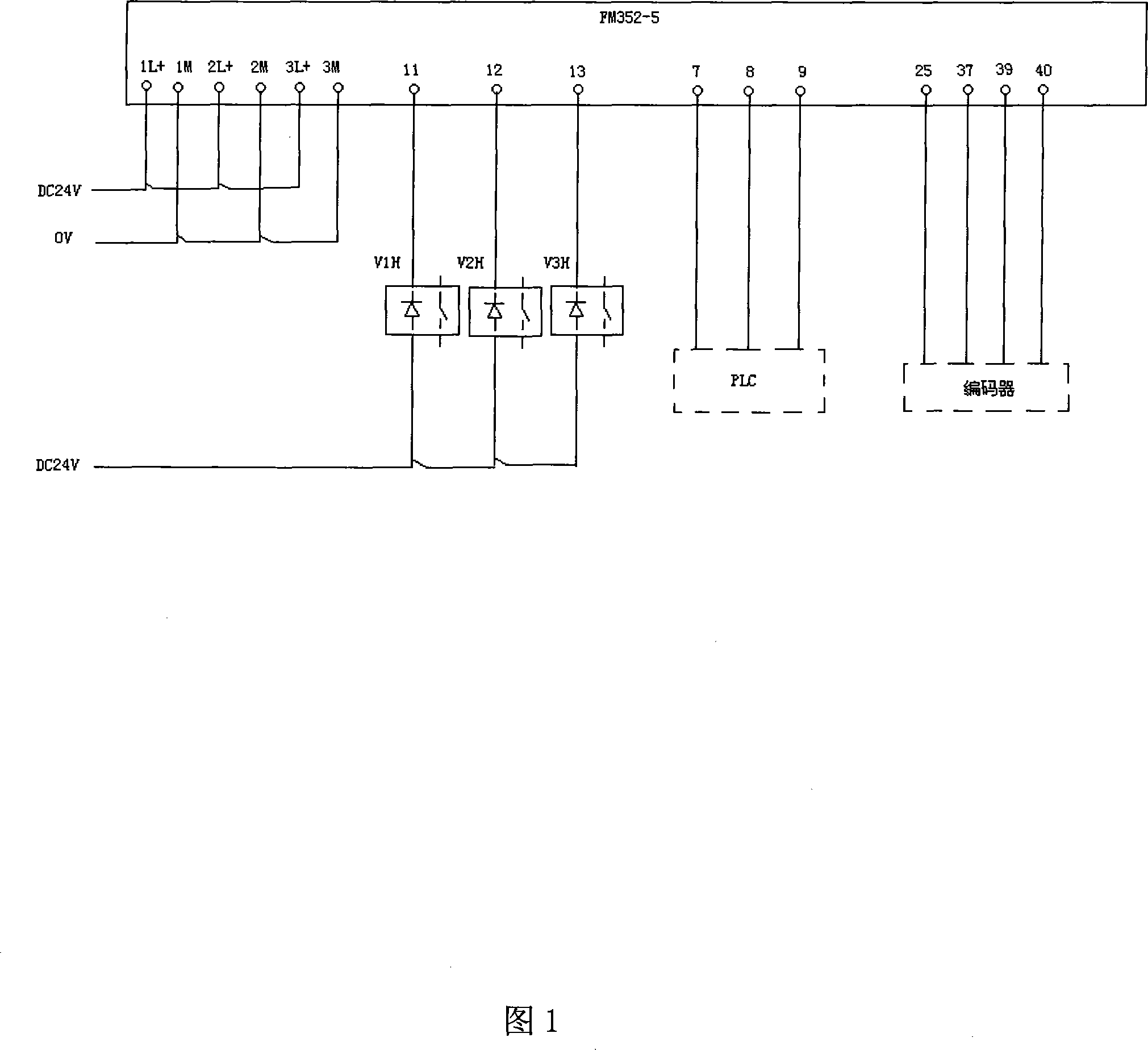

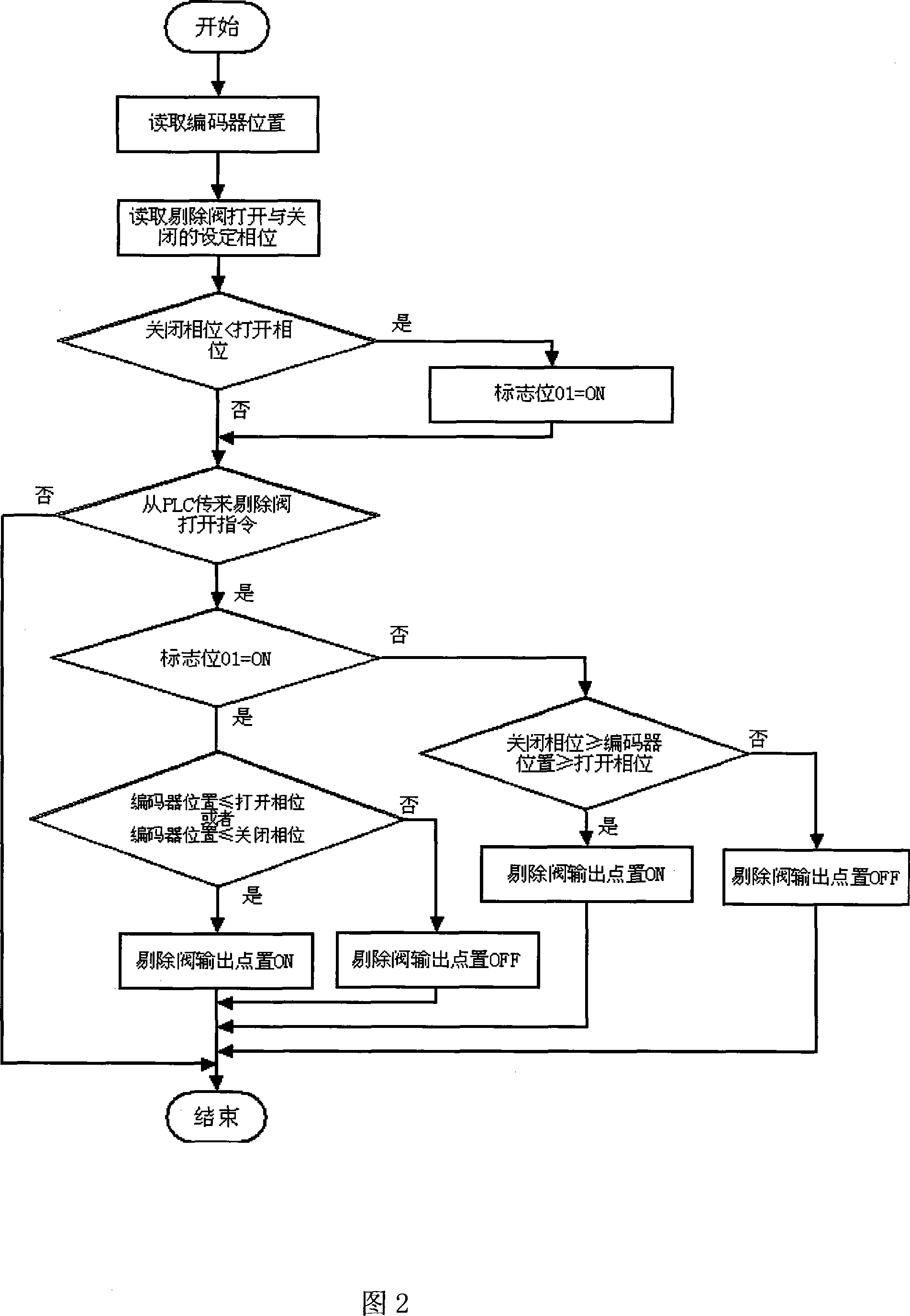

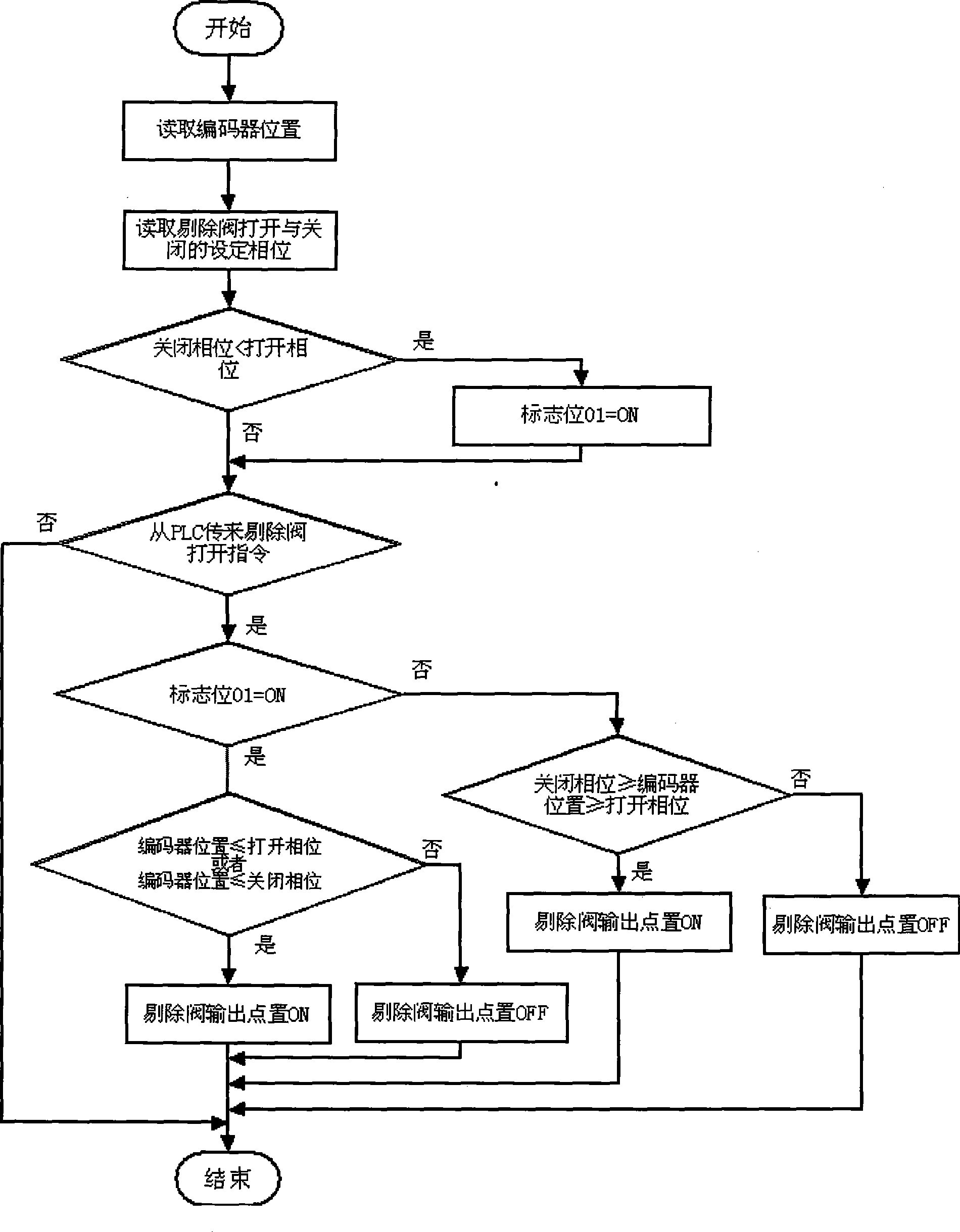

[0012] The invention adopts FM352-5 high-speed Boolean processor to control the action of the rejection valve, so as to complete the high-speed rejection of waste products in the production process. The specific interface control circuit such as figure 1 As shown, it is mainly composed of Siemens S7-300 series CPU315-2DP (PLC), FM352-5 high-speed Boolean processor, pulse encoder, and rejection valve.

[0013] There are three digital input interface signals output from the PLC to the FM352-5 high-speed Boolean processor: V-groove waste rejection signal (input terminal 7 of the FM352-5 high-speed Boolean processor), drum waste rejection signal (FM352-5 high-speed Boolean The input terminal 8 of the processor), sampling and rejecting the signal (the input terminal 8 of the FM352-5 high-speed Boolean processor).

[0014] The digital output interface signals of FM352-5 high-speed Boolean processor are three: V-type valve Y1H control signal (output terminal 11 of FM352-5 high-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com