Oil-seal press-mounting clamp and using method thereof

An oil seal and press-fit technology, which is applied to hand-held tools and manufacturing tools, can solve the problems of serious accumulation on site, affect production efficiency, and waste space, and achieve the effects of improving coaxiality, simple structure, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

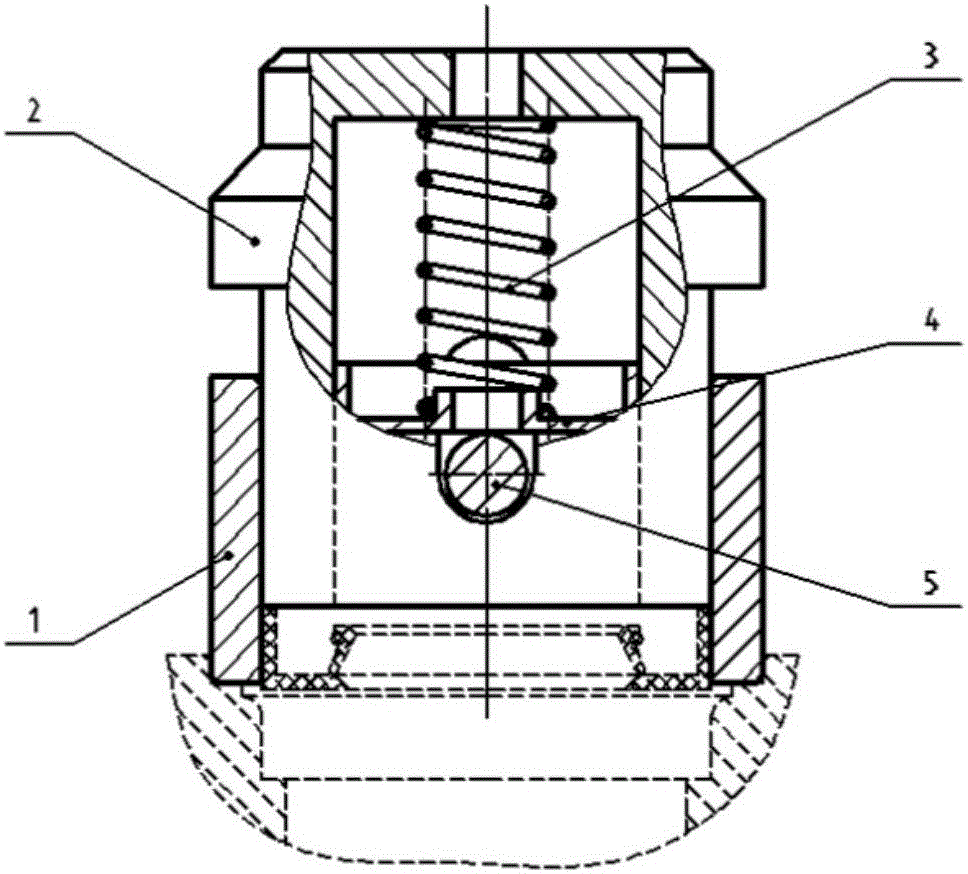

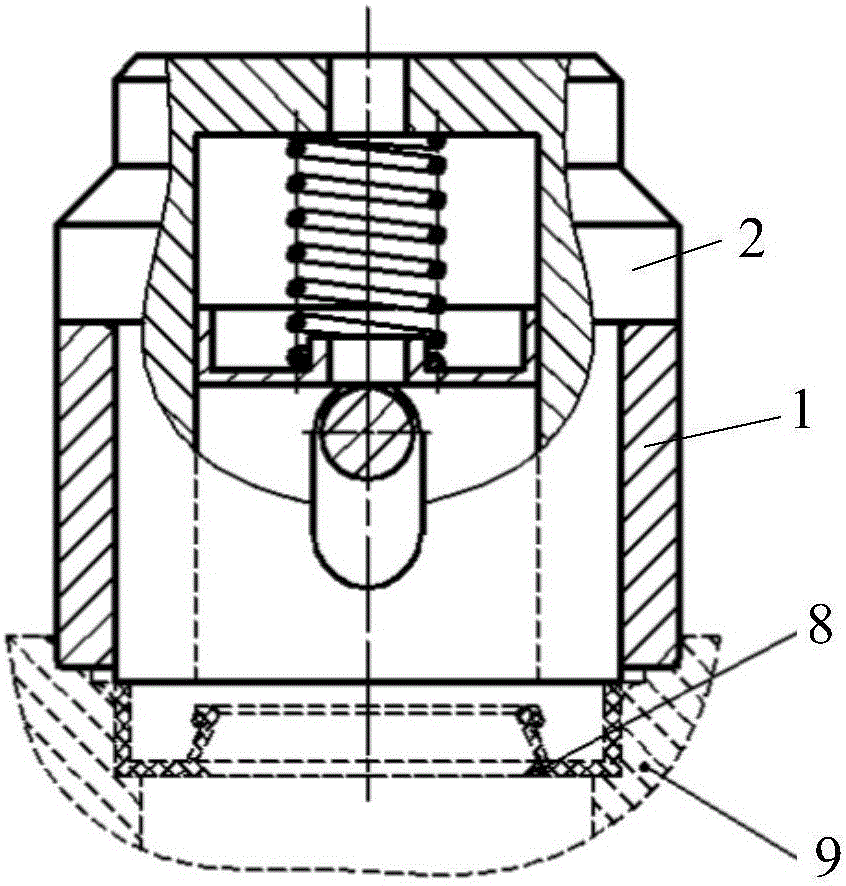

[0035] like figure 2 and image 3 As shown, the present invention includes five parts: outer ring 1, inner pressure sleeve 2, spring 3, baffle plate 4 and cylindrical pin 5.

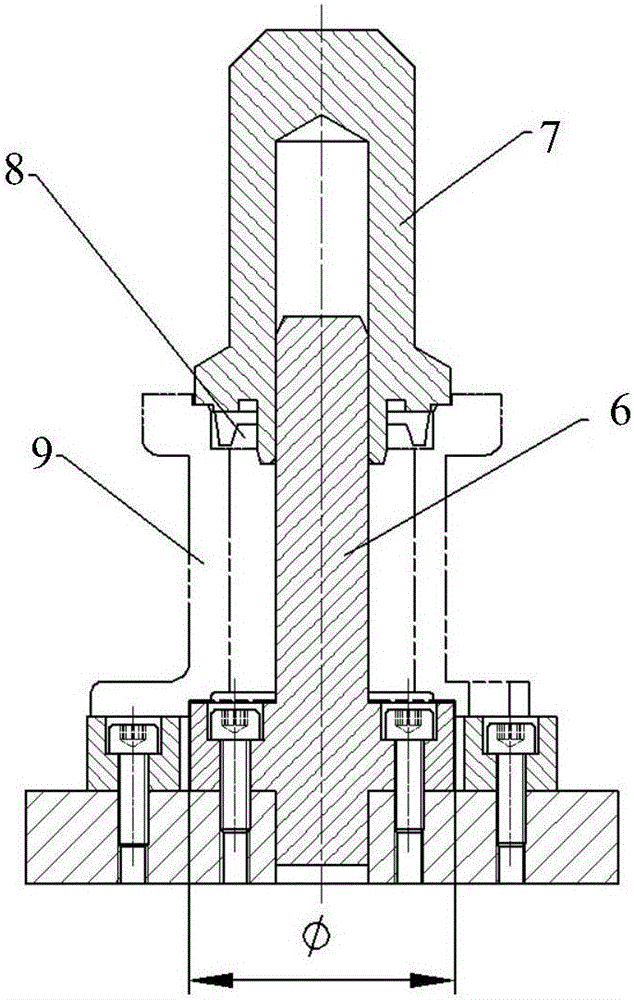

[0036] The outer ring 1 is arranged vertically and can be sleeved on the oil seal stop of the bearing cover 9. The inner pressure sleeve 2 is coaxially arranged in the outer ring 1 and can slide up and down along the axis direction of the outer ring 1. 8 is pressed into the oil seal hole of the bearing cover 9; the side wall of the outer ring 1 is provided with a relative circular hole, and the cylindrical pin 5 is inserted into the circular hole, and the end of the cylindrical pin 5 is provided with an outer ring for fixing the cylindrical pin 5 Pin; the inner pressure sleeve 2 is provided with a bar-shaped keyway for the cylindrical pin 5 to pass through, the bar-shaped keyway is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com