Spring spinning mechanism

A spinning and indenter technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as unqualified pump body product quality, and achieve the effect of saving labor costs, ensuring product quality, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

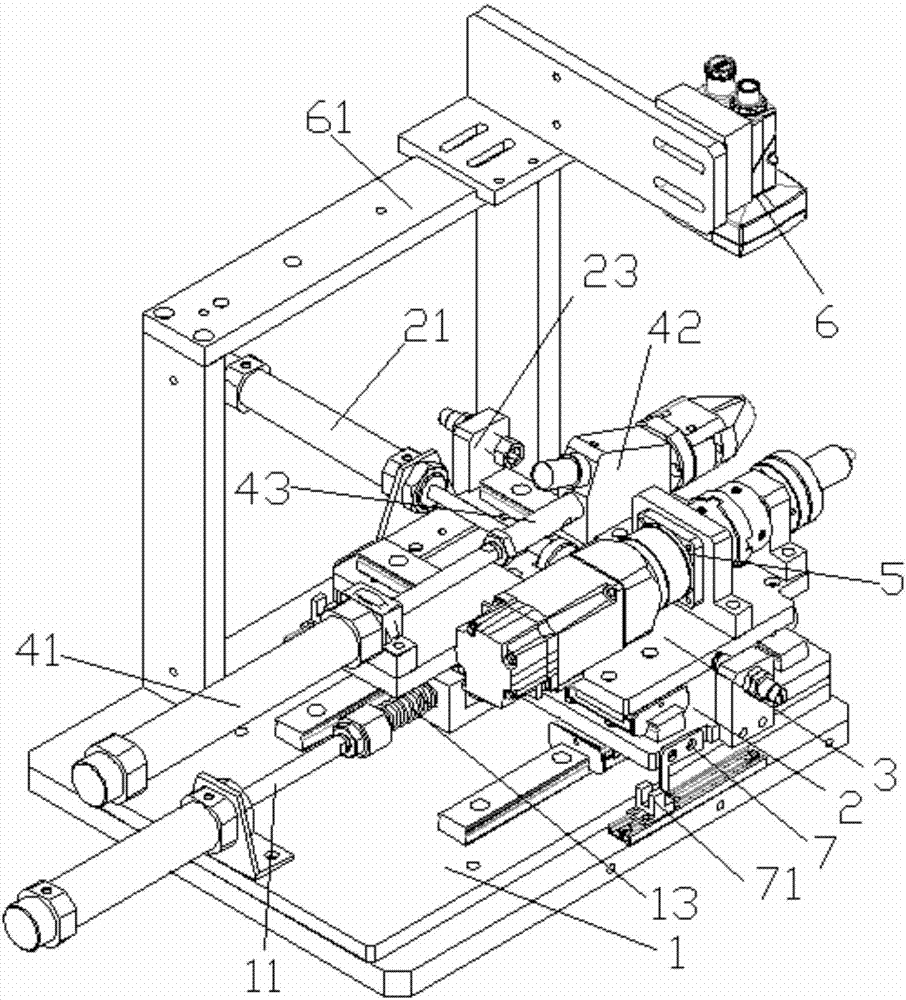

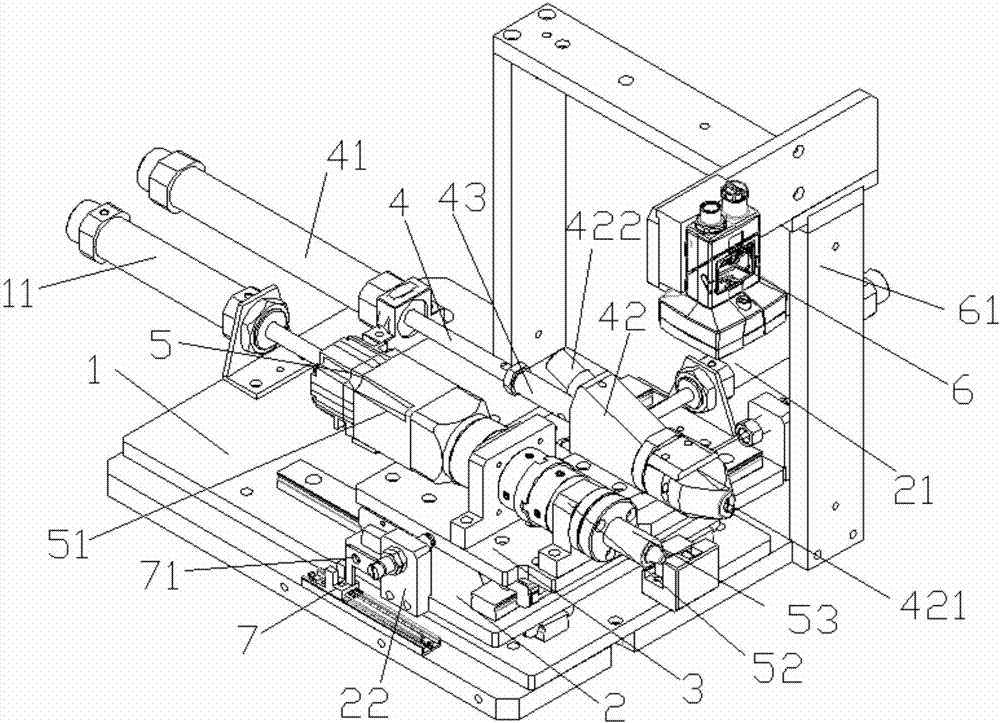

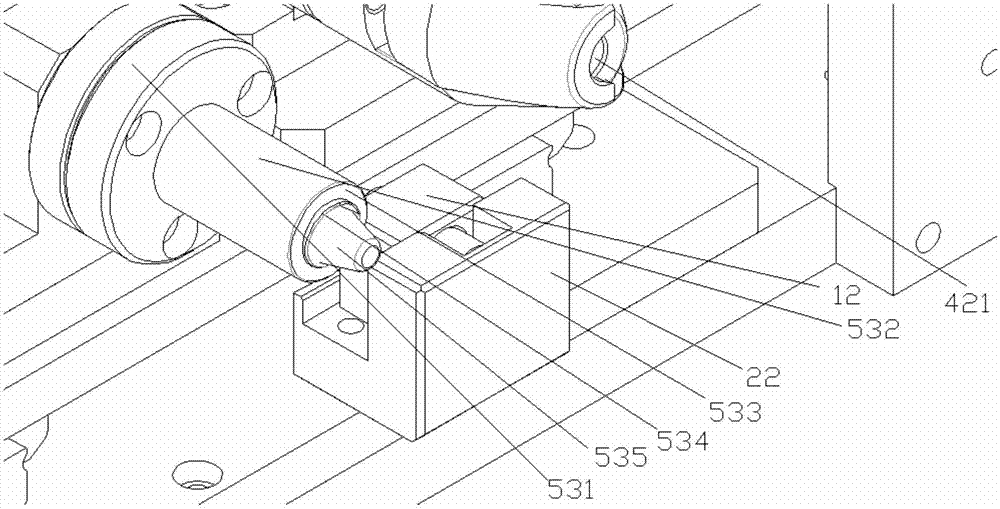

[0032] see Figure 1 to Figure 3 , this embodiment shows a spring spinning mechanism:

[0033] It includes a support plate 2 that can be slid back and forth on the bottom plate 1, a bearing plate 3 that can slide left and right on the support plate 2, a spring introduction assembly 4 and a spring spinning assembly 5 that are correspondingly installed on the support plate 3, and the passing inspection The installation frame 61 is arranged on the base plate 1 and cooperates with the spring introduction assembly 4 and the spring spinning assembly 5 to be used as a visual inspection device 6;

[0034] In this embodiment, the visual detection device 6 may be composed of a high-definition CDD detection camera;

[0035] The bottom plate 1 is provided with an induction device 7 composed of a grooved grating, and the support plate 2 is provided with an induction sheet 71 used in conjunction with the induction device 7, and the induction device 7 and the induction sheet 71 are used tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com