Floating pressure head device

A floating indenter and indenter technology, applied in the field of press-fitting devices, can solve the problems of complex installation, long press-fitting time, and high cost, and achieve the effects of improving press-fitting accuracy, uniform press-fitting force, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

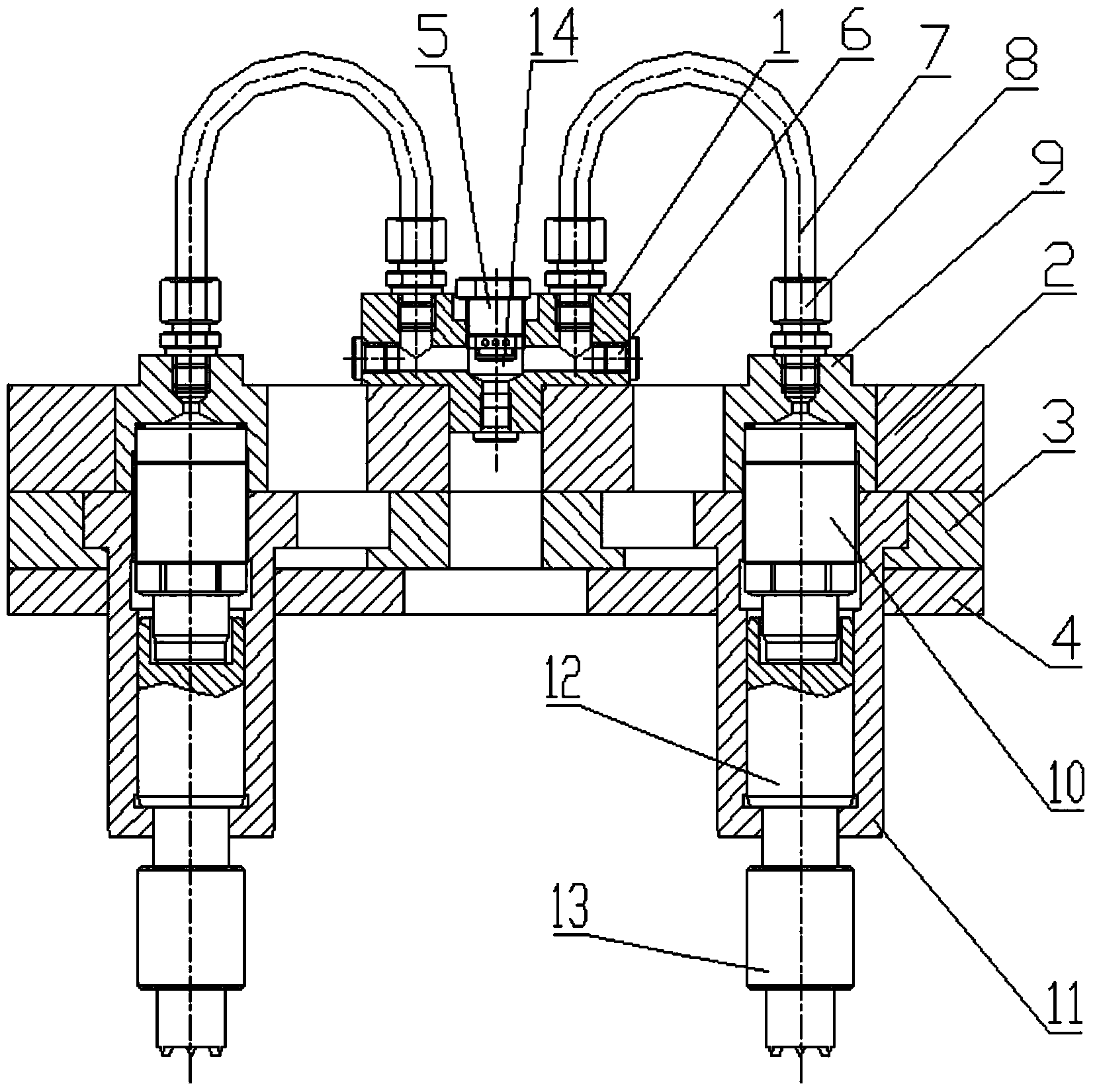

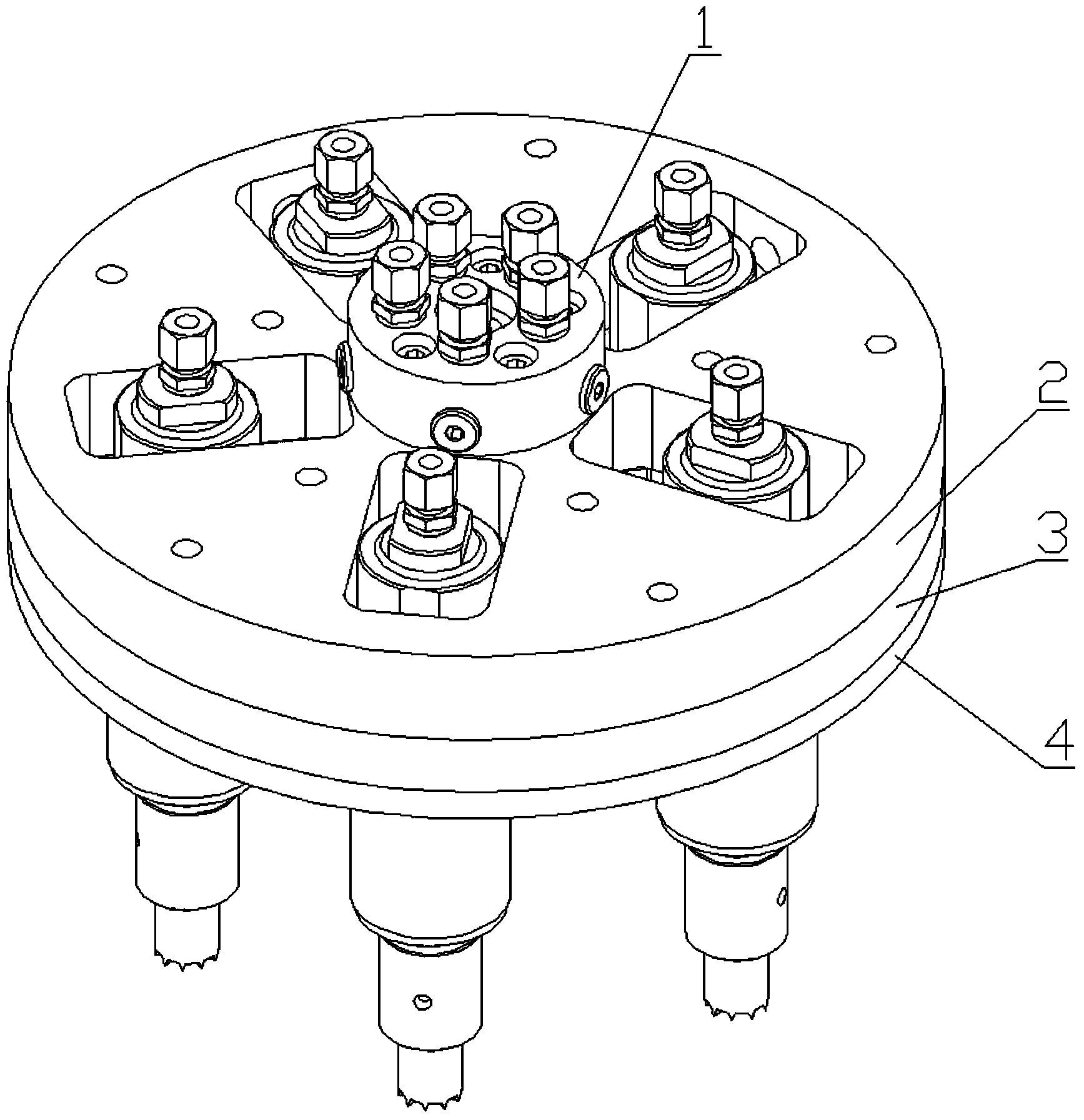

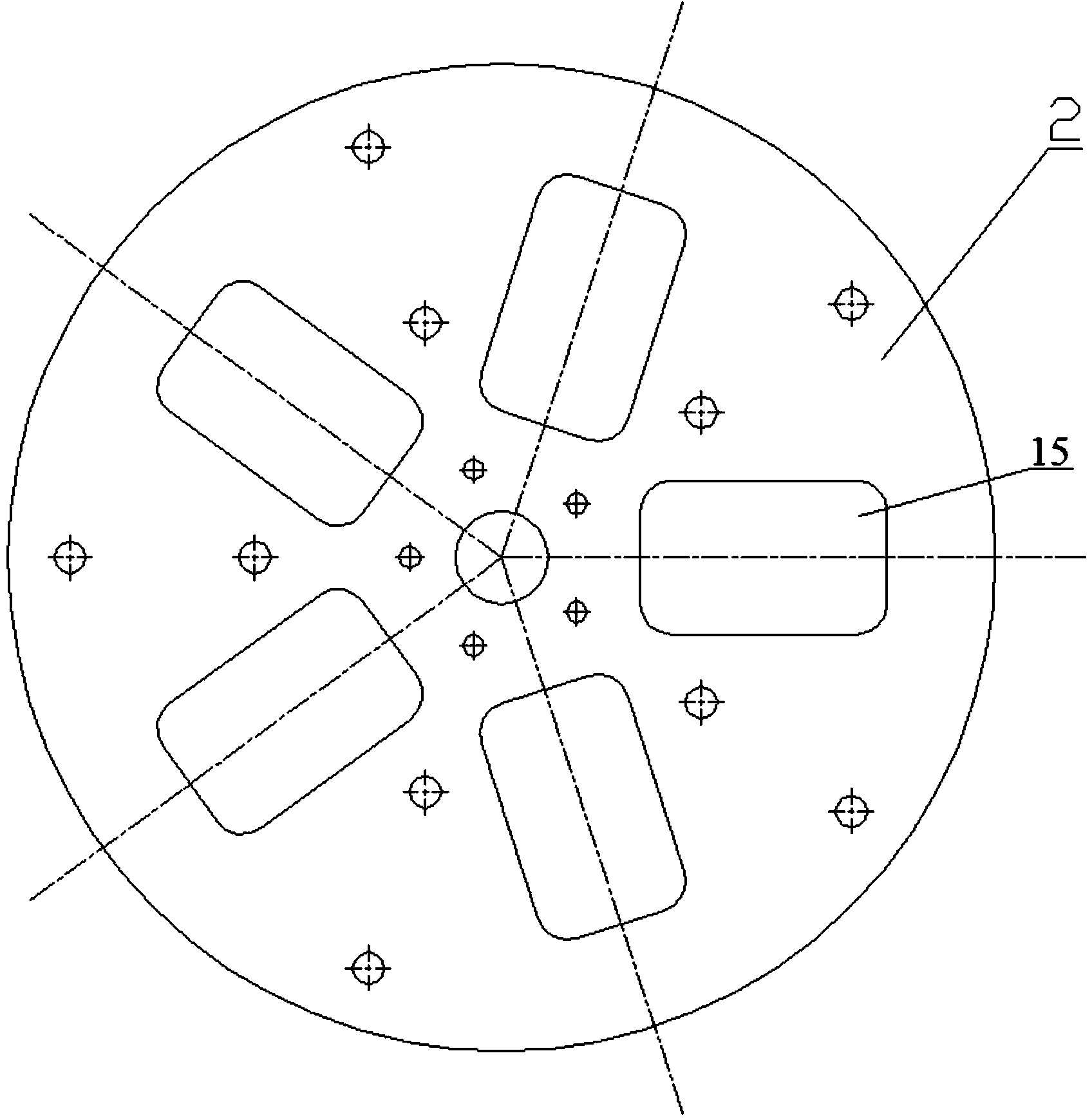

[0021] Referring to the accompanying drawings, a floating pressure head device includes sequentially stacked oil distribution seat 1, base 2, indexing plate 3 and positioning plate 4 and a plurality of pressure head assemblies, on the base 2 and indexing plate 3 A plurality of mounting grooves 15 are provided, and a plurality of pressure head assemblies are correspondingly arranged in a plurality of installation grooves 15, and each pressure head assembly can move horizontally in the mounting groove where it is located, and the oil distribution seat 1 is provided with There is a cavity 14, the oil distribution seat 1 is provided with an oil filling port leading to the cavity 14 and a check valve 5 is installed, and the oil distribution seat 1 is respectively provided with a plurality of oil outlets leading to the cavity 14, and a plurality of Hydraulic hoses 7 are correspondingly connected between the oil outlet and the plurality of pressure head assemblies.

[0022] In the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com