Double-arch-bridge type installation machine for railway tunnel formwork trolley

A formwork trolley and double-arch bridge technology, which is applied to walking bridge cranes, cranes, rail systems, etc., can solve the problems of high labor intensity, reduced efficiency, and prolonged construction period, and achieve a streamlined and ingenious overall structure and release manpower. The effect of labor and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

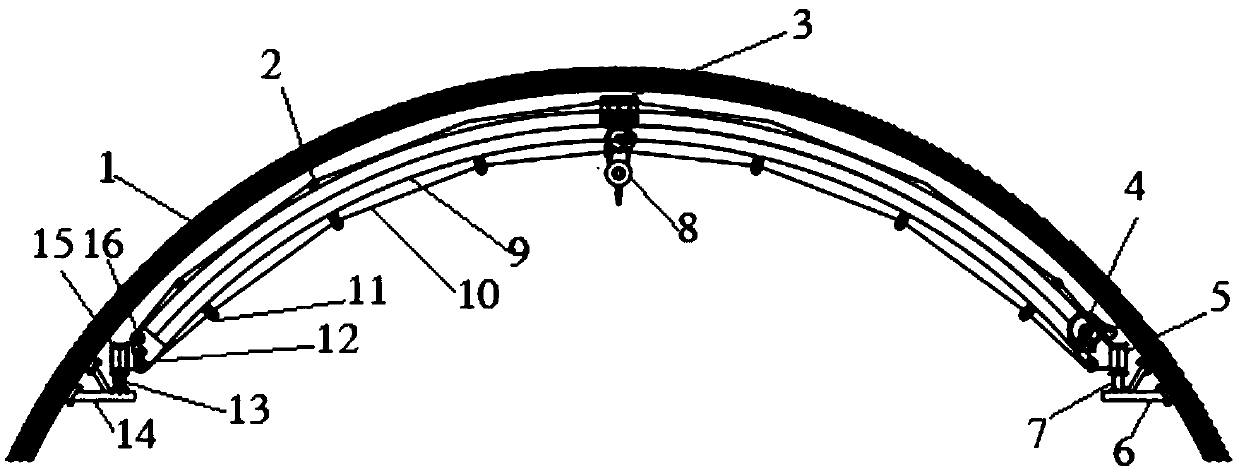

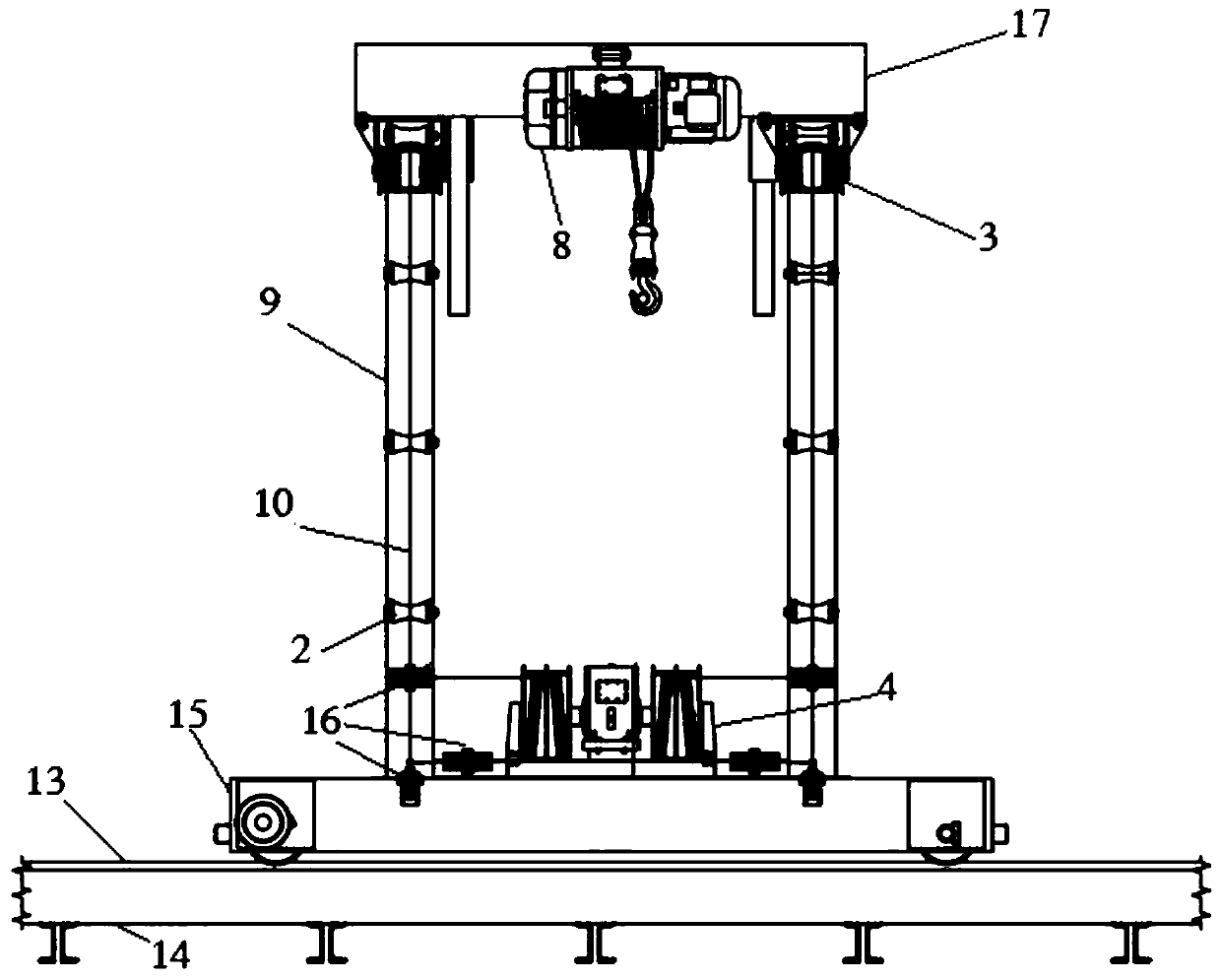

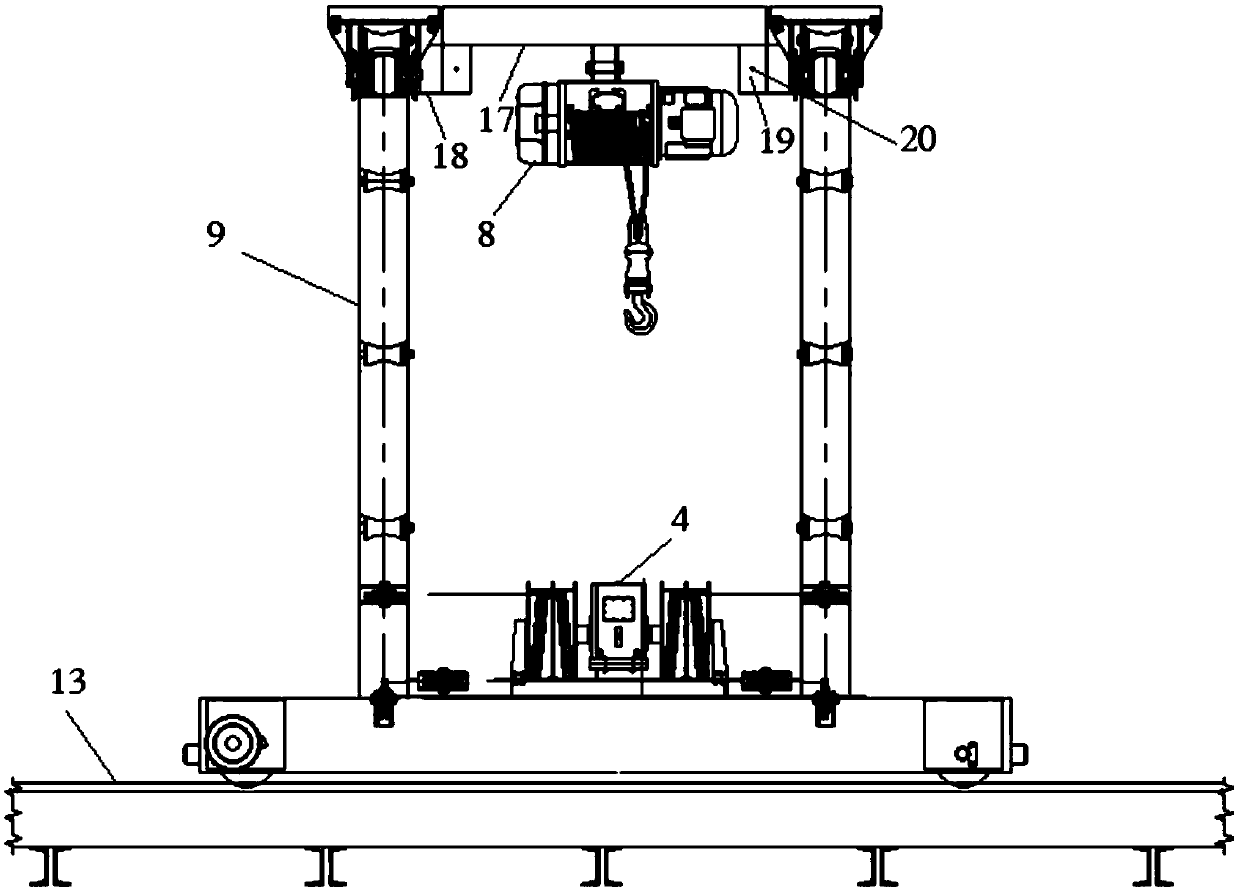

[0021] Such as figure 1 As shown, a double-arch bridge installation machine for a railway tunnel formwork trolley according to the present invention includes a first rail bracket 14 and a second rail bracket 6 arranged on both sides of the tunnel primary section 1 .

[0022] combine figure 2 , wherein: the first rail bracket 14 is slidably installed with the first rail 13, the first rail 13 is slidably installed with the first walking beam 15; the second rail bracket 6 is slidably installed with the second rail 7, and the second rail 7 is A second walking beam 5 is slidably installed, and a traction mechanism 4 is arranged on the second walking beam 5, and the traction mechanism 4 includes two rotatable driving ends.

[0023] A pair of arched beams 9 are arranged between the first traveling beam 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com