A distribution transformer fuel tank suitable for welding robot operation and its design and processing method

A technology for welding robots and fuel tanks, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problem of poor aesthetics of factory transformers and station transformers, and the accuracy of human control is accurate to within two decimal places. Problems such as low production efficiency, achieve reasonable production accuracy and aesthetics, facilitate standardized work, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

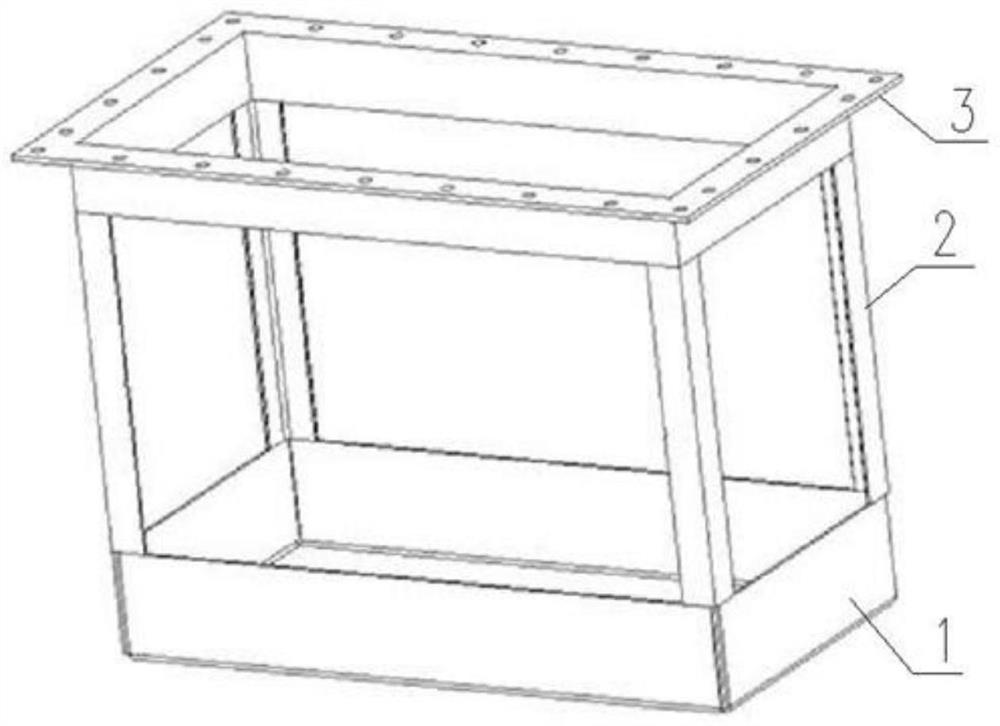

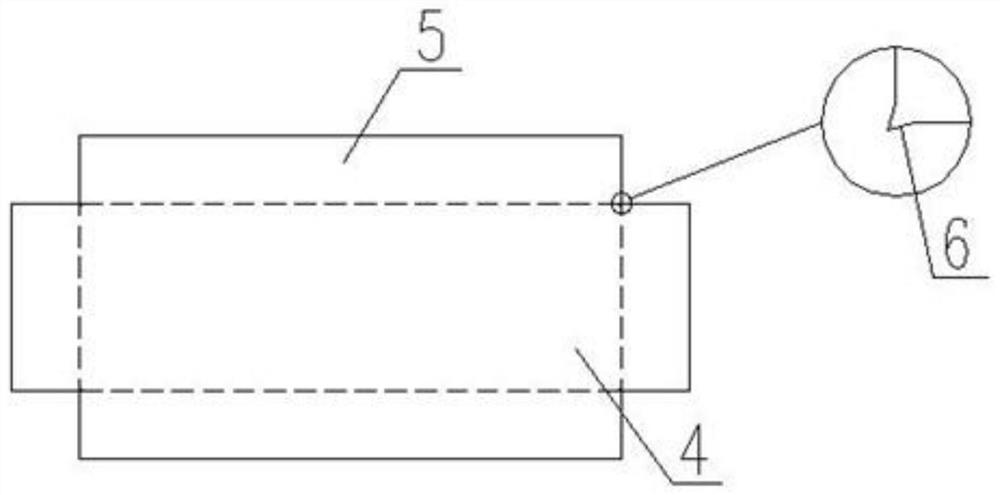

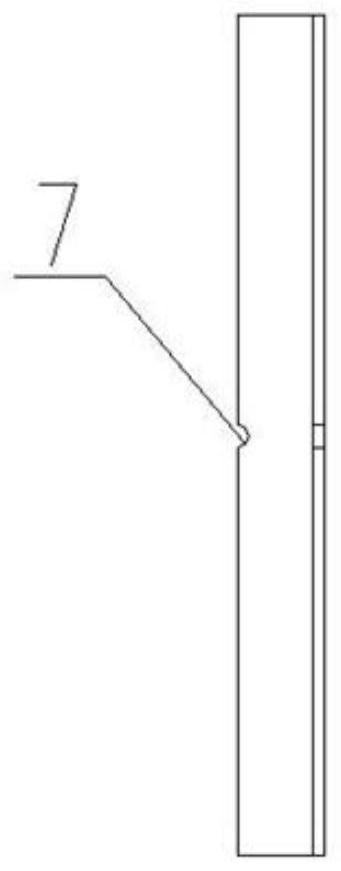

[0034] Attached below Figure 1-3 The specific method of the present invention and the manufacturing scheme of the robot welding are further described.

[0035] The traditional hand-welded fuel tank does not have the so-called skeleton structure, but simply uses the outer side walls of four angle steels to weld the box edge and the inner wall of the box bottom together, and then use the transformer's heat sink (corrugated wall) to connect the box edge and the outer side of the bottom of the box. Wrap welding. This traditional welding method is obviously not suitable for robot welding operations, because the robot welding needs to be supported by an inner support tool that can rotate freely in a plane, and then the robot welding torch is welded along a fixed route from the outside to complete the work. , the design scheme of the traditional hand-welded fuel tank adopts the internal welding mode in terms of the fixed edge and bottom of the tank (that is, the welding of the four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com