Self-sucking biological 3D printing nozzle device and method thereof

A 3D printing, self-priming technology, applied in the field of tissue engineering technology and biological 3D printing, can solve the problems that affect the printing efficiency and cannot realize continuous printing, and achieve the effect of improving printing efficiency, easy automatic control, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific structure, working principle and working process content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

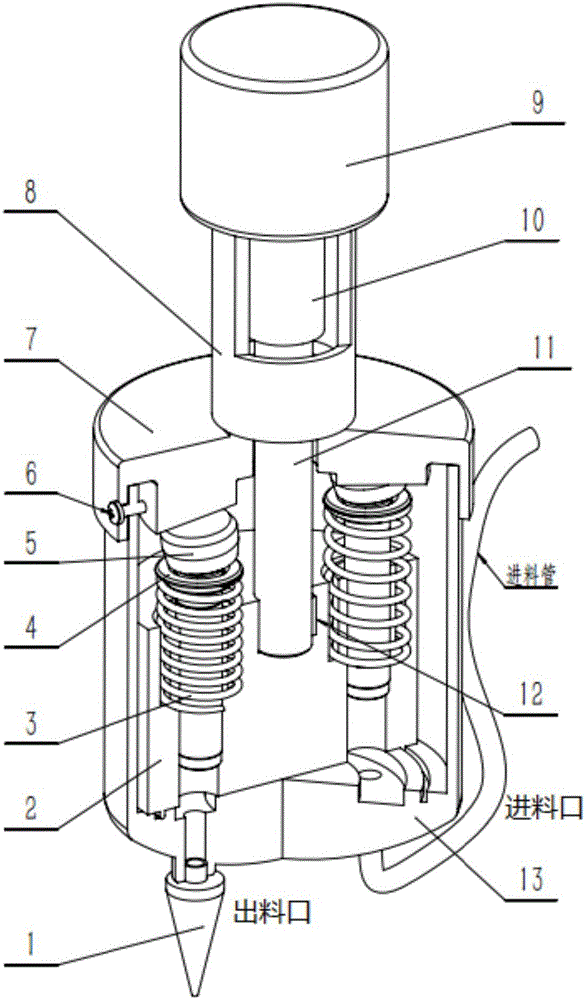

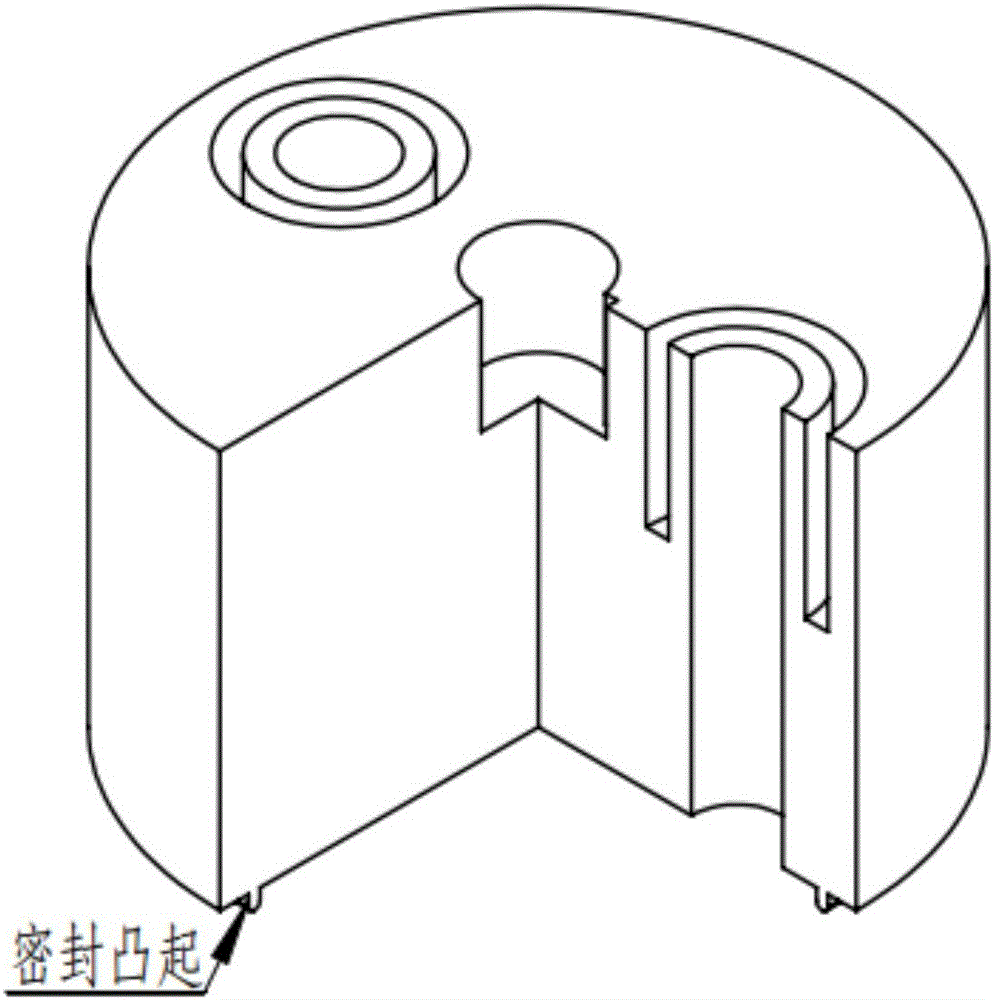

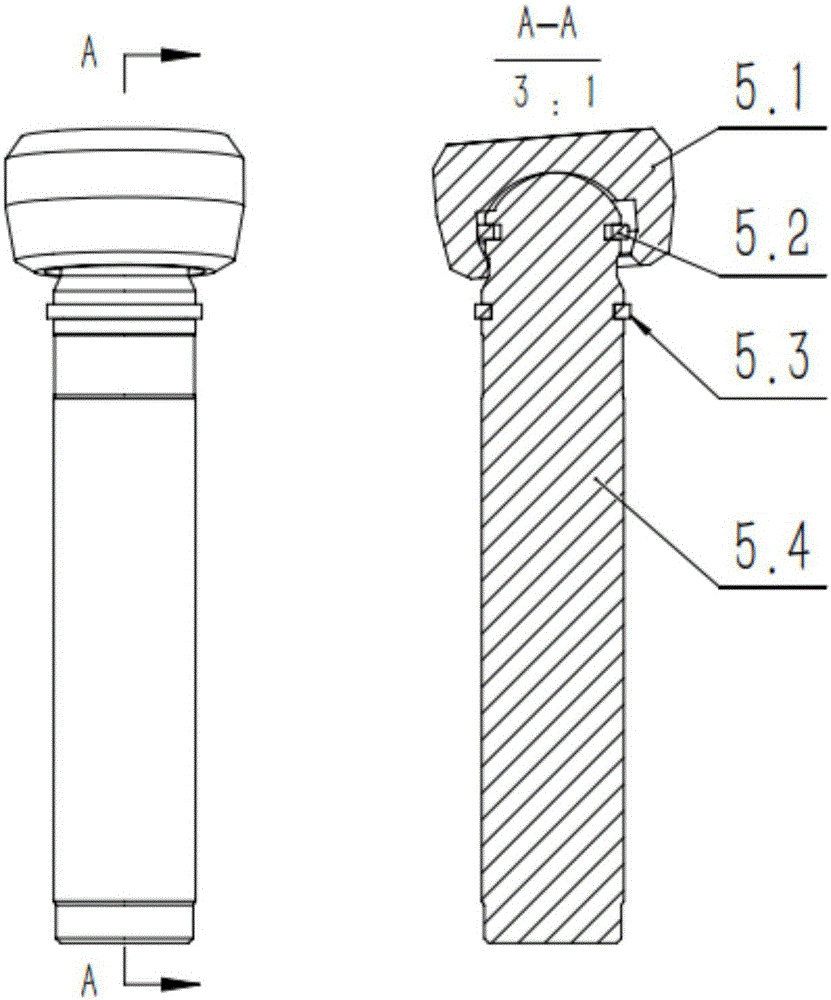

[0030] Such as figure 1 As described above, a self-priming biological 3D printing nozzle device includes a nozzle 1, a plunger cylinder, a screw 6, a swash plate cover 7, a motor base 8, a motor 9, a coupling 10, a transmission shaft 11, a flat key 12, The distribution cylinder 13.; the distribution cylinder 13 is fixed on the frame, and its lower part is provided with a material inlet and a material outlet. Solid connection; the plunger cylinder is installed inside the distribution cylinder 13, the lower end surface of the plunger cylinder is in contact with the internal end surface of the distribution cylinder 13, and the sealing protrusion on the lower part of the plunger cylinder is sealed with the internal end surface of the distribution cylinder 13. The grooves are matched a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com