Nickel base self-lubricating coating on surface of titanium alloy by laser cladding and preparation method thereof

A technology of self-lubricating coating and lubricating coating, applied in metal material coating process, coating and other directions, can solve the problem that the proportion and distribution of lubricating phase and reinforcing phase are easily affected by external factors, and the self-lubricating and wear-resistant performance of coating cannot be Fully reflect and prepare nickel-based self-lubricating coatings, etc., to achieve the effect of easy automatic control, ideal engineering application value, and precise control of coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

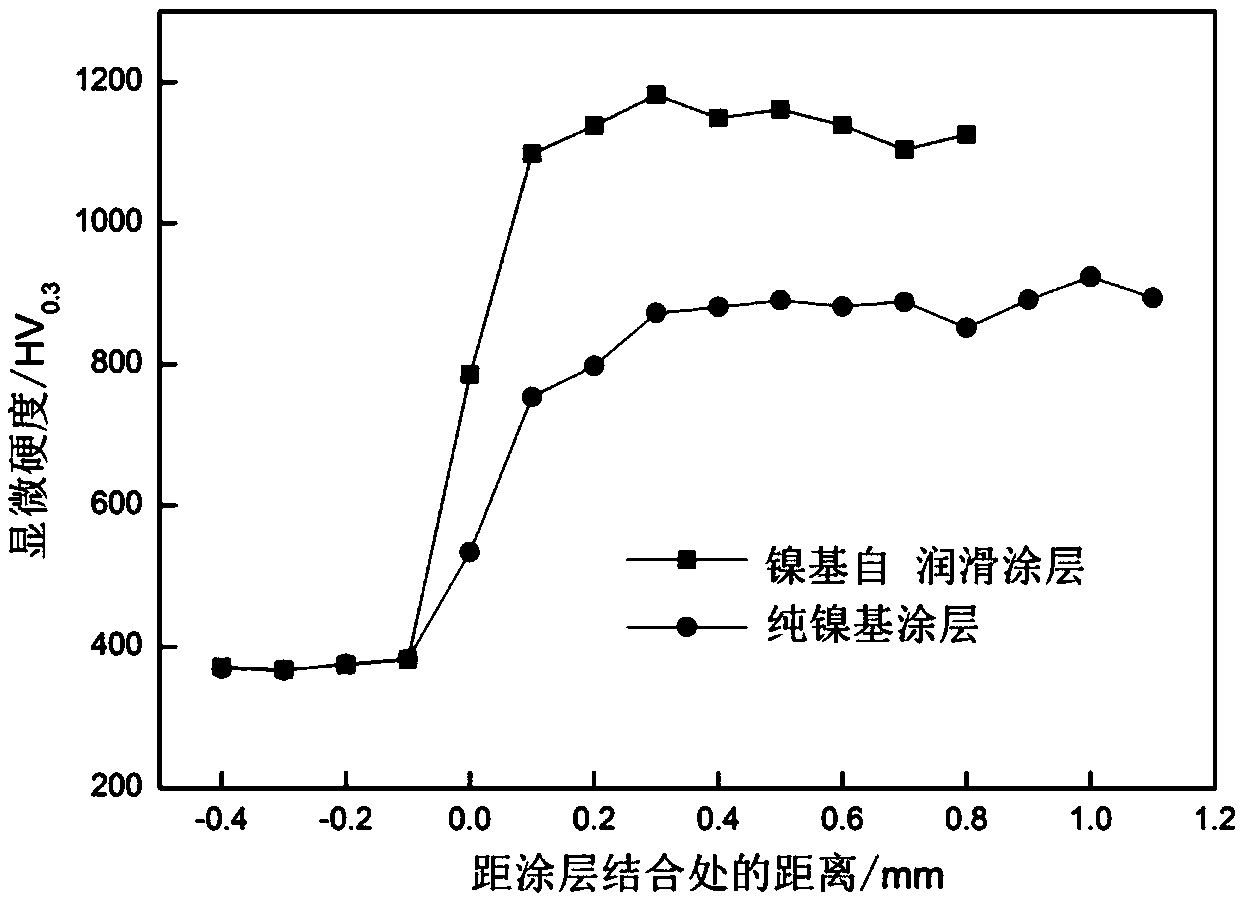

[0025] On the surface of Ti-6Al-4V titanium alloy plate of 50 (length) × 50 (width) × 5 (thickness) mm, Nd:YAG laser is used for laser cladding nickel-based self-lubricating composite coating, and the preparation method is carried out according to the following steps:

[0026] 1. Surface activation treatment of titanium alloy plate

[0027] Use 120# coarse sandpaper to grind and roughen the surface of the titanium alloy plate with a thickness of 5mm to remove the surface oxide layer and stains, strengthen the combination of the titanium alloy surface and the nickel-based self-lubricating composite cladding layer, and then clean it with alcohol or acetone. Let dry naturally.

[0028] 2. Prepare nickel-based composite coating precursor raw materials and prefabricate cladding powder layer

[0029] Prepare the nickel-based composite coating precursor by the following composition (mass percentage): 33.4wt.% nickel-based alloy, 33.3wt.% titanium nitride and 33.3wt.% nickel-coated m...

Embodiment 2

[0033] On the surface of Ti-6Al-4V titanium alloy plate of 50 (length) × 50 (width) × 5 (thickness) mm, Nd:YAG laser is used for laser cladding nickel-based self-lubricating composite coating, and the preparation method is carried out according to the following steps:

[0034] 1. Surface activation treatment of titanium alloy plate

[0035] Use 120# coarse sandpaper to grind and roughen the surface of the titanium alloy plate with a thickness of 5mm to remove the surface oxide layer and stains, strengthen the combination of the titanium alloy surface and the nickel-based self-lubricating composite cladding layer, and then clean it with alcohol or acetone. Let dry naturally.

[0036] 2. Prepare nickel-based composite coating precursor raw materials and prefabricate cladding powder layer

[0037]Prepare nickel-based composite coating precursor by following composition (mass percentage): 50wt.% nickel-based alloy, 25wt.% titanium nitride and 25wt.% nickel-clad molybdenum disulfi...

Embodiment 3

[0041] On the surface of Ti-6Al-4V titanium alloy plate of 50 (length) × 50 (width) × 5 (thickness) mm, Nd:YAG laser is used for laser cladding nickel-based self-lubricating composite coating, and the preparation method is carried out according to the following steps:

[0042] 1. Surface activation treatment of titanium alloy plate

[0043] Use 120# coarse sandpaper to grind and roughen the surface of the titanium alloy plate with a thickness of 5mm to remove the surface oxide layer and stains, strengthen the combination of the titanium alloy surface and the nickel-based self-lubricating composite cladding layer, and then clean it with alcohol or acetone. Let dry naturally.

[0044] 2. Prepare nickel-based composite coating precursor raw materials and prefabricate cladding powder layer

[0045] Prepare nickel-based composite coating precursor by following composition (mass percentage): 50wt.% nickel-based alloy, 20wt.% titanium nitride and 30wt.% nickel-clad molybdenum disulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com