Environment-friendly type liquid degreasing agent for cleaning strip steel before annealing

A degreasing agent, an environment-friendly technology, applied in the field of degreasing agent, can solve the problems of small size of hydrogen molecules, reduce the physical properties of the steel base itself, weak carrying capacity and stripping ability, and achieve automatic control, easy automatic control, and good environment The effect of friendliness

Inactive Publication Date: 2017-12-01

SHANGHAI PARKERIZING CO LTD

View PDF9 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, because a large amount of hydrogen is always generated in the cathode area, and the hydrogen molecules are small in size and can easily penetrate into the steel plate, which can easily cause hydrogen embrittlement of the steel plate, which will not only reduce the physical properties of the steel base itself, but also produce hydrogen during hot-dip galvanizing. bubble defect

[0013] (2) Oxygen is precipitated on the anode, because the oxygen molecule has a large volume, large bubbles, and a small number, and its buoyancy is smaller than that of hydrogen bubbles, so its carrying capacity and stripping ability are weak

However, the technical solution disclosed in this patent document is also a powder degreasing agent, and there are many inconveniences during use.

At the same time, phosphate is used as a builder in the formula, and the use of phosphorus-containing degreasing agents will cause eutrophication of the water body and pollute the water body

[0018] In the technical solutions disclosed in the above-mentioned patent documents, the degreasing agent used in the cold-rolled strip steel is either a powder degreasing agent, which is inconvenient to use, or a degreasing agent containing phosphate, which is more harmful to the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

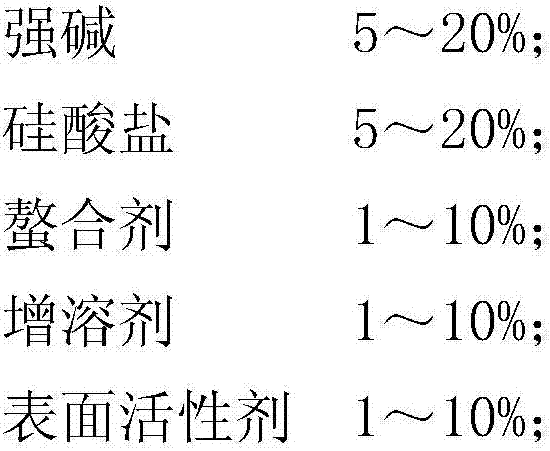

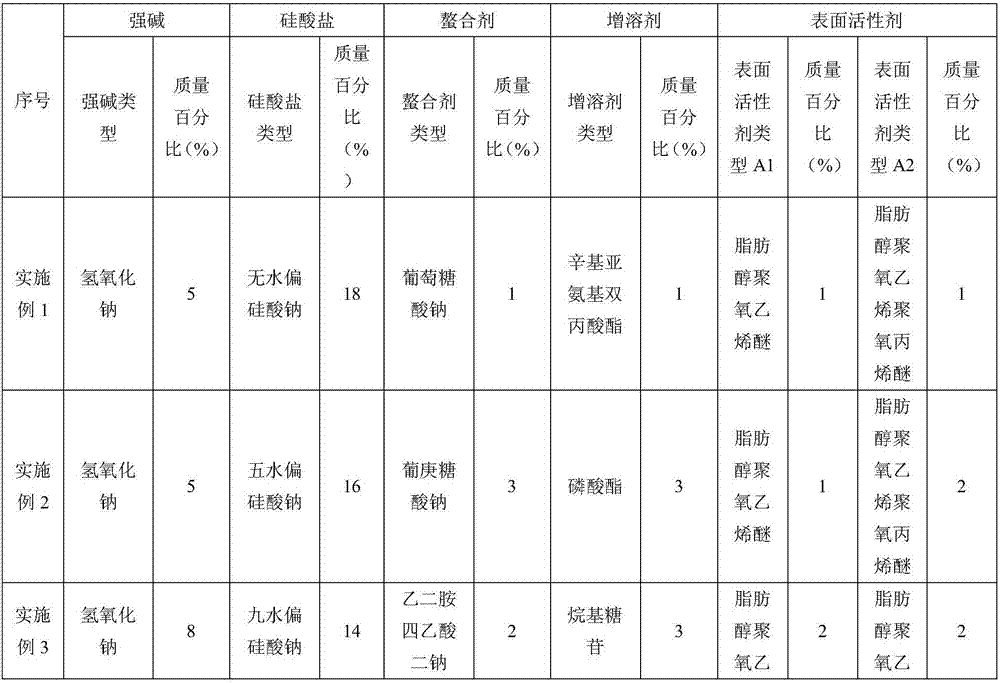

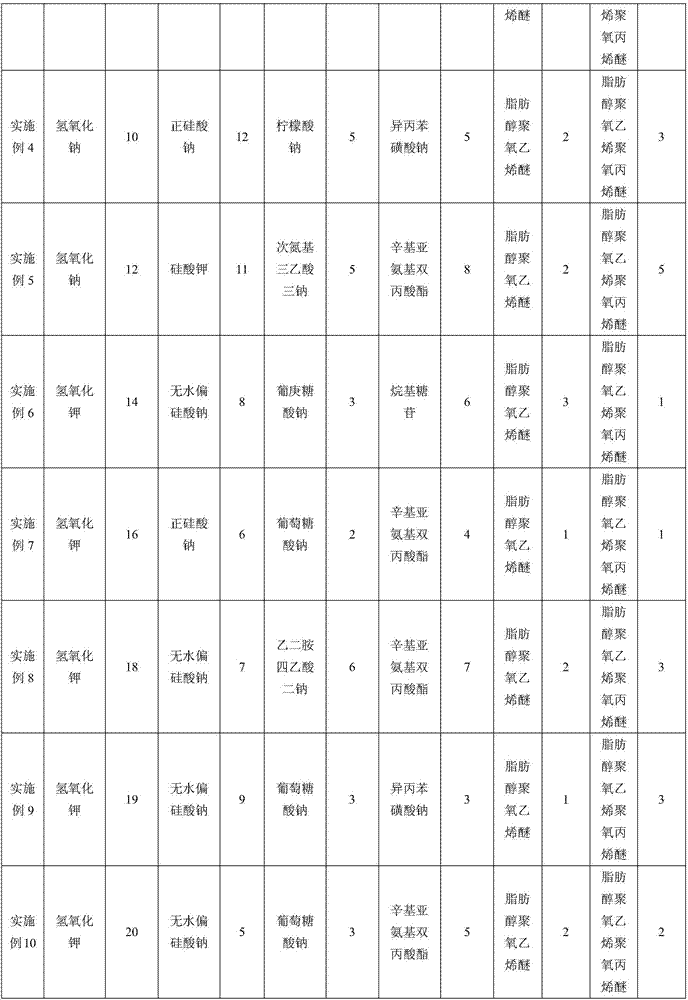

Embodiment 1-10

[0052] Table 1 lists the mass percentages of the components of the environment-friendly liquid degreaser used for cleaning the steel strip before annealing in Examples 1-10.

[0053] Table 1. (wt%, balance is water and other unavoidable impurities)

[0054]

[0055]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an environment-friendly liquid degreasing agent used for cleaning steel strips before annealing. After the environment-friendly liquid degreasing agent is applied to the surface of the steel strip, a silicon dioxide layer is adsorbed on the surface of the steel strip. The environment-friendly liquid degreasing agent of the present invention is easy to add in the production process because it is a liquid type degreasing agent, thereby facilitating the realization of automatic control. In addition, the environment-friendly degreasing agent does not use phosphorus-containing additives, has low harm to the environment, and has good environmental friendliness.

Description

technical field [0001] The invention relates to a degreasing agent, in particular to a degreasing agent used for cleaning steel strips before annealing. Background technique [0002] Cold-rolled steel strip is widely used in automobiles, home appliances, machinery, electronics, chemicals, food packaging and other industries, covering almost all walks of life related to the national economy and people's livelihood. The actual development of the international iron and steel industry shows that with the development of economy and society, the proportion of cold-rolled products in steel consumption is constantly increasing, and they are playing an increasingly important role. [0003] During the cold rolling of the strip, in order to reduce the friction between the strip and the roll, the emulsion is sprayed on the contact surface between the strip and the roll. During the cold rolling process, due to the existence of friction, iron powder will fall off from the surface of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25F1/06

CPCC25F1/06

Inventor 徐笑邵辉苏云鹤

Owner SHANGHAI PARKERIZING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com