Hydraulic controllable sluice valve

A gate valve and hydraulic technology, applied in the direction of sliding valve, valve detail, valve device, etc., can solve the problems that the valve cannot meet the requirements, high labor intensity and low efficiency, and achieve the effect of easy automatic control, reduced labor intensity and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

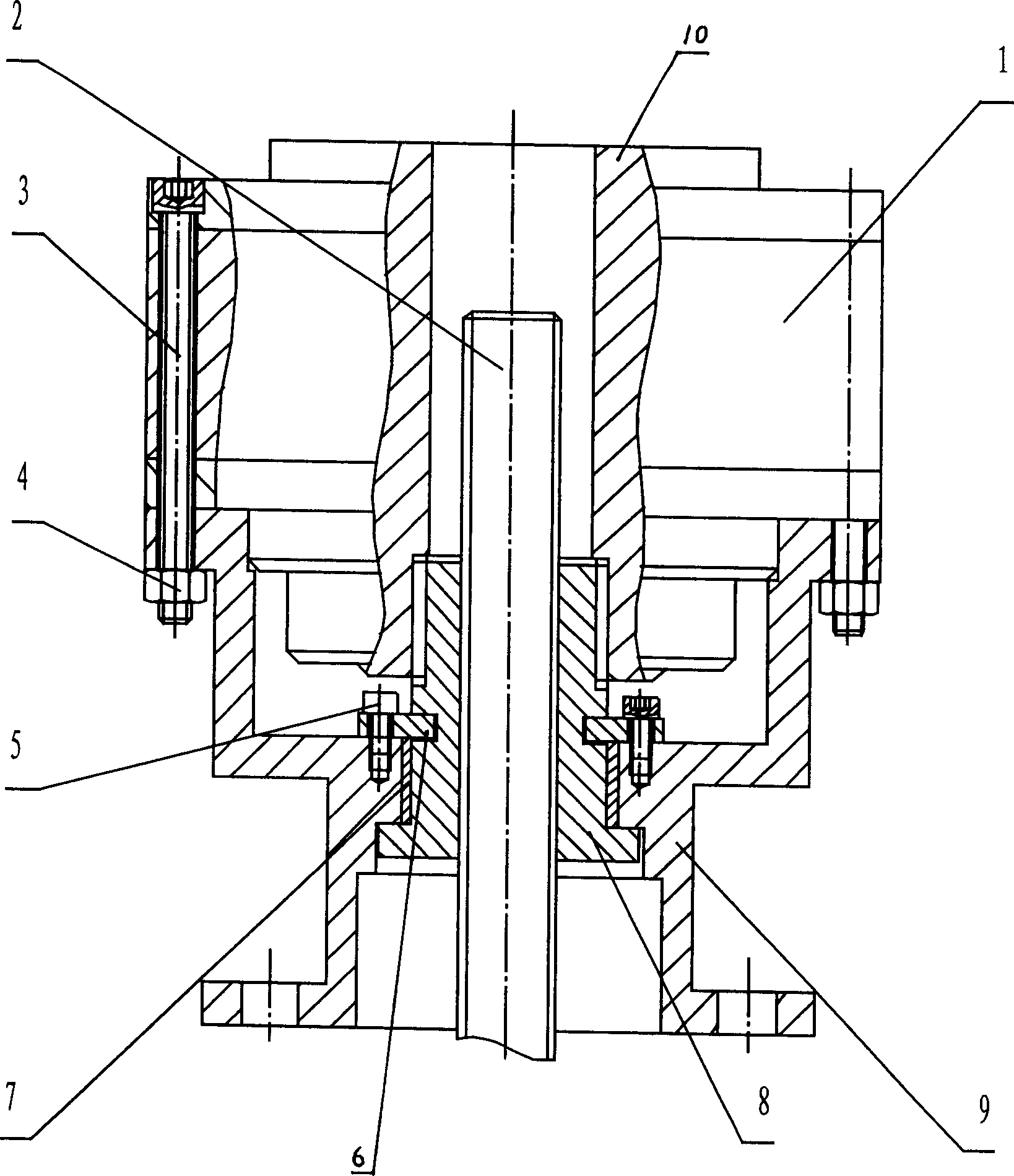

[0011] The bottom of the connecting frame 9 is connected with the valve body by bolts, and the leading screw 2 passes through its central hole and is screwed with the drive nut 8 . The drive nut 8 is in plane contact with the connecting frame 9 . The collar 6 is semicircular, and the longitudinal section of the drive nut 8 is T-shaped. The drive nut 8 is axially positioned by two collars 6 , the drive nut 8 and the copper sleeve 7 are in clearance fit, and the copper sleeve 7 and the connecting frame 9 are in tight fit. The transmission nut 8 is connected with the output shaft 10 of the hydraulic motor through a spline, and the hydraulic motor 1 is fixed on the connecting frame 9 through the bolt 3 and the nut 4 .

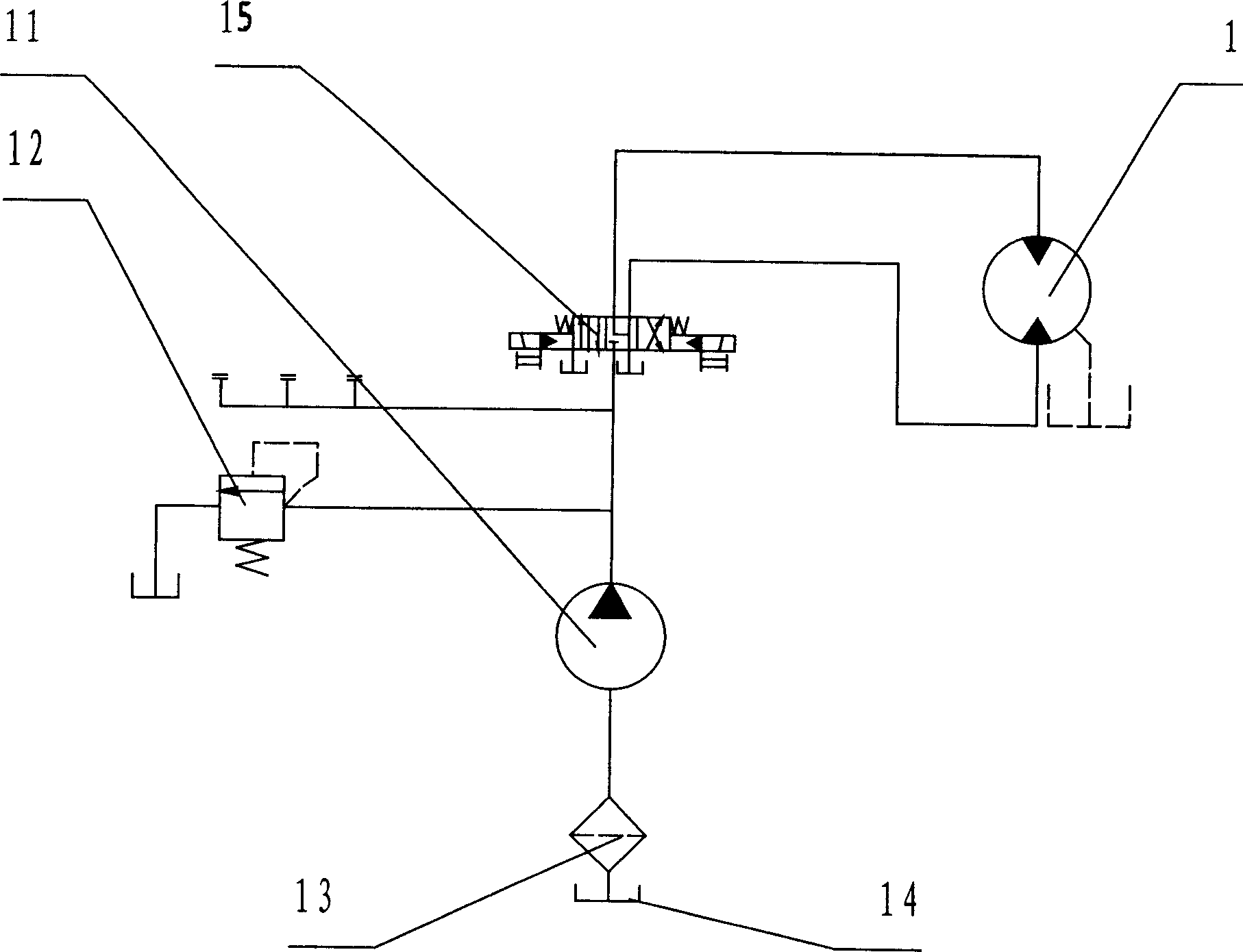

[0012] The hydraulic motor 1 adopts a low-speed high-torque hydraulic motor. The hydraulic pump 11 is a one-way pump, and multiple solenoid valves can be connected in parallel at the outlet of the hydraulic pump 11 to control multiple gate valves, and the paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com