Three-stage type hydraulic driving biomass reciprocating fire grate

A reciprocating grate and three-stage technology, which is applied in the field of three-stage hydraulically driven biomass reciprocating grate, can solve the problem of inability to cope with complex combustion conditions, inability to adjust speed and stroke arbitrarily, and unusable equipment shutdown, etc. problems, to achieve the effect of good use, stable hydraulic propulsion, and prevention of biomass burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: taking this as an example to further describe and illustrate the present application.

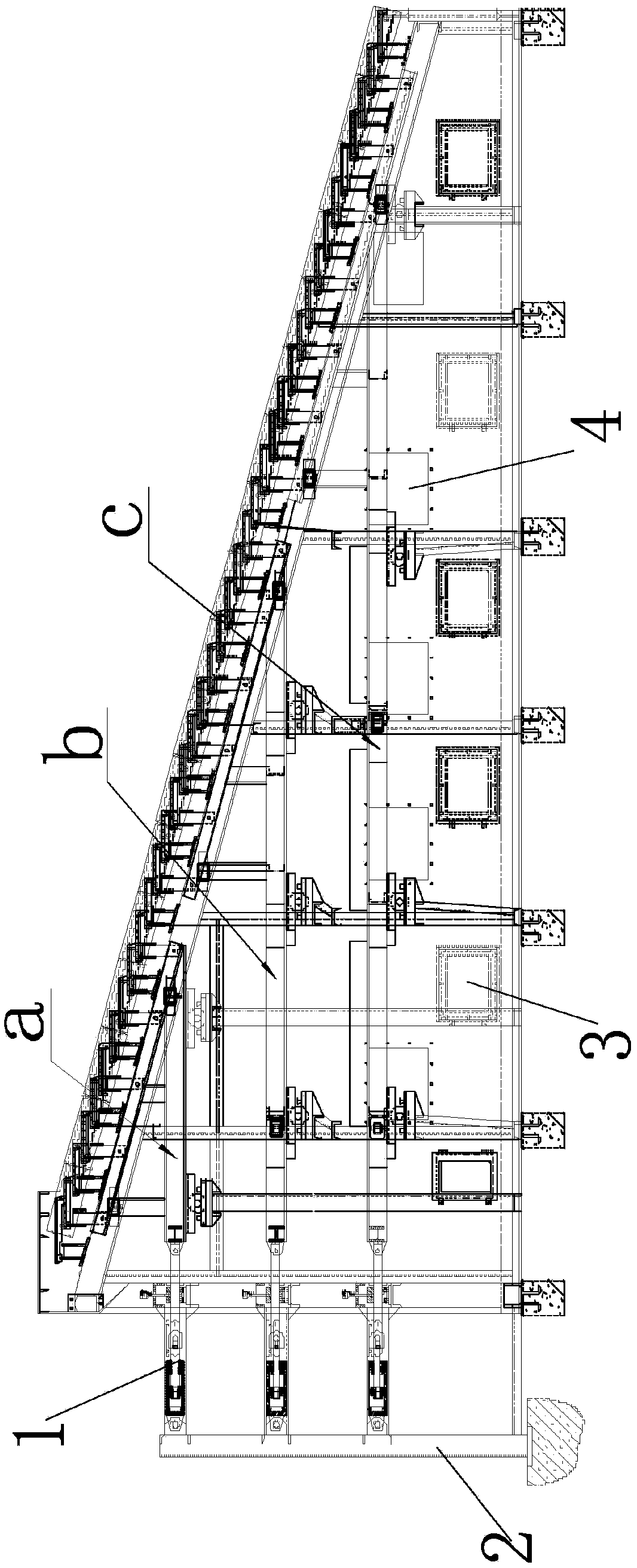

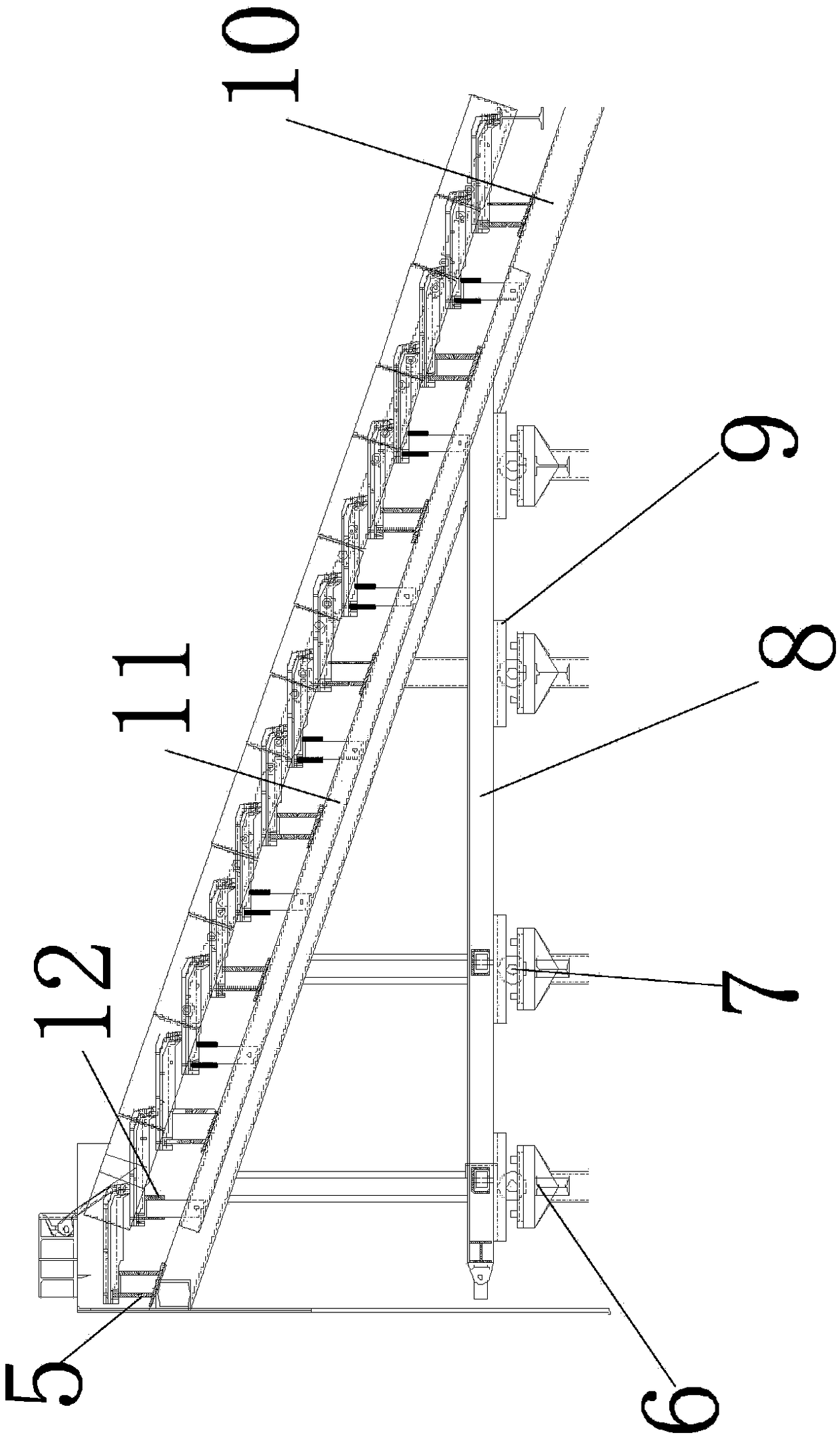

[0017] Such as Figure 1-2 As shown, this embodiment provides a three-stage hydraulically driven biomass reciprocating fire grate, including: a fixed column, three hydraulic drive devices, and a frame, in which the first stage of the fire grate, the second stage Fire grate and the third section of fire grate, each section of fire grate includes a movable frame, a connecting shaft, a grate piece, a movable beam, a fixed beam, a steel plate, rollers, and a support frame, and the movable frame includes: a connected bottom beam and a movable slope Beams, several reinforced beams are arranged between the bottom beam and the movable inclined beam, the movable inclined beam is installed on the frame, several steel plates are arranged under the bottom beam, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com