Patents

Literature

107results about How to "Stable and reliable structure operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

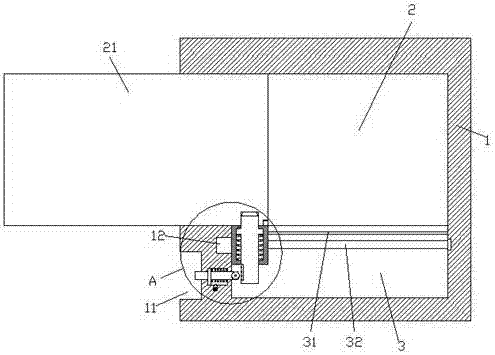

Drawer-type electric power control cabinet

InactiveCN106451187ARealize routine maintenanceEasy maintenanceSwitchgear with withdrawable carriageMechanical engineeringElectric power

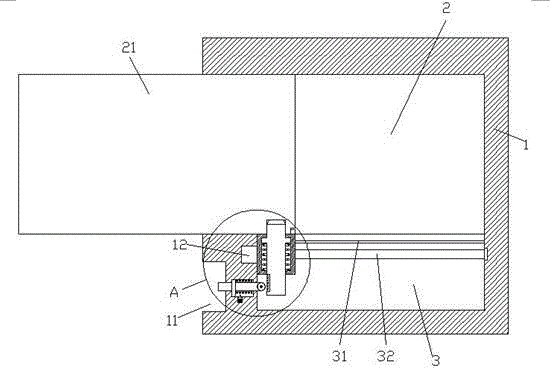

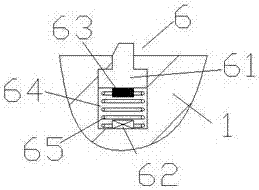

The invention discloses a drawer-type electric power control cabinet which comprises a cabinet body. A storage cavity is formed in the cabinet body, a propulsion groove is formed in the cabinet body below the storage cavity, a drawer component is arranged in the storage cavity, a pressing area is arranged on the outer wall of the cabinet body of the left side of the propulsion groove, a pressing cavity and a clamping device are arranged in the cabinet body between the pressing area and the propulsion groove, the clamping device is arranged below the pressing cavity, a pressing rod is arranged in the pressing cavity and extends to the left side and the right side, and a left extending section of the pressing rod penetrates the left side wall of the cabinet body and extends into the pressing area. The drawer-type electric power control cabinet automatically shifts in and shifts out, the drawer component is individually disassembled, different maintenance requirements can be met, the cabinet is conveniently maintained by staff, maintenance efficiency is improved, and the whole control cabinet is stable to operate.

Owner:广东兴宏业电器有限公司

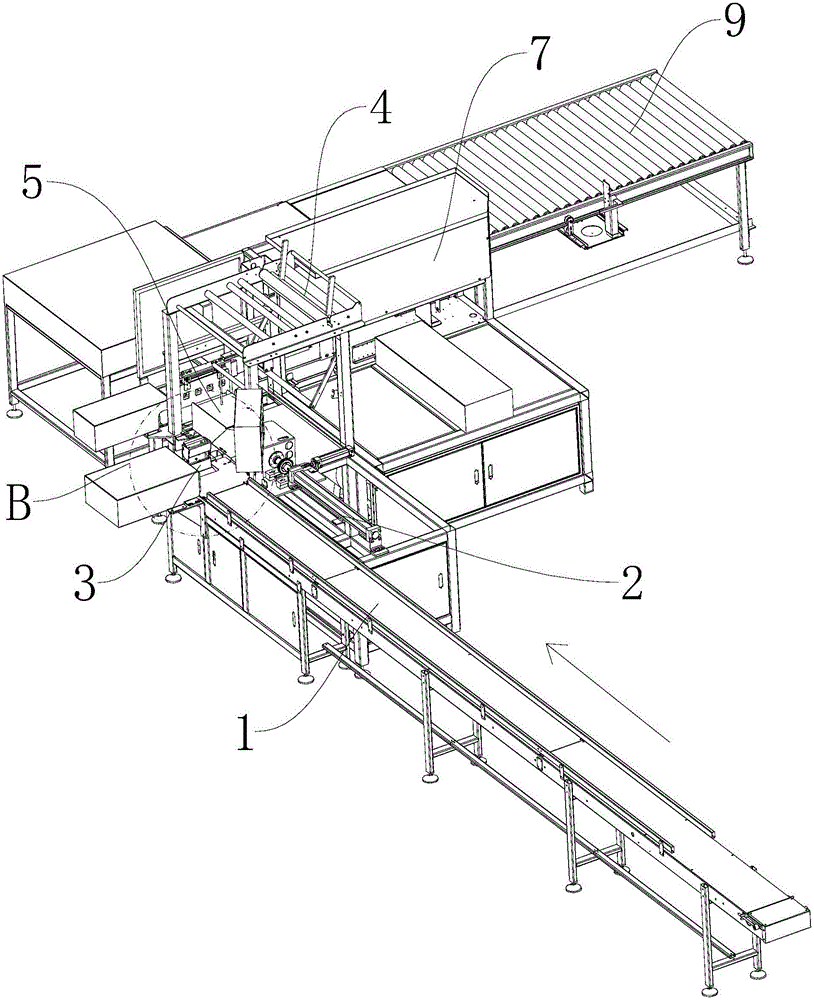

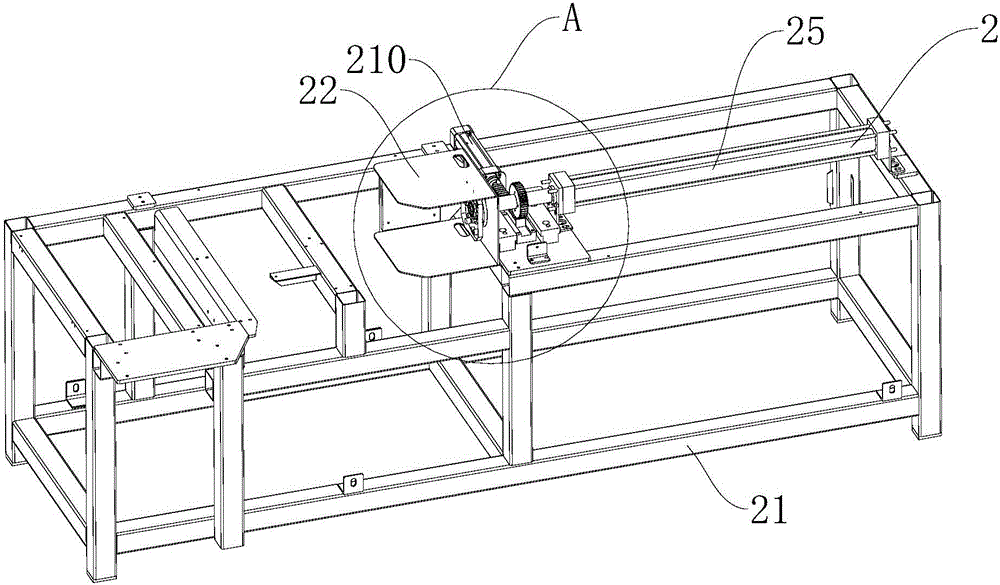

Full-automatic intelligent cheese packaging machine

ActiveCN105151355ALink connection is tight and reliableImprove efficiencyPackaging automatic controlIndividual articlesProgrammable logic controllerHigh-density polyethylene

The invention relates to a full-automatic intelligent cheese packaging machine. The machine comprises a programmable logic controller (PLC) control panel, a cheese input roller device, a cheese charging barrel automatic overturning mechanism, a bobbin positioning information testing device, a high-density polyethylene (HDPE) film conveying and compositing roller structure, an HDPE film inlet assembly, a cheese hot shearing system, a cheese semi-packaged finished product pushing system, a finished cheese product woven bag packaging device and a bagged cheese output roller device. The full-automatic intelligent cheese packaging machine fully takes procedures of all links of cheese packaging into consideration, and mechanical and automatic improvement is carried out according to all the links; link connection among a cheese weighing machine, a cheese packaging machine and a cheese stacking machine is close and reliable; a running mechanism can work for a long time, the whole production line only needs one operator, and packaging efficiency is greatly improved. Meanwhile, the weight of cheese of each batch is precisely controlled, deviation is reduced, and economic benefits in all aspects can be remarkably improved.

Owner:江苏晨阳机械有限公司

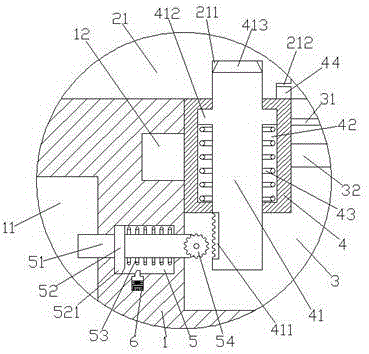

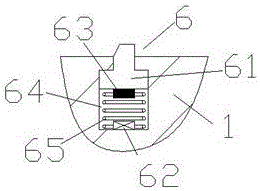

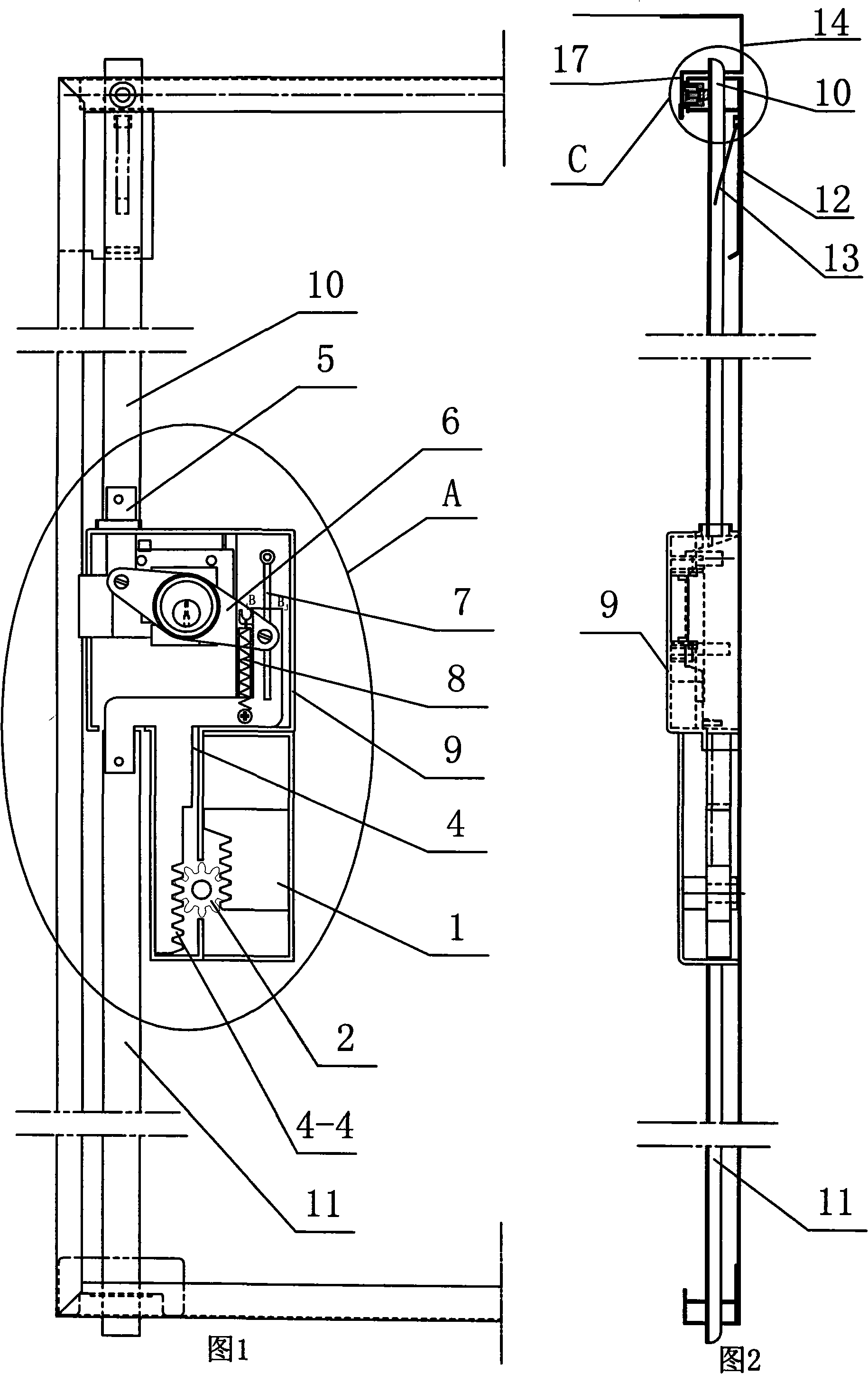

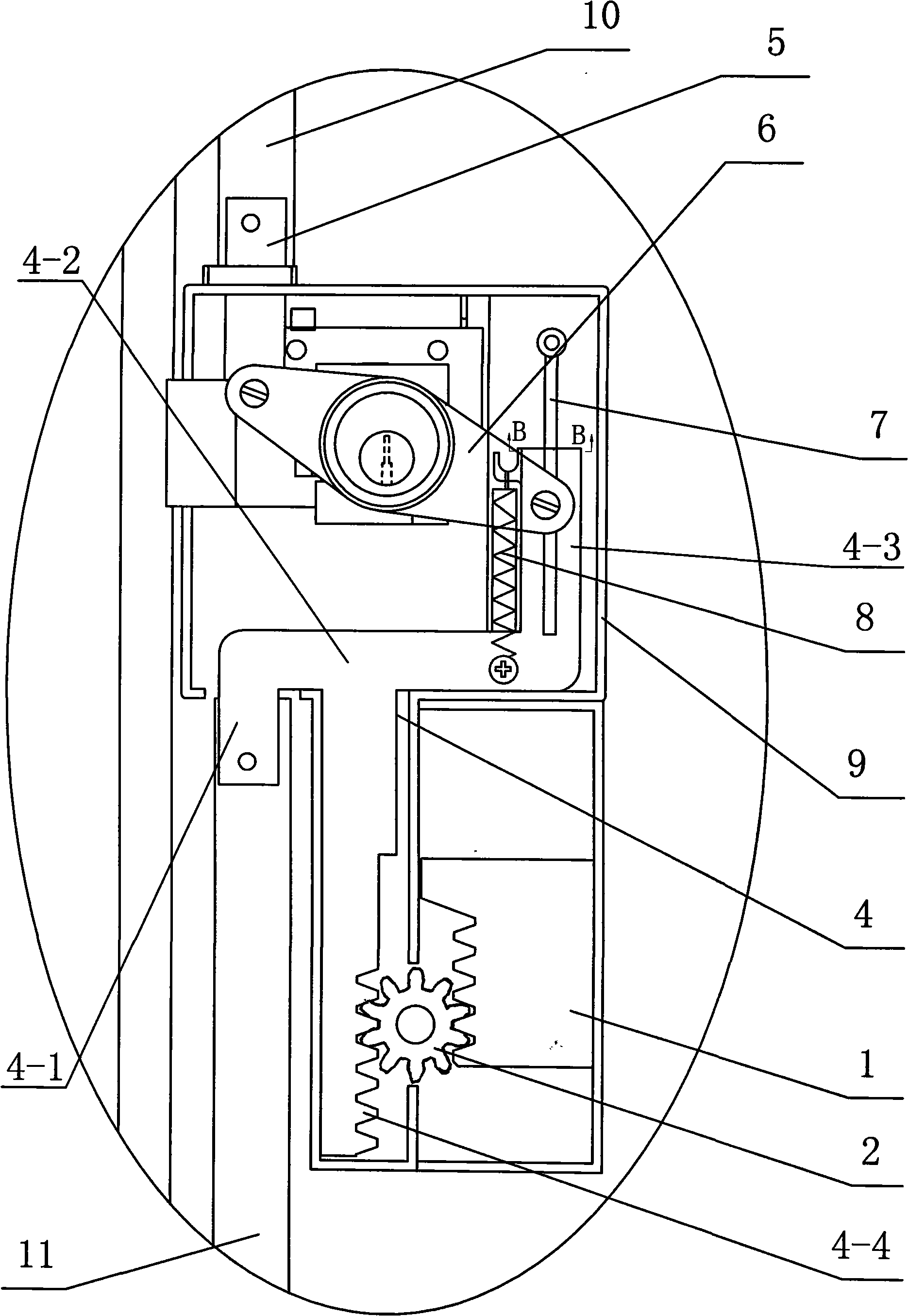

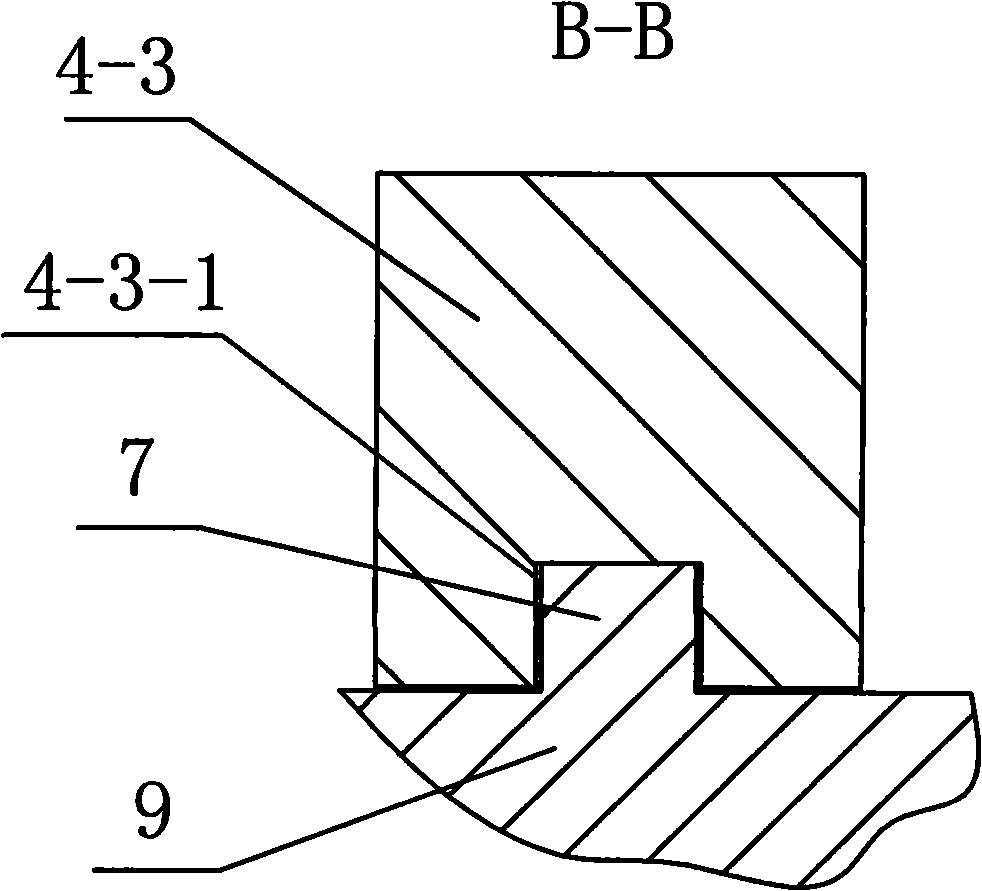

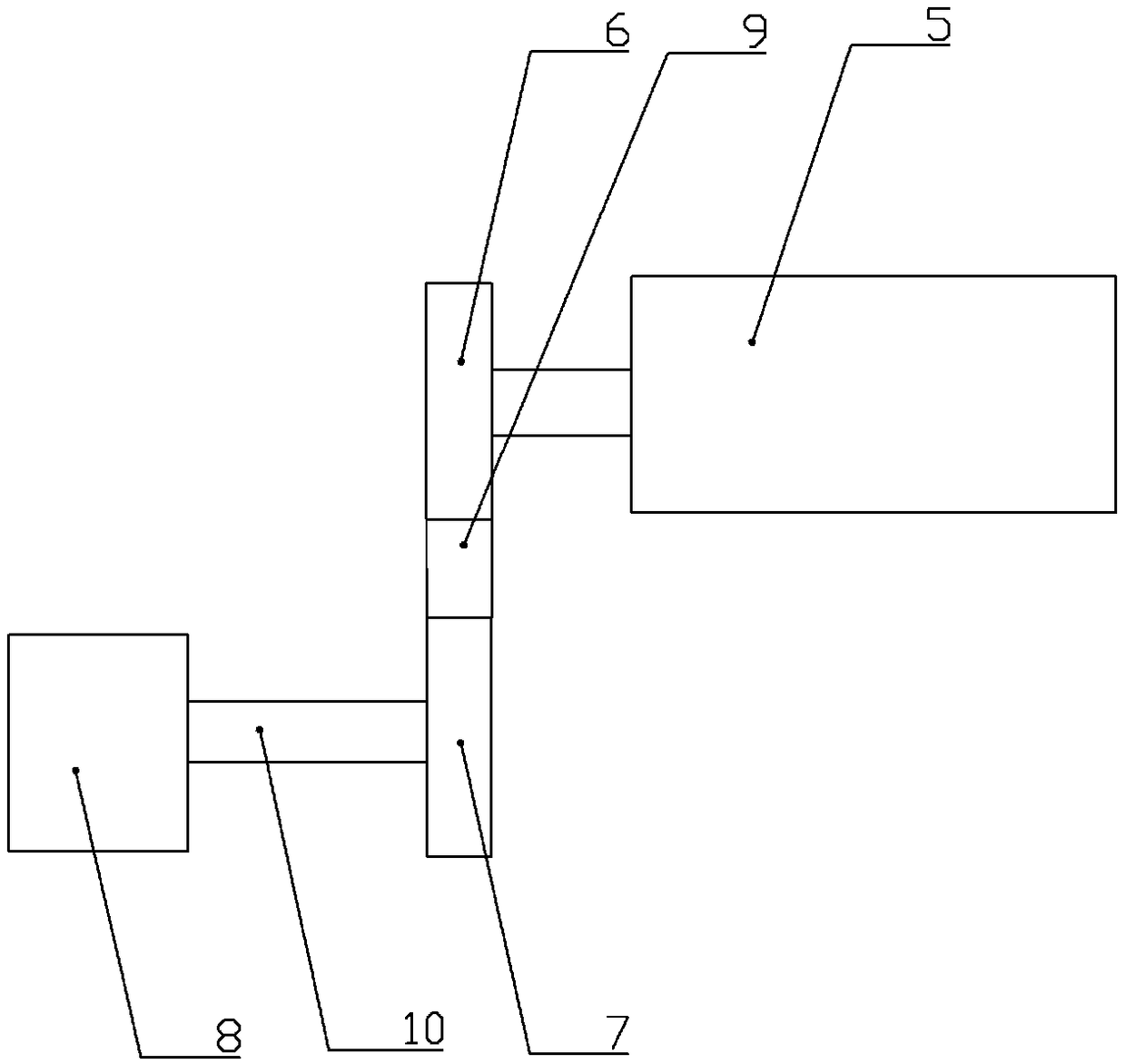

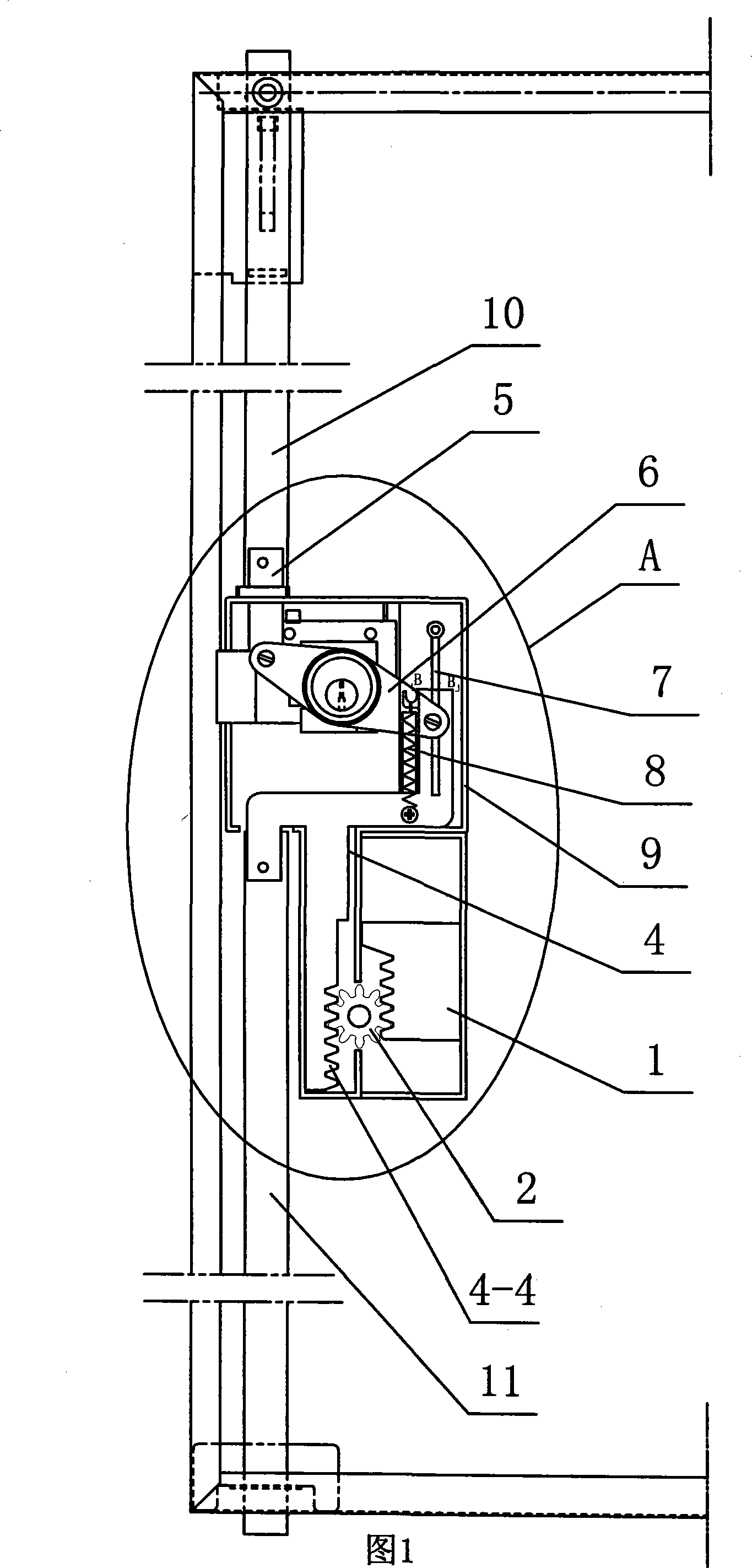

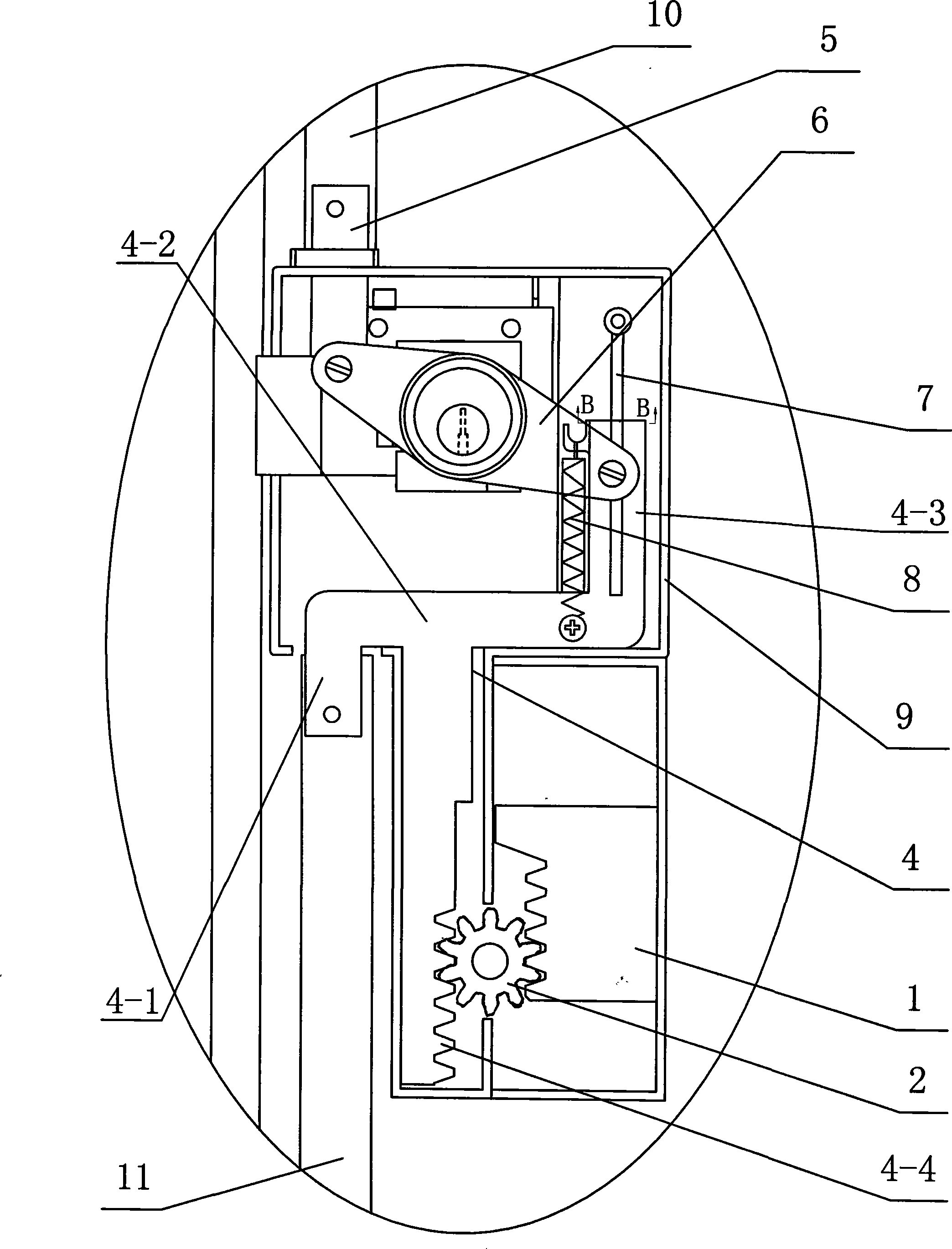

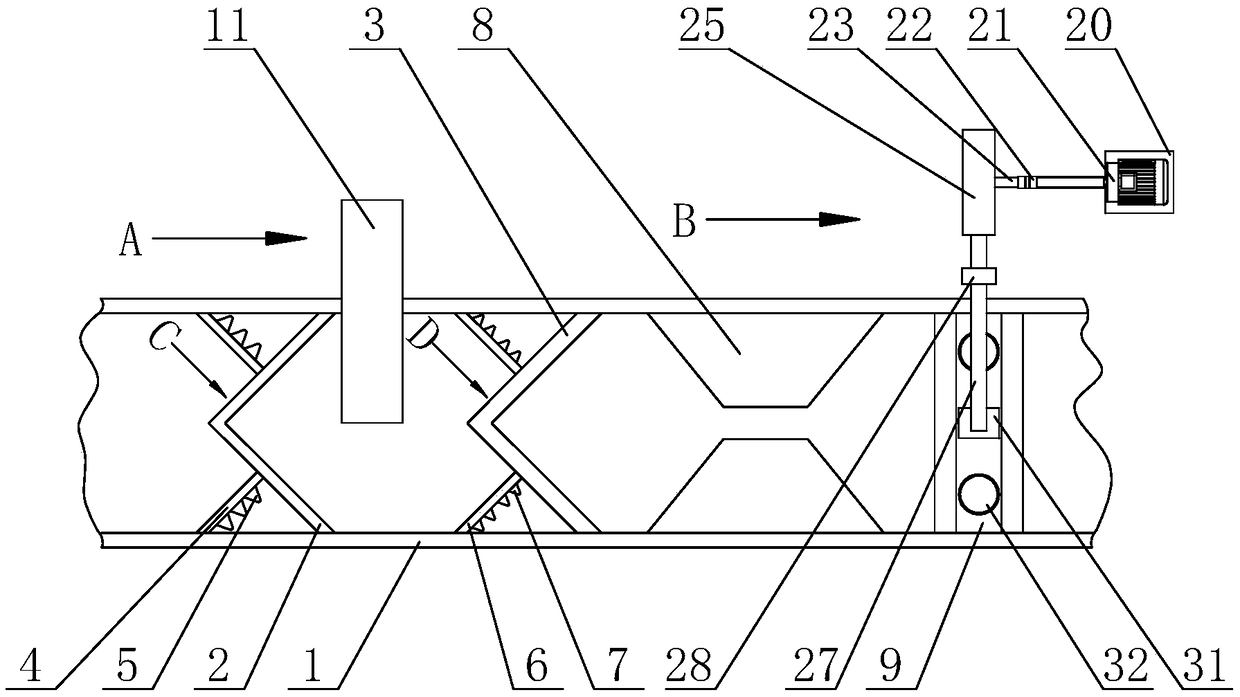

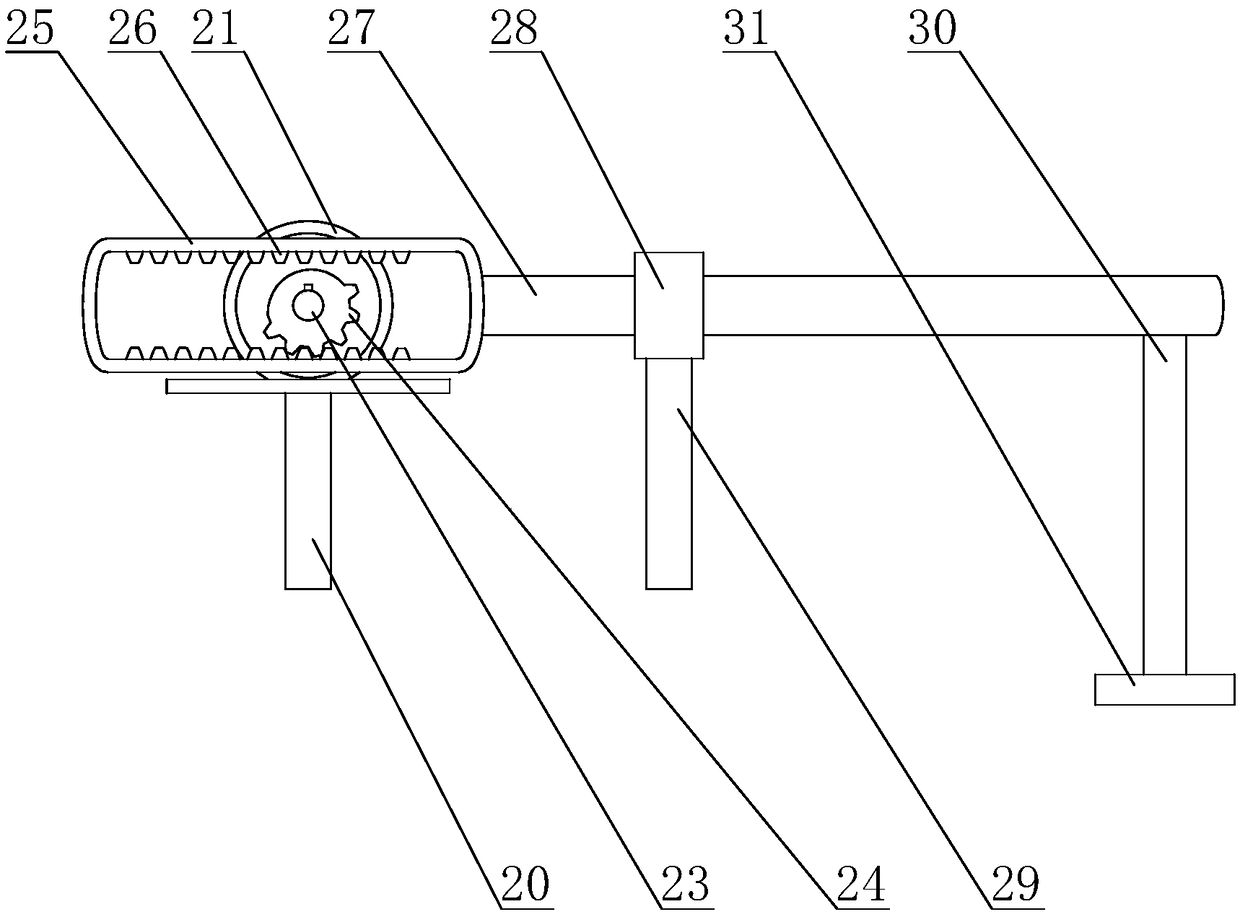

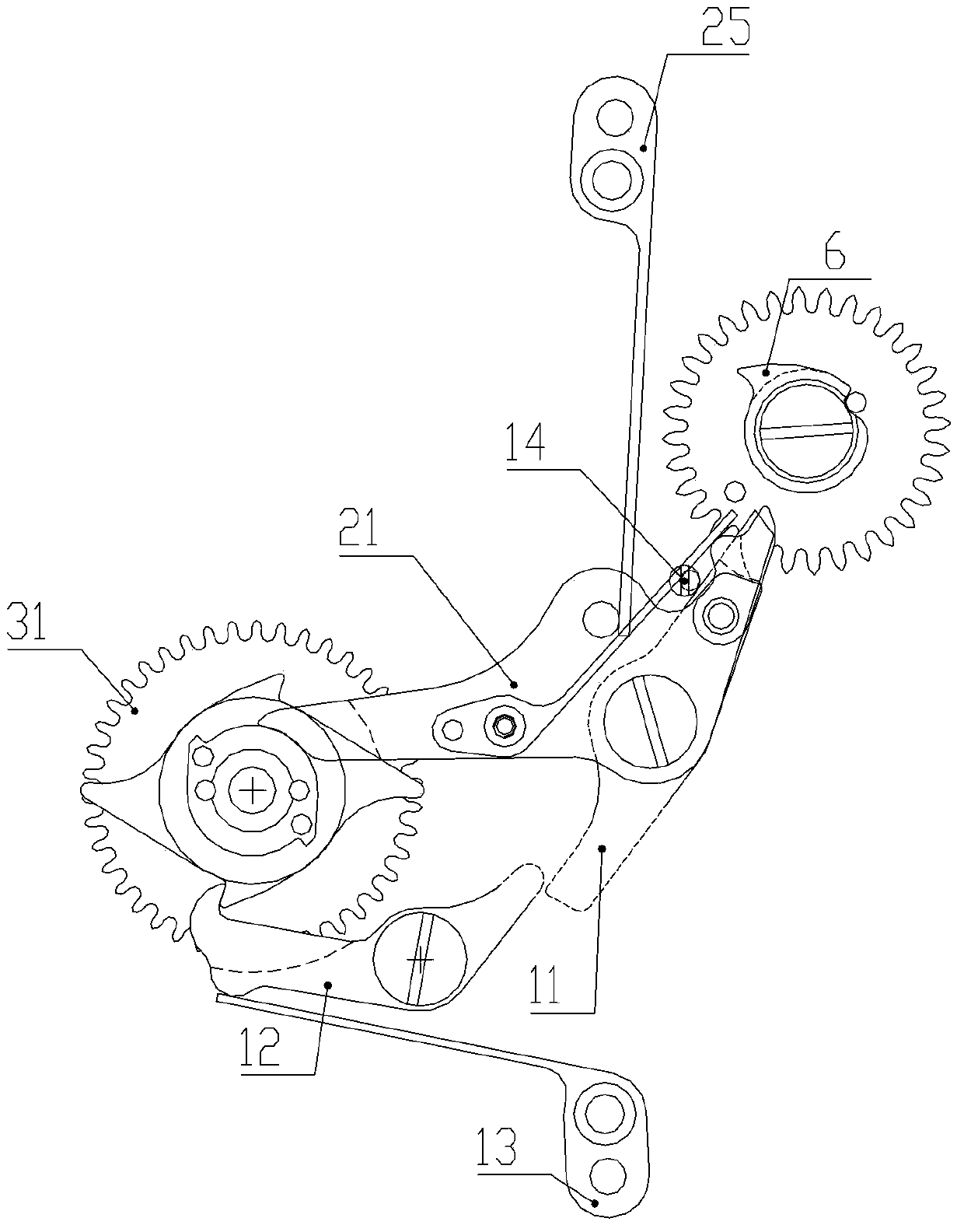

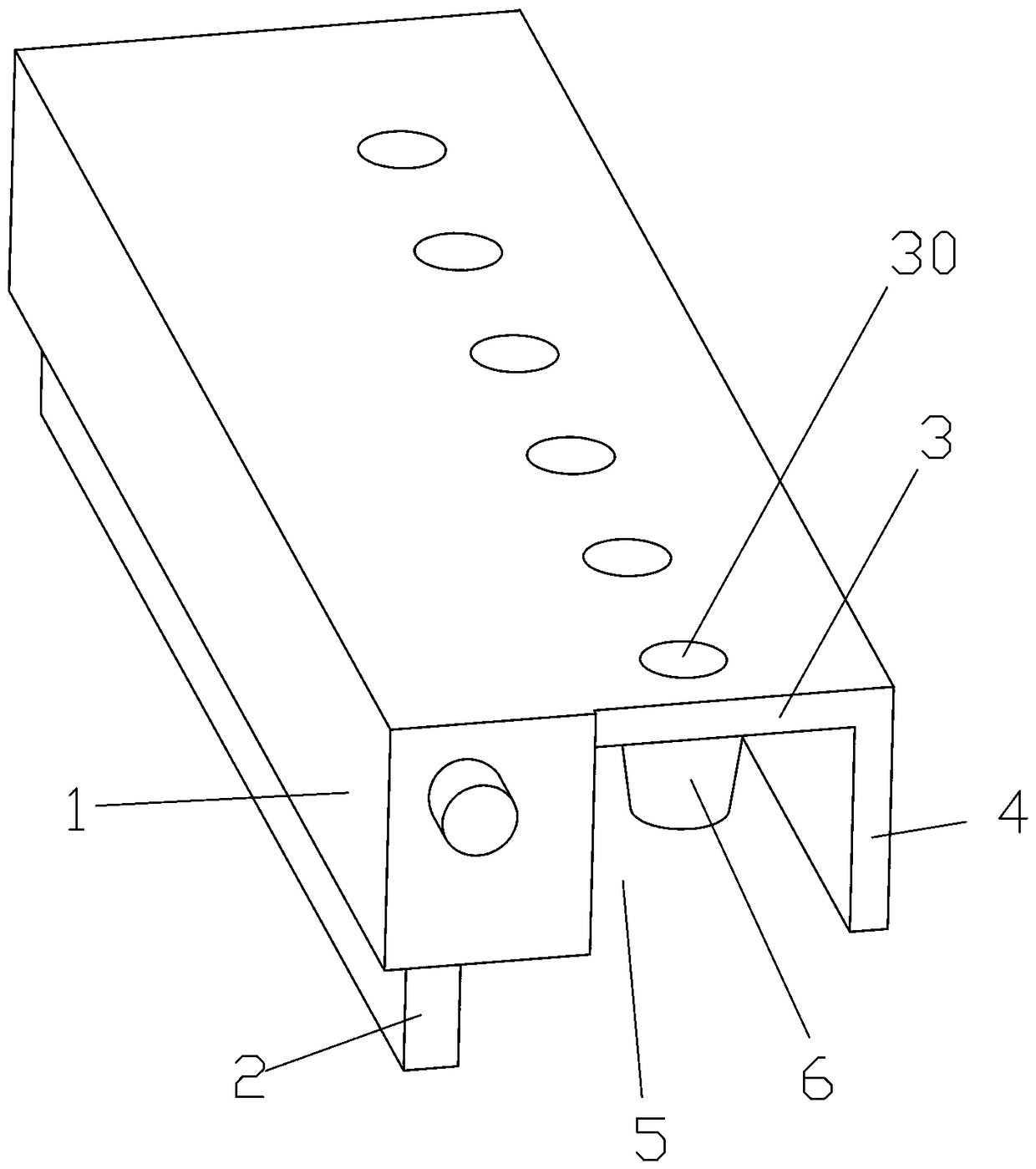

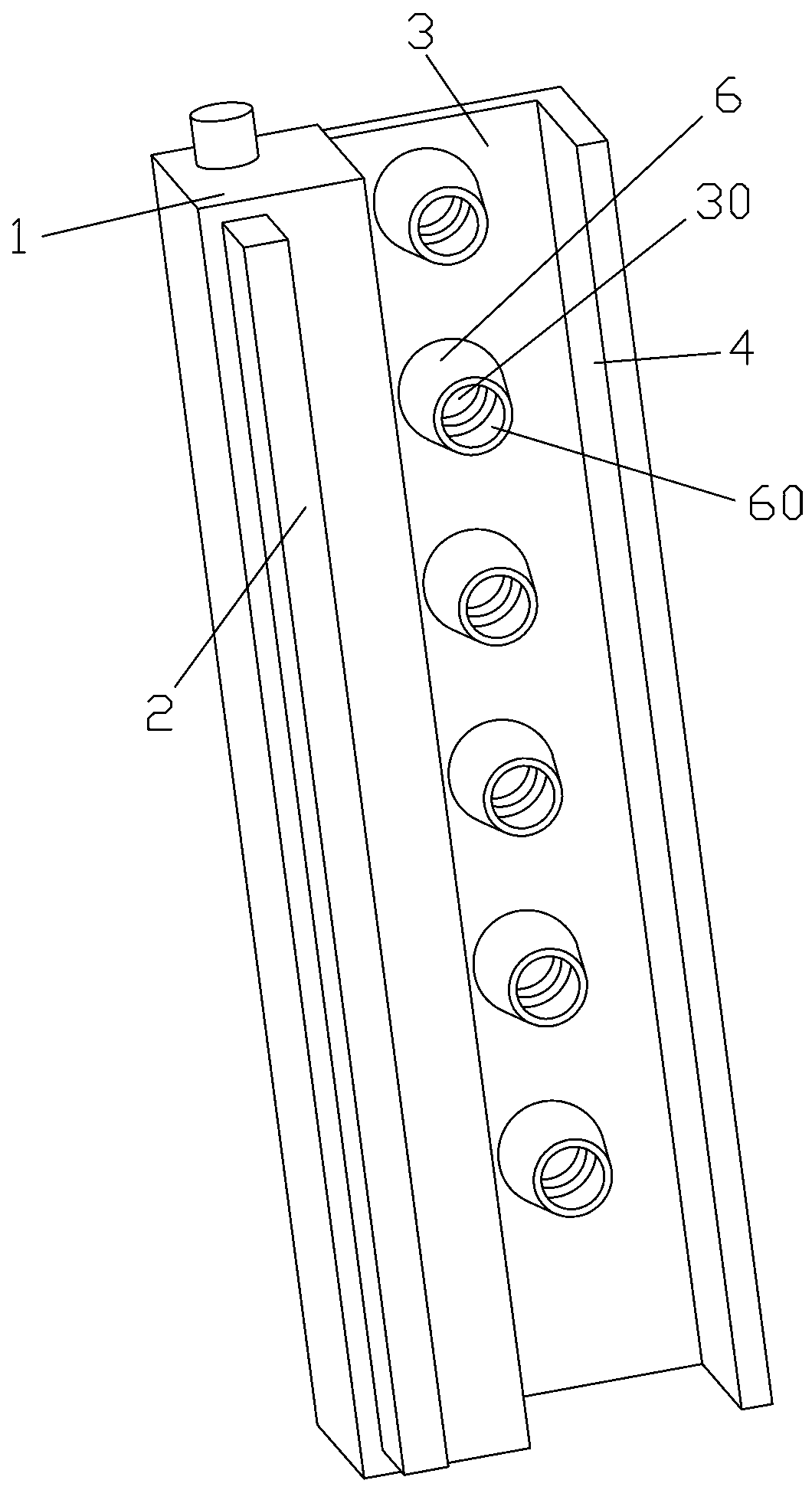

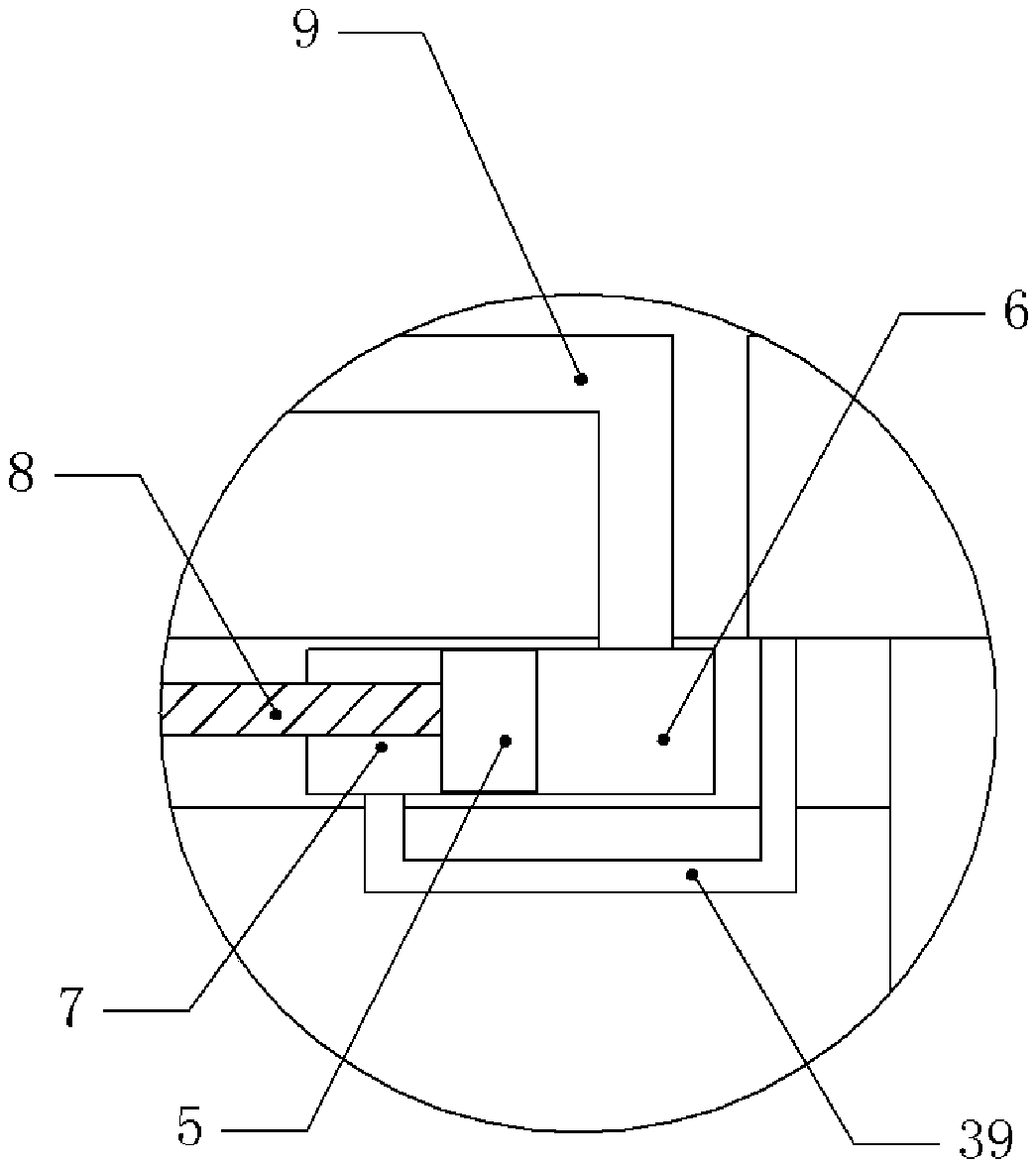

Gear rack transmission type automatic locking device

InactiveCN101260759ASolve the bounce problemOpen flexibleBuilding locksConstruction fastening devicesLocking mechanismGear wheel

The invention discloses a gear and rack driving type automatic locking mechanism, relating to a locking mechanism used for a file cabinet. The invention resolves the problems that the prior lock on the file cabinet can not realize the functions of automatic closing and locking, the prior locking mechanism is dumb when unlocked and locked. One end of a lock (6) is connected with the lower end of an upper connecting rod (5), the upper end of the upper connecting rod (5) penetrates a casing (9), the other end of the lock (6) is connected with a mechanism support (4), gears (2) and racks on a rack lever (3) are meshed, the gears (2) are meshed with hand pulling racks (1), an energy storage elastic part is connected with an energy storage elastic part connecting rod (4-3), and the lower end of the energy storage elastic part (8) is fixed on the casing (9). The gear and rack driving type automatic locking mechanism realizes that the door of the file cabinet can be closed and locked at the same time, and solves the problem of the rebounding of the cabinet door. The gear and rack driving type automatic locking mechanism has the advantages of flexible unlocking and locking, excellent stability, low cost and convenient unlocking and locking.

Owner:哈尔滨飞云实业有限公司

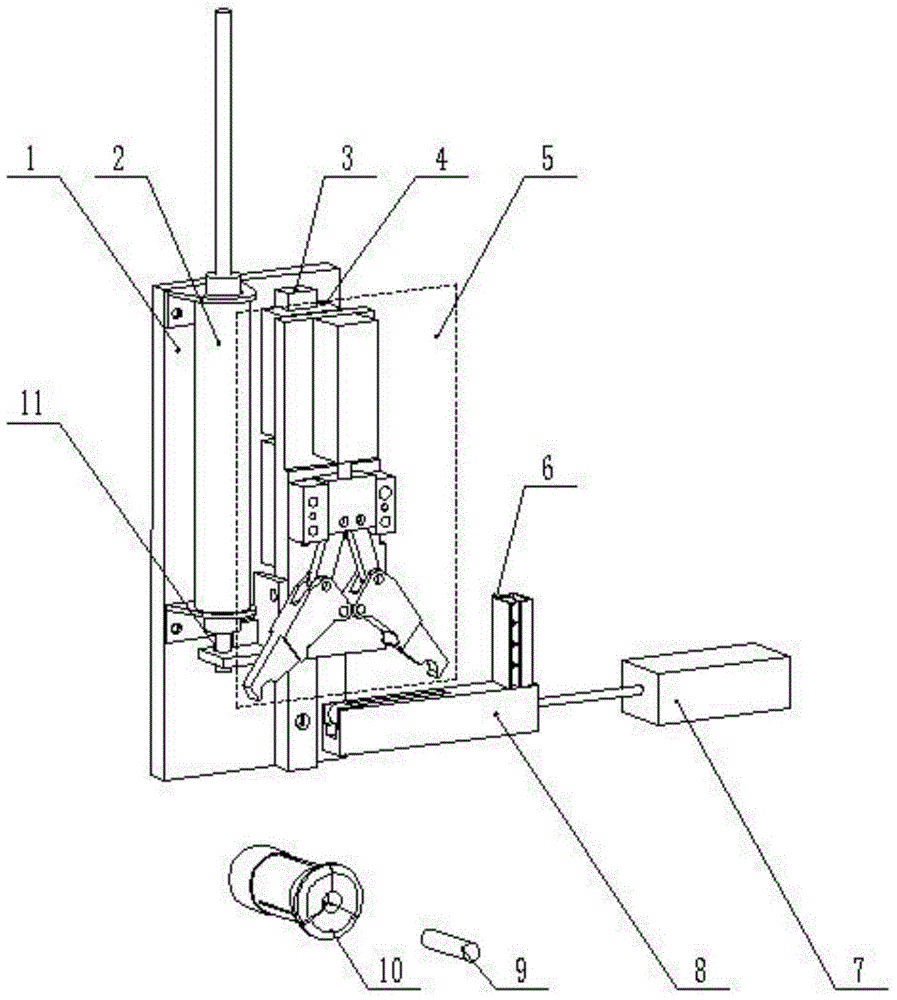

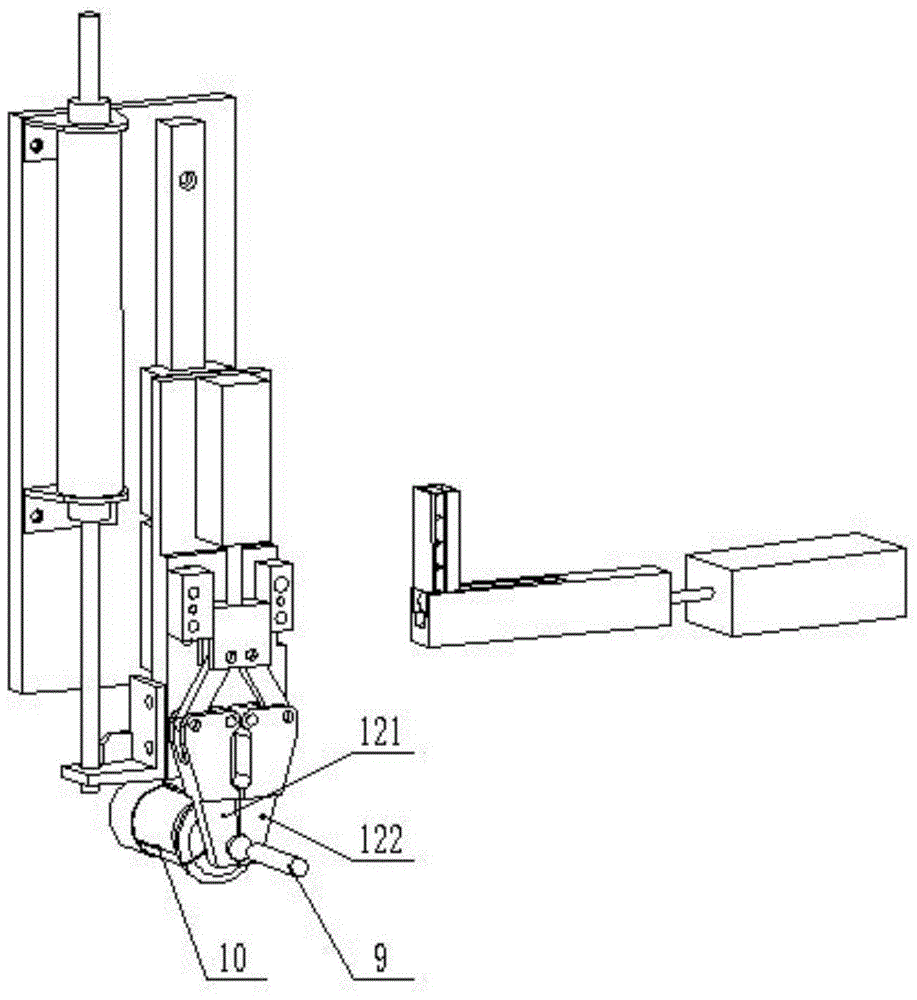

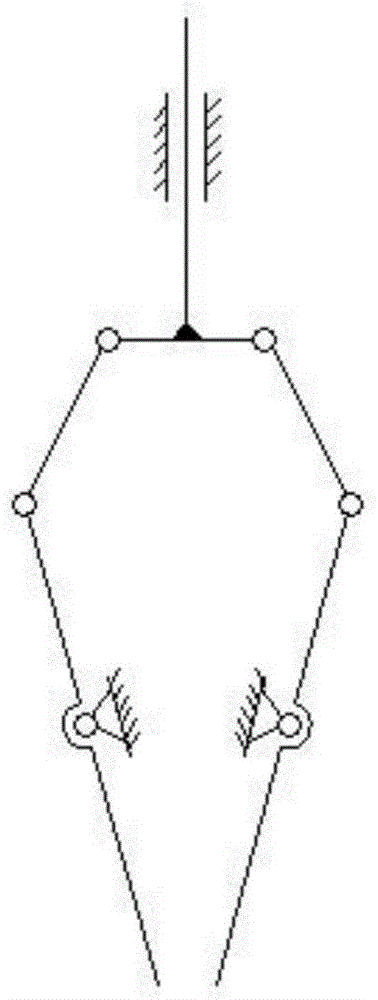

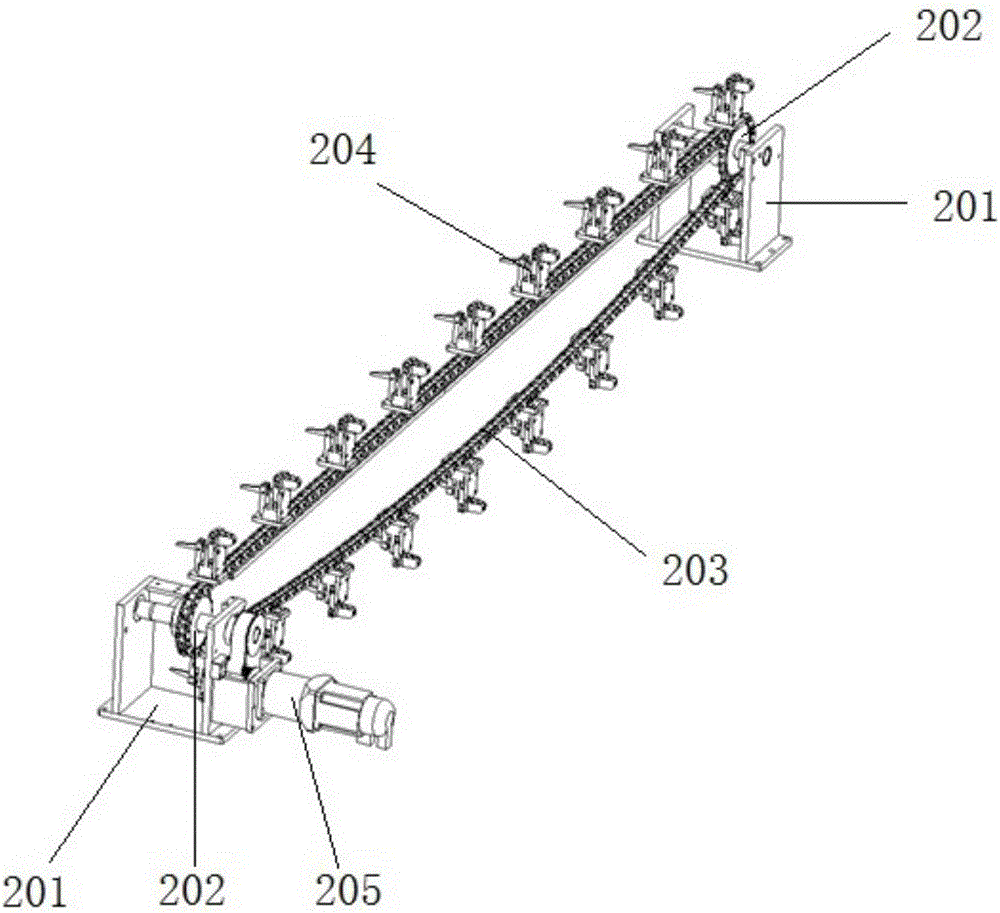

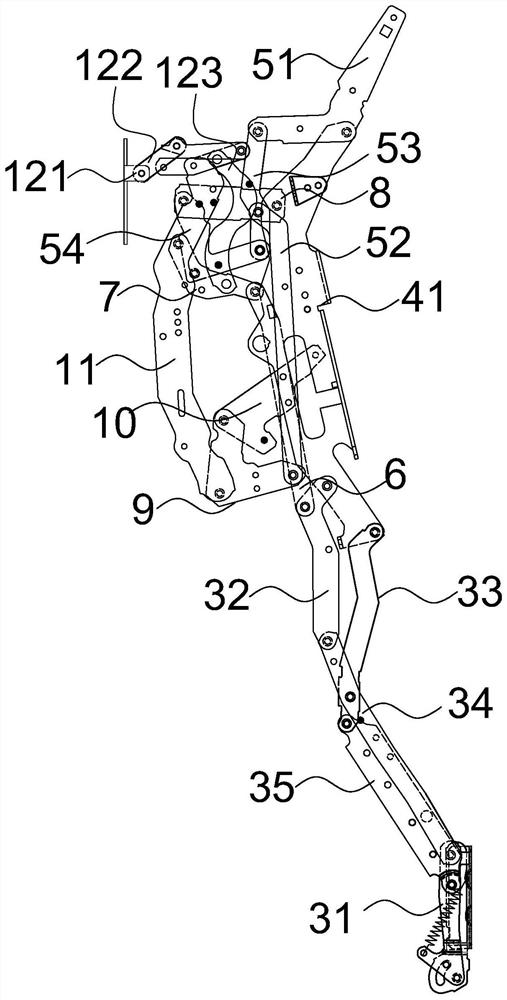

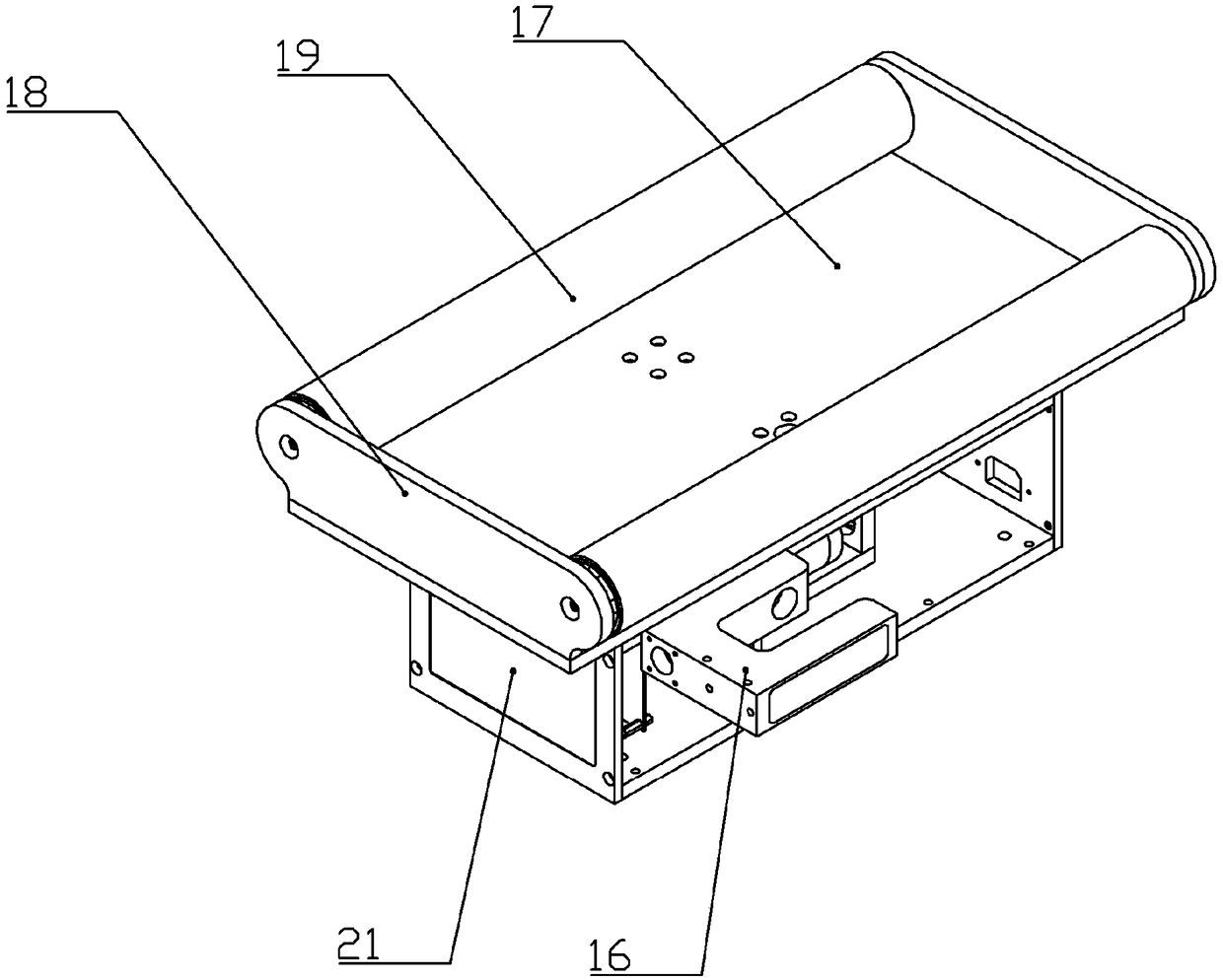

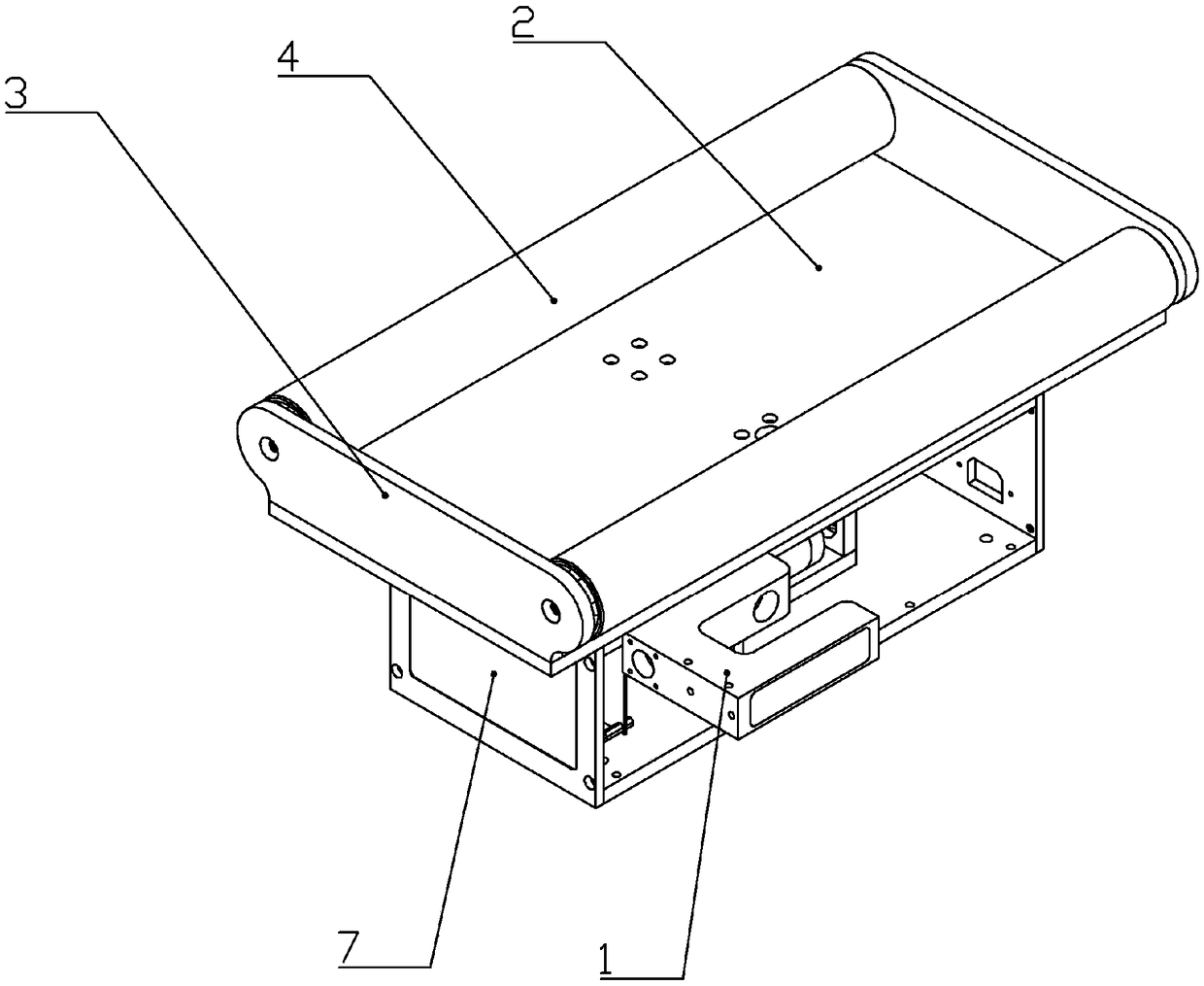

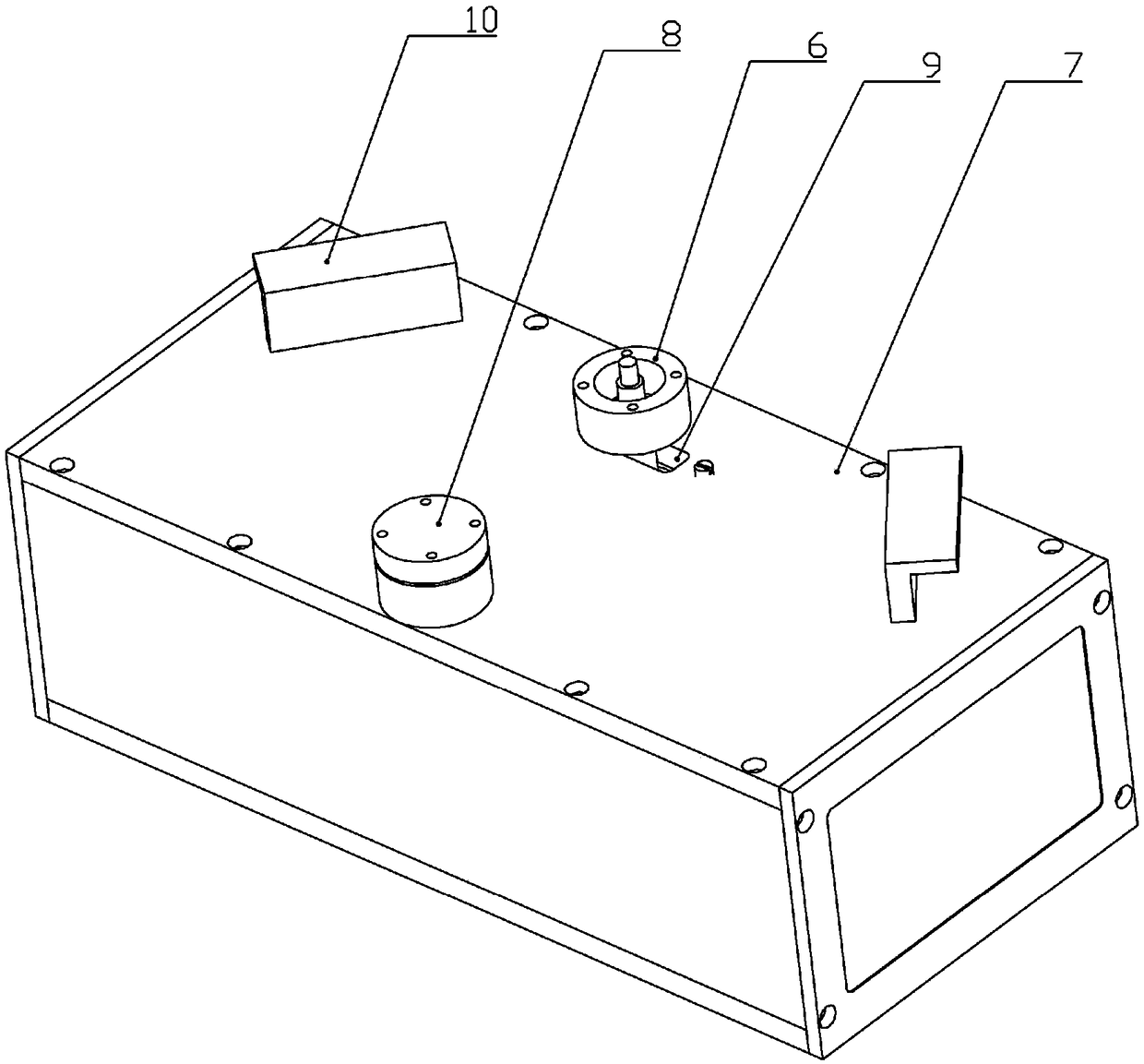

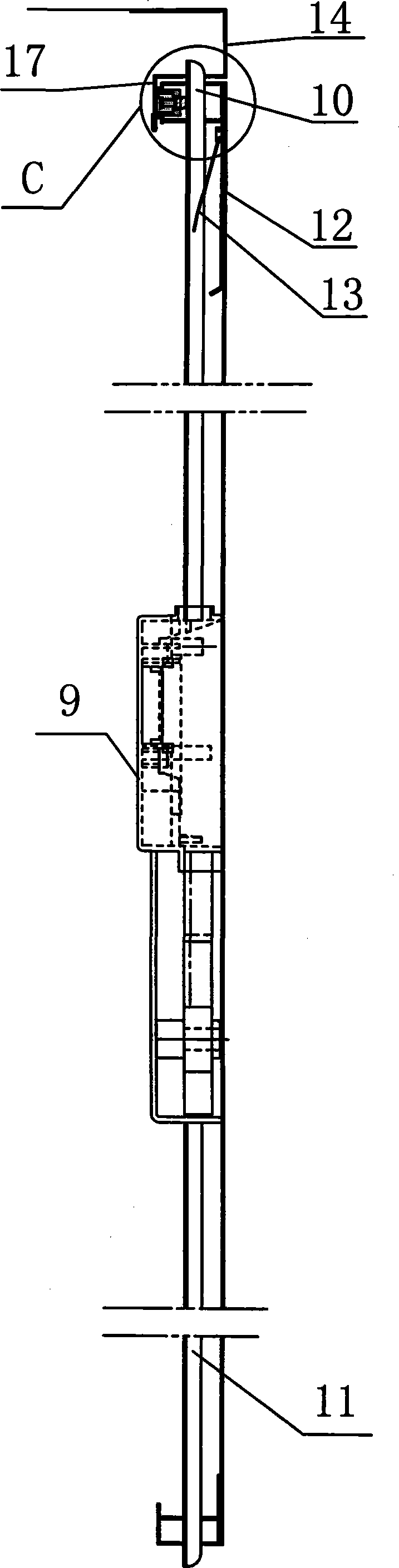

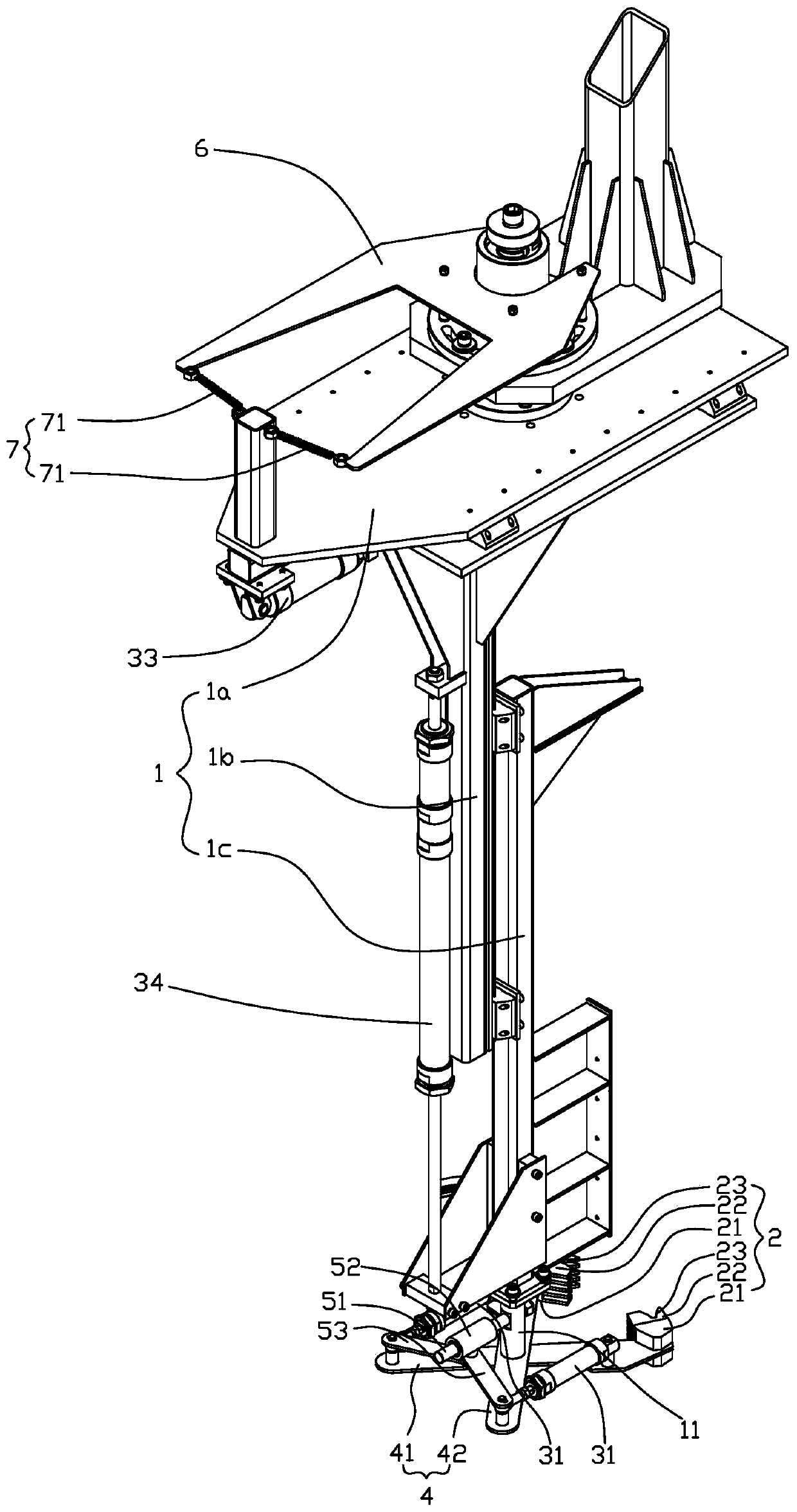

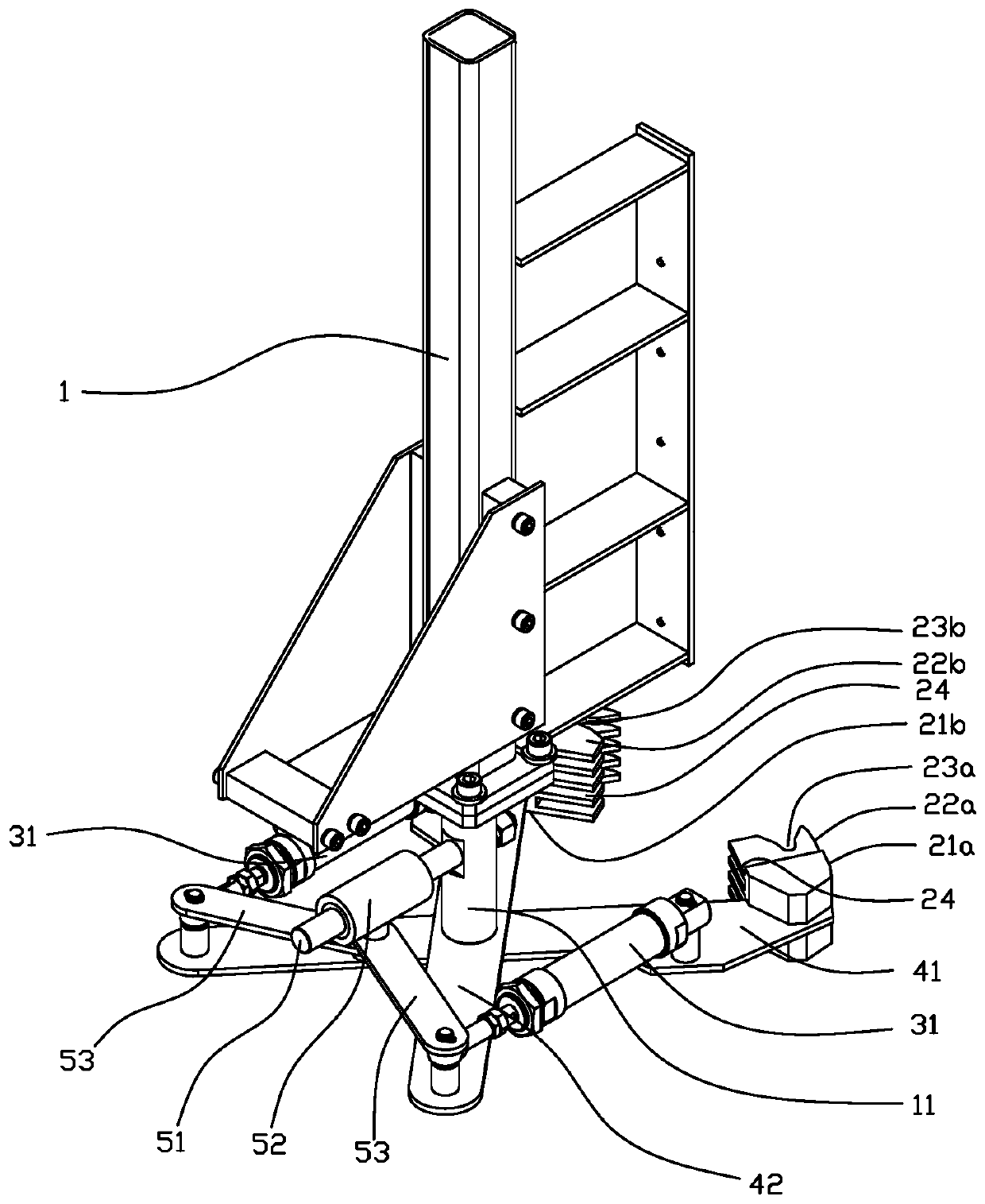

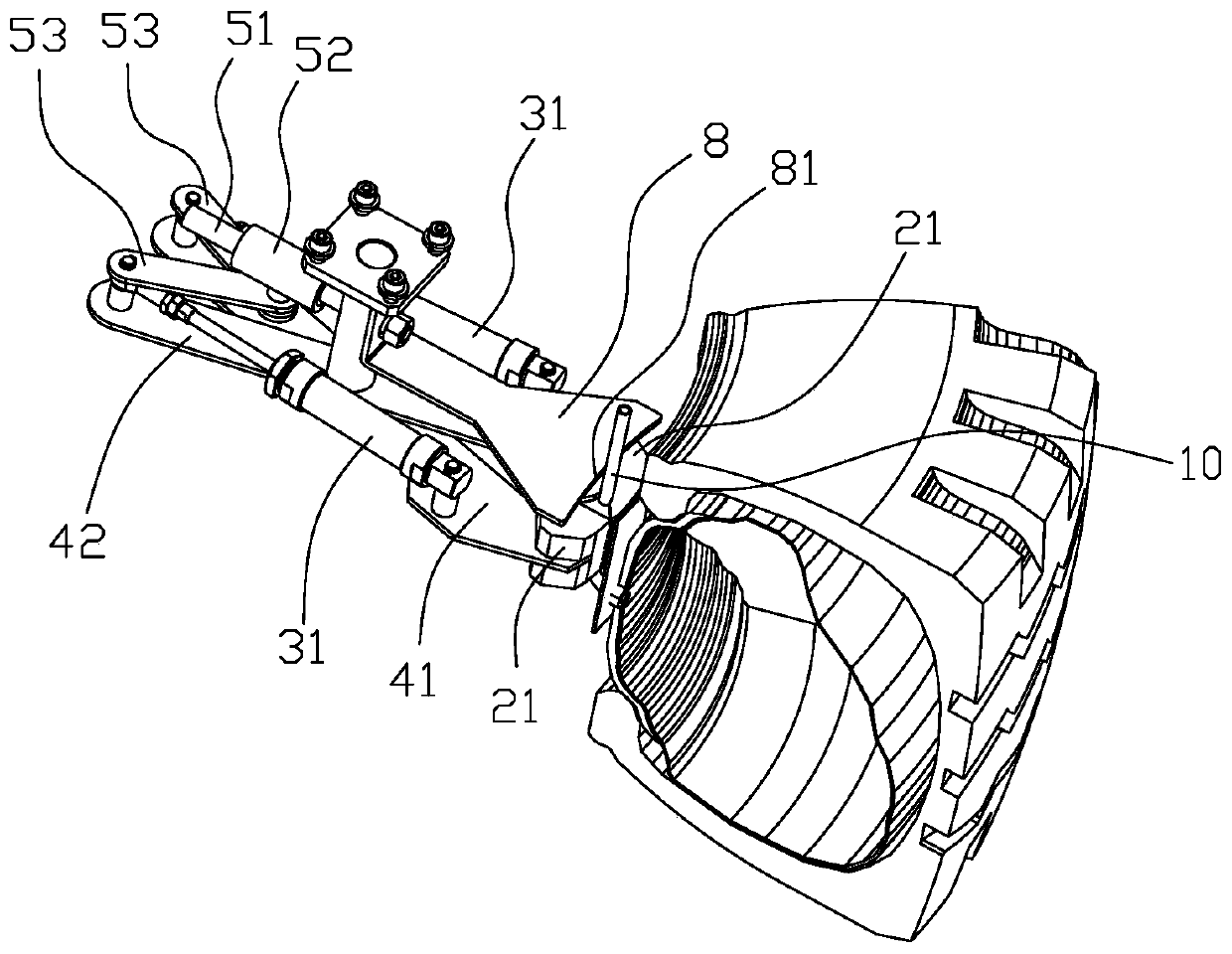

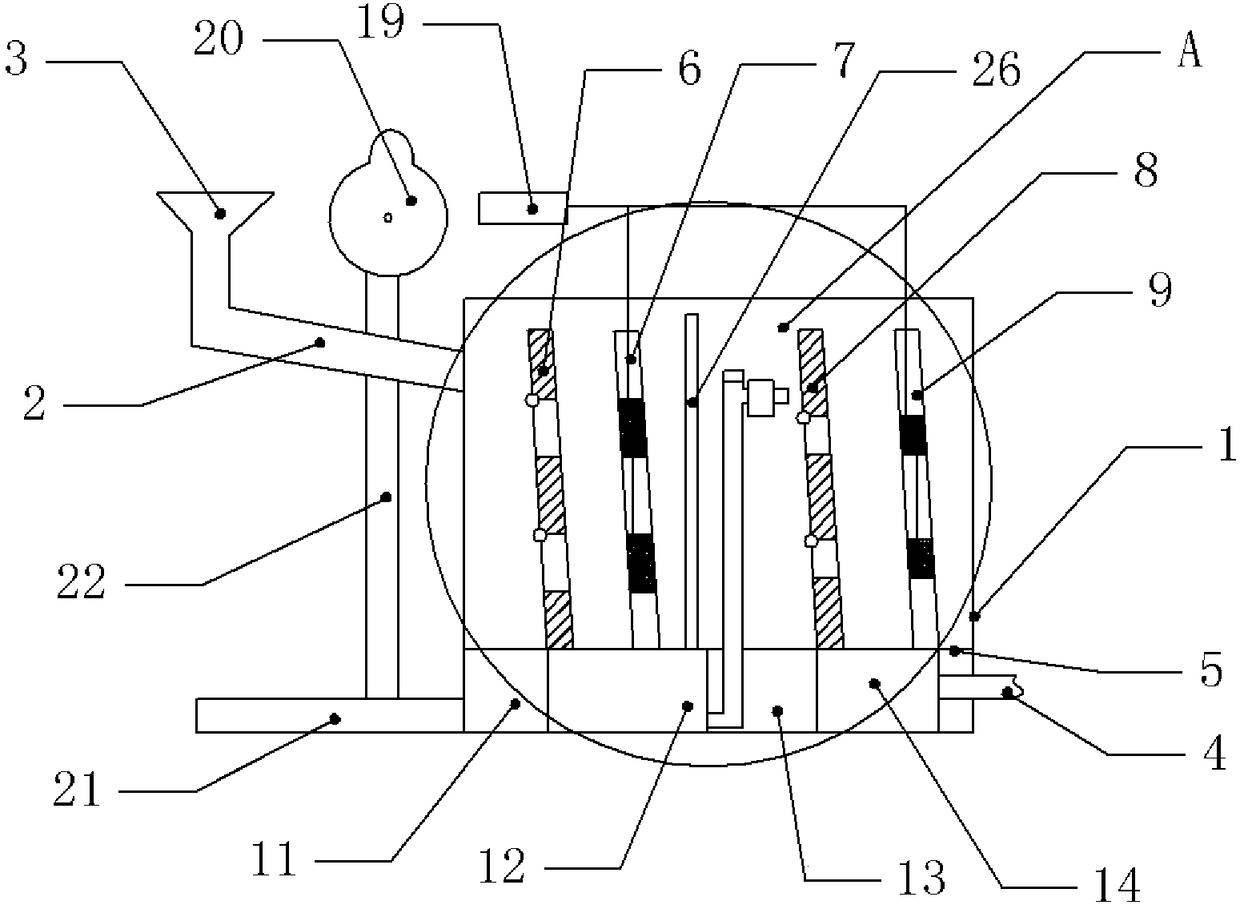

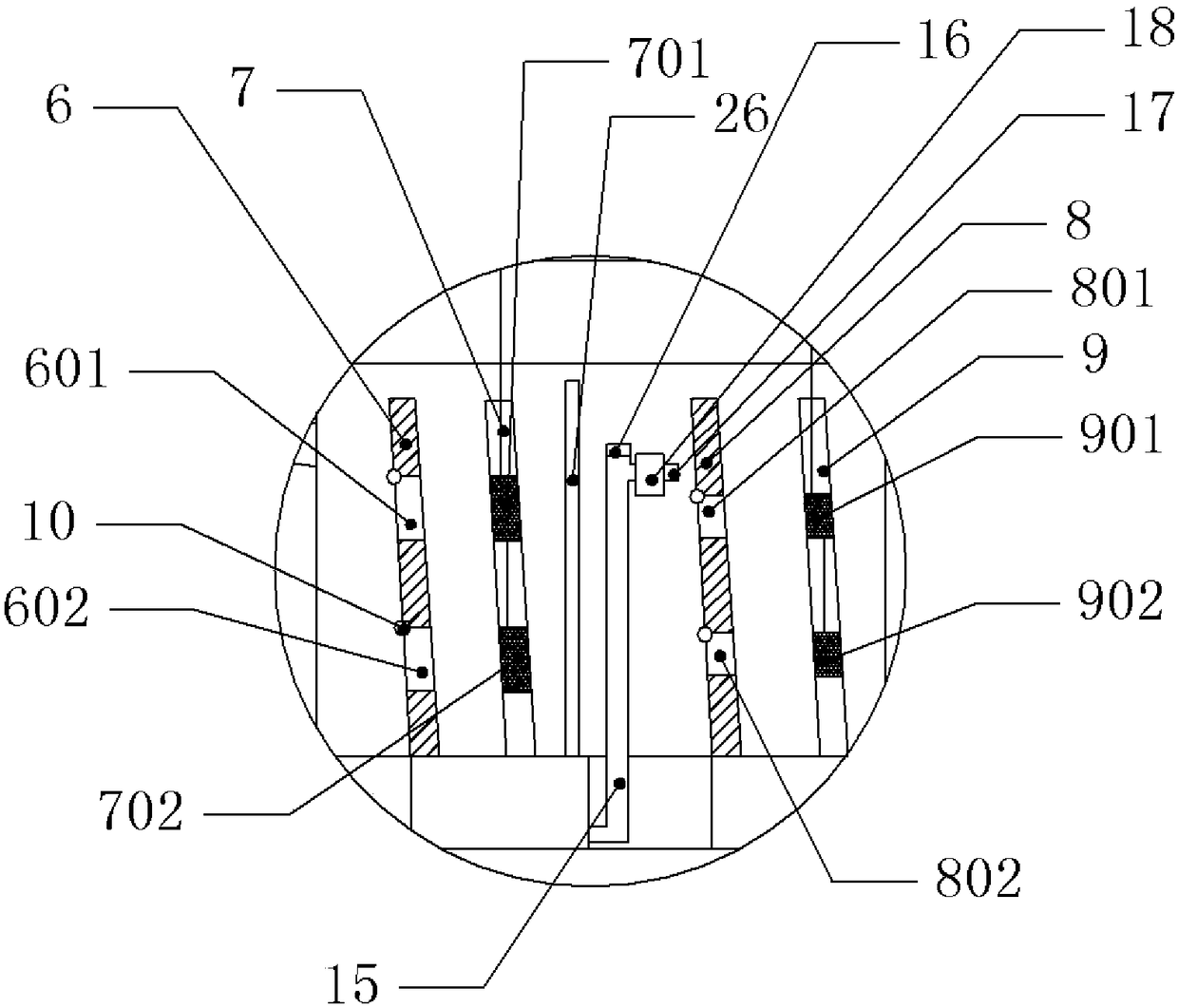

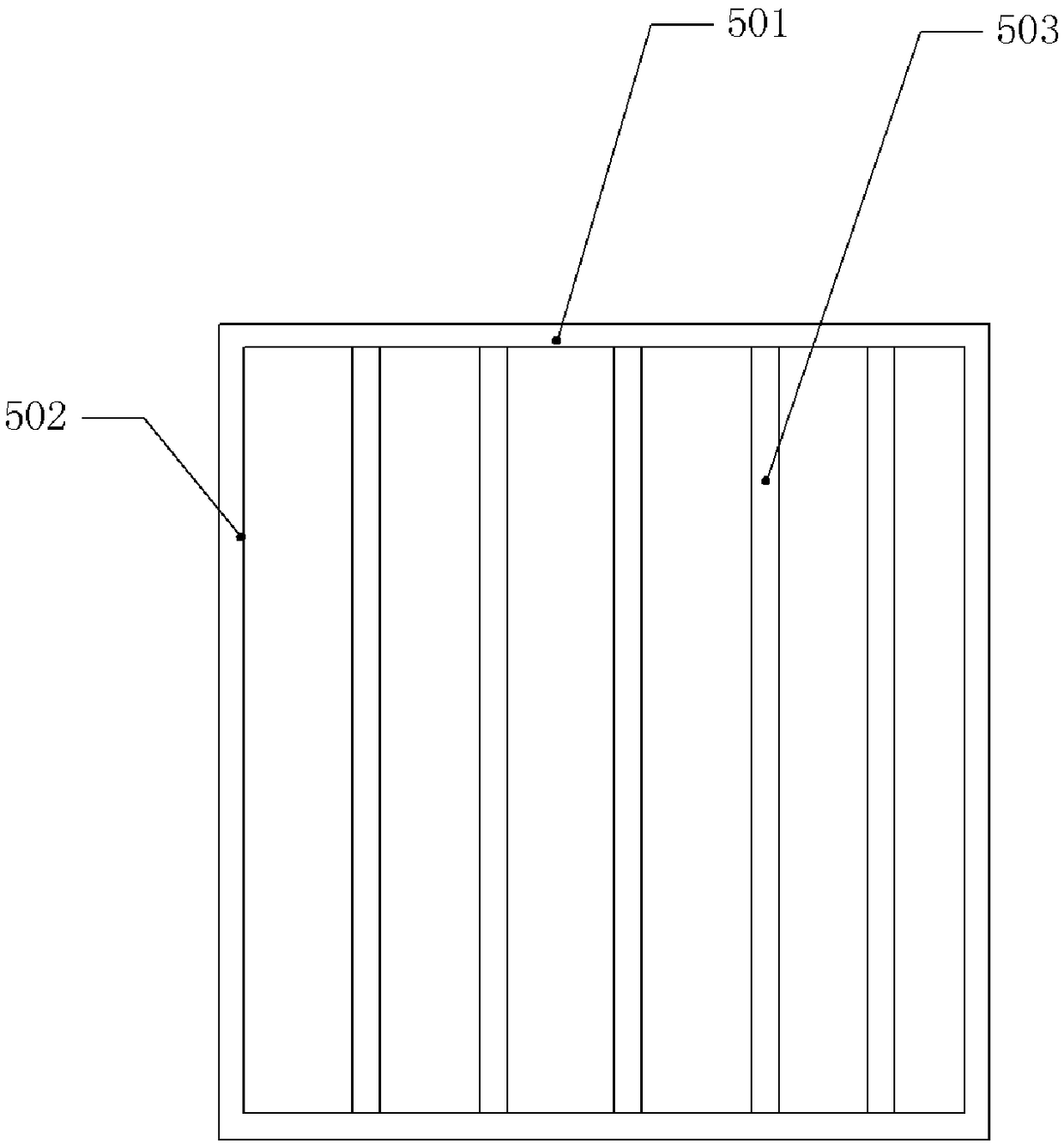

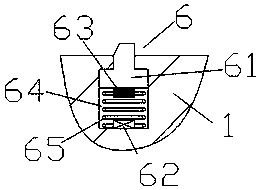

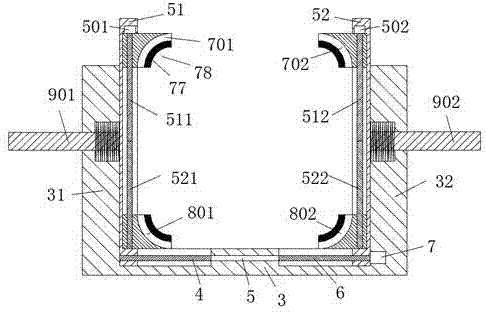

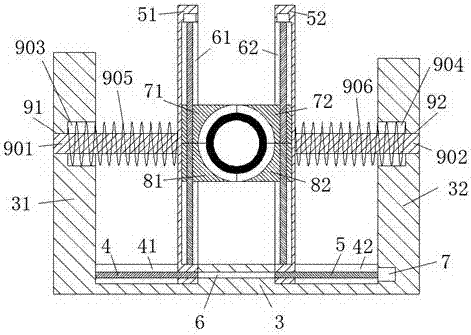

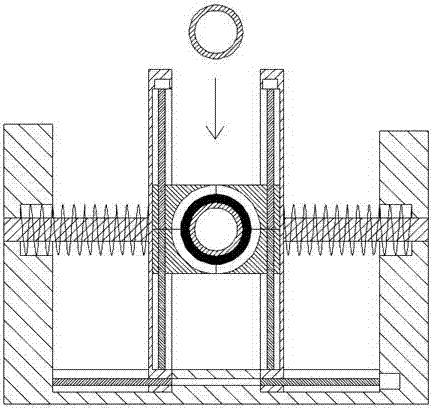

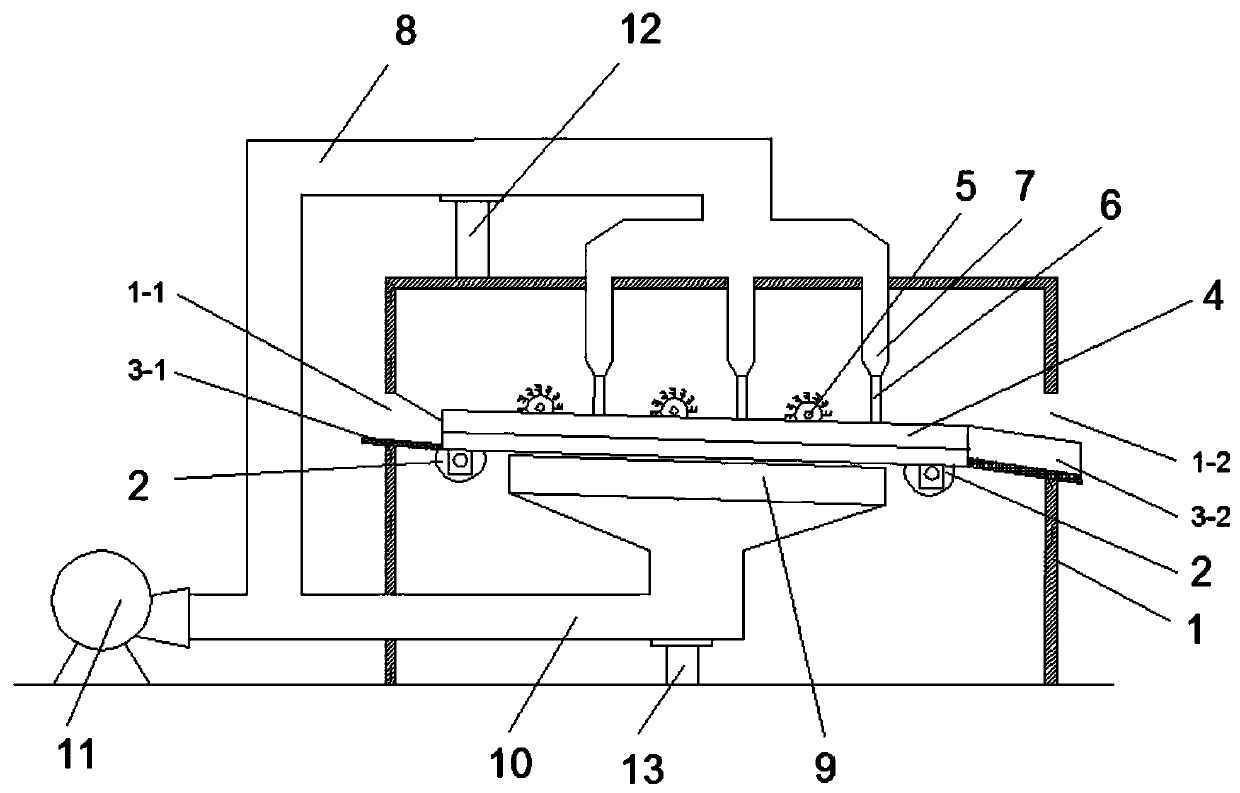

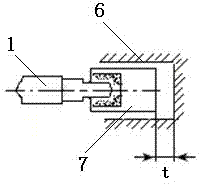

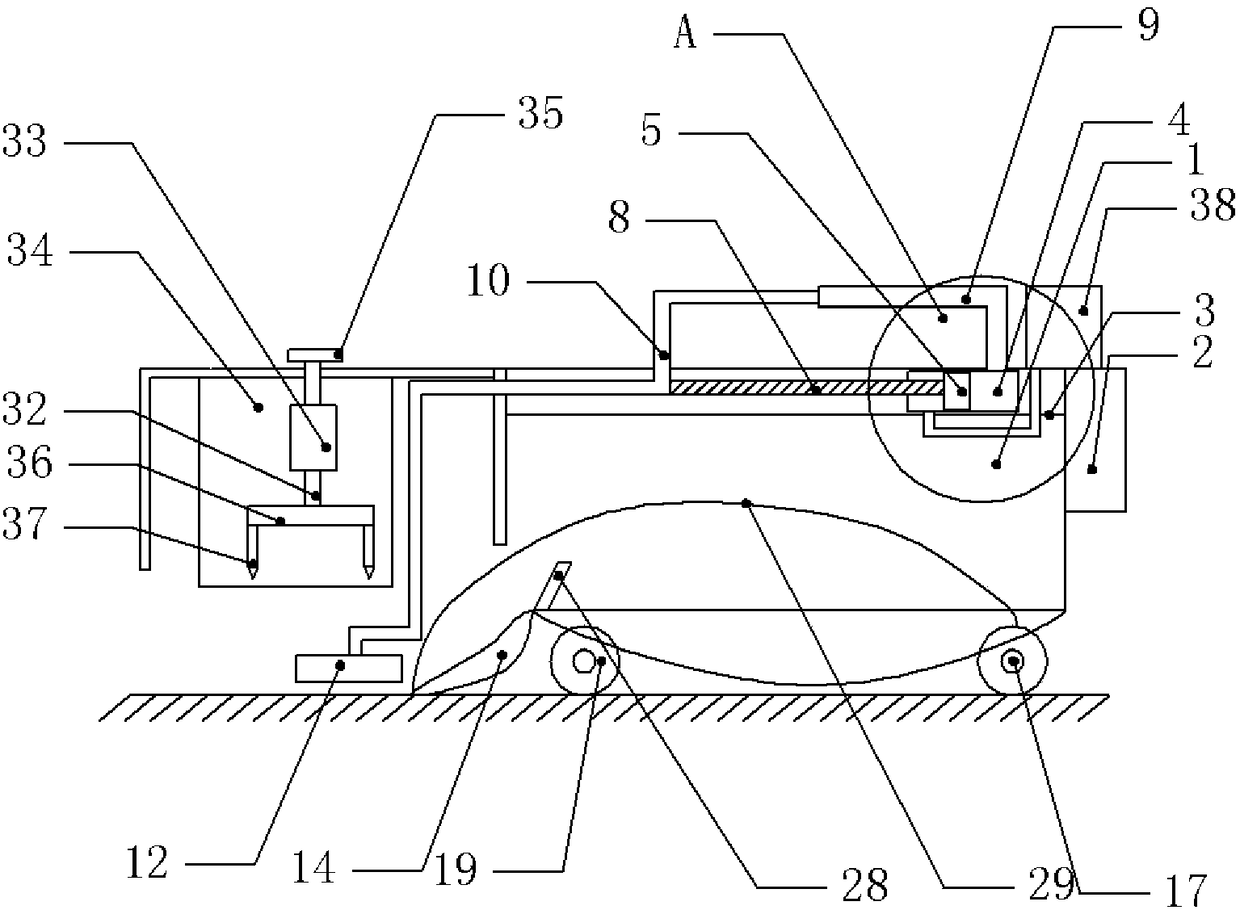

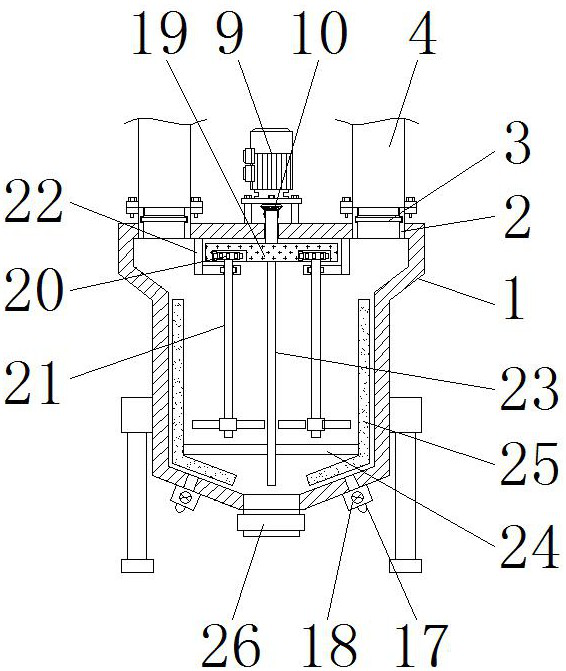

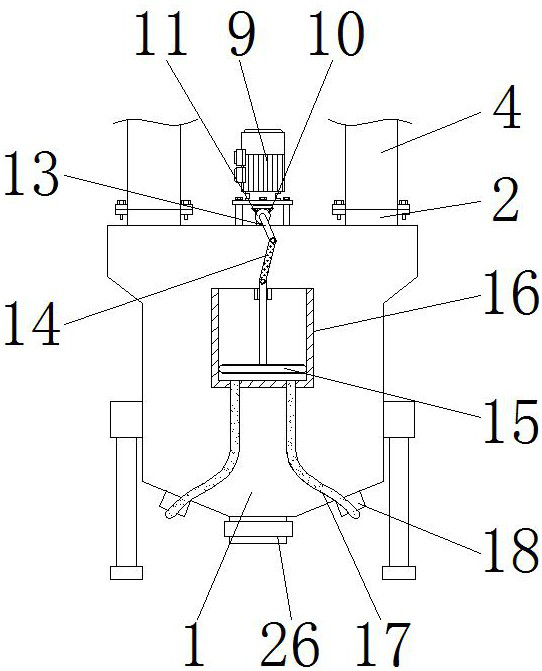

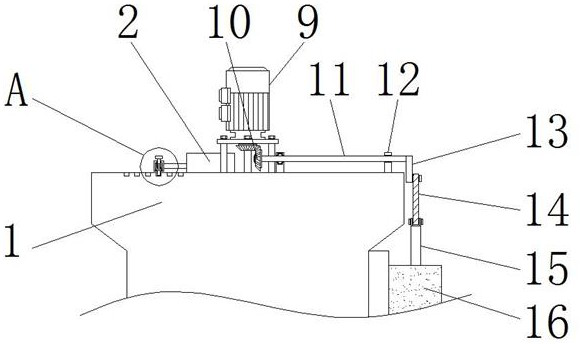

Feeding device with pneumatic clamping jaw

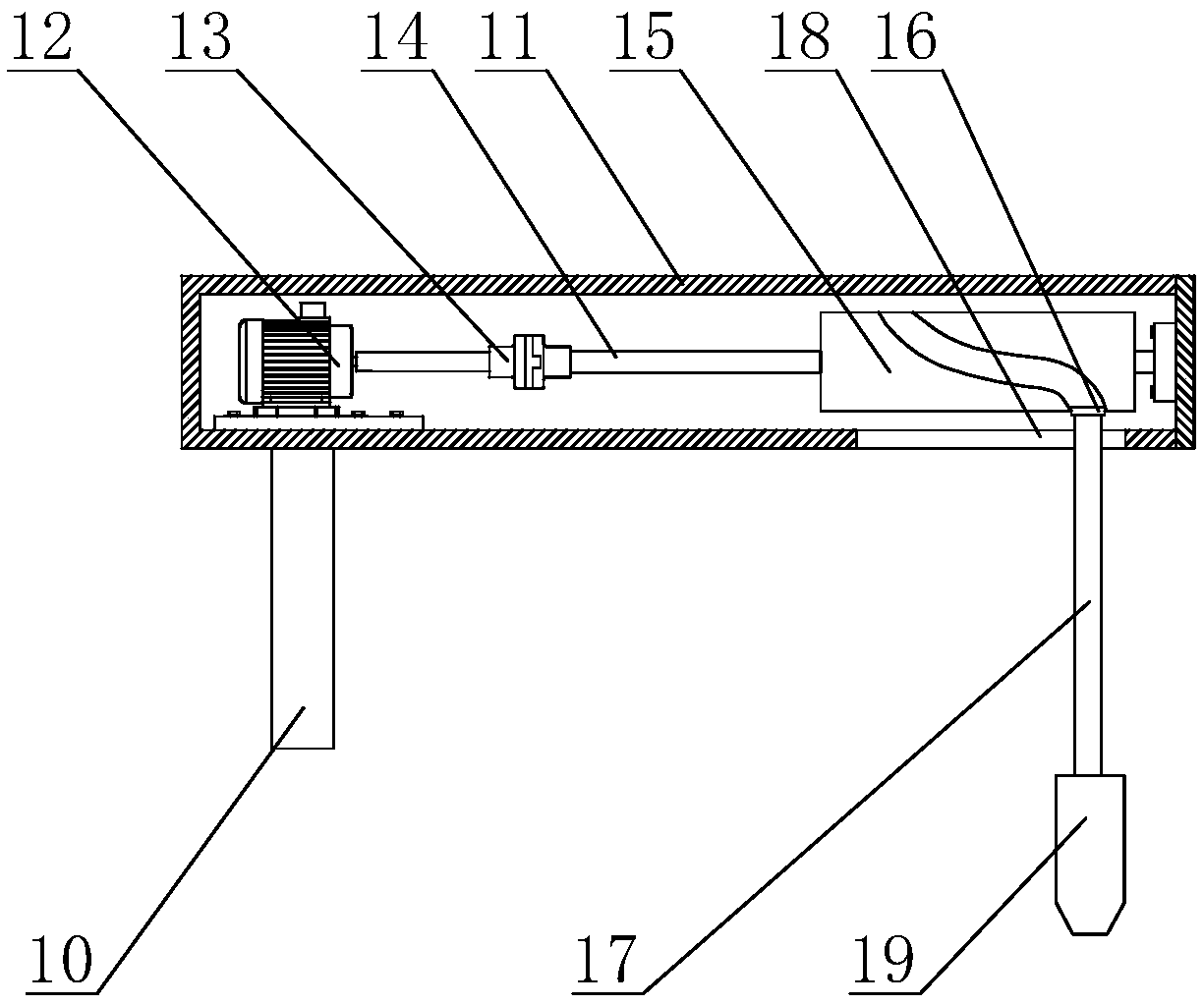

InactiveCN104648998AAvoid collisionStable and reliable structure operationConveyor partsEngineeringDelayed time

The invention relates to a pneumatic feeding device and discloses a feeding device with a pneumatic clamping jaw. The feeding device comprises the pneumatic clamping jaw (5), a spring clamping head (10) and a feeding arm (8), wherein the pneumatic clamping jaw (5) comprises a base (16); the base (16) is provided with a first cylinder (15); a piston rod of the first cylinder (15) is connected with a sliding plate (14) by virtue of threads; the sliding plate (14) is articulated with a left connecting rod (131) and a right connecting rod (132); one end of the feeding arm (8) is provided with a first groove capable of accommodating only one blank (19); the feeding arm (8) can move to a position below the pneumatic clamping jaw (5); the pneumatic clamping jaw (5) can move to a position above the axis of the spring clamping head (10). According to the feeding device, the supply delay time of the spring clamping head (10) is greatly shortened; the structure operation is stable and reliable, and the feeding device can be adapted to automatically feeding blanks with variable shapes.

Owner:NINGBO YONGBO MACHINERY MFG

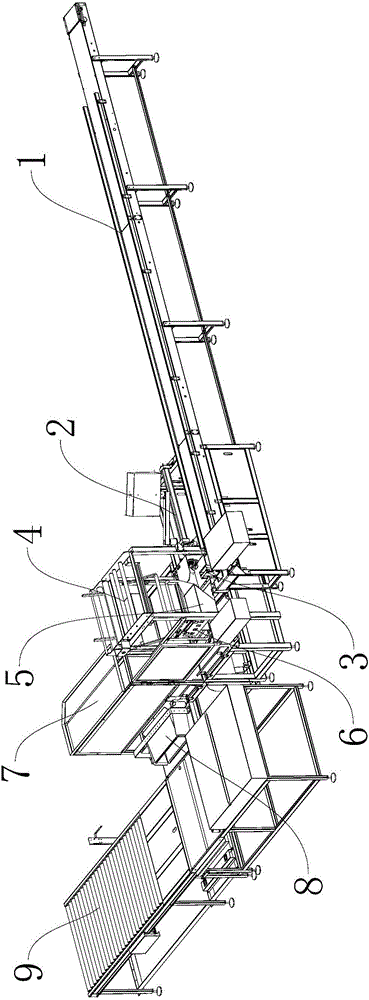

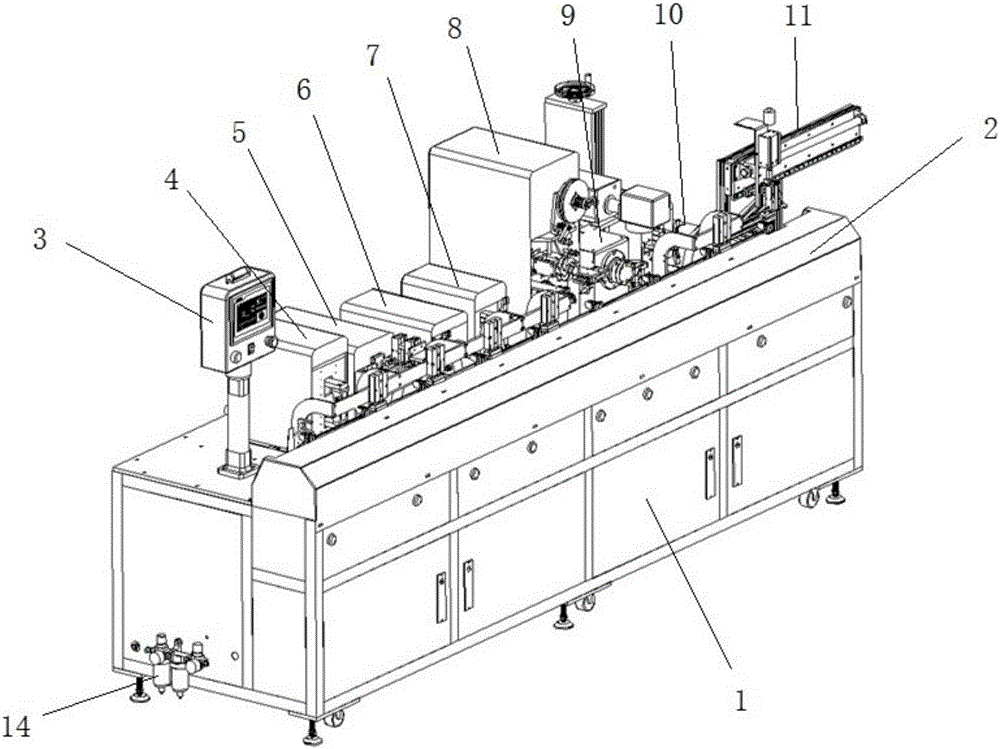

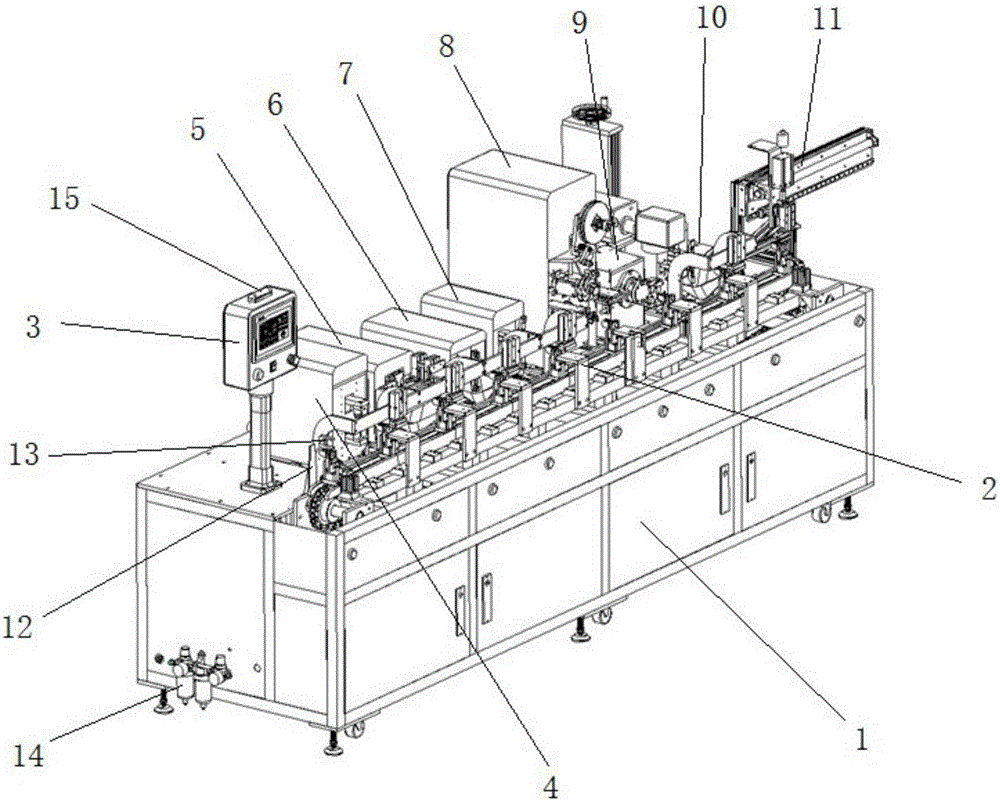

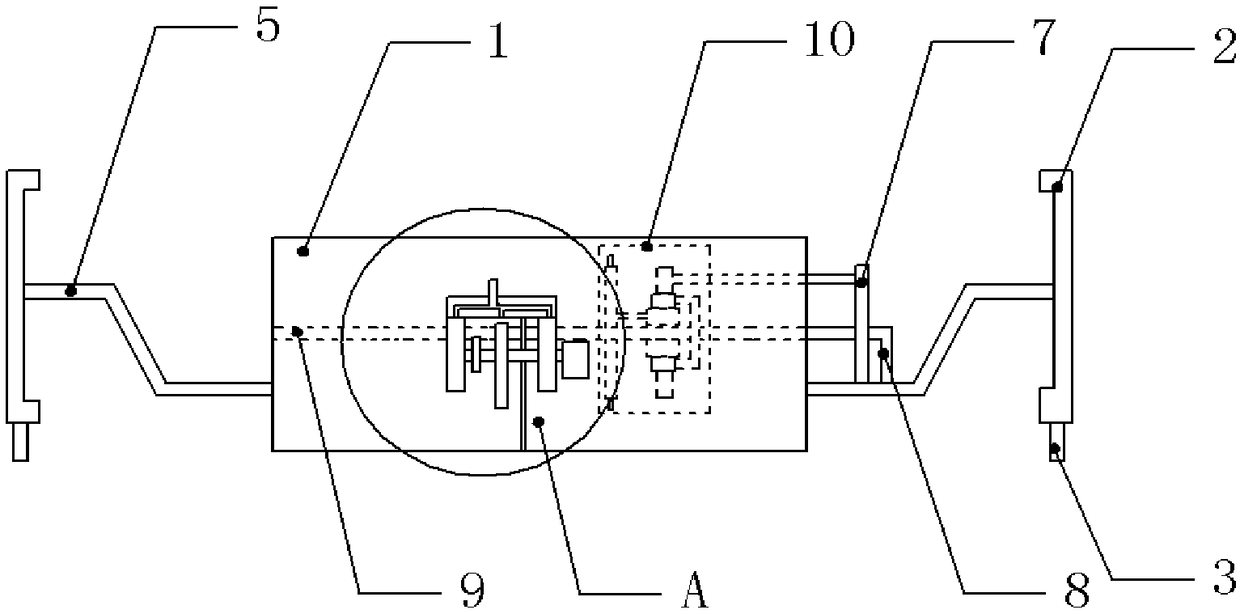

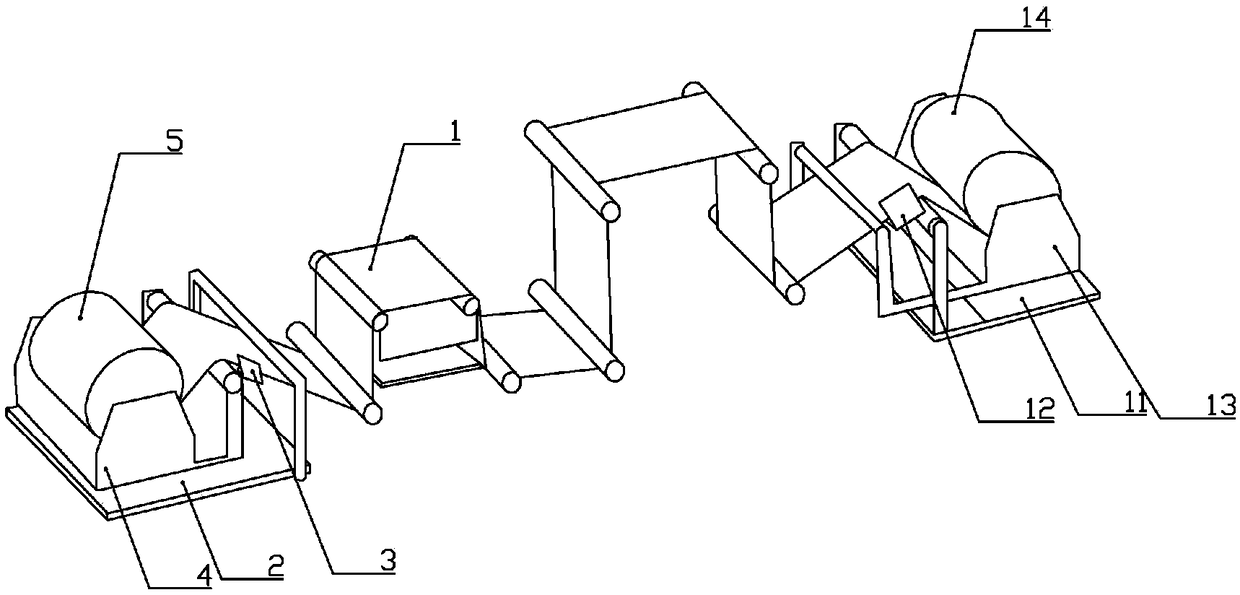

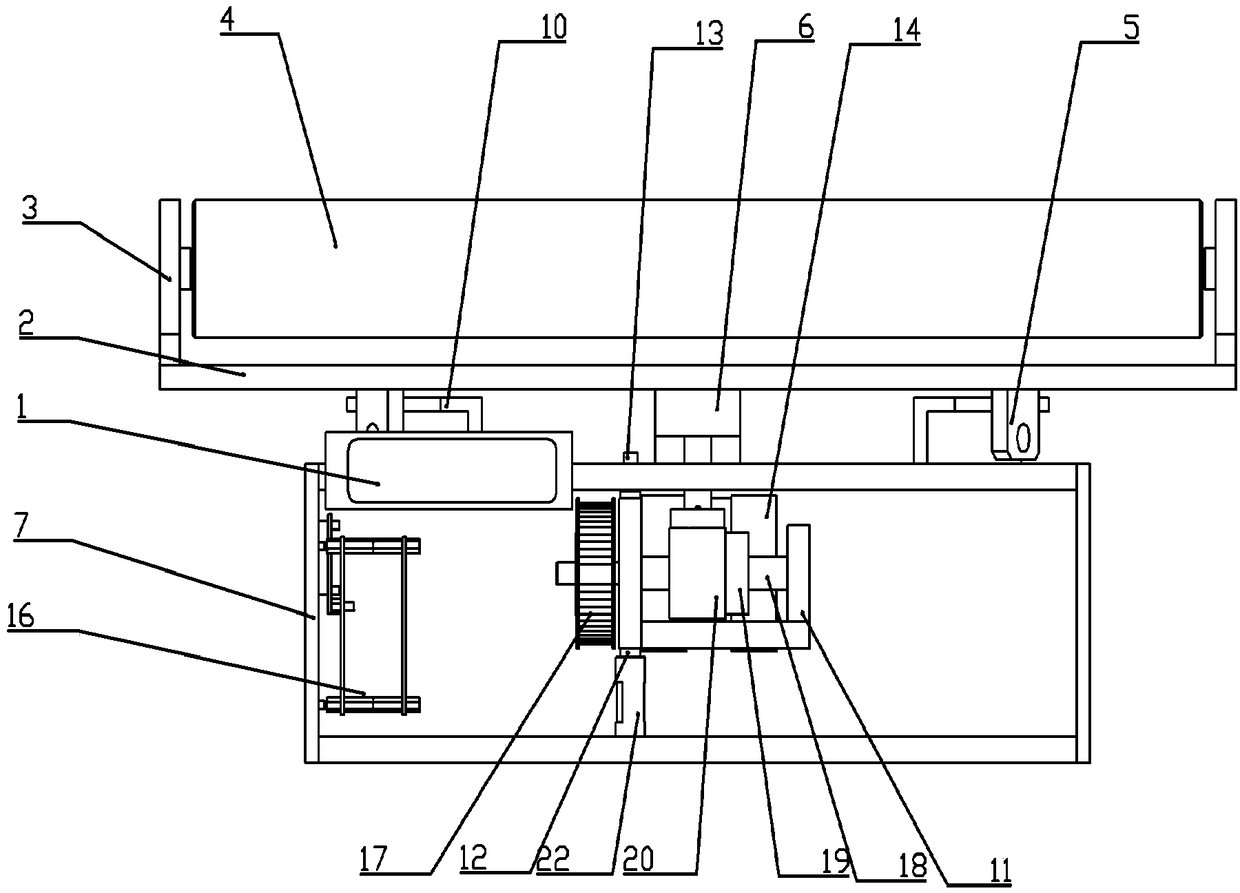

Full-automatic peeling, knit cutting and copper foil winding machine and working method thereof

InactiveCN106654970AImprove work efficiencyReduce manual laborLine/current collector detailsApparatus for removing/armouring cablesWinding machineHuman–machine interface

The invention discloses a full-automatic peeling, knit cutting and copper foil winding machine, and belongs to the field of processing equipment. The full-automatic peeling, knit cutting and copper foil winding machine comprises a machine body, a chain transmission group arranged on the machine body, a human-computer interface, a jacket peeling work station, a knit cutting work station, a jacket and knit taking work station, a knit pushing work station, a copper foil winding work station, an aluminum foil laser cutting work station, an aluminum foil taking work station and a finished product taking work station, wherein the jacket peeling work station, the knit cutting work station, the jacket and knit taking work station, the knit pushing work station, the copper foil winding work station, the aluminum foil laser cutting work station, the aluminum foil taking work station and the finished product taking work station are arranged on the side surface of the chain transmission group and evenly distributed along the chain transmission direction in sequence; a wire locating plate fixed on the machine body is arranged in the front of the jacket peeling work station; a starving sensor is arranged between the wire locating plate and the jacket peeling work station; and the wire locating plate corresponds to the positions of mechanical grips. Eight work stations are integrally designed on the machine body, so that the processing cycle is greatly shortened, the production efficiency is improved, the manual labor is reduced and the cost is reduced. According to the working method, assembly line work and continuous production of a product can be achieved, and the starving condition can be timely detected through the starving sensor.

Owner:KUNSHAN MINGSONG MACHINERY

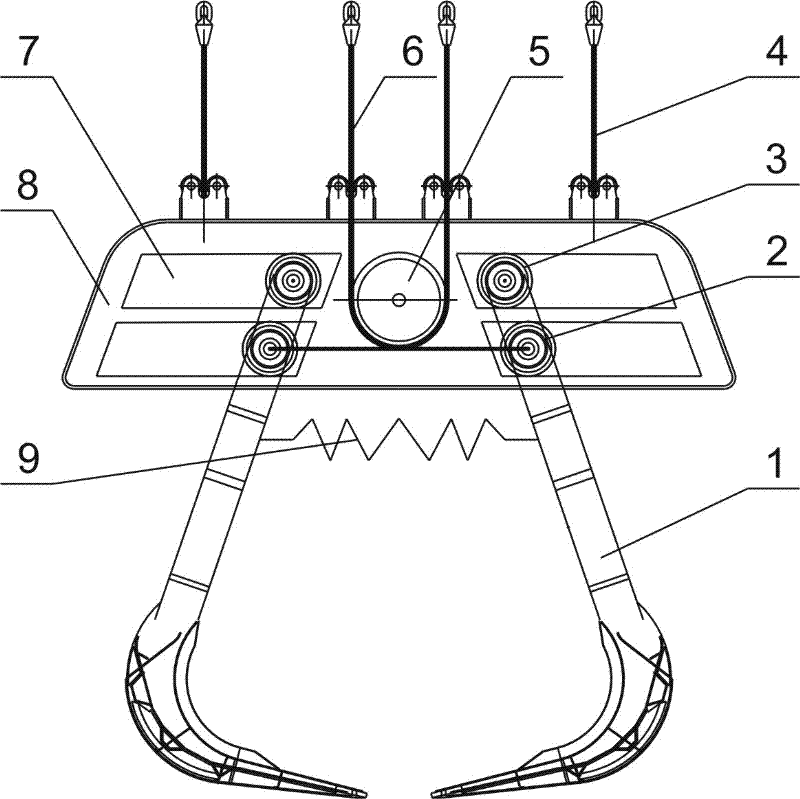

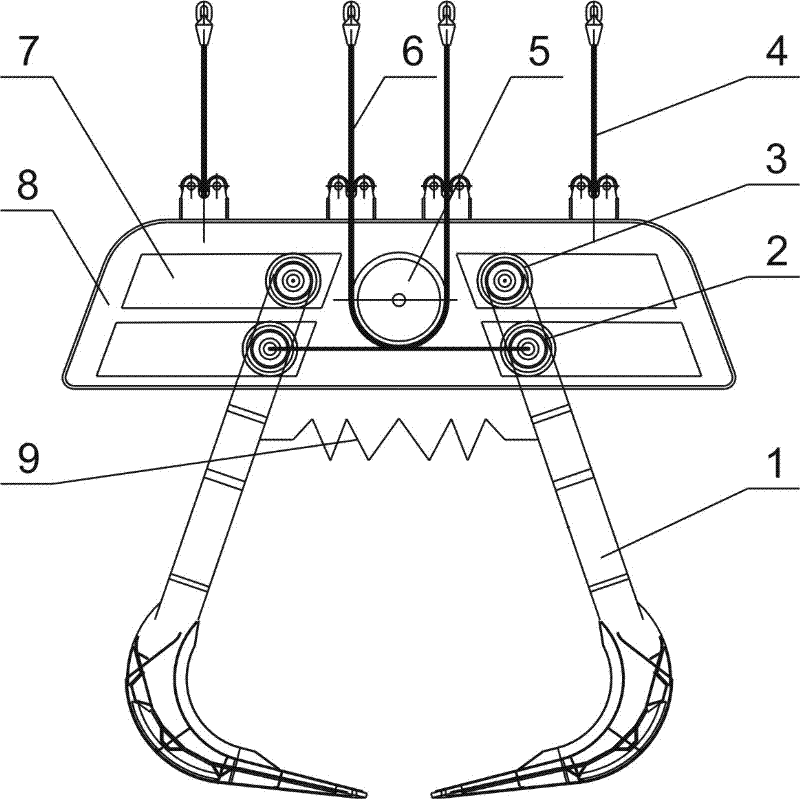

Translation-type flat-digging grab bucket

InactiveCN102644301AStable and reliable structure operationImprove securityMechanical machines/dredgersEngineeringUnderwater

The invention relates to a translation-type flat-digging grab bucket, in particular to a grab bucket used in the digging fields such as the field of dredgers. The translation-type flat-digging grab bucket comprises a grab bucket base and a pair of jaw plates, wherein the pair of jaw plates are respectively articulated with the grab bucket base, and the digging action can be realized by the opening and closing of the jaw plates; the translation-type flat-digging grab bucket is characterized in that four guide sliding grooves are horizontally arranged at the side of the grab bucket base, are arranged up and down in pairs and are in bilateral symmetry; each guide sliding groove is internally provided with a roller wheel; and the pair of jaw plates are respectively articulated with the two adjacent upper and lower roller wheels so as to do translation along the guide sliding grooves by virtue of the roller wheels. Due to the arrangement of the guide sliding grooves on the grab bucket base, the jaw plates can always do translation along the guide sliding grooves by virtue of the roller wheels arranged in the guide sliding grooves, and the translation-type flat-digging grab bucket is simpler, more convenient and lower in cost compared with the traditional way in which accurate control is used to realize flat digging; furthermore, a structure of the guide sliding grooves is reliable in running and high in safety, so that the translation-type flat-digging grab bucket is suitable for operation underwater and in other complicated environments.

Owner:WUHAN UNIV OF TECH

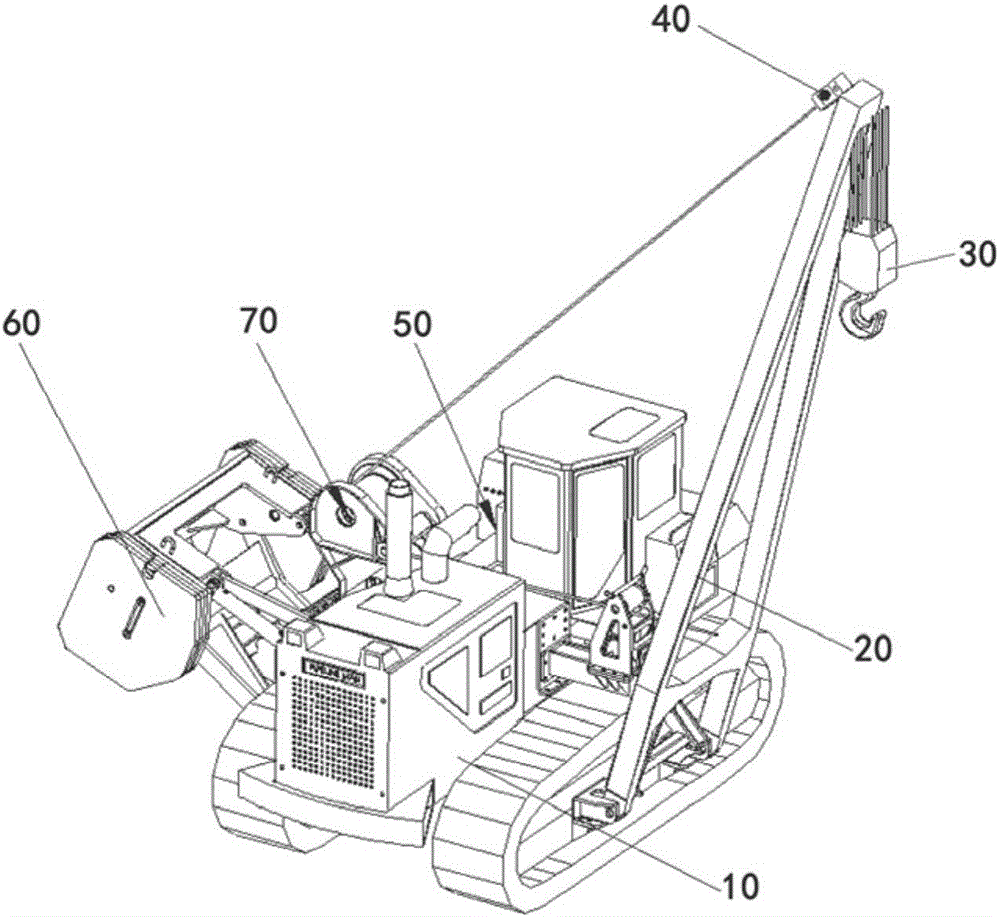

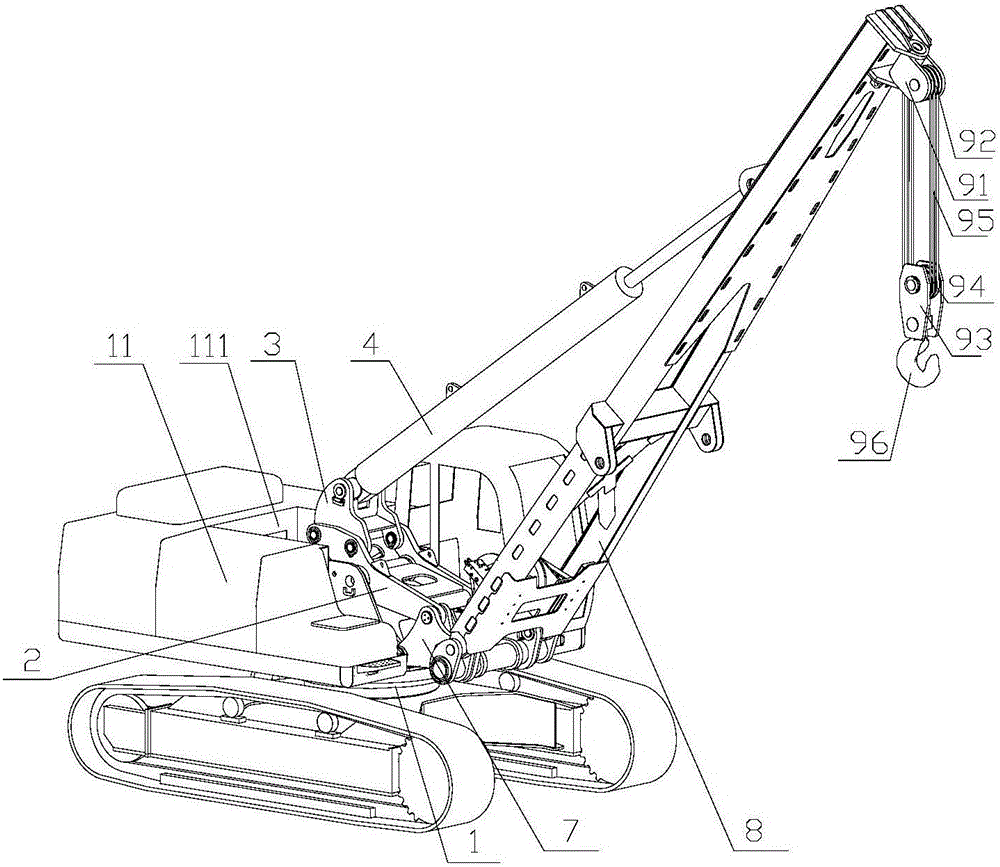

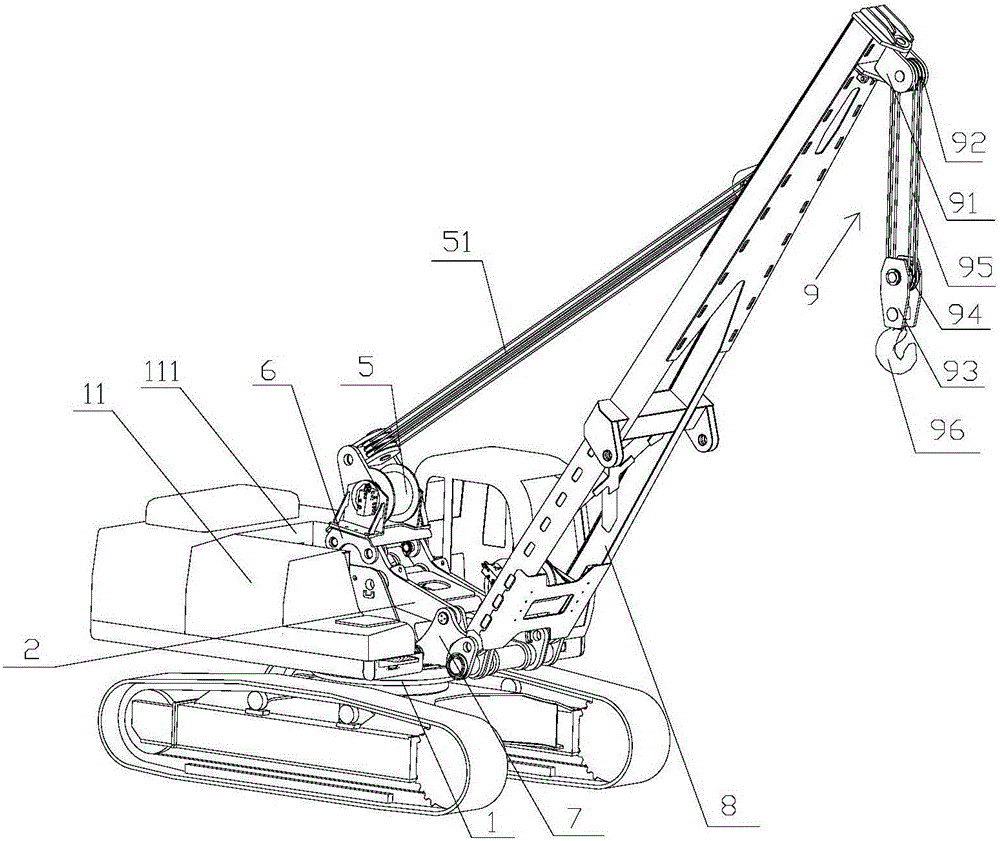

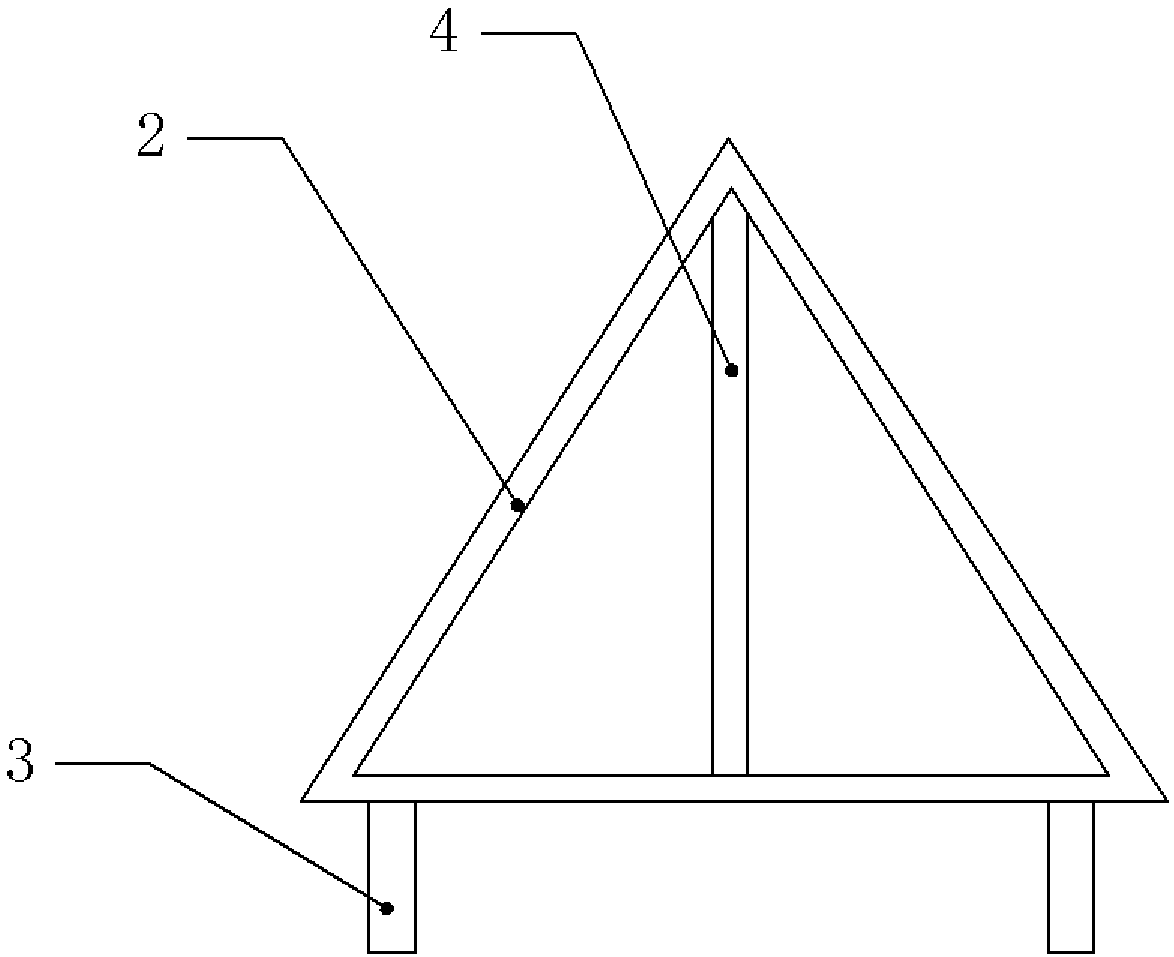

Pipe lifting device

InactiveCN106516999AImprove work efficiencyStable and reliable structure operationCranesEngineeringExcavator

The invention discloses a pipe lifting device. The pipe lifting device comprises an excavator chassis, a lifting arm frame and a platform frame, wherein a platform is arranged on the excavator chassis, and is provided with a mounting groove; front mounting holes are oppositely formed in the front ends of two opposite side walls of the mounting groove, and back mounting holes are oppositely formed in the back ends of the two opposite side walls of the mounting groove; the lifting arm frame is detachably connected to the platform through the front mounting holes, and is hinged with a lifting arm; a pipe lifting module is arranged at the top end of the lifting arm; the platform frame is detachably connected to the platform through the back mounting holes, and is provided with a luffing mechanism for driving the lifting arm to perform luffing; and the platform frame is connected with the lifting arm frame. The lifting arm frame and the platform frame use existing mounting holes in the platform for forming stable triangular connection with the platform, so that the overall structure is more stable in operation, can rotate with loads by 360 degrees, realizes multiple purposes on one machine, increases the equipment utilization rate, and improves the pipe lifting efficiency.

Owner:廊坊市管道人机械设备有限公司

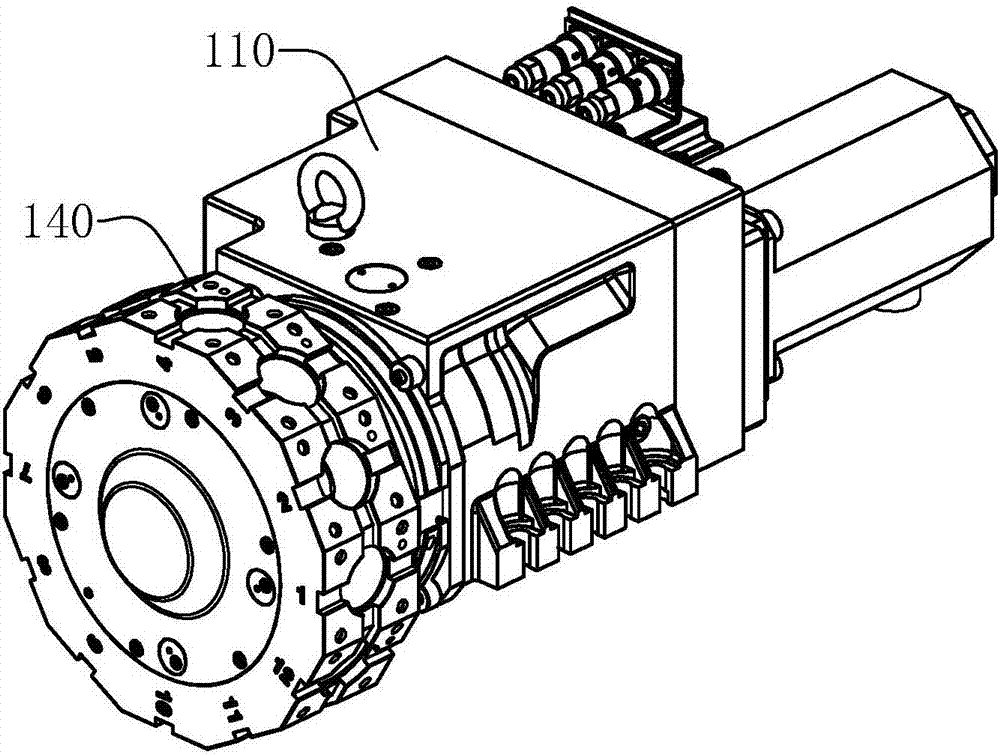

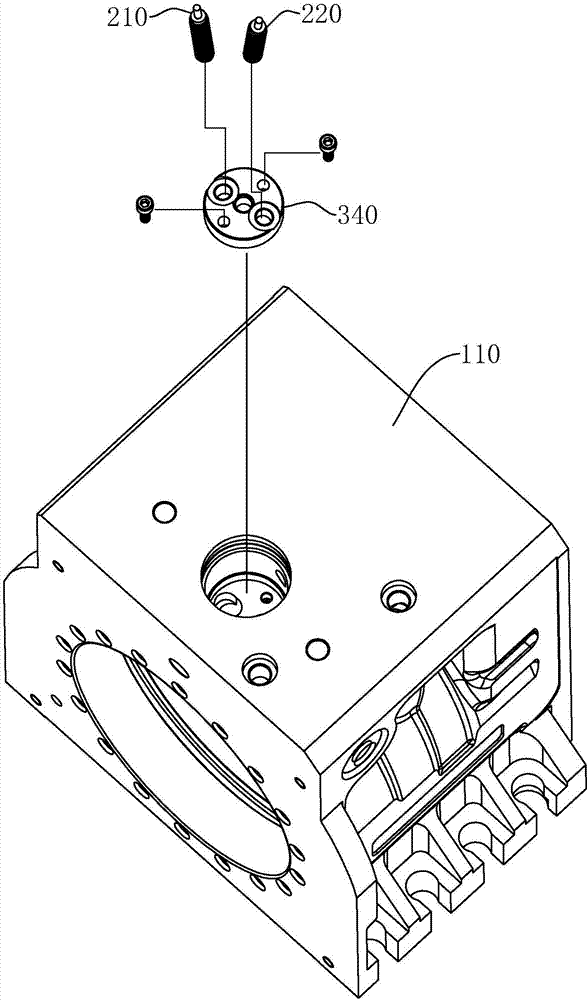

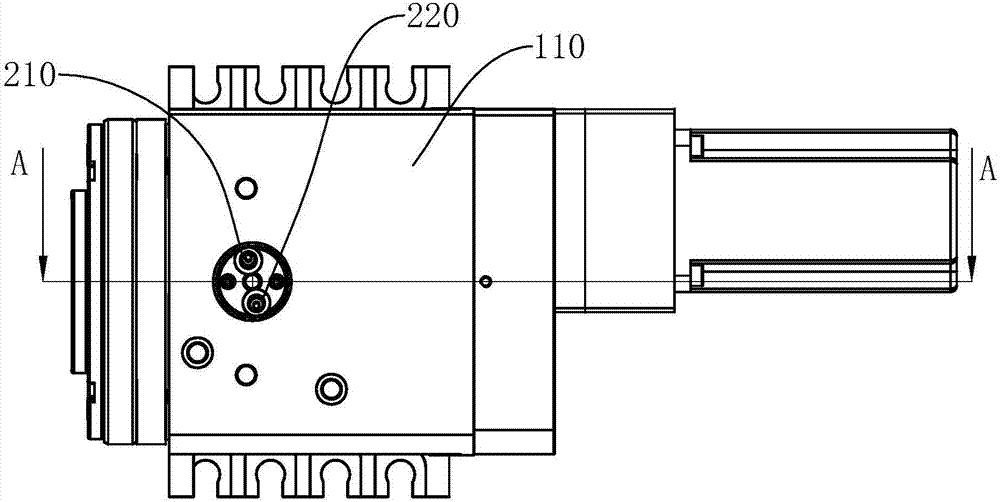

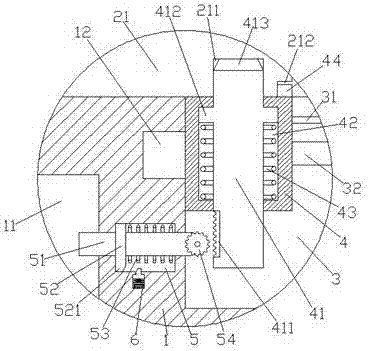

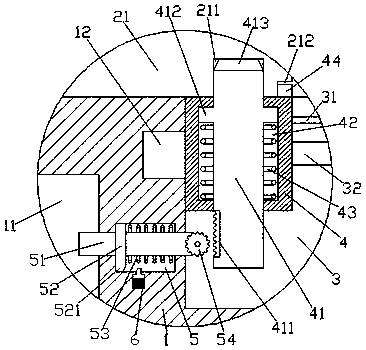

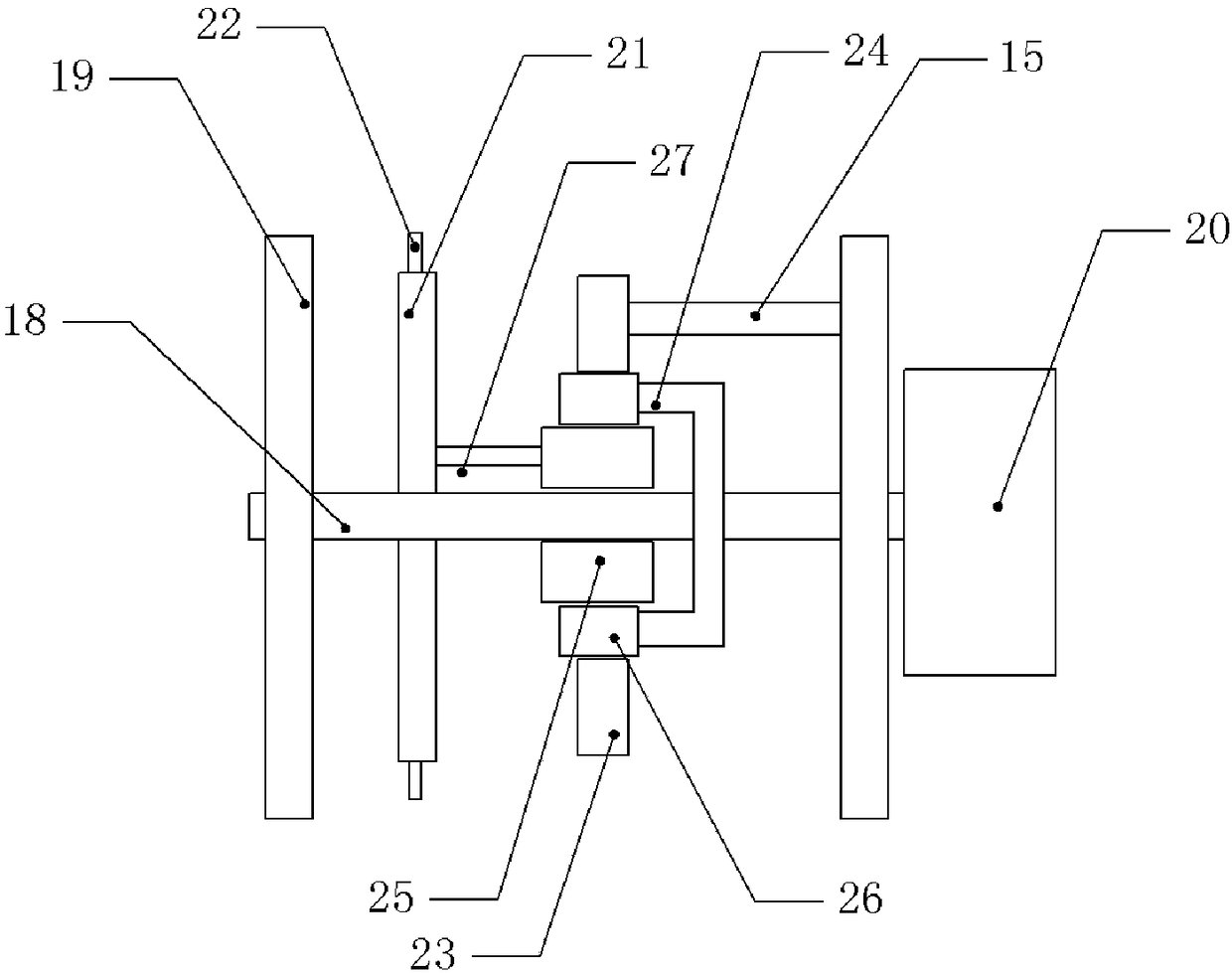

Power knife turret protection structure, power knife turret system and control method

PendingCN107350495AStable operation of the structureSwitching Rotation High EfficiencyTool holdersPositioning apparatusPistonElectrical and Electronics engineering

The invention discloses a power knife turret protection structure, a power knife turret system and a control method, and aims to provide the power knife turret which is highly-reliable and safe and stable in operation. The technical scheme of the invention is characterized in that safe locking is performed through a duplex fluted disc, a static gear ring and a movable fluted disc structure; reliability is improved through a pushing spring; a piston-type unlocking function is formed by utilizing an oil cavity; and working stability and reliability are improved by adopting a sealing ring.

Owner:WENLING SANHE CNCEQUIP

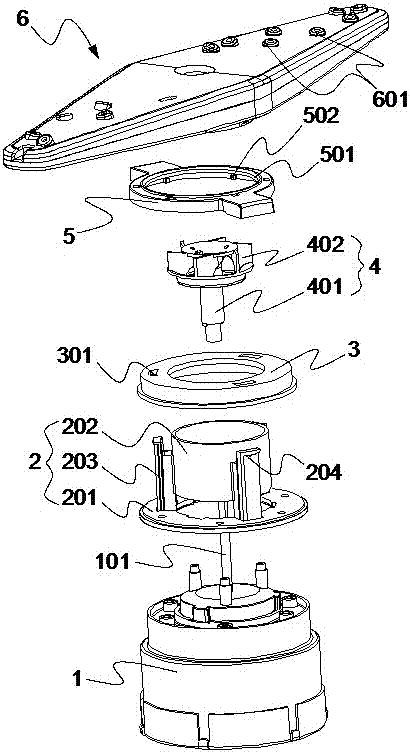

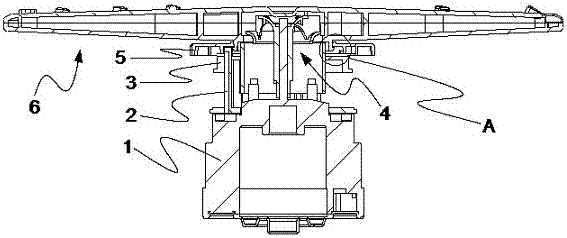

Dish washing machine

PendingCN107320045ASmall installation sizeSimple structureTableware washing/rinsing machine detailsCleaning equipmentImpellerRetaining ring

The invention discloses a dish washing machine. The dish washing machine comprises a motor, a mounting frame, a mounting seat, an impeller, a fixing ring and a spraying arm which are successively arranged coaxially, wherein a driving shaft is arranged on the motor in an extending manner; the driving shaft penetrates through the mounting frame and the mounting seat and is fixedly connected to the impeller; the mounting frame partially penetrates through the mounting seat and is buckled onto the fixing ring; a water flowing channel is formed in the spraying arm; a plurality of nozzles are arranged on the shell; the spraying arm can be freely and rotatably buckled on the fixing ring; the impeller comprises a sleeve mounted on the driving shaft and a plurality of guiding plates which are arranged on the sleeve in an extending manner; the guiding plates are connected through a positioning ring; a notch is formed between the guiding plates and the outer wall of the sleeve; and a water supply path extends along the outer wall of the sleeve, the notch and space between each two adjacent guiding plates successively. The dish washing machine has novel impeller and connector structures, the mounting size of the whole machine is reduced axially, meanwhile, the structure is simplified, the dish washing machine runs stably, the working efficiency is improved effectively, and meanwhile, maintenance and repair are facilitated.

Owner:SUZHOU FULEKA ELECTRICAL SCI & TECH DEV

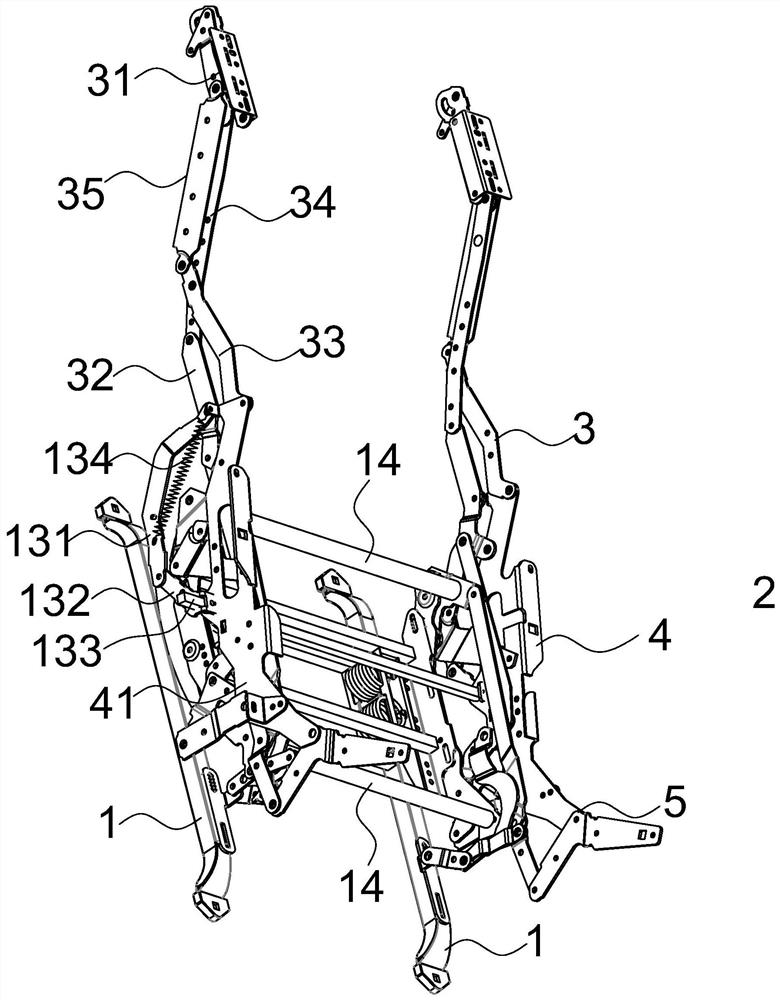

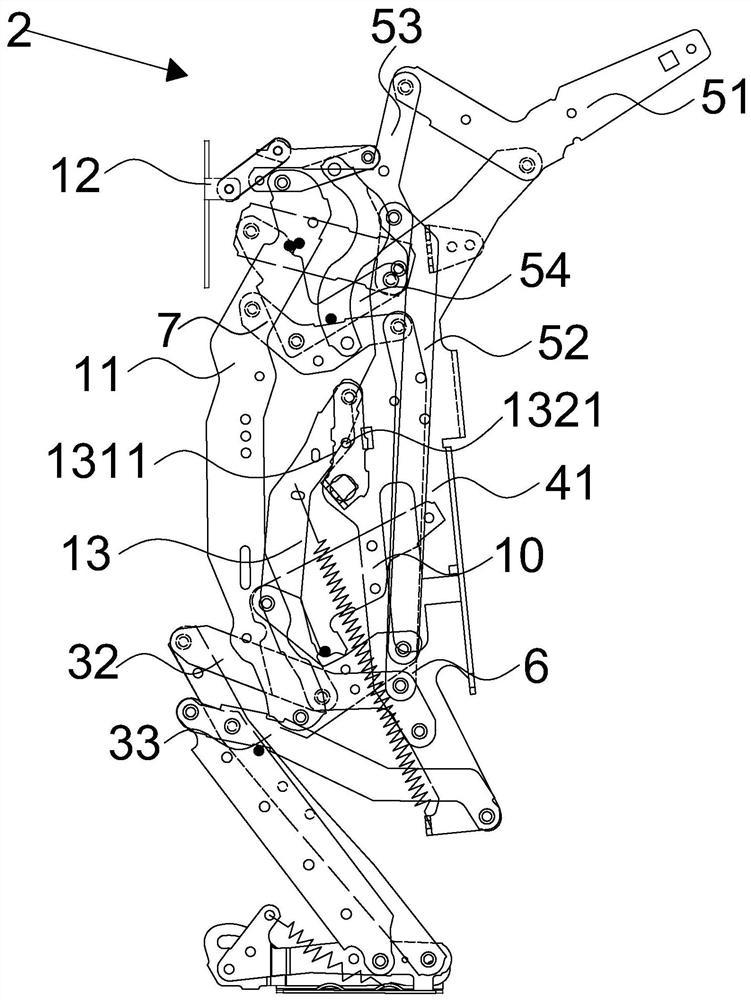

Mechanical stretching unit and mechanical stretching device

The invention discloses a mechanical stretching unit and a mechanical stretching device. The mechanical stretching unit comprises a footstool assembly, a cushion supporting assembly and a backrest assembly. The cushion supporting assembly comprises a seat mounting plate, and a first connecting rod mechanism is formed by a rear supporting connecting rod, a first stool collapse connecting rod, a second stool collapse connecting rod, a first transverse connecting rod, a first longitudinal connecting rod and the seat mounting plate and is used for driving the footstool assembly to move between a folding position and an unfolding position relative to the seat mounting plate; the backrest assembly comprises a backrest piece and a second transverse connecting rod, the second transverse connectingrod is arranged on one side of the first transverse connecting rod in parallel, and a second connecting rod mechanism is formed by arranging a front longitudinal connecting rod, a bottom connecting rod, a rear longitudinal connecting rod and the second transverse connecting rod and used for driving the backrest assembly to move between a leaning position and a reclining position. The footstool assembly and the backrest assembly are driven by the two sets of connecting rod mechanisms correspondingly, movement is stable, and the stretching process is coherent.

Owner:UE FURNITURE CO LTD

River channel garbage dredging device

The invention relates to the technical field of garbage treatment, and discloses a river channel garbage dredging device. The device comprises a supporting mechanism, an intercepting mechanism and a height adjusting mechanism, wherein the height adjusting mechanism comprises a plurality of adjustable floating bodies, each adjustable floating body comprises a horizontal edge and vertical edges, anelectric saw blade is rotationally connected between the two vertical edges of each adjustable floating body through a first rotating shaft, one end of the first rotating shaft penetrates through andgoes out of the vertical edges to be connected with a motor, the other end of the first rotating shaft is fixedly connected with a first bevel gear, the first bevel gear is meshed with a second bevelgear, the second bevel gear is fixedly connected with a second rotating shaft, the first rotating shaft is perpendicular to the second rotating shaft, the end part of the second rotating shaft is rotationally connected with a water pumping box, the part, located in the water pumping box, of the second rotating shaft is fixedly connected with a second blade, the top of the water pumping box communicates with the horizontal edges through water pipes, the end, close to the horizontal edge, of each water pipe communicates with a plurality of branch pipes, and the free ends of the branch pipes extend out of the horizontal edges. According to the device, the garbage on the adjustable floating bodies is cut off through the device, so that the garbage can be smoothly collected.

Owner:宁波清智环保科技有限公司

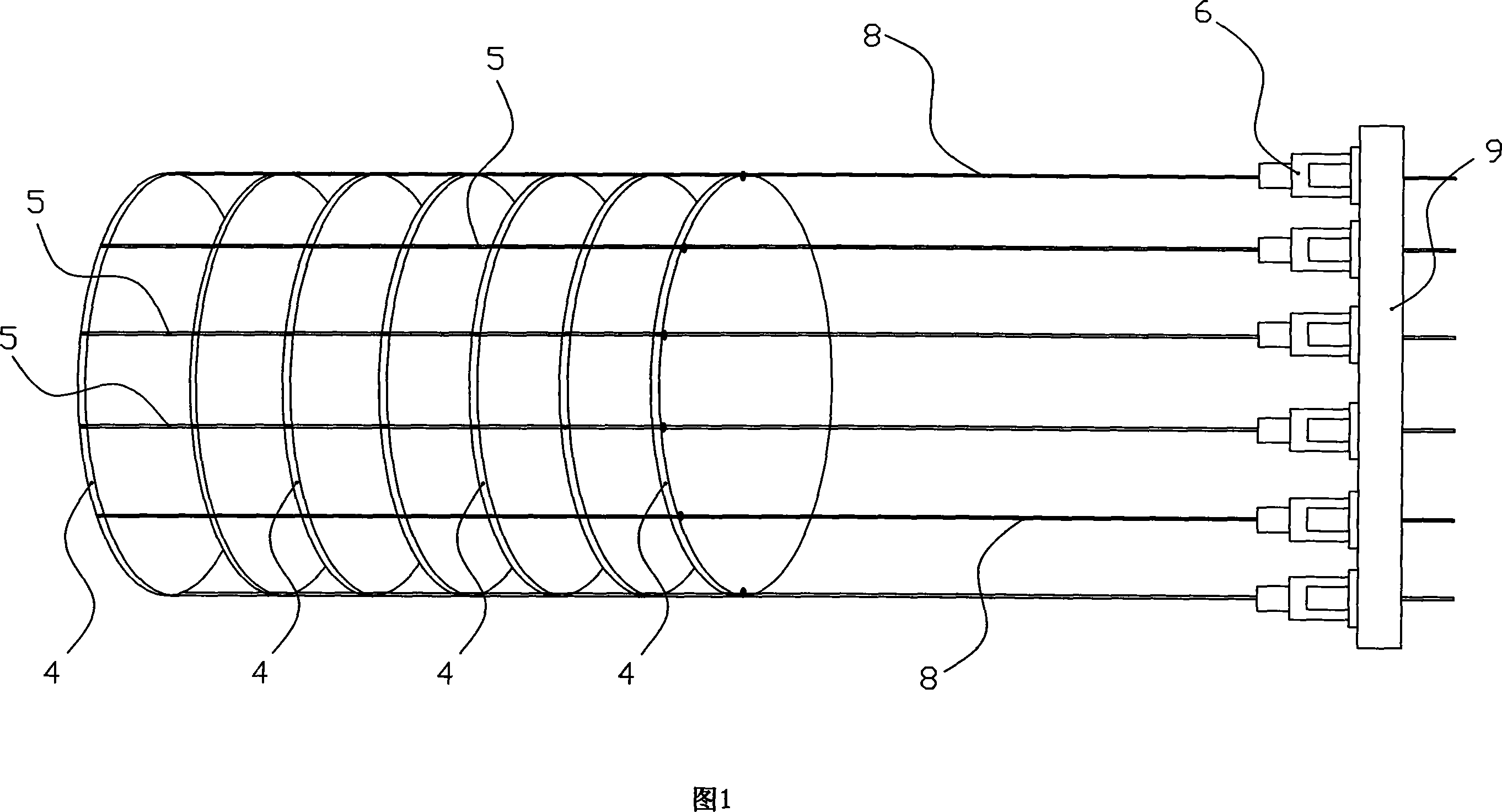

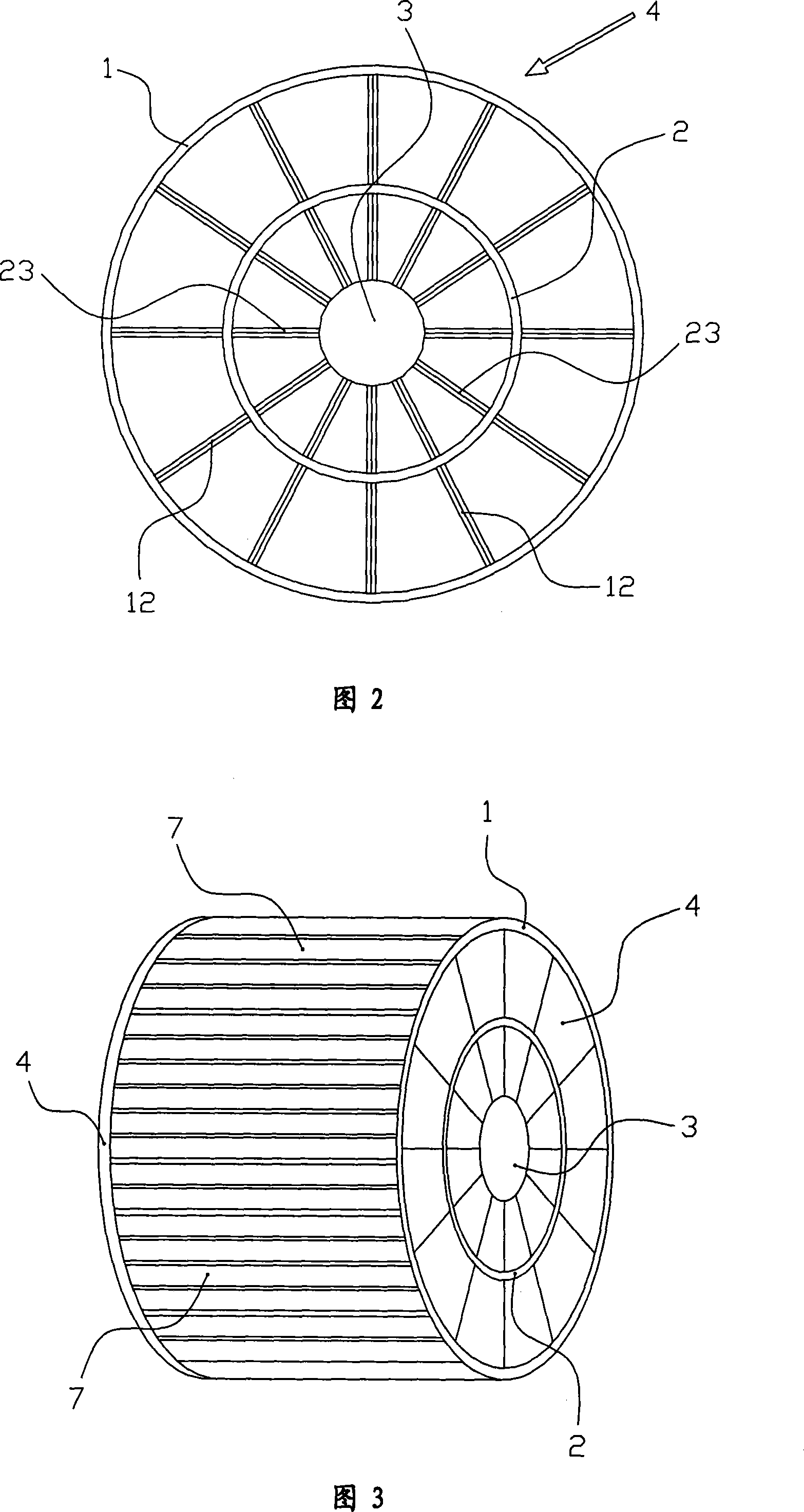

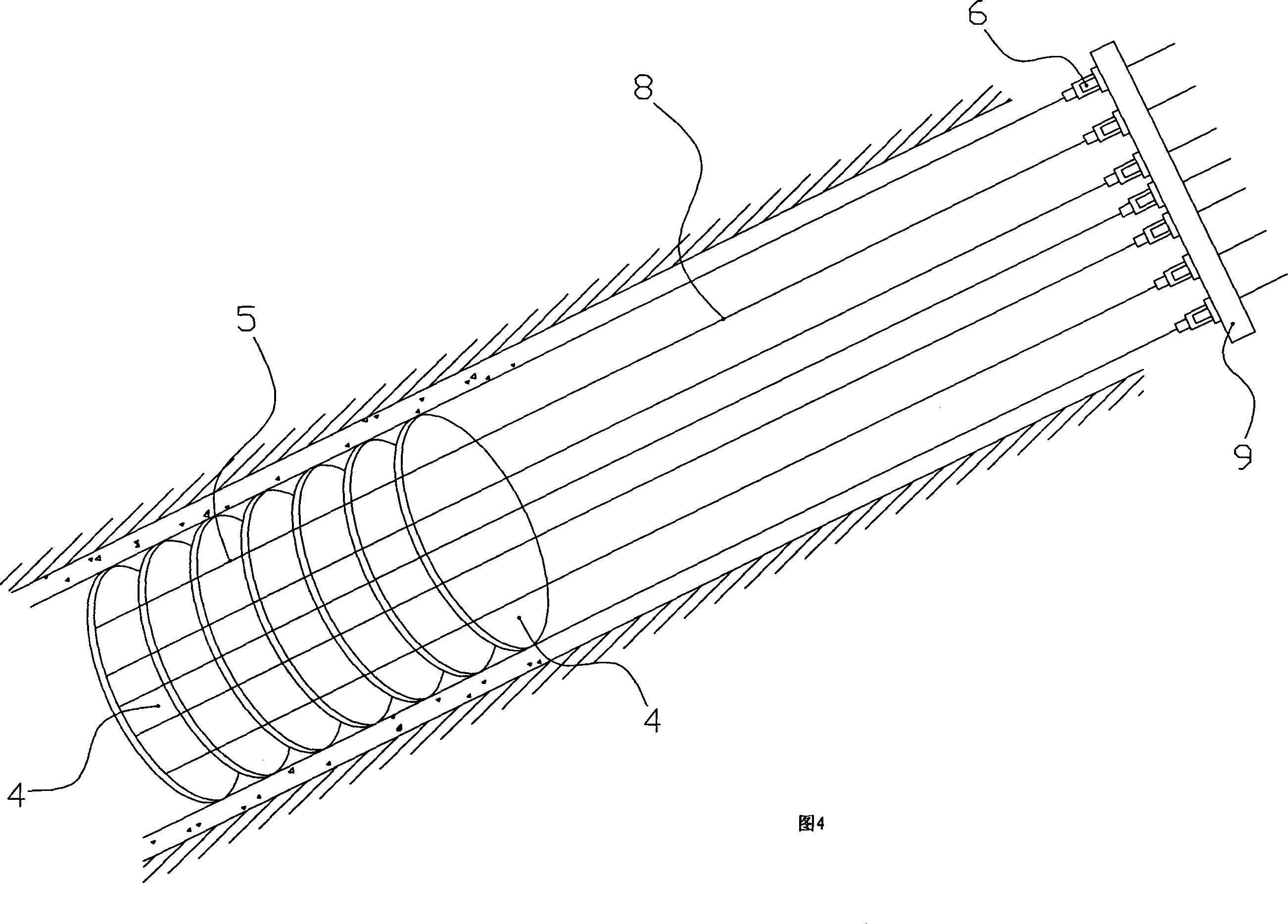

Inclined shaft sliding mode structure and inclined shaft pull-crawling construction process

The invention provides a structure of an inclined shaft slip form body, and an inclined shaft pull and climb-type construction process. The structure of the slip form body comprises a slip form body consisting of at least two sets of slip form monomers. The slip form monomer comprises an encirclement ring, a bulging ring and a central round disc. The central round disc supports and is connected with the bulging ring through a spoke support. The bulging ring supports and is connected with the encirclement ring through the spoke support. The encirclement ring, the bulging ring and the central round disc are homocentric. Encirclement rings of adjacent slip form monomers are connected into one piece through connection steel bodies. Bulging rings of adjacent slip form monomers are connected into one piece through steel bodies. The centers of the encirclement rings line on a beeline. In this way, the slip form body is formed. Templets are arranged on the encirclement rings of adjacent slip form monomers. The structure is simple, needs little investment, and runs smoothly with small warp. Construction of concrete can be carried out continuously, conveniently and quickly. The appearance quality of the concrete is excellent without construction joint. Much copper seal and rubber seal can be saved. The construction speed of the process is high, and the daily inclined length of slip rise ranges from 4.5 m to 5.5m. The construction period can be reduced effectively.

Owner:周二萍

Attitude detection system and method of coiled material under motion state

InactiveCN109230729AEliminates the possibility of driftReduce scrap rateWebs handlingProcess deviationsEngineering

The invention relates to the technical field of coiled material deviation rectification, and discloses an attitude detection system and method of the coiled material under a motion state. The system comprises an unreeling deviation rectification mechanism, a winding deviation rectification mechanism and a process deviation rectification mechanism, wherein the process deviation rectification mechanism comprises a process deviation rectification controller and a process deviation rectification sensor, a process deviation rectification guide mechanism and a process deviation rectification transmission mechanism, the process rectification guide mechanism comprises a base, two mounting plates and a guide roller, wherein two ends of the guide roller are rotatably connected with the inner walls of the two mounting plates respectively; the process deviation rectification transmission mechanism comprises a transmission box which is arranged below the base, a supporting rod is fixedly connectedon the transmission box, in a feeding direction, a first through groove is formed in the transmission box, in a discharging direction, a shell is arranged in the transmission box, and the shell is rotatably connected with the upper part and bottom part of the transmission box. According to the invention, the deviation rectification is carried out during the unwinding, winding and conveying processes of the coiled material, and the transverse displacement of the coiled material is reduced.

Owner:CHONGQING DONGDENG TECH

Automatic deviation rectification system and method for coiled material

InactiveCN109230730AHigh degree of automationCorrection efficiency is fastFunction indicatorsWebs handlingEngineeringMechanical engineering

The invention relates to the technical field of coiled material deviation rectification, and discloses an automatic deviation rectification system and method for the coiled material. The system comprises a deviation rectification controller, a deviation rectification sensor, a deviation rectification guide mechanism and a deviation rectification transmission mechanism, wherein the deviation rectification guide mechanism comprises a base, two mounting plates and a guide roller; the deviation rectification transmission mechanism comprises a transmission box positioned below the base, a supporting rod is fixedly connected on the transmission box, in a feeding direction, a first through groove is formed in the transmission box, in a discharging direction, a shell is arranged in the transmission box, and the shell is rotatably connected with the upper part and bottom part of the transmission box, a first motor is arranged in the shell; the first motor is fixedly connected with a first gearthrough a first rotating shaft; the first gear is connected with a second gear through a belt; the second gear is fixedly connected with a screw rod; a nut and a pushing block sleeve on the screw rod;a push rod is fixedly connected with the upper end surface of the pushing block vertically; the upper end of the push rod extends from the first through groove. According to the invention, the deviation rectification is carried out in the coiled material conveying process, and the transverse displacement of the coiled material is reduced.

Owner:CHONGQING DONGDENG TECH

Gear rack transmission type automatic locking device

InactiveCN101260759BSolve the bounce problemOpen flexibleBuilding locksConstruction fastening devicesGear wheelLocking mechanism

The invention discloses a gear and rack driving type automatic locking mechanism, relating to a locking mechanism used for a file cabinet. The invention resolves the problems that the prior lock on the file cabinet can not realize the functions of automatic closing and locking, the prior locking mechanism is dumb when unlocked and locked. One end of a lock (6) is connected with the lower end of an upper connecting rod (5), the upper end of the upper connecting rod (5) penetrates a casing (9), the other end of the lock (6) is connected with a mechanism support (4), gears (2) and racks on a rack lever (3) are meshed, the gears (2) are meshed with hand pulling racks (1), an energy storage elastic part is connected with an energy storage elastic part connecting rod (4-3), and the lower end ofthe energy storage elastic part (8) is fixed on the casing (9). The gear and rack driving type automatic locking mechanism realizes that the door of the file cabinet can be closed and locked at the same time, and solves the problem of the rebounding of the cabinet door. The gear and rack driving type automatic locking mechanism has the advantages of flexible unlocking and locking, excellent stability, low cost and convenient unlocking and locking.

Owner:哈尔滨飞云实业有限公司

Clamping device and inflating device

The invention discloses a clamping device and an inflating device. The clamping device comprises a bracket, a clamping assembly and a first driving unit; and the inflating device comprises the clamping device and further comprises an inflating unit, the inflating unit comprises a guiding rail, a fixed frame, an inflating joint and a second driving unit. According to the clamping device, through inserting connection of claw teeth on a clamping claw, the claw teeth are arranged in a staggered mode, a cylindrical gas nozzle is clamped, the number of clamping contact points is increased, the firmness of clamping the gas nozzle is improved, upward friction force of a gas nozzle shaft is increased, inserting connection of the inflating joint can be resisted, it is ensured that the inflating joint and the gas nozzle can be connected tightly, and thus smooth inflating is ensured. The inflating joint is guided by the guiding rail to rise and fall, thus the inflating joint can be automatically connected to the clamped and fixed gas nozzle in an inserted mode, an inner tube can be automatically inflated in the tire assembling process, the labor intensity of workers is reduced, and the overallspeed of tire assembly operation is increased.

Owner:青岛科力达机械制造有限公司

Sundry blocking device of environment protection ditch

InactiveCN108867562AImprove fishing efficiencyImprove cleanlinessArtificial water canalsSewageEngineering

The invention discloses a sundry blocking device of an environment protection ditch, and relates to the field of ditch environment protection. The device comprises a ditch body, a first filtering screen is arranged in the ditch body, and a second filtering screen is arranged on the right side of the first filtering screen; the first filtering screen and the second filtering screen are V-shaped, agap is formed between the bottom of the first filtering screen and the bottom wall of the ditch body, and grids of the first filtering screen are greater than those of the second filtering screen; twofirst baffle plates are fixedly arranged on the left side of the first filtering screen and symmetrically arranged in the ditch body, first sundry collecting pieces are arranged on the first baffle plates, and a sewage stirring device is arranged between the first filtering screen and the second filtering screen; a sediment gathering block is arranged on the right side of the second filtering screen, and a sediment depositing groove is formed in the right side of the sediment gathering block. The sundry blocking device has the advantages that trash in the sewage can be blocked through sorting, the trash catching efficiency is improved, the siltation caused by the sewage is effectively relieved, and the cleanliness of the sewage flowing to a sewage treatment plant is improved.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

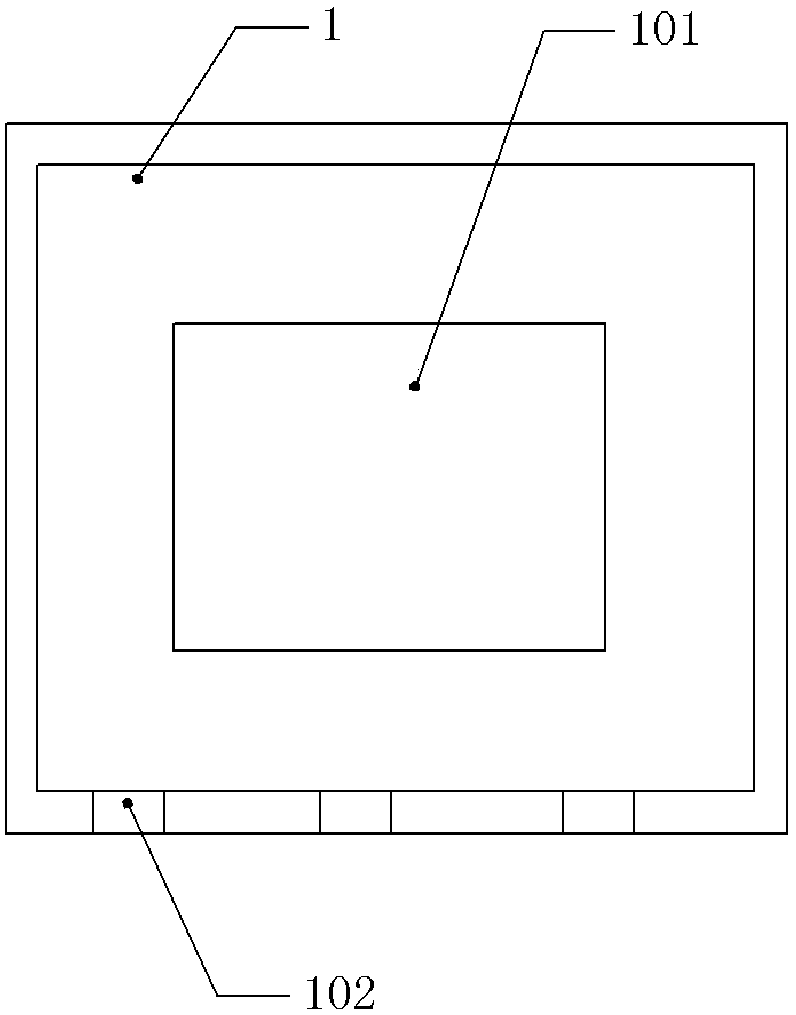

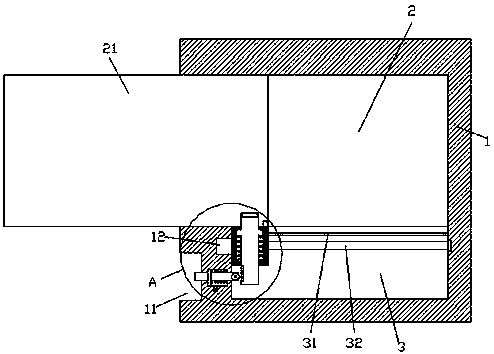

Drawer type power control cabinet device convenient to maintain

ActiveCN107342549ARealize routine maintenanceEasy maintenanceSwitchgear with withdrawable carriageEngineeringMechanical engineering

The invention discloses a drawer type power control cabinet device convenient to maintain. The device comprises a cabinet body in which an accommodating cavity is arranged, wherein a pushing groove is arranged in the cabinet below the accommodating cavity, a drawer component is arranged in the accommodating cavity, a pressing area is arranged on the outer wall of the cabinet on the left of the pushing groove, a pressing cavity is arranged in the cabinet between the pressing area and the pushing groove and a clamp connection device is arranged below the pressing cavity, a pressing rod extending to left and right sides is arranged in the pressing cavity, and the extension section on the left of the pressing rod stretches into the pressing area after penetrating through the left side wall of the cabinet body. According to the device provided by the invention, automatic inward and outward moving is achieved, and the drawer component is independently dismounted, so that different overhauling requirements can be met, overhauling of staffs is facilitated, overhauling efficiency is improved, and the whole structure is stable in operation.

Owner:徐州新电高科电气有限公司

Steel shot sorting device

ActiveCN108499873AChange direction of motionRealize continuous operationGradingMagnetMotion direction

The invention relates to the technical field of steel shot production, and discloses a steel shot sorting device. The steel shot sorting device comprises a shell, a feeding hopper and a discharging pipe. The shell is divided by a supporting frame into an upper cavity and a lower cavity. Screens are arranged at the bottom of the upper cavity, the hole diameter of meshes is sequentially reduced fromthe feeding pipe direction to the discharging pipe direction, and the upper ends, in the steel shot feeding direction, of the meshes are connected with hard balls. A plurality of collecting frames are arranged in the lower cavity, and a material collecting frame is arranged between every two adjacent collecting frames. An intermittent magnet material sucking mechanism is arranged between every two adjacent screens, wherein a material sucking pipe is arranged between the intermittent magnet material sucking mechanism and the next adjacent screen, the lower end of the material sucking pipe penetrates the supporting frame and communicates with the bottom of the corresponding material collecting frame. The material collecting frames are located in front of the intermittent magnet material sucking mechanism, the side wall of the part, located on the upper cavity, of the material sucking pipe is connected with a spraying pipe, the spraying pipe is connected with an induced draft fan, and the free end of the spraying pipe faces the next screen. According to the steel shot sorting device, large steel shots are prevented from blocking the meshes by changing the motion direction of the large steel shots, and small steel shots conveniently pass through the meshes.

Owner:CHONGQING QINGLAN MACHINERY MFG

Impulse voltage generator

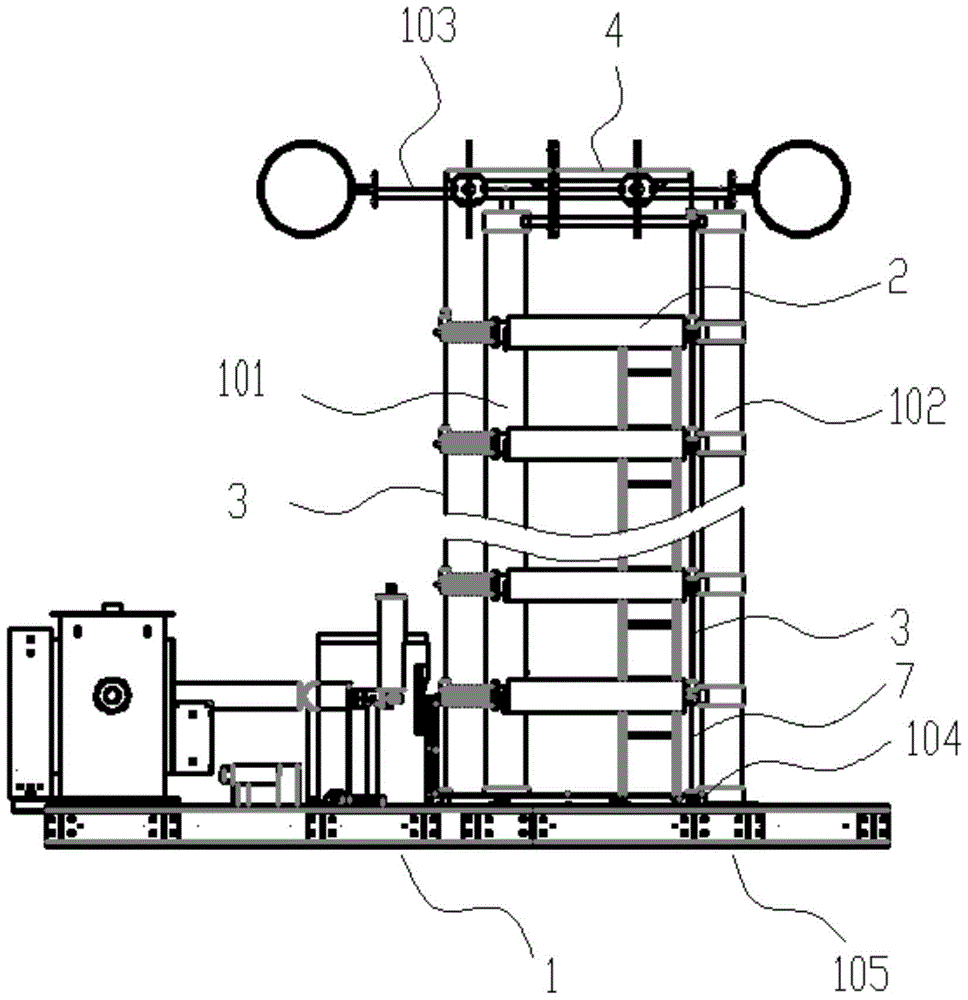

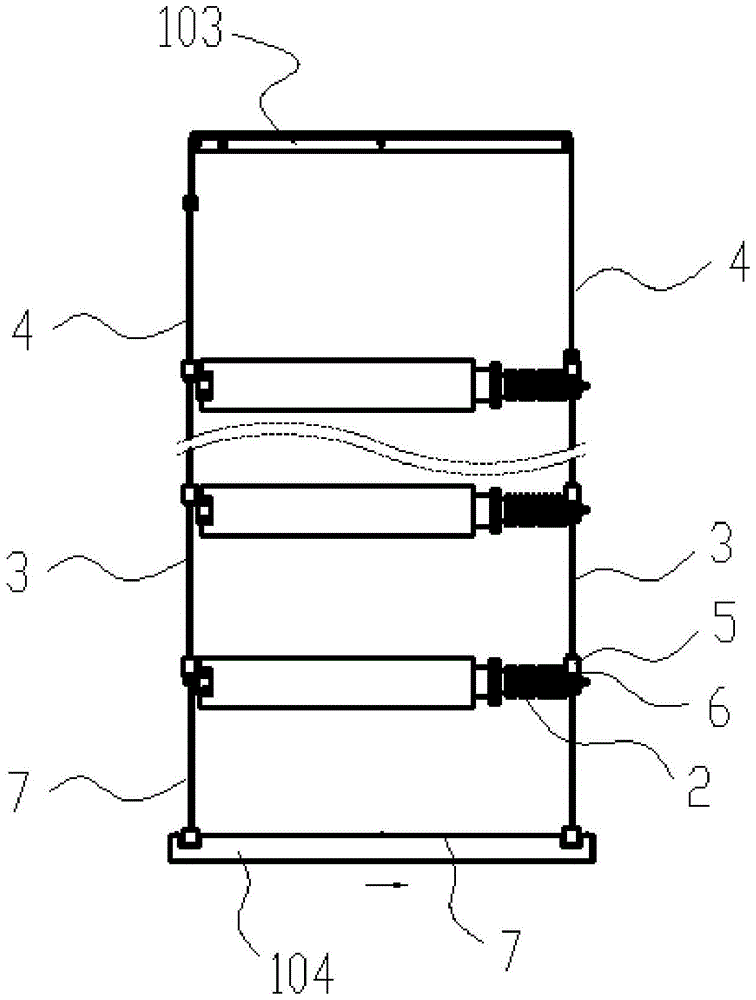

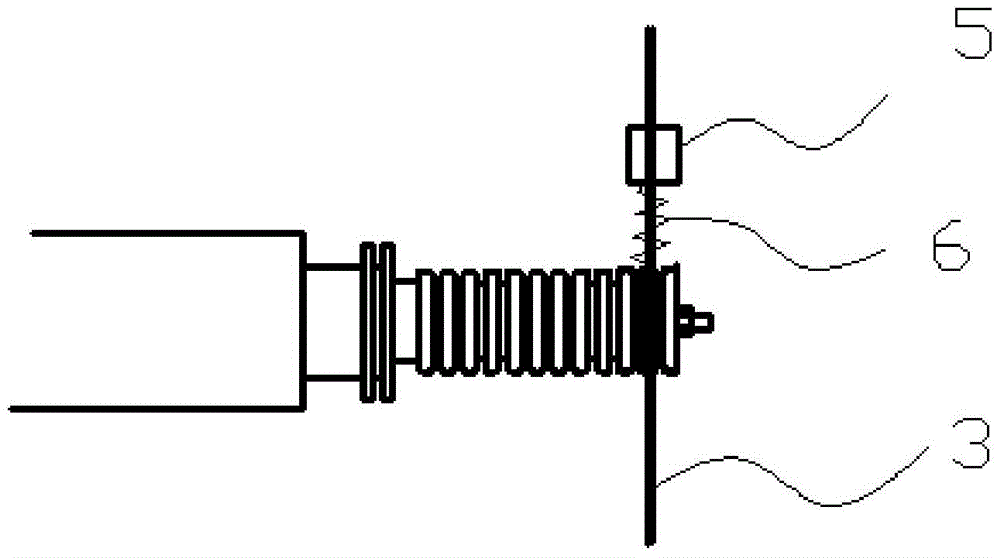

InactiveCN105044410AShort discharge timeStable and reliable structure operationTesting dielectric strengthElectrical measurement instrument detailsVoltage generatorCapacitance

The invention provides an impulse voltage generator. The generator comprises a rack, a capacitor, an insulation pull rod, an insulation synchronization belt and a discharge apparatus. The rack comprises a base plate 105, an insulation support column, an insulation crossbeam 103 and a conductive seat. The discharge apparatus comprises a metal block, a conductive tension spring and a conductive belt. During charging, capacitors, the capacitor and the conductive belt, the capacitor and the conductive seat and the like are disconnected so as to realize the charging. During discharging, the insulation synchronization belt moves so as to drive the insulation pull rod to move and drive the metal block to move. When the metal block moves to an adjacent capacitor pole, a loop is formed between all the capacitors and the conductive seat so that positive and negative electrode discharge of the capacitors and discharge to the ground are realized. Discharge time of the impulse voltage generator is short and structure operation is stable and reliable.

Owner:WUHAN HUAGAO H V EQUIP CO LTD

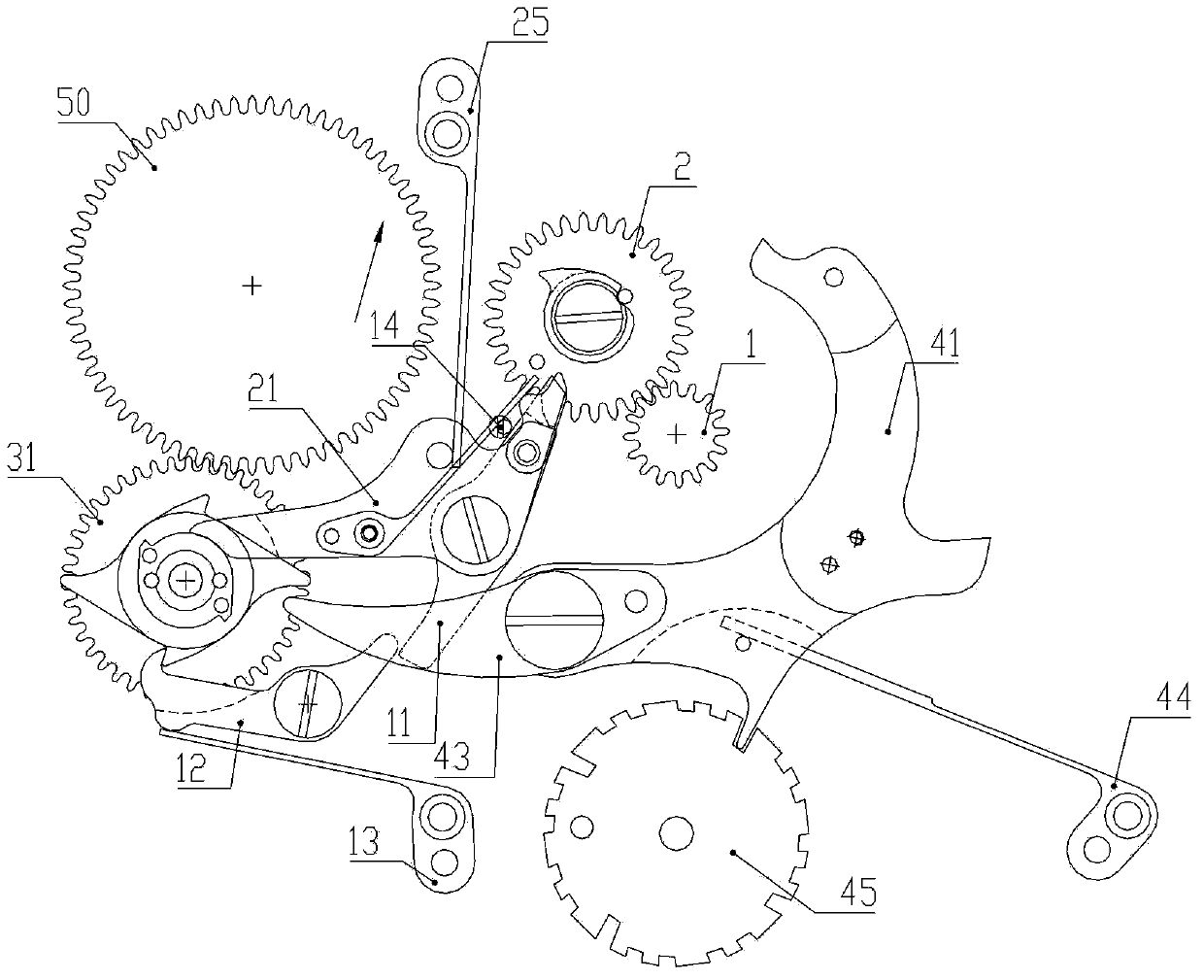

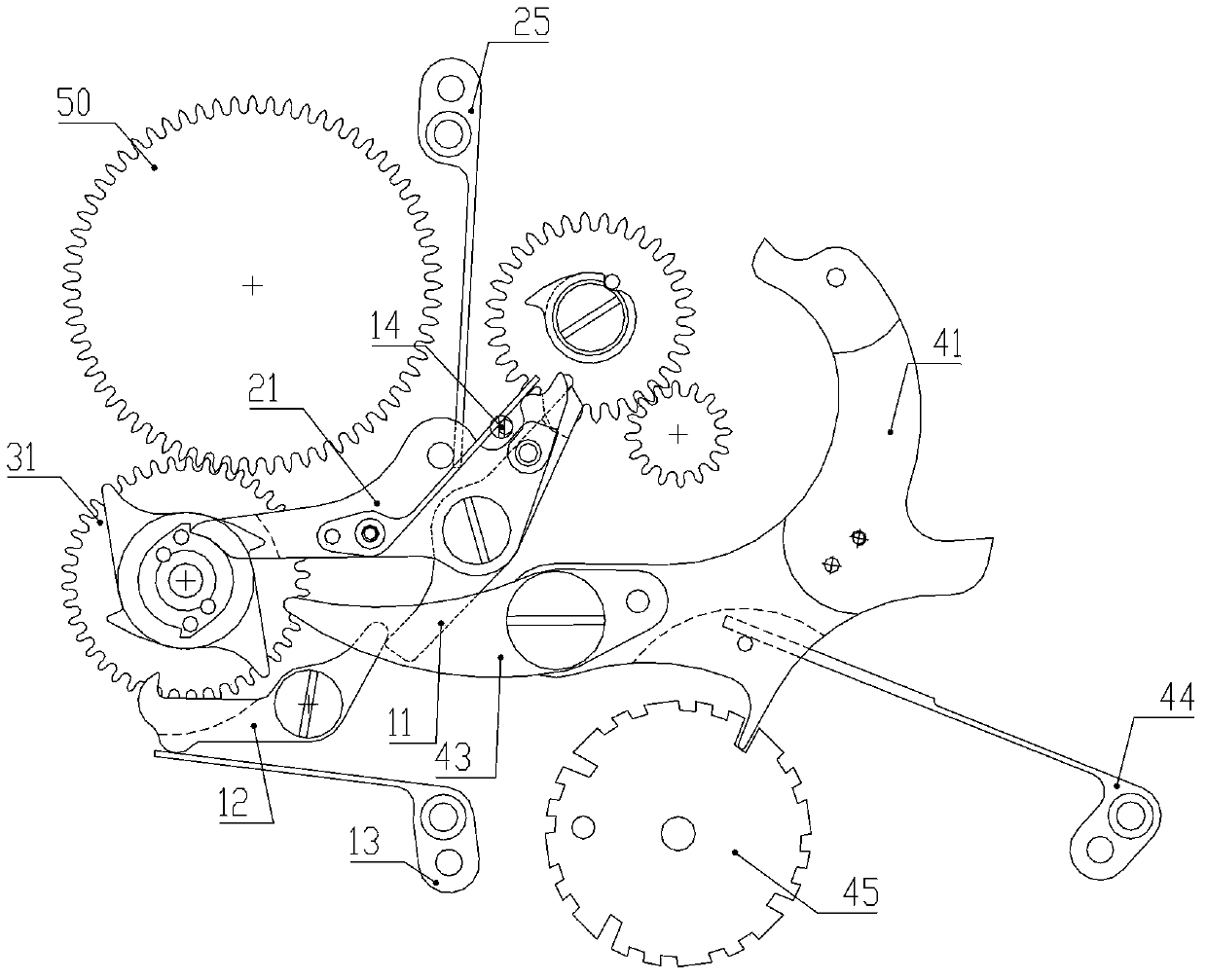

Staring mechanism with insurance device

ActiveCN103631127AImprove stabilityAvoid chaotic situationsVisual indicationAcoustic indicationMachine controlEngineering

The invention discloses a starting mechanism with an insurance device; an insurance starting shifting block is arranged on a wheel sheet; a first lever is in screw connection with an insurance rod part, and the first lever and the insurance rod part can rotate around a rotation center; one end of the first lever contacts with or disengages from one end of a second lever, the other end of the first lever contacts with or disengages from a starting position screw of the wheel sheet, the other end of the second lever abuts against or disengages from a starting wheel assembly; the insurance starting shifting block contacts with or disengages from one end of the insurance rod part, the other end of the insurance rod part contacts with or disengages from the starting wheel assembly. The beneficial effects are that the insurance device is added, starting is accurate, so the device can be applied in the precision machine control fields like an instantaneous jump perpetual calendar on a machinery watch, calendar changing motion can be timely started and is accurate, thereby preventing multi-calendar changes caused by massive energy, and movement work stability is improved; the starting mechanism with the insurance device is reliable in operation, easy in assembling, good in techniques, and low in processing precision requirement.

Owner:TIANJIN SEAGULL WATCH CO LTD

Drawer-type control cabinet equipment for power

ActiveCN107706799ARealize routine maintenanceEasy maintenanceSwitchgear with withdrawable carriageMechanical engineeringElectric power

The invention discloses drawer-type control cabinet equipment for power. The drawer-type control cabinet equipment comprises a cabinet body, wherein an accommodating cavity is arranged in the cabinetbody; a push tank is arranged in the cabinet body at the lower part of the accommodating cavity; a drawer assembly is arranged in the accommodating cavity; a pressing area is arranged on an outer wallof the cabinet body at the left side of the push tank; a pressing cavity and a clamping device arranged at the lower part of the pressing cavity are arranged in the cabinet body between the pressingarea and the push tank; a pressing lever which extends towards the left and right sides is arranged in the pressing cavity; and an extended segment at the left side of the pressing lever penetrates through a left side wall of the cabinet body and extends into the pressing area. The drawer-type control cabinet equipment can meet different maintenance requirements through automatic shift-in and shift-out and separate disassembly of a drawer component, maintenance of workers is facilitated, the maintenance efficiency is improved and the overall structure is stable in operation.

Owner:胜华电气有限公司

Steel pipe fixing device

ActiveCN107096957AEasy to fixFixed, safe and reliableTube shearing machinesShearing machine accessoriesRight convexEngineering

The invention discloses a steel pipe fixing device. The steel pipe fixing device comprises a base; a left convex column and a right convex column are symmetrically arranged at the left and right ends of the top of the base; a left guide hole and a right guide hole are symmetrically formed in the left convex column and the right convex column; a left counter bore communicating with the left guide hole and a right counter bore communicating with the right guide hole are symmetrically formed in the inner side ends of the left convex column and the right convex column; a first left chute and a first right chute are symmetrically formed in the parts, positioned at the inner side ends of the left convex column and the right convex column, of the top of the base; a left slide frame and a right slide frame capable of sliding left and right are symmetrically arranged in the first left chute and the first right chute; and a second left chute and a second right chute are symmetrically formed in the inner side ends of the left slide frame and the right slide frame. The device is simple in structure and low in production cost, can clamp and fix steel pipes of different diameters, is convenient and fast in taking-down, clamping and fixation of the steel pipes, improves the machining efficiency of subsequent cutting segmentation of the steel pipes, is simple and convenient to operate, is safe, reliable and reasonable in overall structure operation, and is suitable for popularization and application.

Owner:NANTONG YONGDA PIPE IND

Installing structure for bottom sealing strip of automatic lifting door

PendingCN109372404AStable and reliable structure operationImprove punching effectNoise insulation doors/windowsSealing arrangementsEngineeringMechanical engineering

Owner:福清市龙港金属制品有限公司

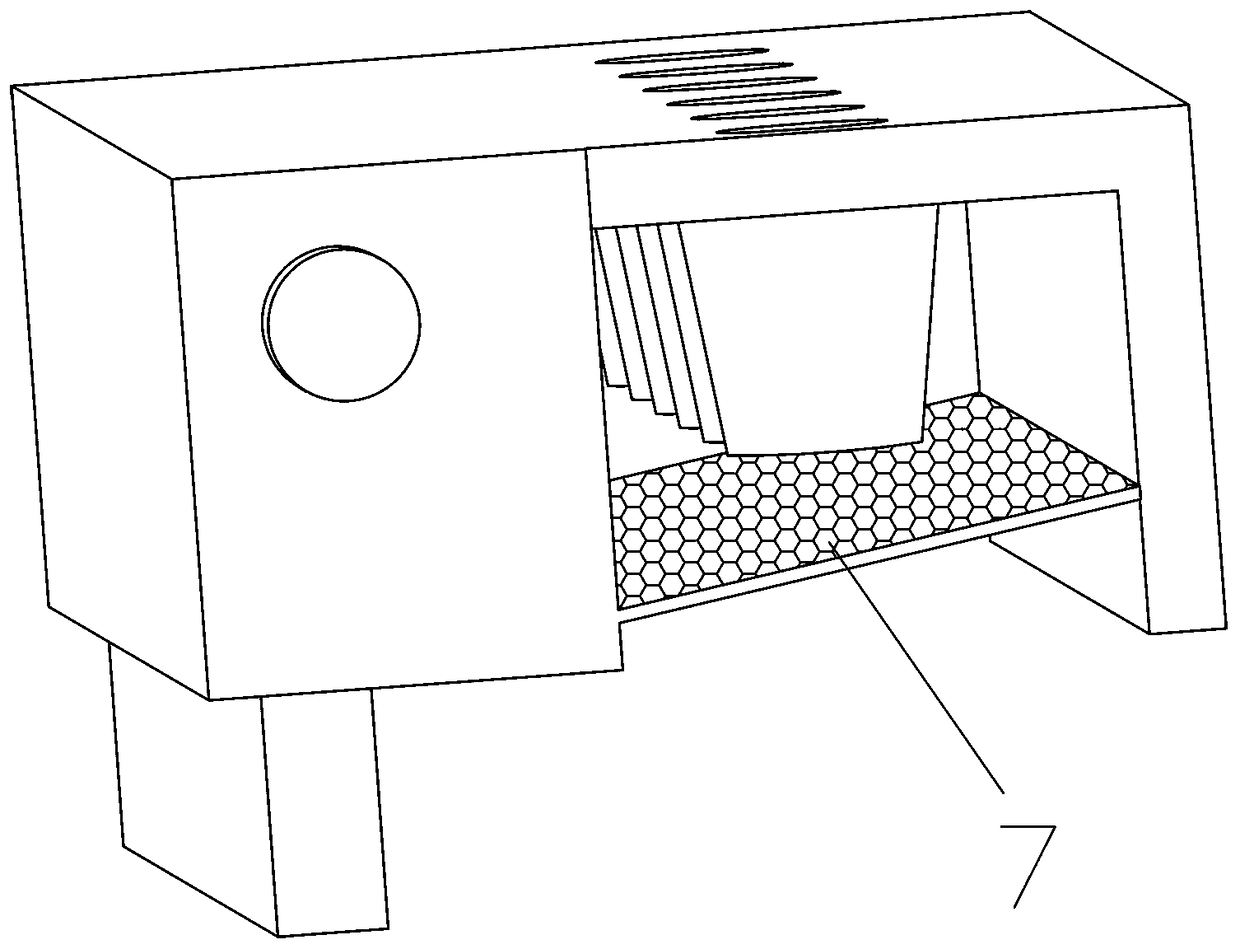

High-efficiency powerful dust cleaner special for cotton textiles

InactiveCN110117844AImprove dust collection efficiencySmooth slidingFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by beater armsFiberSystem structure

Disclosed is a high-efficiency powerful dust cleaner special for cotton textiles. The high-efficiency powerful dust cleaner special for cotton textiles comprises a housing, conveying rollers, a conveying plate, baffles, scattering roller, cylinder air pipes, cylinder air pipe cavities, an upper exhaust pipe, a dust sucking plate, a lower exhaust pipe and a dust sucking fan, wherein the conveying rollers are arranged at both ends inside the housing; the conveying plate is obliquely arranged inside the housing; the baffles are arranged on both sides of the conveying plate; every scattering roller comprises a roller body, scattering rods and scattering lugs; the scattering rollers are arranged on the upper surface of the conveying plate; the cylinder air pipes are arranged on the upper surface of the conveying plate; the cylinder air pipe cavities are arranged at the top ends of the cylinder air pipes; the upper exhaust pipe is vertically communicated with the cylinder air pipe cavities;the dust sucking plate is arranged on the lower surface of the conveying plate; the lower exhaust pipe is arranged at the bottom end of the dust sucking plate, and one end of the lower exhaust pipe isfixedly connected with the dust sucking fan. The high-efficiency powerful dust cleaner special for cotton textiles can achieve repeated multi-angle dust sucking effects on cotton fiber at high efficiency, ensure smooth sliding of the cotton fiber inside the housing and stable operation of the system structure.

Owner:丹阳市永泰纺织有限公司

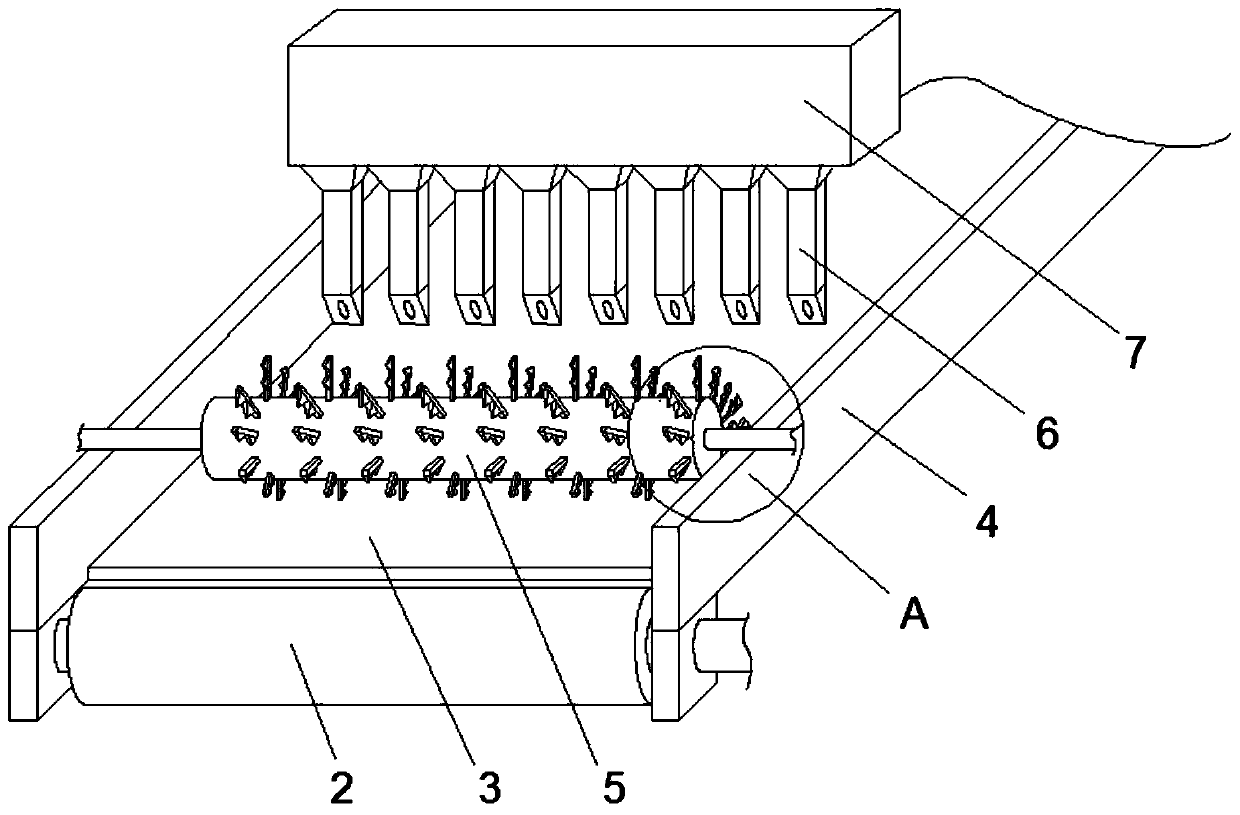

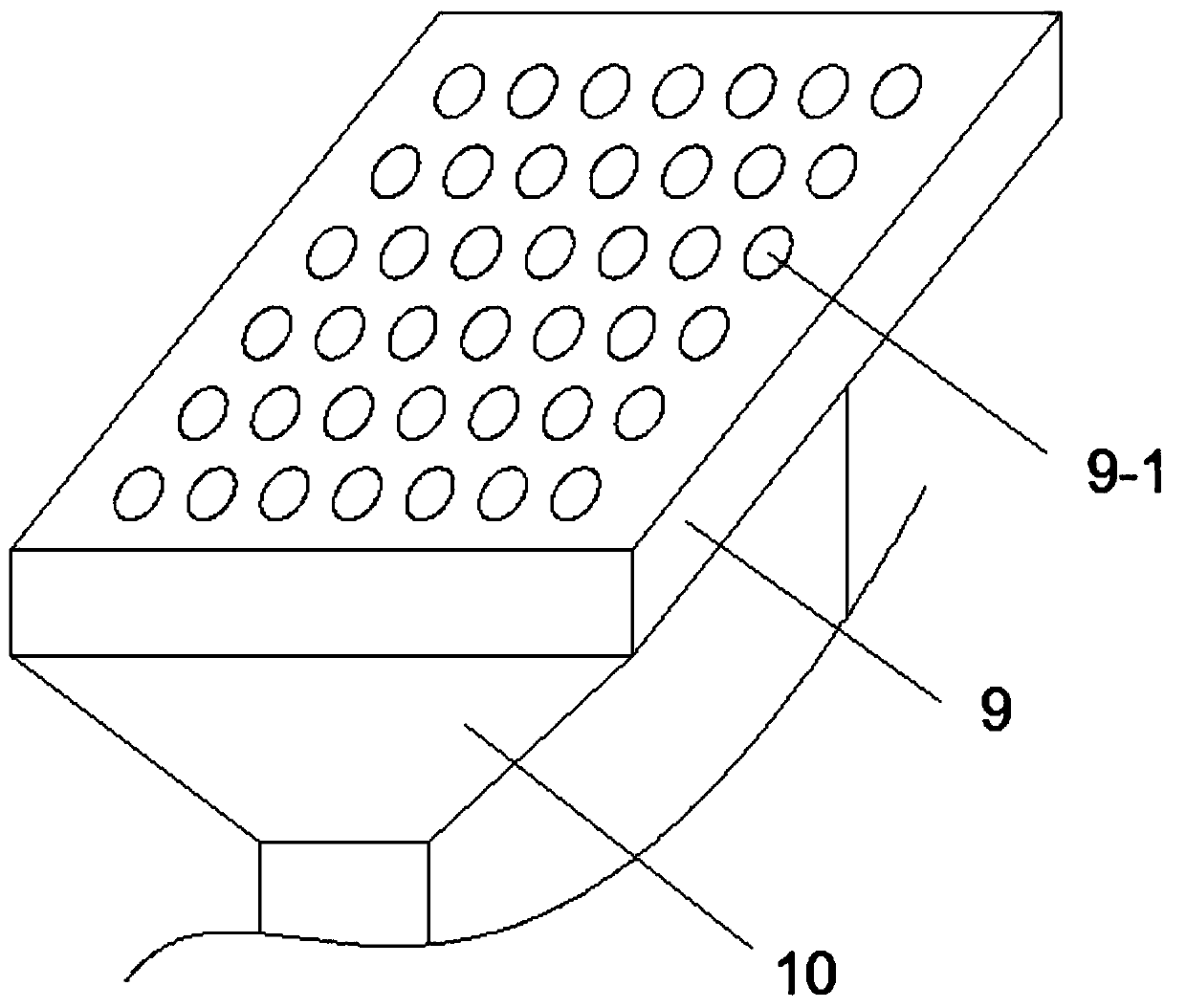

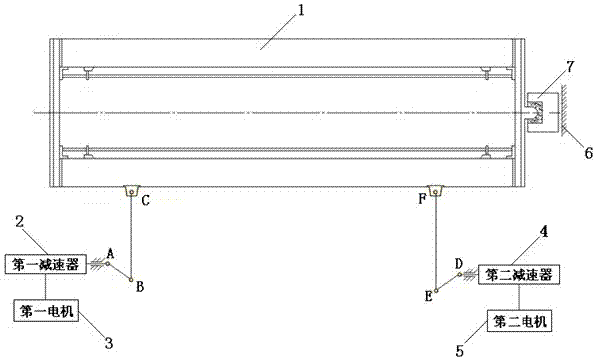

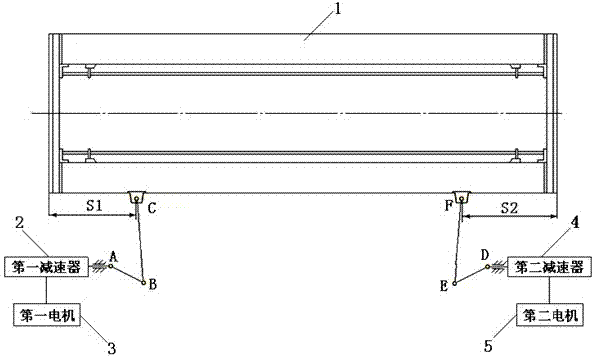

A Bilaterally Driven Asymmetric Link Slider Opening Mechanism

ActiveCN103898654BEliminate hysteresis on the first sideStable and reliable structure operationOther shedding mechanismCrankReciprocating motion

The invention discloses a double-side drive asymmetric connecting rod slide block opening mechanism which comprises a heald frame arranged in a sliding rail, wherein the heald frame is fixed on an opening mechanism frame; a first hinge point and a second hinge point are arranged on the left side and the right side of the bottom end of a lower transverse beam of the heald frame, respectively; a first connecting rod is hinged to the first hinge point; the first connecting rod is hinged with a first crank; the first crank is connected with a first motor on a weft insertion side through a first speed reducer; a second connecting rod is hinged to the second hinge point; the second connecting rod is hinged with a second crank; the second crank is connected with a second motor on a weft catching side through a second speed reducer; a slide block is arranged between the middle of a right side stopper of the heald frame and the sliding rail. Synchronous movement on two sides of the heald frame is realized, a phenomenon that one side of the heald frame moves at first and the other side of the heald frame is lagged is eliminated, and the slide block is arranged on one side of the heald frame and reciprocates on the sliding rail, so that the aim of two sets of driving parts need to be mutually and adaptively coordinated in the process of driving the same heald frame is achieved, and novel degree of freedom and constraint are provided for the movement of the heald frame.

Owner:WUJIANG WANGONG ELECTROMECHANICAL EQUIP

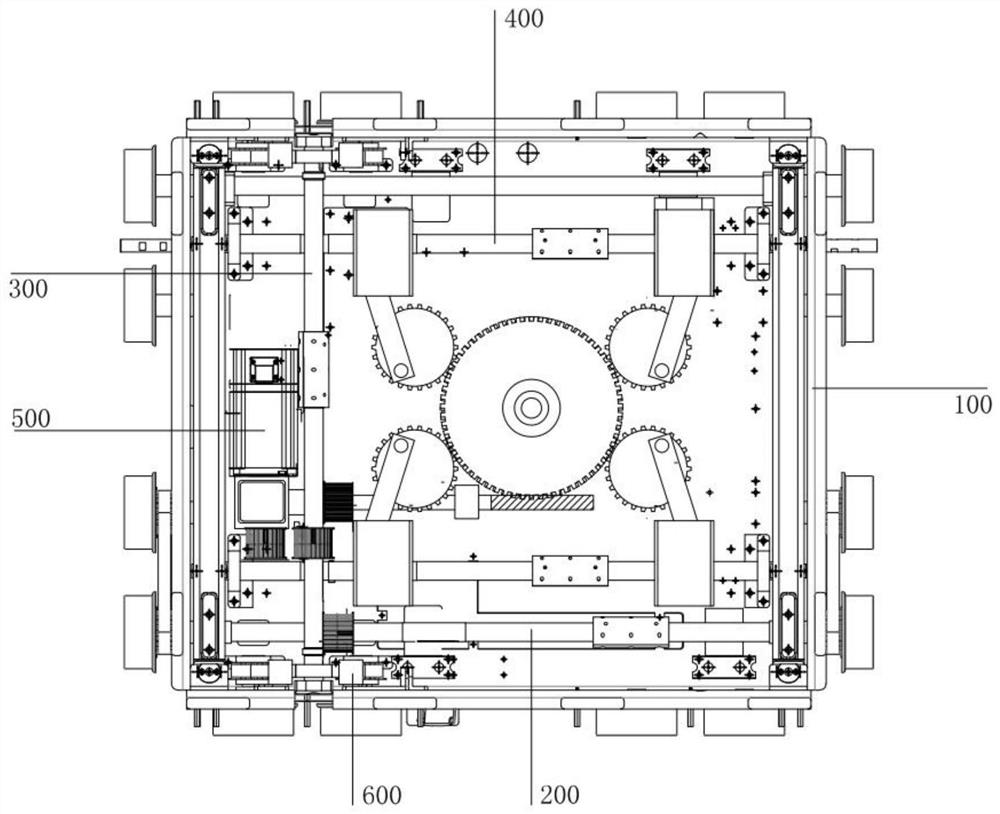

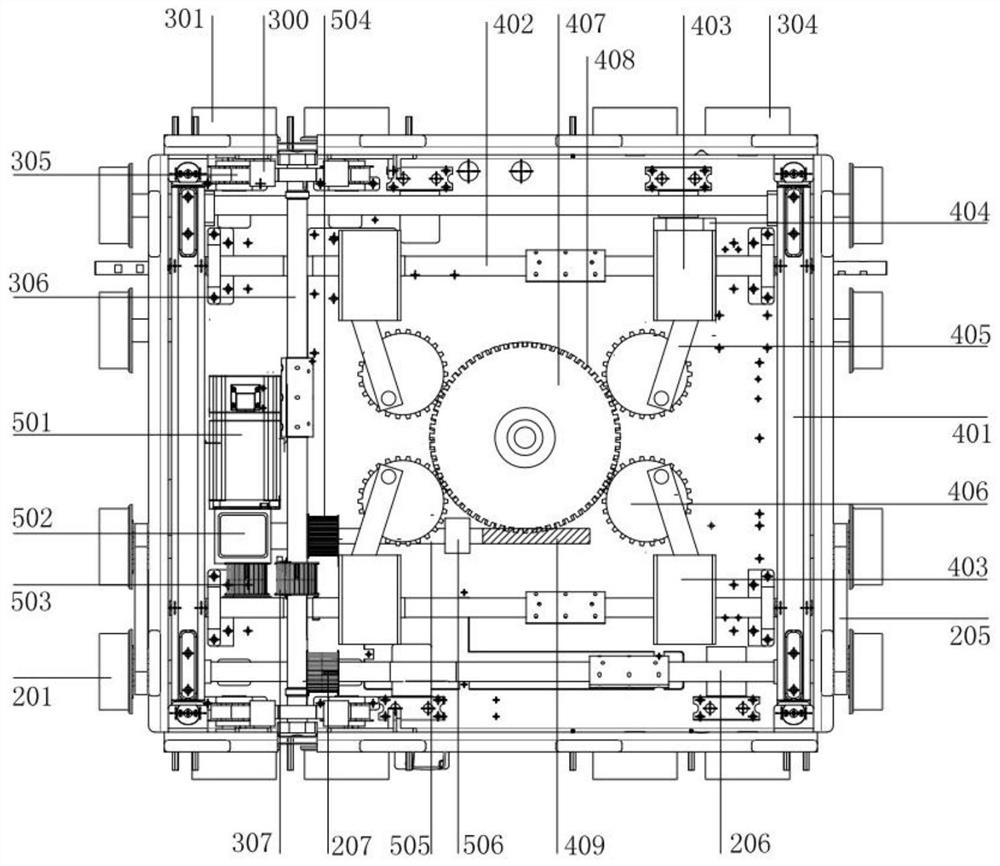

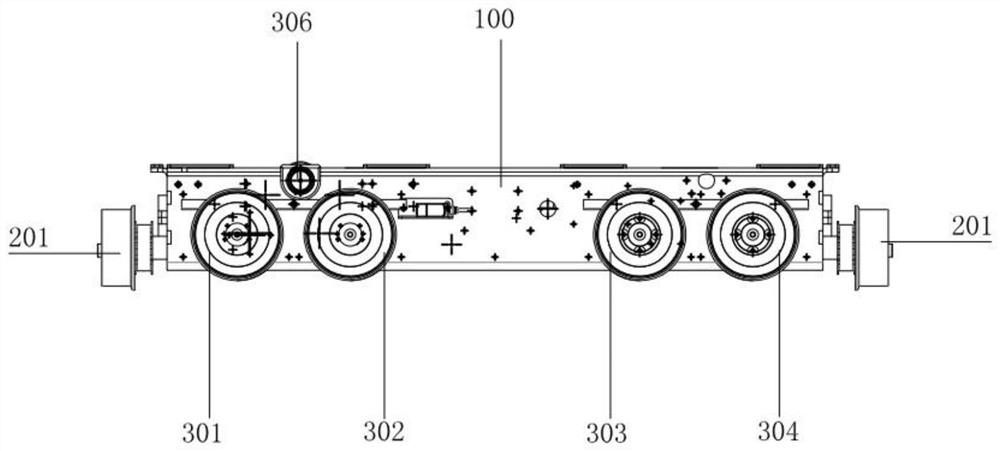

Single-power cable-stayed jacking sixteen-wheel four-way shuttle vehicle

ActiveCN113428544AImprove transmission efficiencyEven by forceStorage devicesMechanical conveyorsPower cableMarine engineering

The invention discloses a single-power cable-stayed jacking sixteen-wheel four-way shuttle vehicle. The single-power cable-stayed jacking sixteen-wheel four-way shuttle vehicle comprises a supporting frame, a transverse walking driving mechanism, a longitudinal walking driving mechanism, a cable-stayed reversing and jacking mechanism and a power conveying mechanism. The cable-stayed reversing and jacking mechanism comprises jacking transverse plates, jacking shafts and cable-stayed jacking sliding blocks. The cable-stayed jacking sliding blocks on the front side and the rear side are eccentrically connected with transmission cams through connecting rods correspondingly, the two transmission cams on the left side and the right side are connected with a center straight gear in a meshed mode, and the center straight gear is connected with a longitudinal output shaft of a cross-shaped speed reducer. According to the cable-stayed reversing and jacking mechanism, the linkage lifting action of the jacking shafts is achieved in the linkage mode of the transmission cams and the cable-stayed jacking sliding blocks, the cable-stayed jacking sliding blocks arranged at the four corners are connected through the four transmission cams, stress is uniform, and structural operation is stable; and the cable-stayed reversing and jacking mechanism, the transverse walking driving mechanism and the longitudinal walking driving mechanism are in linkage control and share one driving motor, so that the production cost is greatly reduced.

Owner:LONLINK SMART STORAGE SOLUTION SHANGHAI CO LTD

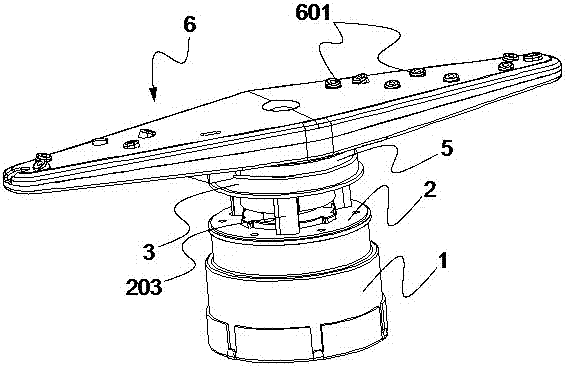

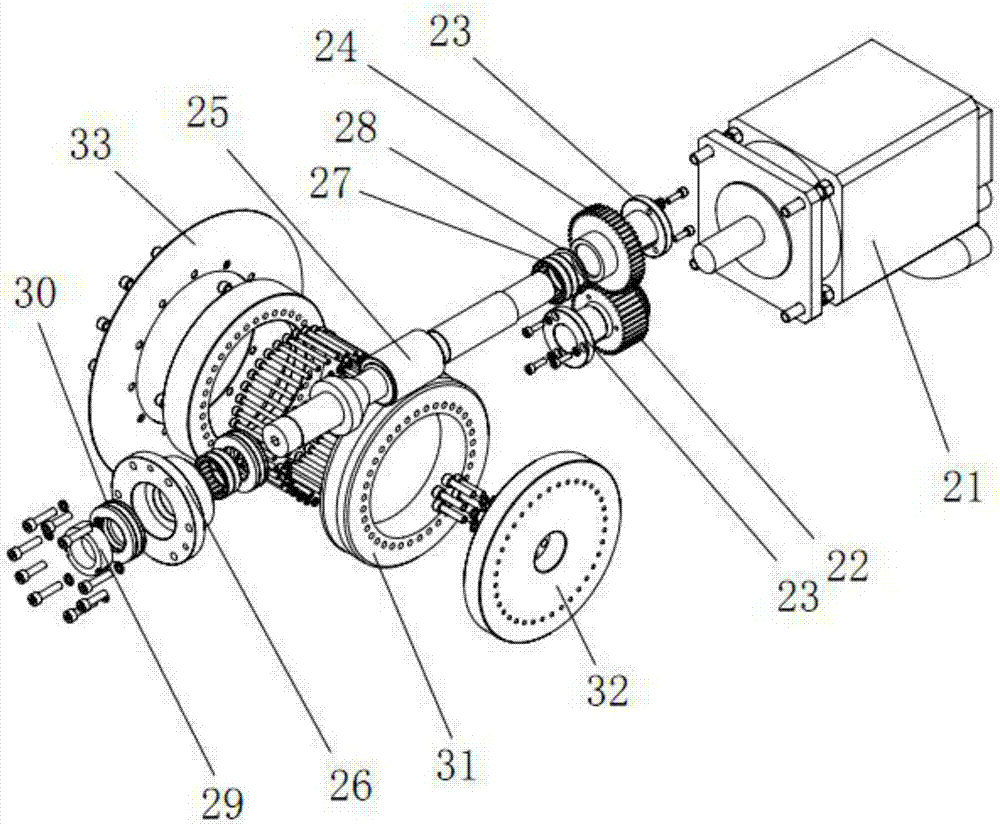

Drive system of three-face rotation workbench

PendingCN106975960AStable and reliable structure operationPrecise positioningFeeding apparatusGear wheelControl engineering

The invention discloses a drive system of a three-face rotation workbench. The drive system comprises a servo motor, a worm assembly and a worm wheel assembly. A rotating shaft of the servo motor is provided with a large spur gear. The large spur gear is provided with a belt wheel compression ring. The worm assembly comprises a small spur gear, a worm and a bearing bush. The small spur gear is provided with a belt wheel compression ring. The small spur gear is matched with the large spur gear. The worm wheel assembly comprises a worm wheel, a rotating shaft connection disc and a brake pad. The rotating shaft connection disc is matched with a main rotating shaft of the three-face workbench, the brake pad is connected with the worm wheel through multiple longitypical hexagon socket head cap screws, and the worm wheel is connected with the worm. According to the drive system of the three-face rotation workbench, the servo motor outputs power, the large spur gear drives the worm assembly through the small spur gear to rotate, then, the worm wheel assembly rotates, the rotating shaft connection disc of the worm wheel assembly drives the workbench to turn over in three stations, the overall structure is stable in operation, and accurate positioning of overturning in three stations of the workbench is ensured.

Owner:SUZHOU QUNZHI MACHINERY EQUIP CO LTD

Garbage treatment device

The invention relates to the technical field of garbage treatment, and discloses a garbage treatment device. The garbage treatment device comprises a control part, a vehicle body and a pretreatment mechanism; the internal of a cylinder is divided into a front cavity and a back cavity through a piston; the side, near the back cavity, of the piston is connected with a piston rod; a free end of the piston rod is connected with an air pipe capable of extending; one end of the air pipe communicates with the front cavity of the cylinder, and the other end of the air pipe penetrates out of the vehicle body to communicate with a sucker; the back edge of the bottom of the vehicle body is hinged with a tipping bucket capable of automatically overturning front and back; the bottom of the vehicle bodyis rotationally connected with a front wheel through a first fixed shaft, and is rotationally connected with a rear wheel through a second fixed shaft; a roller is rotationally connected to the second fixed shaft; multiple blades are peripherally arranged on the outer edge of the roller; the roller is fixedly connected with the rear wheel through an acceleration mechanism; the pretreatment mechanism comprises a lead screw, a nut and a support plate; the lower end of the lead screw is connected with a turntable; and the bottom edge of the turntable is vertically connected with a drill bit. Thegarbage treatment device can collect garbage in ice blocks to prevent falling into a river to flow away.

Owner:宁波清智环保科技有限公司

Chemical production reaction device capable of quickly cleaning conveying pipe

InactiveCN112387238AQuick washBlanking speed controlChemical/physical/physico-chemical stationary reactorsFeed devicesElectric machineryProcess engineering

The invention discloses a chemical production reaction device capable of quickly cleaning a conveying pipe. The chemical production reaction device comprises a reaction box, a spoiler, a driving motorand a one-way valve, a mounting cylinder is arranged at the upper end of the reaction box, the spoiler is arranged on the inner side of the mounting cylinder, a control rod is arranged in front of the spoiler, a reset spring is arranged on the outer surface of a limiting rod, the driving motor is installed in the middle of the upper end of the reaction box, a connecting rod is fixed behind the conical teeth, and a fixing rod is arranged at the tail end of the connecting rod. The chemical manufacturing reaction device capable of quickly cleaning the conveying pipe can quickly clean chemical residues in the conveying pipe, can control the falling speed of raw materials, can prevent the raw materials from being accumulated at the bottom due to gravity in the reaction process, and is high inreaction efficiency, stable in device structure operation, and reasonable in energy application. Stirring reaction is sufficient, processing and using are convenient, and the inner wall of the deviceis convenient to clean.

Owner:新乡贝诺电子信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com