Inclined shaft sliding mode structure and inclined shaft pull-crawling construction process

A sliding form and formwork technology, applied in shaft equipment, shaft lining, mining equipment, etc., to achieve the effects of scientific mechanical structure, less defect treatment, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

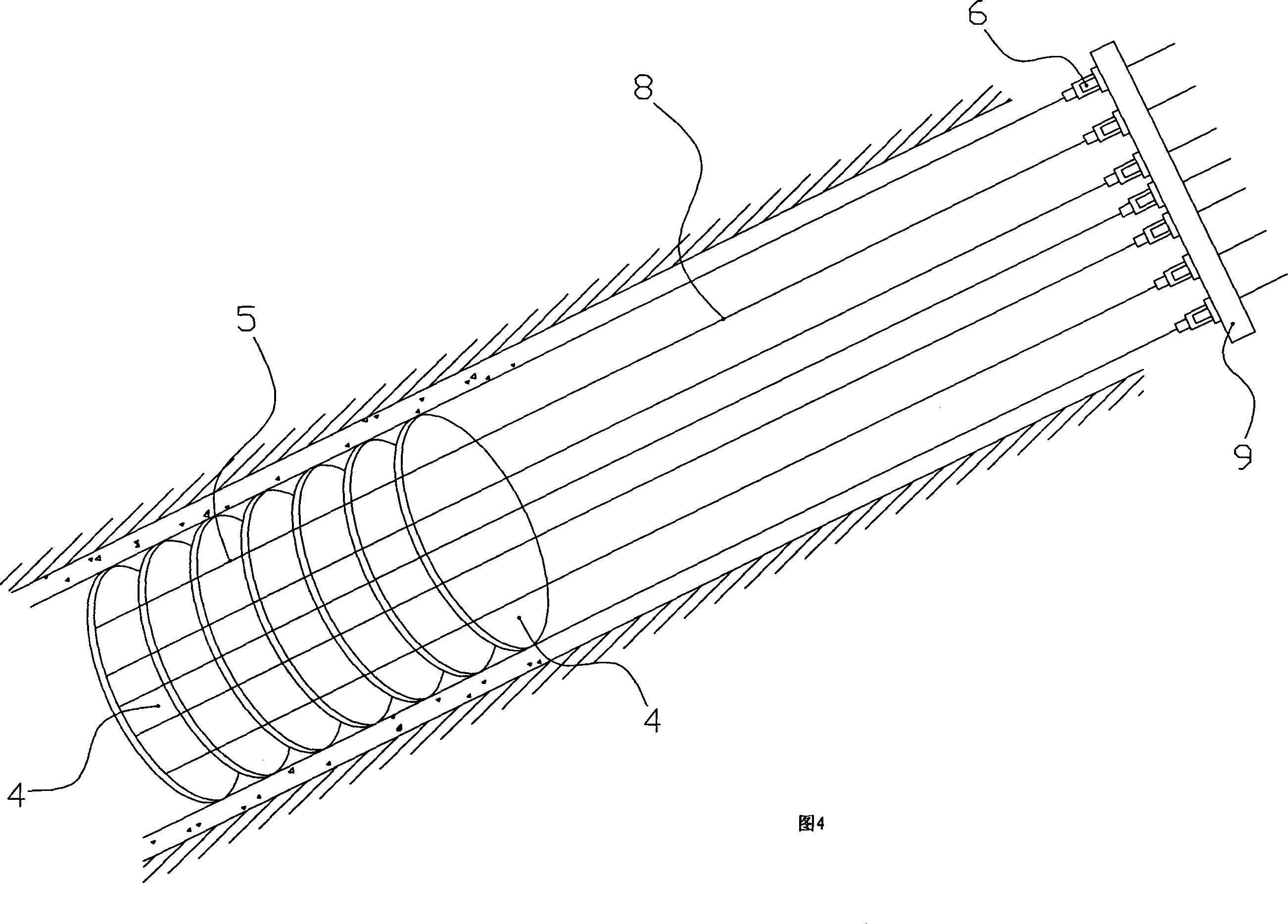

[0032] Example: General situation of the concrete lining project for the inclined shaft in Yilantan, Yunnan: the inclined length of the shaft is 56m, the net diameter is 7.5m, and the thickness of the concrete lining is 0.6m.

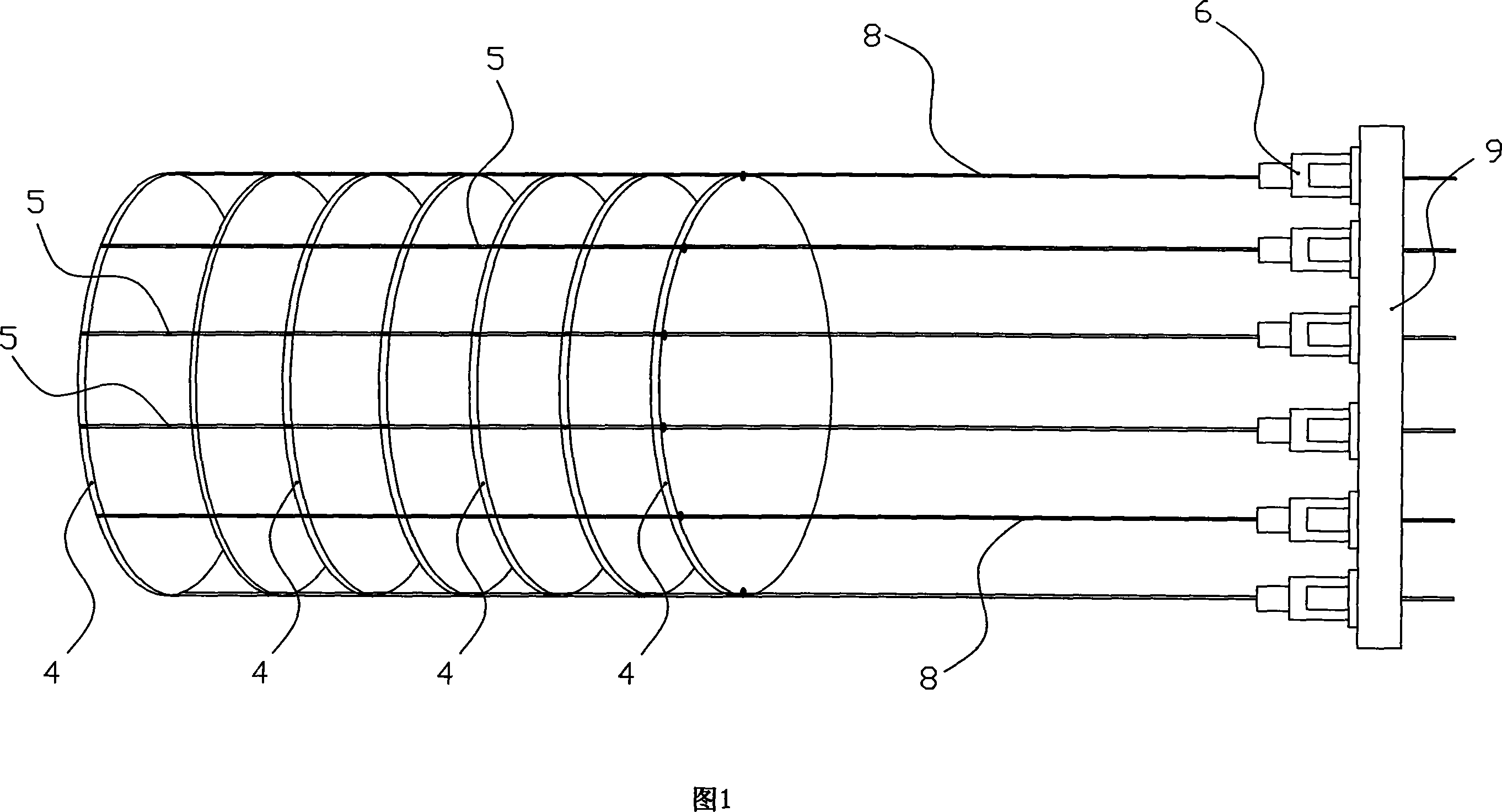

[0033] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, a kind of inclined shaft sliding formwork structure, described sliding formwork structure comprises the sliding formwork form body and traction sliding formwork body that are made up of seven groups of sliding formwork monomers 4 The pull-climb power system of the mold body;

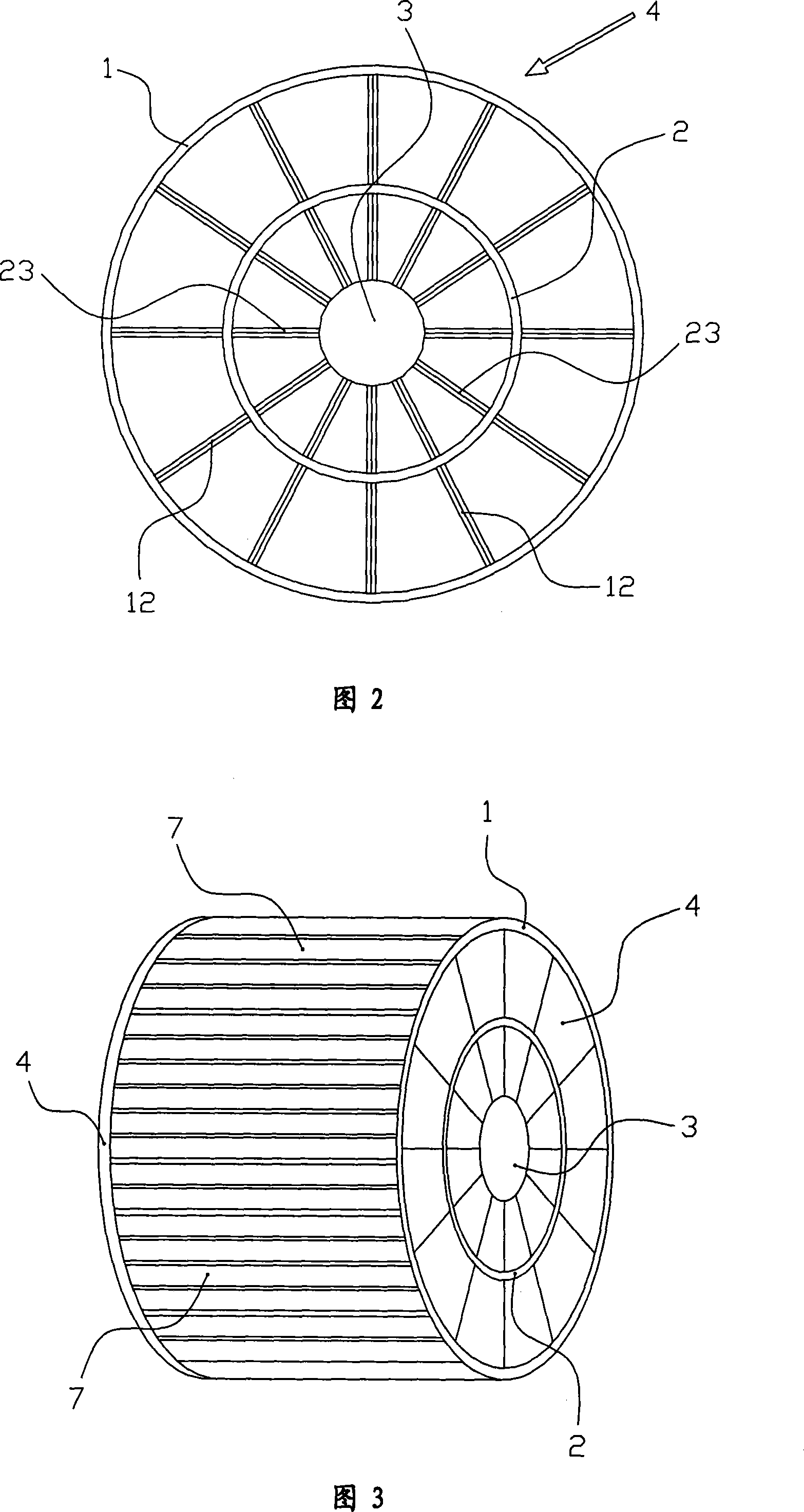

[0034] The sliding form unit 4 includes a surrounding ring 1, a drum ring 2 and a disc 3, and the disc 3 is supported and connected to the drum ring 2 located at the periphery of the disc 3 through a spoke stay 23, and the drum ring 2 is radiated Support 12 supports and connects the circle 1 that is positioned at the periphery of described drum circle 2, and the center of circle of described circle 1, described drum circle 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com