Power knife turret protection structure, power knife turret system and control method

A technology of power turret and protective structure, which is applied in the direction of manufacturing tools, clamping, support, etc., can solve the problems of turret displacement error, reduce reliability, wear and other problems, and achieve stable structure operation, high precision, and efficient switching and rotation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

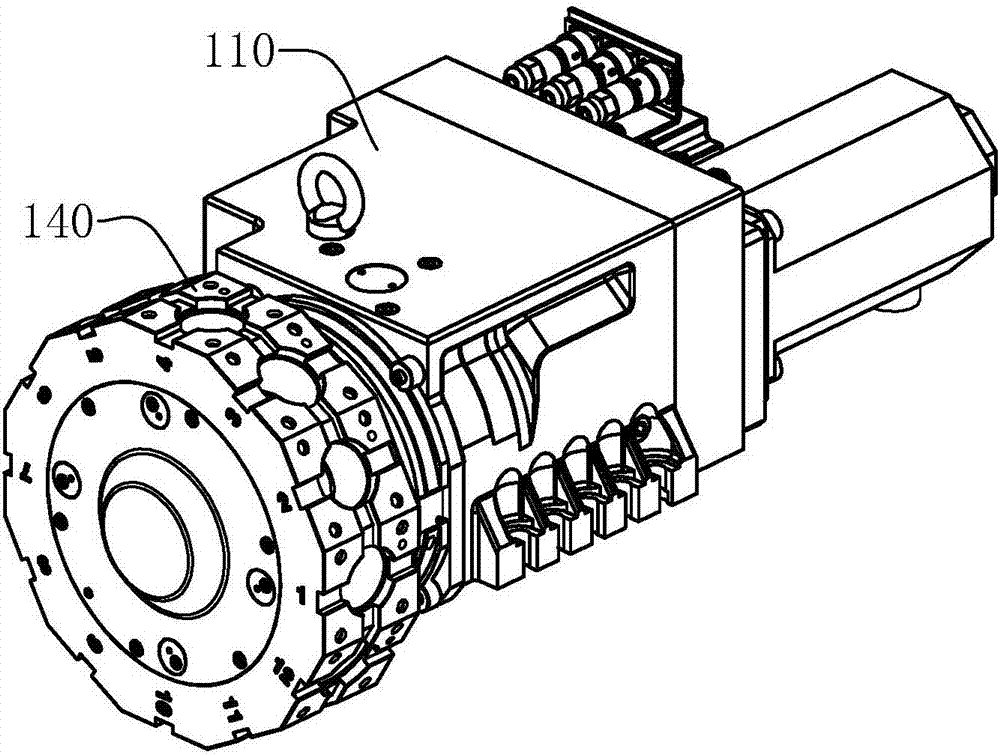

[0044] Such as figure 1 As shown, this is the overall structure of the power turret, which includes a turret body 110 and a cutter head 140, the turret body 110 and the cutter head 140 can rotate relatively, and the turret body 110 is fixed on the equipment.

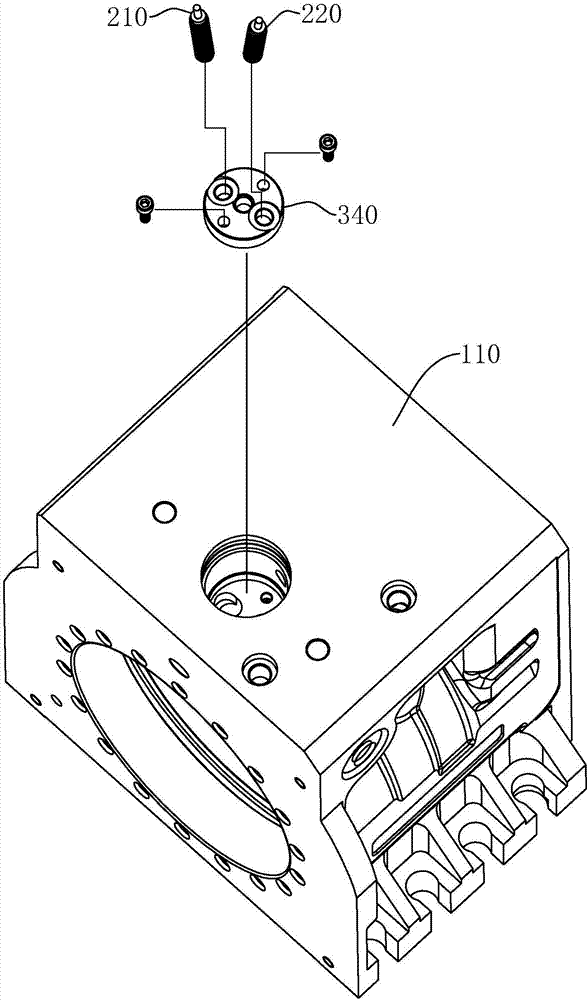

[0045] Such as figure 2 As shown, an installation cavity is opened on the turret body 110, in which the first proximity switch 210, the second proximity switch 220 and the positioning plate 340 are assembled. The positioning plate 340 is fixed on the turret body 110 by bolts.

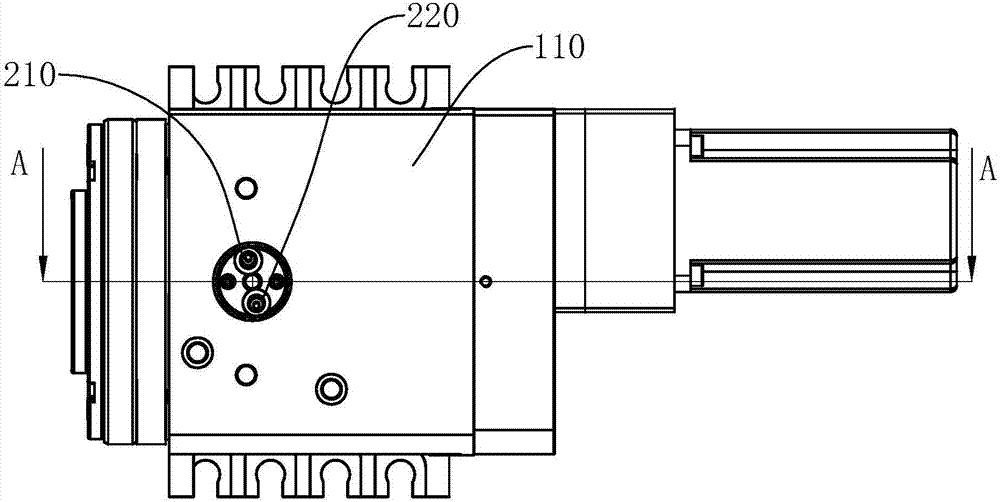

[0046] to combine image 3 and Figure 4 , the following describes the internal structure of the turret body 110 and the gist of the invention.

[0047] A power turret protection structure further includes a turret body 110 , a first transmission shaft 120 , a movable toothed plate 130 , a double chained plate 150 and a thrust spring 160 . Figure 4 Among them, the driving source may be a transmission gear device 500, which is connected to the...

Embodiment 2

[0058] Such as Figure 6 As shown, a power turret system includes the above-mentioned power turret protection structure, and also includes a hydraulic mechanism 410 , a servo motor 420 , a controller 430 and a power supply 440 . The servo motor 420 is used to drive the first transmission shaft 120 to rotate. The first proximity switch 210 , the second proximity switch 220 , the hydraulic mechanism 410 , and the servo motor 420 are connected to a controller 430 . The forward position of the distance between the first proximity switch 210 and the second proximity switch 220 and the middle part of the double chainring 150 from the through ring groove 190 changes. Thereby, the stroke of the duplex chainring 150 can be detected.

[0059] The controller 430 does not receive the signal of the first proximity switch 210 and receives the signal of the second proximity switch 220 to output a locking signal, and the locking signal is specifically a level signal.

[0060] The controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com