Single-power cable-stayed jacking sixteen-wheel four-way shuttle vehicle

A single-power, shuttle car technology, applied in the field of shuttle cars, can solve the problems of low transmission efficiency, reduce shelves and compartments, and large power consumption, and achieve the effects of improving load capacity, optimizing installation position, and stable structure operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail and concretely below by specific embodiment, so that understand the present invention better, but following embodiment does not limit the scope of the present invention.

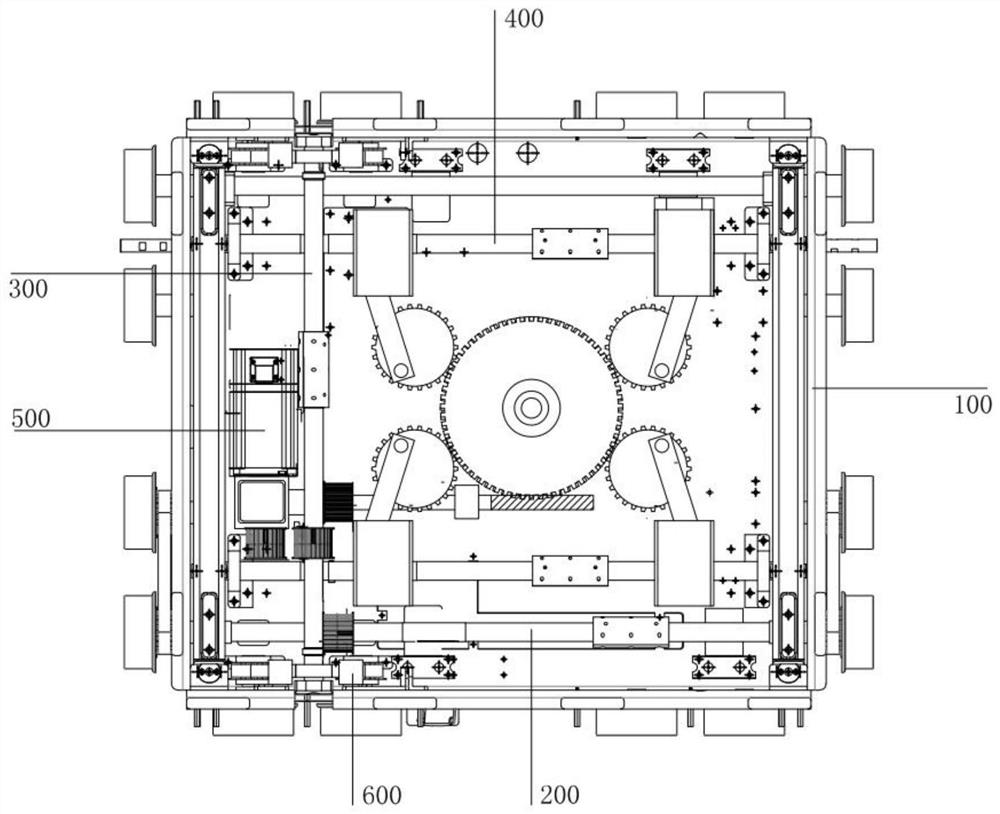

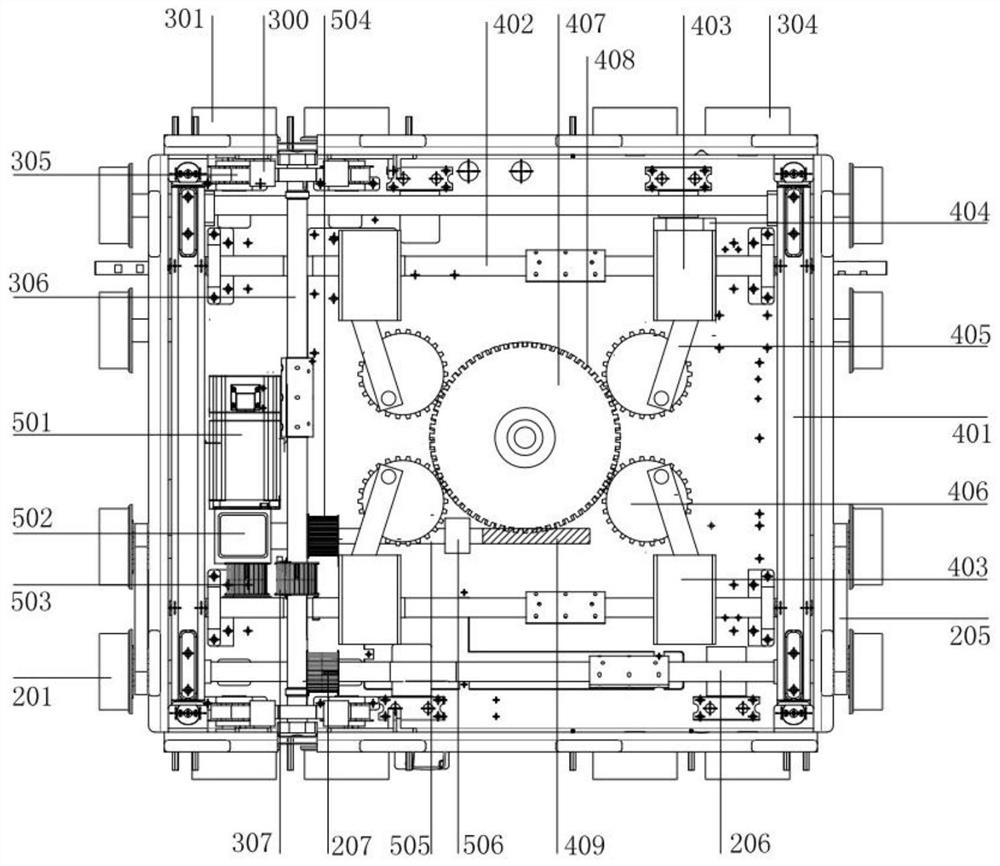

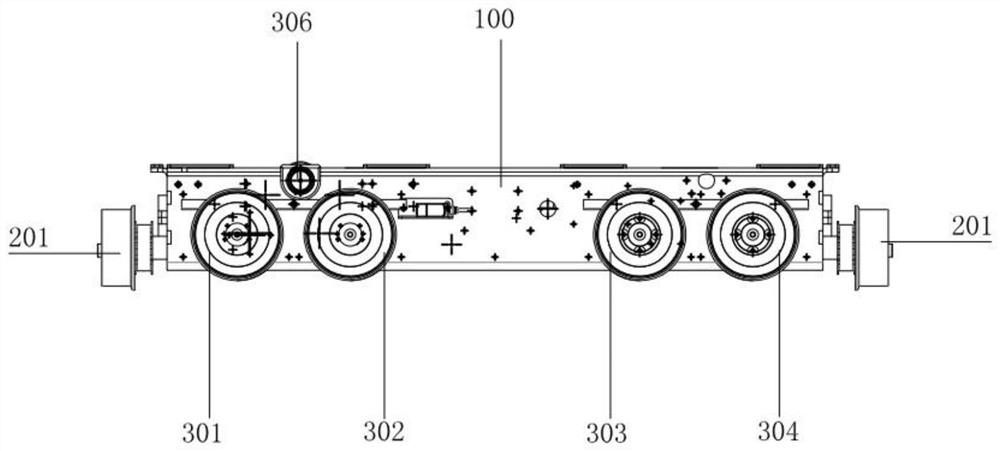

[0051] In some embodiments, such as figure 1 As shown, a single-power cable-stayed jack-up sixteen-wheel four-way shuttle vehicle is provided, including a support frame 100, a lateral travel drive mechanism 200 installed on the support frame 100, a longitudinal travel drive mechanism 300, a cable-stayed reversing and a jacking mechanism. The lifting mechanism 400 and the power transmission mechanism 500 also include a battery pack and a controller.

[0052] In one of the embodiments, the support frame 100 is formed as a whole through sheet metal bending and local reinforcing ribs, which greatly improves the carrying capacity of the vehicle; the battery pack acts as a power source to increase the power of the vehicle, and the battery pack can Lithium-ion re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com