Gear rack transmission type automatic locking device

An automatic locking, rack and pinion technology, used in building locks, building structures, building fastening devices, etc., can solve the problem that the automatic door closing function cannot be realized, the opening and closing are not flexible, and the stability of the cabinet is affected. and other problems, to achieve the effect of convenient opening and locking operation, flexible opening and closing, and solving the rebound of the cabinet door

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

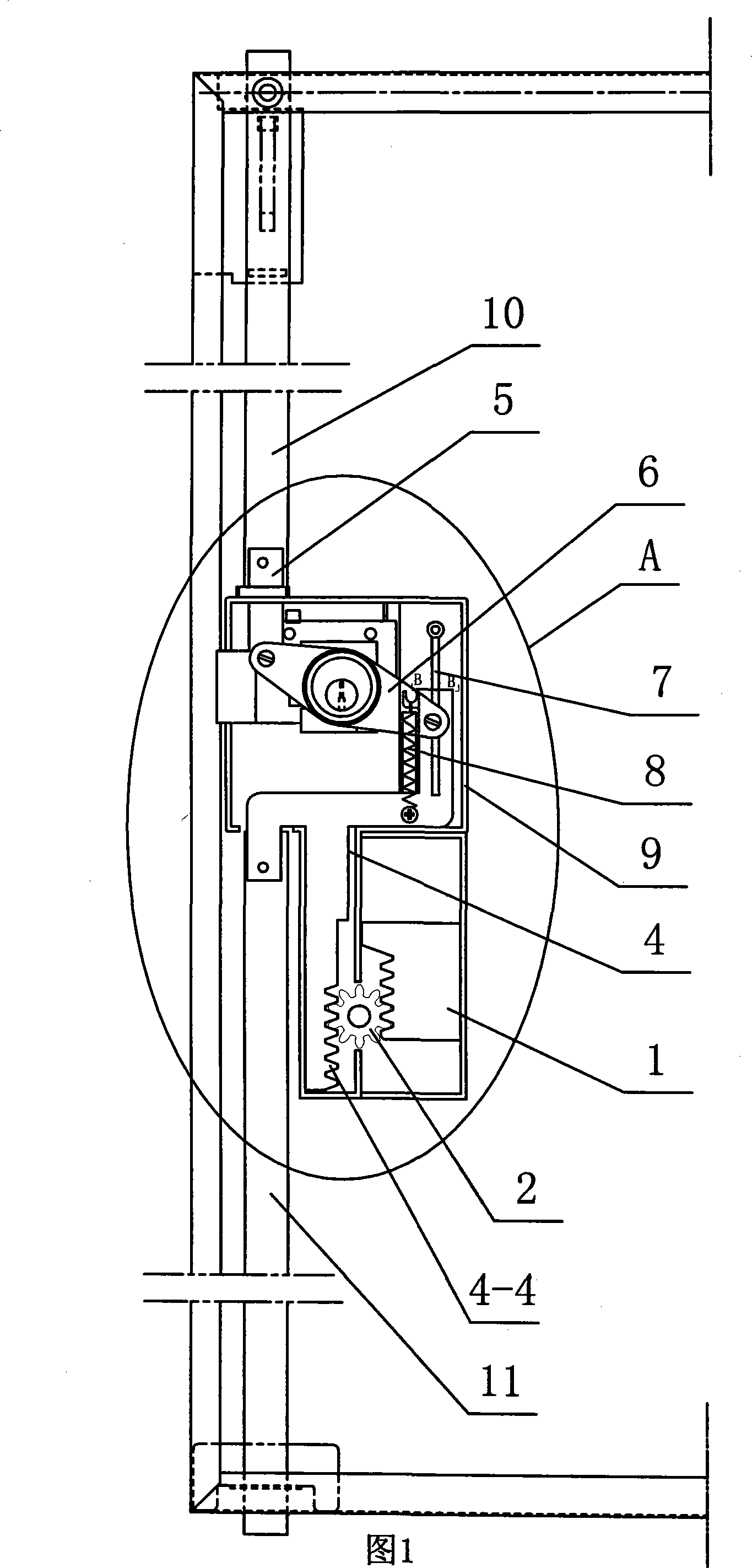

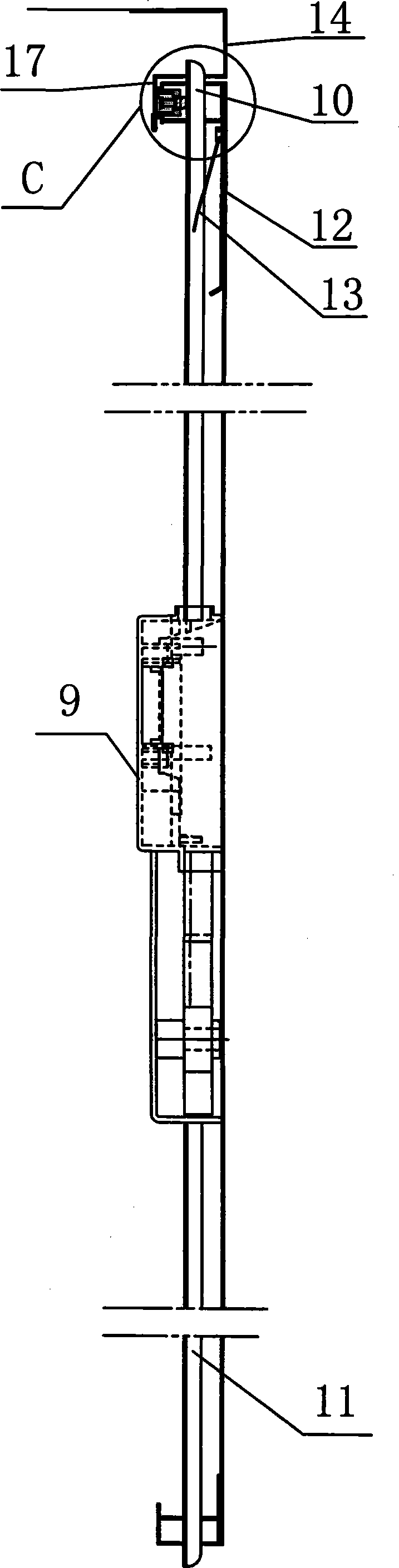

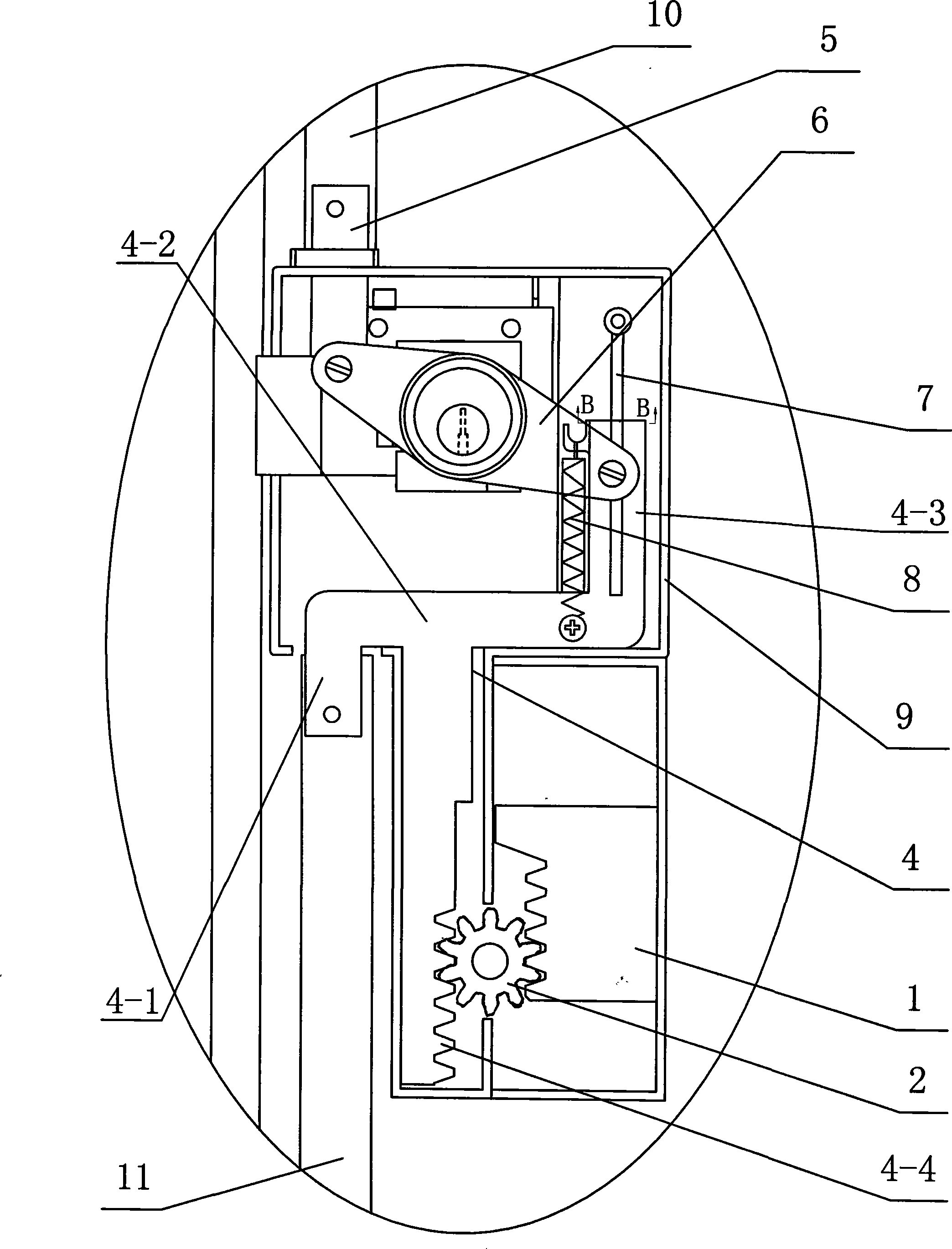

[0007] Specific implementation mode one: combine Figure 1-5 To illustrate this embodiment, the rack and pinion transmission type automatic locking mechanism in this embodiment includes a housing 9, a lock 6, an upper locking lever 10, a lower locking lever 11, and a touch button 15. The automatic locking mechanism also includes a mechanism Frame 4, hand rack 1, gear 2, upper connecting rod 5, energy storage elastic part 8, pulling rod 13; The lower end is connected, and the upper end of the upper connecting rod 5 passes through the housing 9, and the other end of the lockset 6 is connected with the upper end of the energy storage elastic member connecting rod 4-3 on the mechanism frame 4, and the rack bar 4-4 on the mechanism frame 4 The rack on the top meshes with one side of the gear 2, the gear 2 is mounted on the housing 9, the other side of the gear 2 meshes with the handle rack 1, and the upper end of the energy storage elastic member 8 It is connected with one side en...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 with image 3 To illustrate this embodiment, the mechanism frame 4 of this embodiment is composed of a rack bar 4-4, a lower connecting rod 4-1, a horizontal rod 4-2, and an energy storage elastic member connecting rod 4-3. The horizontal rod 4 -2 Both ends are fixedly connected to the upper end of the vertically arranged lower connecting rod 4-1 and the lower end of the vertically arranged energy storage elastic member connecting rod 4-3, and the middle part of the horizontal bar 4-2 is connected to the vertically arranged rack bar 4 The upper end of -4 is affixed. So designed, easy to operate. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 with image 3 To illustrate this embodiment, the rack bar 4-4, the lower connecting rod 4-1, the horizontal rod 4-2, and the connecting rod 4-3 of the energy storage elastic member described in this embodiment are integrated. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com