Multichannel coil filter ion composite film plating device and method

A composite coating and filter technology, which is applied in the field of material surface treatment, can solve the problems of the influence of the surface finish of the film layer and restrict the application, and achieve the effect of reducing the pollution of macroscopic large particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Two cathodic arc targets use a multi-channel coil filter ion composite coating device with two guiding channels to perform (Ti, Al)N composite film plating

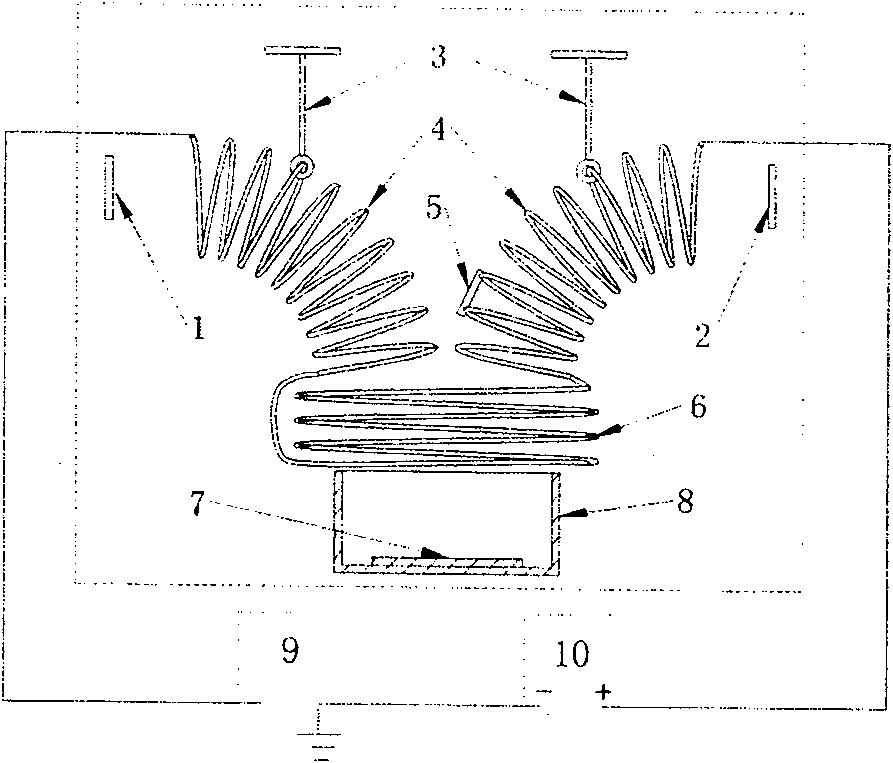

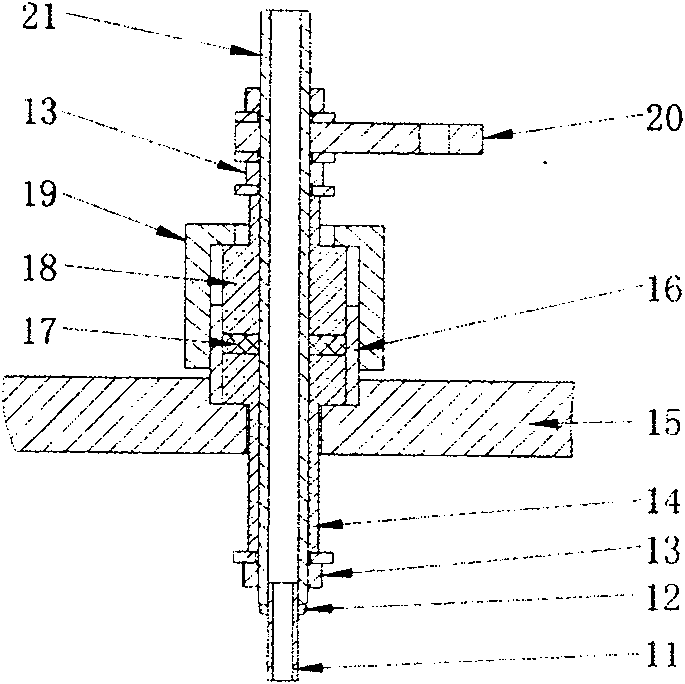

[0027] Such as figure 1As shown, two cathodic arc targets are connected by the structure and circuit of a multi-channel coil filter ion composite coating device with two guiding channels. The dotted box in it represents the vacuum furnace, the inside of the box is a schematic diagram of the furnace device, and the outside of the box is an external circuit. As can be seen from the figure, the device mainly includes a multi-channel free and open coil filter (including two guiding channels 4 and a mixing channel 6), a filter shaping and insulating device 5, a filter positioning device 3, and a workpiece cover 8; The entrances of the two guide channels 4 of the multi-channel free and open coil filter are respectively facing the cathode arc targets 1 and 2, and the outlets are all facing the entrance of the mixing chann...

Embodiment 2

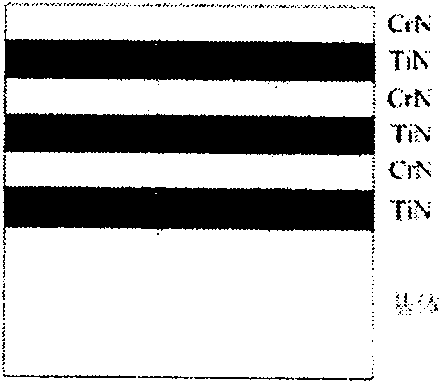

[0040] Plating of TiN / CrN / TiN multilayer structure film with two cathodic arc targets using a multi-channel coil filter ion composite coating device with two guiding channels

[0041] The device of this embodiment is almost exactly the same as that of Embodiment 1, the difference is that: 1) the cathodic arc target uses Ti target and Cr target, so that a multilayer structure film can be obtained; 2) the power supply of the multi-channel free open coil filter Use direct current 600A, can obtain better transmission efficiency with respect to embodiment 1 like this; 3) do not connect the high-power resistance box in series in the circuit, can guarantee like this that the coil in the free open coil filter is in +20V to + with respect to the anode potential 70V; 4) workpiece cover height 150mm, can obtain better filter effect with respect to embodiment 1 like this.

[0042] After the entire device is arranged, the TiN / CrN / TiN multilayer structure film is plated according to the fol...

Embodiment 3

[0048] Two cathodic arc targets use a multi-channel coil filter ion composite coating device with two guiding channels to perform (Ti, Al)N composite film plating

[0049] The device of this embodiment is almost exactly the same as that of Embodiment 1, except that 1) the power supply of the multi-channel coil filter uses DC 400A; 2) the high-power resistance box is not connected in series in the circuit.

[0050] After the entire multi-channel coil filter ion composite coating device is arranged, the (Ti, Al)N composite composition film is plated according to the steps similar to that of Example 1.

[0051] In this embodiment, the current used for the multi-channel coil filter will be greater than that of embodiment 1, and the transmission efficiency obtained will be higher than that of embodiment 1, but the heating value of the entire coil in the free and open coil filter will also be greater than that of embodiment 1 . In addition, when the coil current is 400A, the maximu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com