Attitude detection system and method of coiled material under motion state

A technology of motion state and detection system, which is applied in the field of coil deviation correction, can solve the problems of uneven coil winding and easy generation of waste products, etc., and achieve the effects of fast deviation correction efficiency, reduced scrap rate, and high degree of deviation correction automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

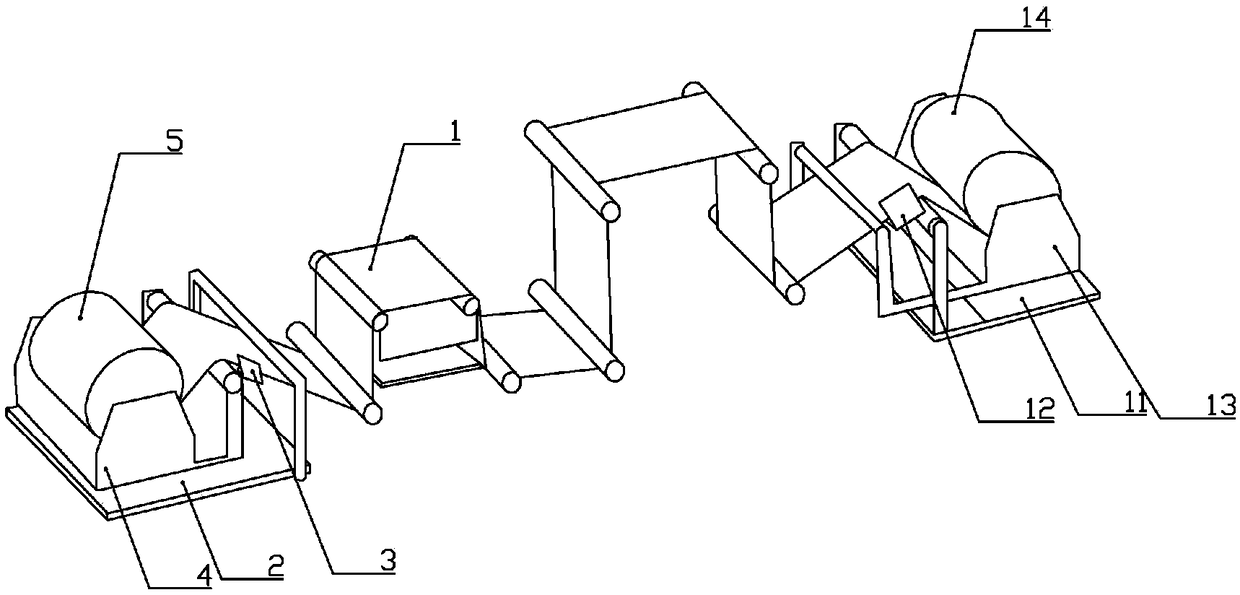

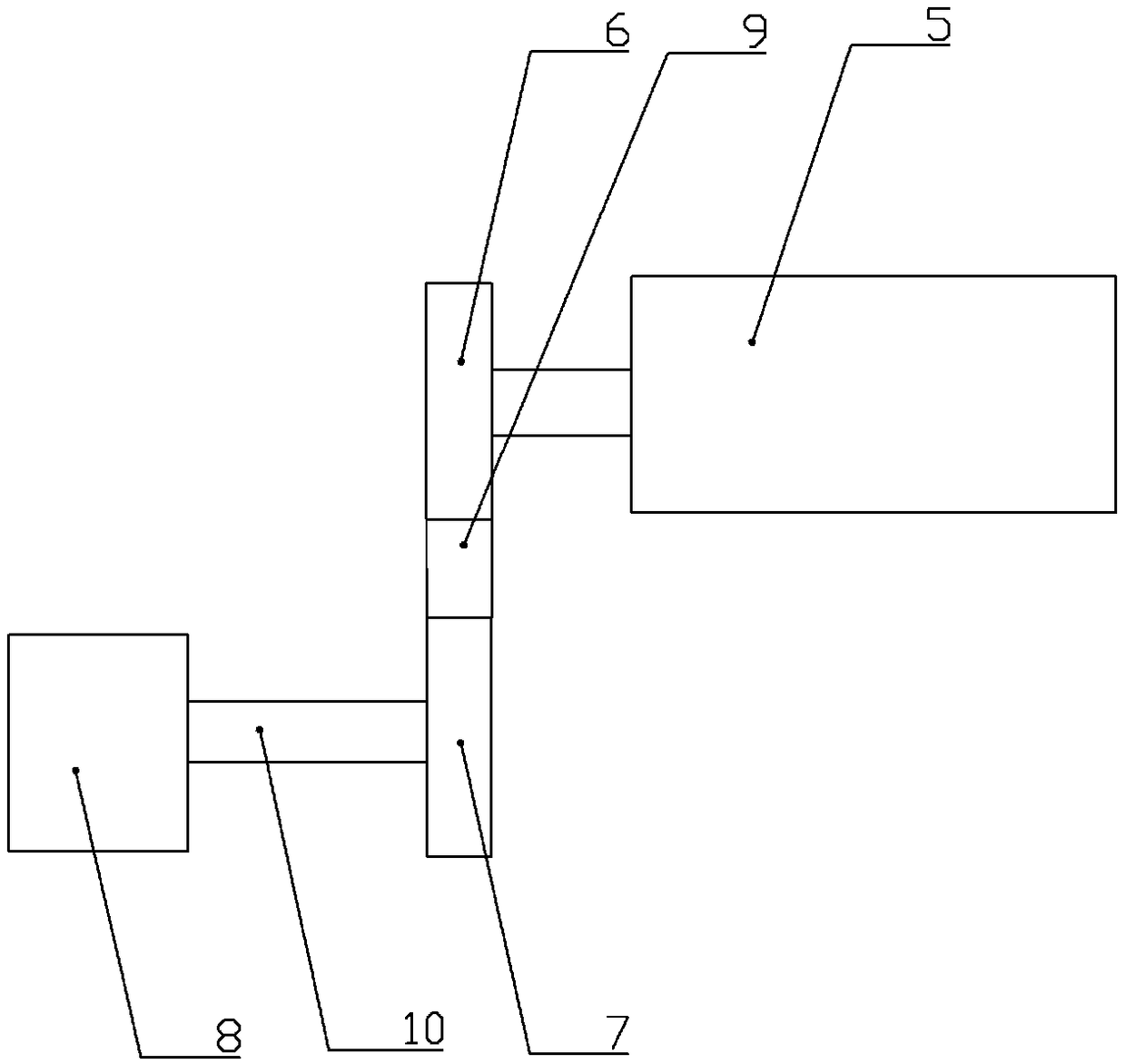

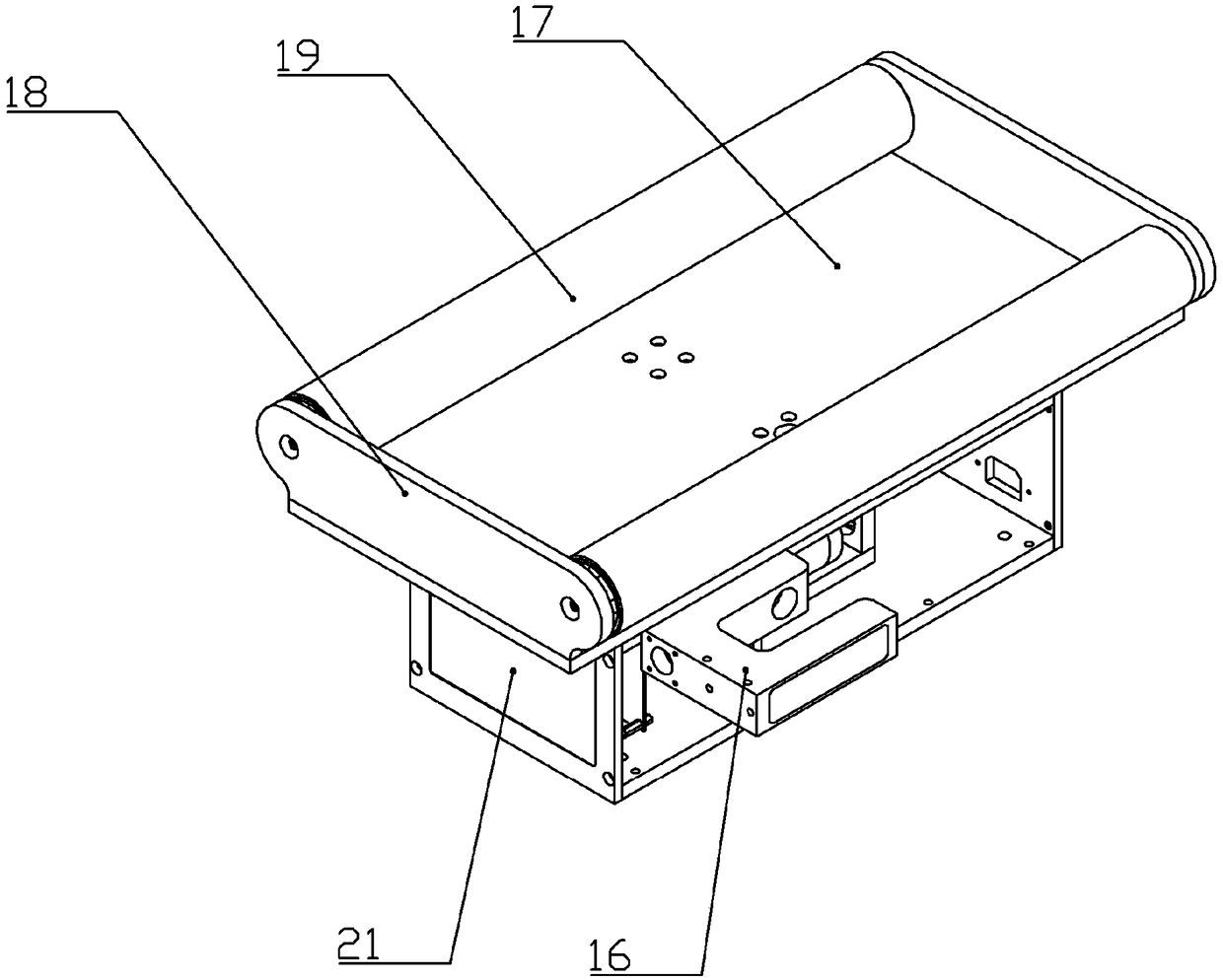

[0037] Such as figure 1 with figure 2 Shown: the attitude detection system in the state of coil motion, including the unwinding correction mechanism, the winding correction mechanism and the process correction mechanism 1, wherein the unwinding correction mechanism includes the first fixed seat 2, the first fixed seat 2 The unwinding deviation correction controller and an unwinding deviation correction sensor 3, the unwinding deviation correction frame 4 is arranged on the first fixed seat 2, the first guide rail is welded on the first fixed seat 2, and the unwinding deviation correction frame 4 moves along the first guide rail Sliding, one side of the unwinding deviation correction frame 4 is connected with an unwinding push cylinder, the moving direction of the unwinding deviation correction frame 4 is perpendicular to the traveling direction of the coil, and the unwinding deviation correction sensor 3 is located at the discharge end of the unwinding deviation correction fr...

Embodiment 2

[0048] The difference between embodiment 2 and embodiment 1 is that both the process deviation correction sensor 16 and the unwinding deviation correction sensor 3 are photoelectric sensors, and the number of the unwinding deviation correction sensor 3 is two, and the unwinding deviation correction sensor 3 is respectively arranged on the coil sides of the edge. Since the two sides of the edge of some coils are not straight lines, a part will protrude, so two unwinding deviation correction sensors 3 need to be used for cooperation, and the signals of the two unwinding deviation correction sensors 3 are sent to the unwinding deviation correction controller, and the unwinding deviation correction The controller performs comprehensive average calculation on the two signals, and calculates the moving stroke of the unwinding deviation correction frame 4, so that the central axis of the coil can be aligned with the central axis of the unwinding roller 5.

[0049] A method using an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com