A Bilaterally Driven Asymmetric Link Slider Opening Mechanism

A technology of opening mechanism and connecting rod slider, which is applied in other opening mechanisms, textiles, textiles and papermaking, etc., can solve the problems of loose weft insertion airflow, occupying a small space, occupying a large space, etc., and achieve tight weft insertion airflow , the effect of stable structure operation, dynamic moment and vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

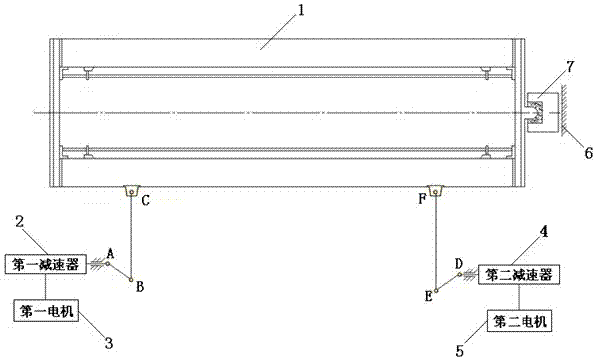

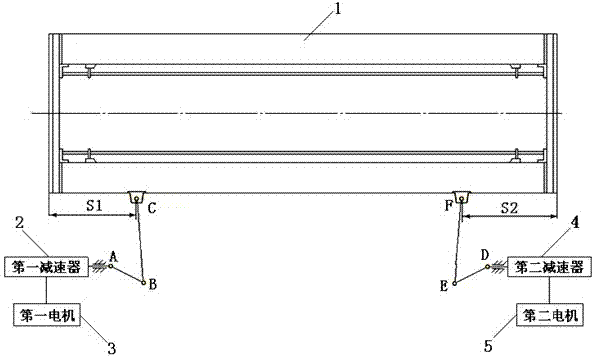

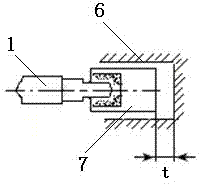

[0031] see figure 1 As shown, a double-sided driving asymmetric link slider opening mechanism includes a heald frame 1 arranged in a slide rail 6, and the slide rail 6 is fixed on the frame of the opening mechanism, and the lower beam of the heald frame 1 The left and right sides of the bottom end are respectively provided with a first hinge point C and a second hinge point F; the first hinge point C is hinged with a first connecting rod BC, and the first connecting rod BC is hinged with the first crank AB , the first crank AB is connected to the first motor 3 on the weft insertion side through the first reducer 2; the second connecting rod EF is hinged on the second hinge point F, and the second connecting rod EF is connected to the second The two cranks DE are hinged, and the second crank DE is connected to the second motor 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com